Abstract

Cotton textiles are mercerized with anhydrous ammonia liquefied at ca. − 33 °C to improve their mechanical performance, appearance, and handle. Similar effects may also be achieved with NaOH mercerization, but goods mercerized with liquid ammonia (L-NH3) are judged qualitatively better (e.g., softer hand) and thus command a greater price. Therefore, it is of interest to be able to test and confirm whether cotton textiles labeled as L-NH3 treated are indeed so. Building on previous work, we report on tests in collaboration with a process house on identifying ammonia-mercerized fabrics from a pool of cotton textiles treated with L-NH3, NaOH, neither, or both––using FTIR-ATR spectroscopy. It is based on detecting the change in crystal lattice structure from type I (native cellulose) to type II (after NaOH mercerization) or type III (after ammonia mercerization). We could consistently differentiate the ammonia-mercerized fabrics from the untreated and those mercerized with NaOH, but the latter could not be differentiated from fabrics mercerized with both. It was also possible to detect evidence of ammonia mercerization in 4- and 14-year-old samples.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Mercerization is the term given to swelling treatments on cotton textiles, which is performed early on in their processing sequence, with a view to improving their esthetic qualities, such as the texture, resilience, softness, dye uptake, and evenness of coloration. The treatment may be performed in concentrated solutions of NaOH (20–30% w/w) or in liquefied anhydrous ammonia (L-NH3) at − 33 °C [1,2,3]. The latter treatments are more effective in improving fabric texture and mechanical properties than the former, and thus may be preferred in some instances. Due to the greater operation costs of processing with L-NH3, the final goods also command a greater price.

The changes in mechanical properties and dye uptake caused by mercerization with NaOH or L-NH3 differ only in relative degree, and it is not easy conclusively to differentiate between one and the other treatment. However, in some instances, e.g., in public tendering contracts, it may be of interest to categorically confirm whether a cotton textile is indeed mercerized with L-NH3 if so claimed, rather than with NaOH.

Previously [4], we reported on our investigation into the use of FTIR-ATR spectroscopy to identify and differentiate between NaOH- and L-NH3-mercerized cotton fabrics from laboratory- and pilot-scale treatments that imitated full-scale treatments. It is based on detecting changes in the crystal lattice structure of cotton. The allomorph in native cellulose such as cotton, cellulose I, changes after NaOH mercerization to cellulose II or to cellulose III after L-NH3 mercerization.

In parallel, the samples were also analyzed with FTIR transmittance spectroscopy (KBr pellet method) and powder X-ray diffraction (PXRD). With principal component analysis (PCA) and visual inspections of the resulting spectra, it was determined that whereas FTIR-ATR spectroscopy enabled differentiation between the two mercerization types, that was not possible with FTIR transmittance spectroscopy or PXRD. The reason behind is believed to be that commercial-scale treatments, optimized to maximize output speed, minimize the residence time of fabrics in swelling media, and therefore restrict changes of supramolecular structure to only the surface.

The L-NH3 mercerization has two variants based on the mode of ammonia removal after treatment, which is either by heating to evaporate the fluid or by washing off [1, 5, 6]. Although it was not possible to detect differences between these two variants, it was possible to differentiate between them and NaOH mercerization from their FTIR-ATR spectra. An option practiced in industries is to perform NaOH mercerization followed by L-NH3 mercerization to accrue the benefits of both processes [6,7,8]. It was not possible to differentiate between the FTIR-ATR spectra from samples treated only with NaOH and both NaOH and L-NH3.

The aim of the work reported here was to validate the suitability of FTIR-ATR spectroscopy for confirmation of NaOH vs. L-NH3 mercerization of cotton, by measurements on fabrics treated in commercial-scale operations with kind support of a process house Veramtex s.a. (Brussels, Belgium). The following two sets of experiments were conducted:

-

(a)

Single-blind test The process house supplied the authors with sample pieces (ca. A4-sized) from 24 fabrics mercerized with L-NH3, NaOH, NaOH + L-NH3, or neither (i.e., no mercerization), and the authors were not told which sample was from what fabric. Both the evaporative and wash-off modes of ammonia removal were represented in the sample set.

-

(b)

Test of storage time The process house supplied the authors with ca. A4-sized samples from two fabrics: one treated with L-NH3 (evaporative mode) 4 years prior and the other treated with L-NH3 (wash-off mode) 14 years prior to the identification tests. For comparison, the process house also made available freshly treated as well as untreated samples of the same fabrics.

