Abstract

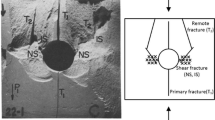

Mechanical behavior and energy evolution of rock around the tunnel are critical for evaluating the instability of geotechnical engineering. To reveal the influence of tunnel section shape on deformation, stress distribution, and fracturing mechanism of rock around the tunnel, a series of physical model shear tests for rock around prefabricated rectangular and circular tunnels were carried out, and corresponding fracturing and energy evolution analysis were also presented. In the shear test, the cracking evolution of rock around tunnel specimens was monitored and recorded by a high-speed camera and acoustic emission monitor to reveal the macro- and meso-fracture features. In addition, to examine the continuous-discontinuous shear process, four typical numerical models of rock around the tunnel were exploited to explore meso-mechanical behavior and fracturing mechanism. In light of the first law of thermodynamics, energy conversion process, damage characteristics and rockburst tendency of rock around tunnel specimens were investigated. The test results manifested that fracturing evolution, energy characteristic conversion, and micro-cracks evolution of rock around tunnel specimens generally were classified as four unified stages. In terms of fracturing evolution, rock around tunnel specimens experienced shearing compression stage (stage I), elastic stage (stage II) dominated by crack initiation, shearing fracture stage (stage III) dominated by crack propagation, coalescence and shear-induced rockburst, and shearing friction stage (stage IV). In the aspect of energy characteristic conversion, rock around tunnel specimens were mainly elastic deformation before peak shearing load, and the plastic deformation was relatively small. Partial dissipated strain energy acted on closing hole and crack initiation, and the rest was stored as elastic strain energy. After peak shearing load, the shear strength dropped rapidly, and a large amount of strain energy was converted into dissipated strain energy for crack propagation, coalescence and shear-induced rockburst. In the evolution of micro-cracks, the specimens underwent crack quiet period (stage I), crack initial increase stage (stage II), crack rapid increase stage (stage III), and crack stable stage (stage IV). Interestingly, the damage stress and rockburst tendency of rock around prefabricated rectangular tunnels were superior to those of rock around prefabricated circular tunnels, indicating that the bearing capacity of rock around prefabricated rectangular tunnels was superior to that of rock around prefabricated circular tunnels, related to the deviatoric stress distribution and confining pressure. In addition, a novel impact tendency index (Sp et) was presented for evaluating shear-induced rockburst tendency, which carved the proportional relationship between elastic strain energy and dissipative strain energy at peak shearing load. The research results were conducive to recognize the fracturing mechanism of rock around a tunnel subjected to shear condition and provided a theoretical basis for the prevention and control of geotechnical engineering.

Highlights

-

Shear characteristic, energy characteristic conversion and micro-cracks number evolution of rock around tunnel specimens generally were classified as four unified stages.

-

Bearing capacity of rock around a prefabricated rectangular tunnel was superior to that of rock around a prefabricated circular tunnel, related to the deviatoric stress distribution and confining pressure.

-

A novel damage variable was proposed to quantify the damage degree of rock

-

A novel impact tendency index (Sp et) was presented for evaluating the shear-induced rockburst tendency

Similar content being viewed by others

Data availability

Data will be made online as requested.

Abbreviations

- δ h :

-

Shear displacement

- \(\delta_{h}^{t}\) :

-

Shear displacement at time t

- δ v :

-

Normal displacement

- \(\delta_{v}^{t}\) :

-

Normal displacement at time t

- γ p :

-

Shear peak strain

- μ :

-

Particle friction coefficient

- v :

-

Poisson ratio

- ρ :

-

Particle density

- σ n :

-

Parallel-bond normal strengths

- τ :

-

Shear stress

- τ n :

-

Parallel-bond shear strengths

- τ p,:

-

Shear strength

- \(\Delta U_{{\text{d}}}\) :

-

Dissipative strain energy increment

- AE:

-

Acoustic emission

- D :

-

Damage variable

- DEM:

-

Discrete element method

- E :

