Abstract

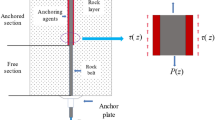

Resin distribution in a borehole is critical to the anchoring performance during resin-anchored bolt installation. The distribution characteristics of the resin may be affected by fractures in the soft and broken surrounding rock of the borehole wall. Accordingly, numerical simulations, theoretical analyses, and laboratory experiments were performed to explore the resin flow characteristics and the anchoring performance of resin-anchored bolts in soft and broken surrounding rock. The results indicate that, for resin mixing in soft and broken surrounding rock, the resin and the curing agent rapidly flow into the fractures in the borehole wall during the rotation and advancement of the bolt toward the bottom of the borehole, resulting in resin loss. The amount of resin loss increases with the fracture aperture, number of fractures, and fracture angle, continuously weakening the anchoring performance. With increasing number of fractures, the deformation of the anchoring system before reaching the maximum anchoring force gradually increases. Conversely, an anchoring system with no fractures can quickly play its bearing role and provide a high working resistance. In addition, an improving method of anchoring performance was proposed: grouting reinforcement and borehole wall repair can enhance the strength of the surrounding rock, reduce the fracture aperture and resin loss, and improve the anchoring quality. This paper provides a theoretical reference for the stability control and anchoring quality improvement of soft and broken surrounding rock.

Highlights

-

The resin and the curing agent will flow into the fractures in the borehole wall during resin mixing process of resin-anchored bolt installation.

-

The amount of resin loss increases with the fracture aperture, number of fractures, and fracture angle.

-

The increase in the resin loss amount will continuously weaken the bearing capacity of an anchoring system.

-

An improving method of anchoring performance was proposed by enhancing the surrounding rock strength and reducing the fracture aperture.

Similar content being viewed by others

Data availability

The data that support the finding of this study are available from the corresponding author upon reasonable request.

Abbreviations

- β :

-

The fracture angle

- P :

-

The axial concentrated tension on the free end of the bolt

- τ m :

-

The mean bonding stress of the interface between the resin and the surrounding rock

- σ fn :

-

The normal stress of the inflow resin subjected to the side of fracture #n

- τ fn :

-

The shear stress of the inflow resin subjected to the side of fracture #n

- D :

-

The diameter of the borehole

- b :

-

The resin inflow depth

- L :

-

The designed anchoring length

- s :

-

The reduced anchoring length as a result of resin loss

- W :

-

The fracture aperture, n denotes the fracture number

- d :

-

The diameter of the bolt

- τ rn :

-

The shear stress of the annular structure of fracture #n subjected by the borehole on the resin

- \({V}_{S}\) :

-

The volume of the resin flowing into the n fractures

- \({\tau}_{{\rm mr}}\) :

-

The mean value of the shear stress of the annular structures formed by the n fractures subjected on the resin by the borehole

- \({\tau}_{{\text{max}}}\) :

-

The shear strength of the surrounding rock

References

Aziz N, Craig P, Mirzaghorbanali A (2016) Factors Influencing the quality of encapsulation in rock bolting. Rock Mech Rock Eng 49:3189–3203

Aziz N, Hillyer J, Joyce D et al (2013) New approach to resin sample preparation for strength testing. In: Aziz N, Kinninmonth B (eds) Proceedings of 13th underground coal operators’ conference, Wollongong, pp 152–155

Aziz N, Nemcik J, Ren T et al (2014) Development of new testing procedure for the assessment of resin performance for improved encapsulated roof bolt installation coal mines. ACARP C21011, Final report

Campbell R, Mould R, Gregor S (2004) Investigation into the extent and mechanisms of gloving and un-mixed resin fully encapsulated roof bolts. In: Proceedings of 2003 coal operator’s conference. Wollongong, pp 203–214

Campbell R, Mould RJ (2005) Impacts of gloving and un-mixed resin in fully encapsulated roof. Int J Coal Geol 64:116–125

Chong ZH, Yue TL, Yao QL et al (2021) Experimental and numerical investigation of crack propagation in bolting systems strengthened with resin-encapsulated rock bolts. Eng Fail Anal 122:1–22

Compton CS, Oyler DC (2005) Investigation of fully grouted roof bolts installed under in-situ conditions. In: Proceedings of the 24th international conference on ground control in mining. Morgantown, pp 302–312

Craig P (2012) Addressing resin loss and gloving issues at a mine with coal roof. In: Proceedings of the 12th coal operators’ conference. Wollongong, pp 120–128

Fu MX, Liu SW, Jia HS, He DY (2020) Experimental study of an orientation and resin-lifting device for improving the performance of resin-anchored roof bolts. Rock Mech Rock Eng 53:211–231

Goel RK, Swarup A, Sheorey PR (2007) Bolt length requirement in underground openings. Int J Rock Mech Min Sci 44(5):802–811

Golait YS, Padade AH, Cherian T (2018) Prediction of quantitative response of under-reamed anchor piles in soft clay using laboratory model study. J Test Eval 46(2):507–522