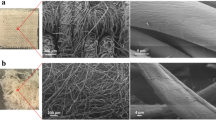

A description of the samples, and their photomicrographs, is available in Table S1 and Fig. S1 (see Supplementary Information I). The samples included both dyed and undyed materials; two weave types; and were of different grammage (i.e., g/m2), to examine whether any of these variables exerted influence on the detectability of mercerization type. The influence of time interval between L-NH3 mercerization and FTIR-ATR measurements was also examined as described in experimental set b above.

All samples were measured, but we present below the typical results, explain our analyses, and discuss where the postulations were successful and where not. The actual treatments awarded to the samples in the set are shown in Table S2 (Supplementary Information I).

Results and discussion

The detection of treatment type is based on analysis of FTIR-ATR spectra in the region 1500–850 cm−1, specifically of changes to the peaks about 1429, 1163, 1111, and 893 cm−1 [9,10,11], as described below:

1429 cm−1: Attributed to symmetric bending of CH2 groups (scissoring), the peak appears as a strong signal in cellulose I; is shifted to 1420 cm−1 with strong reduction of intensity in cellulose II; and is shifted to 1425 cm−1 with moderate reduction of intensity in cellulose III.

1163 cm−1: Attributed to the antisymmetric stretching mode of the C–O–C group, C–O stretching, or O–H bending, there are no differences of intensity between cellulose I, II, and III. A transformation from cellulose I to II is accompanied by a shift of the peak to lower wavenumbers, while there is no shift with a transformation to cellulose III.

1111 cm−1: Attributed to ring asymmetric valence vibration and in addition, thought analogous to a similar signal in primary and secondary alcohols rising from the influence of hydrogen bonding on stretching vibration of the C–O bond. The peak intensity at this position is strong for cellulose I and is shifted to lower wavenumbers in cellulose III. In cellulose II, the peak is transformed into a shoulder, due to the appearance of a strong, broader peak in the region of 1090 cm−1.

893 cm−1: Attributed to valence vibration of the C–O–C group or vibrational modes of groups at the C(1) position. In cellulose I, it appears as a weak, broad peak, but changes to a sharp and strong peak on transformation to cellulose II. In cellulose III, the peak exhibits an intermediate intensity.

Set (a): single-blind test

The approach in this experimental set was that the authors would first postulate on the treatment type awarded to the samples based on analysis of FTIR-ATR spectra, and the process house would then reveal the facts.

Typical examples of the FTIR-ATR spectra in the region 1500–850 cm−1 from samples of the experimental set are shown in Fig. 1. The four key wavenumbers described in the list above are highlighted in the figure, and it may be noted that the absorbance peaks in our measurements did not occur at the exact positions reported in literature.

FTIR-ATR spectra of selected samples from set (a)––A: untreated; B: ammonia mercerized (ARE variant); C: ammonia mercerized (wash-off variant); D: NaOH mercerized; E: NaOH followed by ammonia mercerization (evaporative variant); F: NaOH followed by ammonia mercerization (wash-off variant). The spectra are artificially staggered for clarity of presentation

As may be observed in the figure, there were distinct differences between samples in the peak at 1107 cm−1. As compared to the untreated sample (spectrum A), there is a small but distinct peak shift toward lower wavenumbers in the spectra of ammonia-mercerized samples (B and C). A shoulder appears at the peak position in the NaOH- and NaOH + L-NH3-mercerized samples (spectra D, E, and F). These observations acted as the primary basis for our postulations of the treatment type. The peaks at 895 and 1429 cm−1 were deemed unreliable indicators of treatment differences as we observed only minor changes of peak intensity, sharpness, and of their positions.

There were changes observed in the peak at 1160 cm−1, but they were inconsistent, as explained with examples in Fig. 2. Spectrum G shows a distinct shift of the peak at 1107 cm−1 (indicative of ammonia mercerization) [10], but also a small shift of the peak at 1160 cm−1 (indicative of NaOH mercerization) [10]. This would indicate a combined NaOH + L-NH3 mercerization, but the sample was only L-NH3 mercerized. There were more such instances of samples not mercerized with NaOH showing small shifts of the 1160 cm−1 peak, and samples mercerized with NaOH showing no shifts. Therefore, changes in the peak at 1160 cm−1 were also deemed unreliable as indicators of treatment type.