-

Elastic modulus

- E c :

-

Particle contact modulus

- E c′:

-

Parallel bond modulus

- E t :

-

Tensile modulus

- G :

-

Shear modulus

- ISRM:

-

International society for rock mechanics

- k n/ks :

-

Ratio of normal to shear stiffness of the particle

- K n′/k s′:

-

Ratio of normal to shear stiffness of parallel bond

- PFC:

-

Particle flow code

- R max/R min :

-

Ratio of maximum to minimum of radius

- R min :

-

Minimum radius of the particle

- Sp et:

-

Impact tendency index

- U :

-

Total energy

- U e :

-

Elastic strain energy

- U d :

-

Dissipated strain energy

- U n :

-

Work of normal force

- U s :

-

Work of shear force

- V P :

-

Wave velocity

References

AC10520942 (2008) Standard test method for performing laboratory direct shear strength tests of rock specimens under constant normal force. ASTM

Aydin A (2009) The ISRM suggested methods for rock characterization, testing and monitoring: 2007–2014. Int J Rock Mech Min Sci 46:627–634

Bahaaddini M (2017) Effect of boundary condition on the shear behaviour of rock joints in the direct shear test. Rock Mech Rock Eng 50:1141–1155

Bieniawski Z (1967) Mechanism of brittle fracture of rock: part I—theory of the fracture process. Int J Rock Mech Min Sci Geomech Abstr 4:395–406

Brady B, Rowell G (1986) Laboratory investigation of the electrodynamics of rock fracture. Nature 321:488–492

Bratov V, Petrov Y (2007) Optimizing energy input for fracture by analysis of the energy required to initiate dynamic mode I crack growth. Int J Solids Struct 44:2371–2380

Cao R, Cao P, Fan X, Xiong X, Lin H (2016a) An experimental and numerical study on mechanical behavior of ubiquitous-joint brittle rock-like specimens under uniaxial compression. Rock Mech Rock Eng 49:4319–4338

Cao R, Cao P, Lin H, Pu C, Ou K (2016b) Mechanical behavior of brittle rock-like specimens with pre-existing fissures under uniaxial loading: experimental studies and particle mechanics approach. Rock Mech Rock Eng 49:763–783

Chai Y, Dou L, Cai W, Małkowski P, Li X, Gong S, Bai J, Cao J (2023) Experimental investigation into damage and failure process of coal-rock composite structures with different roof lithologies under mining-induced stress loading. Int J Rock Mech Min Sci 170:105479

Chen S, Xia Z, Feng F, Yin D (2021) Numerical study on strength and failure characteristics of rock samples with different hole defects. Bull Eng Geol Environ 80:1523–1540

Colombo D, Massin P (2011) Fast and robust level set update for 3D non-planar X-FEM crack propagation modelling. Comput Method Appl Mech 200:2160–2180

Cornetti P, Pugno N, Carpinteri A, Taylor D (2006) Finite fracture mechanics: a coupled stress and energy failure criterion. Eng Fract Mech 73:2021–2033

Debecker B, Vervoort A (2013) Two-dimensional discrete element simulations of the fracture behaviour of slate. Int J Rock Mech Min Sci 61:161–170

Fan X, Li K, Lai H, Xie Y, Cao R, Zheng J (2018) Internal stress distribution and cracking around flaws and openings of rock block under uniaxial compression: a particle mechanics approach. Comput Geotech 102:28–38

Fan X, Yu H, Deng Z, He Z, Zhao Y (2022) Cracking and deformation of cuboidal sandstone with a single nonpenetrating flaw under uniaxial compression. Theor Appl Fract Mech 119:103284

Fedotova IV, Kuznetcov N, Pak A (2017) Specific strain energy assessment of hard rocks under different loading modes. Proc Eng 191:317–323

Feng X, Kong R, Zhang X, Yang C (2019) Experimental study of failure differences in hard rock under true triaxial compression. Rock Mech Rock Eng 52:2109–2122