He DY, Liu SW, Fu MX et al (2021) Experimental study on resin-anchored bolt concentricity including a device for more consistent bolt centering. Int J Rock Mech Min Sci 148:1–13

He DY, Liu SW, Fu MX et al (2023) Anchoring effect guarantee method and experiment for the bottom reaming area of borehole in weak surrounding rock of coal mine roadway. J China Coal Soc. https://doi.org/10.13225/j.cnki.jccs

Hsu ST, Tang YG (2013) Anchorage behavior of mechanically under-reamed anchors in silty sand. Disaster Adv 6:31–44

Jia HS, Wang YW, Li YE (2021) Experimental study of stirring and resin-blocking devices for improving the performance of resin-anchored cable bolts. Rock Mech Rock Eng 54(8):3995–4008

Kang HP (2021) Seventy years development and prospects of strata control technology for coal mine roadways in China. Chin J Rock Mech Eng 40(01):1–30

Kang HP, Wang JH, Lin J (2010) Case studies of rock bolting in coal mine roadways. Chin J Rock Mech Eng 29(4):649–664

Lei S, Gao FQ, Wang XQ (2021) Study on statistics and classification of uniaxial compressive strength of coal. Coal Sci Technol 49(3):64–70

Liu SW, Shang PX, Zhang H et al (2015) Reaming mechanism of bolt hole in entry within weak surrounding rock. J China Coal Soc 40:1753–1760

Liu SW, Fu MX, Jia HS et al (2019) Shear characteristics of cuneiform reaming anchorage bolts in coal mine roadways. Rock Mech Rock Eng 52(6):1931–1943

Liu SW, He DY, Fu MX (2020a) Experimental investigation of surrounding-rock anchoring synergistic component for bolt support in tunnels. Tunn Undergr Space Technol 10(4):1–10

Liu SW, He DY, Fu MX (2020b) Numerical simulation of mixing process of resin grout and optimization experiment of high-efficiency mixing component. J China Coal Soc 45(9):3073–3086

Liu SW, He YF, Fu MX (2021) Relationship between catalyst-resin mastic ratio and anchoring performance of mineral resin grout. J China Coal Soc 46(12):3819–3832

Liu SW, Cui L, Ma NJ et al (2022a) Flow characteristics of stirring resin at wedge end of bolts and anchorage test. Chin J Rock Mech Eng 41(1):40–52

Liu SW, Cui L, Ma NJ et al (2022b) Experimental study on optimization of end shape of mixed resin of rebar bolt. J China Coal Soc 47(4):1501–1511

Ma S, Aziz N, Nemcik J et al (2017) The effects of installation procedure on bond characteristics of fully grouted rock bolts. Geotech Test J 40:846–857

Mark C (2000) Design of roof bolt system. In: Proceedings of new technology for coal mine roof support. Cincinnati, pp 111–131

Su HJ, Jing HW, Zhao HH et al (2017) Strength degradation and anchoring behavior of rock mass in the fault fracture zone. Environ Earth Sci 76:179

Villaescusa E, Varden R, Hassell R (2008) Quantifying the performance of resin anchored rock bolts in the Australian underground hard rock mining industry. Int J Rock Mech Min Sci 45:94–102

Wang Q, Qin Q, Jiang B, Wang Q (2019) Study and engineering application on the bolt-grouting reinforcement effect in underground engineering with fractured surrounding rock. Tunn Undergr Space Technol 84:237–347

Wang XK, Xie WB, Bai JB et al (2020) Control effects of pretensioned partially encapsulated resin bolting with mesh systems on extremely soft coal gateways: a large-scale experimental study. Rock Mech Rock Eng 53:3447–3469

Wang W, Pan YS, Xiao Y (2022a) Synergistic mechanism and technology of cable bolt resin anchoring for roadway roofs with weak interlayers. Rock Mech Rock Eng 55:3451–3472

Wang W, Pan YS, Xiao Y (2022b) Synergistic resin anchoring technology of rebar bolts in coal mine roadways. Int J Rock Mech Min Sci 151:1–13

Zingano A, Koppe J, Costa JF et al (2008) In-situ tests and numerical simulation about the effect of annulus thickness on the resin mixture for fully grouted resin bolt. In: Proceedings of 27th international conference on ground control in mining, Morgantown, pp 284–290

Acknowledgements

Critical comments by the anonymous reviewers greatly improved the initial manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (grants 52104083 and 52074102), the Open Research Fund of the State Key Laboratory for Fine Exploration and Intelligent Development of Coal Resources, CUMT (SKLCRSM22KF007), the Key R&D and promotion projects in Henan Province (222102320169), and the Key Scientific Research Projects of Colleges and Universities in Henan Province (22A440004).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fu, M., Liu, S., Huang, S. et al. Resin Flow Characteristics and Anchoring Performance of Resin-Anchored Bolts in Soft and Broken Surrounding Rock. Rock Mech Rock Eng 57, 1579–1601 (2024). https://doi.org/10.1007/s00603-023-03622-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-023-03622-7