It was not possible to differentiate between the evaporative and wash-off modes of ammonia removal in L-NH3-treated samples as their FTIR-ATR spectra are very similar (compare spectra B and C in Fig. 1). A differentiation between NaOH and NaOH + L-NH3 is also very difficult, as exemplified by spectra I and J, in Fig. 2, which are both from samples mercerized with NaOH + L-NH3. Both show a shoulder at 1107 cm−1, which indicates NaOH mercerization, but spectrum I also shows a shift of the shoulder region, hinting at L-NH3 mercerization but that is not seen in spectrum J.

Thus, it becomes clear from the results of this set that the FTIR-ATR spectroscopy method could be used to differentiate the samples into three distinct groups: untreated, L-NH3 mercerized, and NaOH mercerized. The method could not be used to differentiate between the two modes of ammonia removal, nor would it detect L-NH3 mercerization post a mercerization with NaOH.

Set (b): test of storage time

The goal here was to investigate the time stability of the FTIR-ATR signal for detection of L-NH3 treatments. To this end, the process house provided sample pieces from fabrics in their storage that had been L-NH3 treated in the past (sample nos. 25 and 26). For comparison, they also provided other pieces from the same fabrics that were untreated and freshly treated with L-NH3 for the test. Sample 25 was subjected to the evaporative mode of ammonia removal and sample 26 to the wash-off mode. The dates when they had been treated previously were in the years 2012 (sample 25) and 2002 (sample 26), and the fresh ammonia mercerization was performed in the year 2016. It should be noted that the fabric storage area at the process house is not temperature or humidity controlled. The FTIR-ATR spectra measured on the samples are shown in Fig. 3.

FTIR-ATR spectra of samples from set (b)––(I) sample 25, ammonia mercerized (ARE variant), A = untreated piece; B = piece mercerized in 2012; and C = piece mercerized in 2016; (II) sample 26, ammonia mercerized (SRE variant), A = untreated piece; B = piece mercerized in 2002; and C = piece mercerized in 2016. The spectra are artificially staggered for clarity of presentation

As can be seen, the spectra from all the treated pieces showed a distinct shift of the 1107 cm−1 peak, which was not observed in the untreated pieces, and there were no differences between the samples treated in the past (i.e., in 2012 and 2002) and those treated in 2016. Thus, the changes observed in the FTIR-ATR spectra appear time stable over a span of at least 14 years.

Kafle et al. [12] compared FTIR-ATR spectroscopy, X-ray Diffraction (XRD), and sum-frequency-generation (SFG) vibrational spectroscopy to detect mercerization type on cotton textiles treated in commercial operations. In the FTIR-ATR measurements, they focused on changes to the –OH stretching peaks in the regions of 3270, 3450, and 3480 cm−1, but we find the changes at the 1107 cm−1 peak to be more distinct.

Kafle et al. [12] found it difficult to obtain clear evidence of cellulose II in the NaOH-mercerized fabrics with XRD measurements, and that is reported by other researchers as well for materials treated in commercial operations [13, 14]. In industrial operations, there is generally insufficient time for complete permeation of the NaOH liquor through the fabric bulk, and therefore seldom a total conversion of lattice structures. Thus, treated substrates exhibit a mix of the type I and II allomorphs along with an increased proportion of amorphous regions [15,16,17,18]. Since XRD is a bulk measurement technique, the resulting signal consists of overlapping contributions from the two allomorphs as well as amorphous regions, and it becomes difficult to isolate the signal of the type II lattice structure.

FTIR-ATR spectroscopy is a surface measurement technique, with the depth of IR beam penetration into substrates limited to typically between 0.5 and 5 µm [19]. There is high likelihood of NaOH liquor penetration to such depths in commercial treatments and thus, clear evidence of cellulose II lattice structures may be obtained with FTIR-ATR spectroscopy as observed in this work. SFG spectroscopy is also a surface measurement technique, but since the cellulose II allomorph produces a very weak signal [20], it was not found possible to obtain clear evidence of NaOH mercerization by [12].

A distinct signal of L-NH3 treatment was consistently observed in the FTIR-ATR spectra of samples from the evaporative mode of ammonia removal, but unexpectedly, the same was observed even for samples from the wash-off mode. This was true even in the sample measured 14 years after the treatment. In general, it is found difficult with XRD to detect the cellulose IIII lattice structure in L-NH3-treated cotton if the ammonia is removed by wash-off, in contrast to the evaporative mode of ammonia removal, where substrates exhibit clear evidence of the lattice transformation [21,22,23,24]. It is attributed to a water-induced reversion of the cellulose IIII to cellulose I, accompanied by an increase in proportion of the amorphous or disordered fraction in the polymer. Only if cotton is treated with L-NH3 under greater than atmospheric pressures do materials exhibit a cellulose IIII lattice structure stable to ammonia removal with water [25].