Ferro G (2006) On dissipated energy density in compression for concrete. Eng Fract Mech 73:1510–1530

Griffith A (1921) The phenomena of rupture and flow in solids. Philos Trans R Soc Lond Ser A 221:163–198

Hägele A, Hall S, Sullivan C (2017) Efficient measurement strategies for particle flow simulations: the influence of circle arrangement on accuracy and efficiency. Geotechnique 67(11):986–997

Haijian S, Hongwen J, Honghui Z, Yingchao W (2014) Experimental study on the influence of longitudinal fissure on mechanics characteristic of sandstone. J Min Saf Eng 31:644

Han Z, Li D, Zhou T, Zhu Q, Ranjith P (2020) Experimental study of stress wave propagation and energy characteristics across rock specimens containing cemented mortar joint with various thicknesses. Int J Rock Mech Min Sci 131:104352

Horii H, Nemat S (1985) Compression-induced microcrack growth in brittle solids: axial splitting and shear failure. J Geophys Res Sol EA 90:3105–3125

Huang D, Li Y (2014) Conversion of strain energy in triaxial unloading tests on marble. Int J Rock Mech Min Sci 66:160–168

Huang Y, Yang S, Ranjith P, Zhao J (2017) Strength failure behavior and crack evolution mechanism of granite containing pre-existing non-coplanar holes: experimental study and particle flow modeling. Comput Geotech 88:182–198

Huang S, Liu Y, Guo Y, Zhang Z, Cai Y (2019) Strength and failure characteristics of rock-like material containing single crack under freeze-thaw and uniaxial compression. Cold Reg Sci Technol 162:1–10

Jaeger C (1979) Rock mechanics and engineering. Cambridge University Press, Cambridge

Jiang Q, Feng X, Fan Y, Fan Q, Liu G, Pei S, Duan S (2017) In situ experimental investigation of basalt spalling in a large underground powerhouse cavern. Tunn Undergr Space Technol 68:82–94

Jiang Z, Dou C, Zhang A, Wang Q, Wu Y (2019) Experimental study on earthquake-resilient prefabricated cross joints with L-shaped plates. Eng Struct 184:74–84

Jiang Q, Xin J, Xu D, Liu Q (2022) Shear failure process of rectangular tunnel: physical experimental test and numerical back-analysis. Theor Appl Fract Mech 120:103384

Kaiser PK, Cai M (2012) Design of rock support system under rockburst condition. J Rock Mech Geotech 4:215–227

Kidybiński A (1981) Bursting liability indices of coal. Int J Rock Mech Min Sci Geomech Abstr 4:295–304

Li S, Feng X, Li Z, Chen B, Zhang C, Zhou H (2012) In situ monitoring of rockburst nucleation and evolution in the deeply buried tunnels of Jinping II hydropower station. Eng Geol 137:85–96

Li X, Li C, Cao W, Tao M (2018) Dynamic stress concentration and energy evolution of deep-buried tunnels under blasting loads. Int J Rock Mech Min Sci 104:131–146

Liu C, Jiang Q, Xin J, Wu S, Liu J, Gong F (2022a) Shearing damage evolution of natural rock joints with different wall strengths. Rock Mech Rock Eng 55:1599–1617

Liu Q et al (2022b) Mechanical characteristics of single cracked limestone in compression-shear fracture under hydro-mechanical coupling. Theor Appl Fract Mech 119:103371

Liu X, Zhang K, Liu W, Xie J (2022c) Influence of weak inclusions on the cracking behavior of a jointed rock mass containing an opening: insights from DIC-based approaches. Arch Civ Mech Eng 22:1–25

Nakatani M (2001) Conceptual and physical clarification of rate and state friction: Constitutive equations and steady-state properties. J Geophys Res Solid Earth 106(B5):8485–8502

Ortlepp W, Stacey T (1994) Rockburst mechanisms in tunnels and shafts. Tunn Undergr Space Technol 9:59–65