There is research to suggest that small amounts of the IIII allomorph persist in cotton subjected to the wash-off mode of ammonia removal, and their presence may be detected by employing peak deconvolutions of XRD signals [5, 26]. However, it is unclear how they are spatially distributed within fiber structures so as to account for their detection with a surface-limited method such as FTIR-ATR spectroscopy. In their work, Kafle et al. [12] only investigated the evaporative mode of ammonia removal, and while they did observe a strong signal of the cellulose IIII lattice with SFG spectroscopy, it is not known whether the same will be observed with the wash-off mode of ammonia removal.

Thus, it may be concluded that no one method can differentiate between cotton textiles treated with only NaOH vs. NaOH + L-NH3, but it would be possible with both FTIR-ATR spectroscopy and SFG spectroscopy. The former method would yield confirmation of the NaOH treatment, and with the latter, it would be possible to yield confirmation of the L-NH3 treatment. However, as stated above, Kafle et al. [12] tested SFG spectroscopy only on the evaporative mode of ammonia removal, and it is not clear what effect the washing mode of ammonia removal will have on the results.

It is to be noted that, as the samples were pieces obtained from commercial processing operations, the treatment history of the fabrics is not fully known. For instance, it is not known whether mercerization treatments were awarded to entire fabrics or yarns. In the latter, especially in case of yarn-dyed samples, it is not known whether all yarns in the fabric were mercerized or only the colored yarns. Nevertheless, the mercerized could be differentiated from non-mercerized pieces even though all were measured only at one position located at the approximate center.

Another unknown factor is whether the samples in our work were dyed before or after mercerization. In general, mercerization treatments precede dyeing operations [27]. However, L-NH3 mercerization may also be performed after dyeing, as a preparatory step for finishing treatments, e.g., flame retardance or crease resistance [28]. Therefore, whereas it may be assumed that the NaOH mercerization preceded the dyeing step, the same cannot be stated with respect to L-NH3 mercerization. The presence of colorants on fabric samples did not interfere with the differentiation between non-mercerized and mercerized samples, or between L-NH3 mercerized and NaOH mercerized samples. Moreover, based on the assumption above, it appears that dyeing after NaOH mercerization did not interfere with treatment identification. However, it remains to be investigated whether a dyeing operation after L-NH3 mercerization will interfere with the treatment identification.

Conclusion

The results we obtained in the work suggest that the FTIR-ATR-measured changes to the absorbance peak at ca. 1107 cm−1 could be used as a simple test of mercerization type on cotton textiles treated in commercial operations. One can differentiate between NaOH mercerization, L-NH3 mercerization, and no mercerization. Surprisingly, clear signs of L-NH3 mercerization are evident even if the wash-off mode of ammonia removal is employed, which is not the case with other methods such as XRD. The method also appears robust to differences of thickness, weave type, as well as dyeing.

It is difficult with FTIR-ATR spectroscopy to confirm whether L-NH3 treatments were awarded if the textiles were previously mercerized with NaOH. There are other methods available, such as XRD and SFG spectroscopy, which can detect evidence of L-NH3 treatments. With these other methods, however, it is difficult to confirm NaOH mercerization, and thus it appears there is no one method that will clearly differentiate between the different mercerization treatments, and a complementarity of testing methods is necessary to elucidate the mercerization history of commercially treated cotton textiles.

It should be noted that the aim of the work was not to arrive at a “quality” measure of mercerization. The textile industry employs a variety of other tests for the purpose. The aim is simply to confirm whether the mercerization history of a cotton textile is truly what it is stated to be. A question is whether post-mercerization treatments, such as cross-linking for wrinkle resistance, will have an influence on the detection of mercerization types. It will be investigated in future work and will be reported on at a later time.

Experimental

All samples tested in this work were woven fabrics of 100% cotton mercerized with L-NH3, NaOH, or their combination in commercial-scale operations, or not mercerized. Both the evaporative and wash-off modes of NH3 removal were included. Descriptions and photomicrographs of the experimental substrates are available in Table S1 and Fig. S1 (Supplementary Information I), and the mercerization process descriptions are available in our previous report [4].