Pan P, Feng X, Hudson JA (2009) Study of failure and scale effects in rocks under uniaxial compression using 3D cellular automata. Int J Rock Mech Min Sci 46:674–685

Potyondy D, Cundall P (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364

Rahimi R, Nygaard R (2015) Comparison of rock failure criteria in predicting borehole shear failure. Int J Rock Mech Min Sci 79:29–40

Ruan S, Liu L, Zhu M et al (2023) Development and field application of a modified magnesium slag-based mine filling cementitious material. J Clean Prod 419:138269

Sun B (2021) a combined discrete element-finite difference model for simulation of double shield TBM excavation in jointed rocks. Rock Mech Rock Eng 54:5867–5883

Wang Y, Cui F (2018) Energy evolution mechanism in process of Sandstone failure and energy strength criterion. J Appl Geophys 154:21–28

Wang J, Yan H (2012) DEM analysis of energy dissipation in crushable soils. Soils Found 52:644–657

Wang C, Tannant D, Lilly P (2003) Numerical analysis of the stability of heavily jointed rock slopes using PFC2D. Int J Rock Mech Min Sci 40:415–424

Wang S, Tang Y, Wang S (2021) Influence of brittleness and confining stress on rock cuttability based on rock indentation tests. J Cent South Univ 28:2786–2800

Wang T, Yan C (2023) Investigating the influence of water on swelling deformation and mechanical behavior of mudstone considering water softening effect. Eng Geol 318:107102

Wang T, Gao R, Yan C (2023a) Dynamic fragmentation and chip formation of water-soaked rock in linear cutting with a coupled moisture migration-fracture model. Comput Geotech 163:105723

Wang T, Yan C, Zheng H et al (2023b) Optimum spacing and rock breaking efficiency of TBM double disc cutters penetrating in water-soaked mudstone with FDEM. Tunn Undergr Sp Technol 138:105174

Wenjie X, Shi W (2016) Meso-mechanics of soil-rock mixture with real shape of rock blocks based on 3D numerical direct shear test. Chin J Rock Mech Eng 35:2152–2160

Whitworth A, Vaughan J, Southam G, van der Ent A, Nkrumah P, Ma X, Parbhakar A (2022) Review on metal extraction technologies suitable for critical metal recovery from mining and processing wastes. Miner Eng 182:107537

Wong R, Lin P (2015) Numerical study of stress distribution and crack coalescence mechanisms of a solid containing multiple holes. Int J Rock Mech Min Sci 79:41–54

Wu Z, Wong LNY (2013) Modeling cracking behavior of rock mass containing inclusions using the enriched numerical manifold method. Eng Geol 162:1–13

Wu H, Kulatilake P, Zhao G, Liang W (2019) Stress distribution and fracture evolution around a trapezoidal cavity in sandstone loaded in compression. Theor Appl Fract Mech 104:102348

Wu H, Dai B, Cheng L, Lu R, Zhao G, Liang W (2021) Experimental study of dynamic mechanical response and energy dissipation of rock having a circular opening under impact loading. Min Metall Explor 38:1111–1124

Wu J, Liao S, Liu M, He J (2022) Analytical investigation on the arching effect of tunnel face in sandy ground. Tunn Undergr Space Technol 119:104207

Xie H, Wang J, Kwaśniewski M (1999) Multifractal characterization of rock fracture surfaces. Int J Rock Mech Min Sci 36:19–27

Xiong X, Li B, Jiang Y, Koyama T, Zhang C (2011) Experimental and numerical study of the geometrical and hydraulic characteristics of a single rock fracture during shear. Int J Rock Mech Min Sci 48:1292–1302

Xin J, Jiang Q, Gong F, Liu L, Liu C, Liu Q, Yang Y, Chen P (2024) Mechanical behaviors of backfill-rock composites: physical shear test and back-analysis. J Rock Mech Geotech Eng 16(4)

Xu G, He C, Wang J, Zhang J (2020a) Study on the damage evolution of secondary tunnel lining in layered rock stratum. Bull Eng Geol Environ 79:3533–3557