FTIR-ATR spectroscopy

The instrument used was a Bruker Vector 22 FTIR spectrometer (Bruker Corporation, USA), equipped with a MIRacle™ Horizontal ATR accessory fitted with a diamond crystal double-reflection universal plate from PIKE Technologies (USA). The absorbance spectra were recorded from an aggregate of 128 scans in the wavenumber range of 4000–500 cm−1 at a resolution of 2 cm−1. The measurements were performed at one position per sample piece (in the approximate middle), and all spectra were smoothened and min–max normalized. Whereas only selected examples are illustrated in the paper, the complete dataset is available in Supplementary Information II.

Data availability

All data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Greenwood PF (1987) J Soc Dye Colour 103:342

Rowland SP, Wade CP, Bertoniere NR (1984) J Appl Polym Sci 29:3349

Jung HZ, Berni RJ, Benerito RR, Carra JH (1975) Text Res J 45:681

Manian AP, Braun DE, Široká B, Bechtold T (2022) Cellulose 29:4183

Bredereck K, Commarmot A (1998) Melliand Textilber 79:64

Commarmot A, Bredereck K (1998) Int Text Bull 44:72

Lin L, Jiang T, Liang Y, Pervez MN, Navik R, Gao B, Cai Y, Hassan MM, Kumari N, Naddeo V (2022) Materials (Basel) 15:1758

Wakida T, Kida K, Lee M, Bae S, Yoshioka H, Yanai Y (2000) Text Res J 70:328

Colom X, Carrillo F (2002) Eur Polym J 38:2225

Nelson ML, O’Connor RT (1964) J Appl Polym Sci 8:1325

Široký J, Blackburn RS, Bechtold T, Taylor J, White P (2010) Cellulose 17:103

Kafle K, Greeson K, Lee C, Kim SH (2014) Text Res J 84:1692

Bredereck K (1981) Textil-Praxis Int 36:1010

Saafan AA, Habib A (1989) Das Pap 43:8

Chidambareswaran PK, Patil NB, Sundaram V (1976) J Appl Polym Sci 20:2297

Kolpak FJ, Weih M, Blackwell J (1978) Polymer (Guildf) 19:123

Niaz A, Tahir KUD (1989) Text Res J 59:772

Ghosh S, Dilanni D (1994) J Text Inst 85:308

Anon (2023) Attenuated Total Reflection ATR: Theory and Applications. Madison, WI (USA). https://www.piketech.com/files/pdfs/PIKE_ATR_Theory-Applications.pdf. Accessed 30 Sept 2023

Lee CM, Mittal A, Barnette AL, Kafle K, Park YB, Shin H, Johnson DK, Park S, Kim SH (2013) Cellulose 20:991

Cheek LB, Chiasson CM (1981) Text Chem Color 13:23

Cheek L, Struszczyk H (1980) Cellul Chem Technol 14:893

Bertoniere NR, King WD, Rowland SP (1986) J Appl Polym Sci 31:2769

Wada M, Nishiyama Y, Bellesia G, Forsyth T, Gnanakaran S, Langan P (2011) Cellulose 18:191

Yatsu LY, Calamari TA, Benerito RR (1986) Text Res J 56:419

Rousselle MA, Nelson ML, Hassenboehler CB Jr, Legendre DC (1976) Text Res J 46:304

Roy Choudhury AK (2011) Pre-treatment and preparation of textile materials prior to dyeing. In: Clark M (ed) Handbook of textile and industrial dyeing: principles, processes and types of dyes. Woodhead Publishing, Oxford, p 64

Lewin M, Rau RO, Sello SB (1974) Text Res J 44:680

Acknowledgements

The research leading to these results was performed in the frame of the project “Textile Competence Center Vorarlberg 2 (Project No. 882502)” funded under the COMET program––Competence Centers for Excellent Technologies––by the Federal Ministry for Climate Protection, Environment, Energy, Mobility, Innovation and Technology (BMK) and the Federal Ministry for Digitization and Business Location (BMDW), with co-financing from the federal province of Vorarlberg. The COMET program is administered by the Austrian Research Promotion Agency (FFG).

Funding

Open access funding provided by University of Innsbruck and Medical University of Innsbruck.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Manian, A.P., Široká, B. & Bechtold, T. Detection of ammonia mercerization in cotton textiles. Monatsh Chem (2024). https://doi.org/10.1007/s00706-024-03181-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00706-024-03181-9