Xu H, Qin Y, Wang G, Fan C, Wu M, Wang R (2020b) Discrete element study on mesomechanical behavior of crack propagation in coal samples with two prefabricated fissures under biaxial compression. Powder Technol 375:42–59

Yang S, Tian W, Huang Y, Ranjith P, Ju Y (2016) An experimental and numerical study on cracking behavior of brittle sandstone containing two non-coplanar fissures under uniaxial compression. Rock Mech Rock Eng 49:1497–1515

Yang Z, Jiang Y, Li S, Li J, Hu Y (2020) Experimental study on shear mechanical properties of soil-rock mixture-bedrock interface. Chin J Geotech Eng 42:1947–1954

Yang B, Jiang Q, Feng X, Xin J, Xu D (2022) Shear testing on rock tunnel models under constant normal stress conditions. J Rock Mech Geotech 14(6):1722–1736

Yang P, Liu L, Suo Y, Qu H, Xie G, Zhang X, Deng S, Lv Y (2023) Investigating the synergistic effects of magnesia-coal slag based solid waste cementitious materials and its basic characteristics as a backfill material. Sci Total Environ 880:163209

Yue Z, Peng L, Yue X, Wang J, Lu C (2020) Experimental study on the dynamic coalescence of two-crack granite specimens under high loading rate. Eng Fract Mech 237:107254

Zhang X, Wong L (2014) Displacement field analysis for cracking processes in bonded-particle model. Bull Eng Geol Environ 73:13–21

Zhang Y, Chen B, Liu A, Pi Y, Zhang J, Wang Y, Zhong L (2019a) Experimental study on shear behavior of high strength bolt connection in prefabricated steel-concrete composite beam. Compos Part B Eng 159:481–489

Zhang Y, Feng X, Yang C, Zhang X, Sharifzadeh M, Wang Z (2019b) Fracturing evolution analysis of Beishan granite under true triaxial compression based on acoustic emission and strain energy. Int J Rock Mech Min Sci 117:150–161

Zhang Y, Feng X, Zhang X, Wang Z, Sharifzadeh M, Yang C, Kong R, Zhao J (2019c) Strain energy evolution characteristics and mechanisms of hard rocks under true triaxial compression. Eng Geol 260:105222

Zhang Y, Jiang Y, Asahina D, Wang C (2020) Experimental and numerical investigation on shear failure behavior of rock-like samples containing multiple non-persistent joints. Rock Mech Rock Eng 53:4717–4744

Zhang K, Liu X, Liu W, Zhang S (2021) Influence of weak inclusions on the fracturing and fractal behavior of a jointed rock mass containing an opening: experimental and numerical studies. Comput Geotech 132:104011

Zhang T, Liu B, Wei Z, Jiao Z, Song Z, Zhang H (2022) Dynamic mechanical responses and crack evolution of burst-prone coal with a single prefabricated fissure. Theor Appl Fract Mech 121:103494

Zhao K, Yu X, Zhou Y, Wang Q, Wang J, Hao J (2020) Energy evolution of brittle granite under different loading rates. Int J Rock Mech Min Sci 132:104392

Zhou J, Li X, Mitri H (2018) Evaluation method of rockburst: state-of-the-art literature review. Tunn Undergr Space Technol 81:632–659

Zhou Z, Cai X, Li X, Cao W, Du X (2020) Dynamic response and energy evolution of sandstone under coupled static-dynamic compression: insights from experimental study into deep rock engineering applications. Rock Mech Rock Eng 53:1305–1331

Zhu Q, Li D, Han Z, Li X, Zhou Z (2019) Mechanical properties and fracture evolution of sandstone specimens containing different inclusions under uniaxial compression. Int J Rock Mech Min Sci 115:33–47

Zhu Q, Li C, Li X, Li D, Wang W, Chen J (2022) Fracture mechanism and energy evolution of sandstone with a circular inclusion. Int J Rock Mech Min Sci 155:105139

Zhu M, Xie G, Liu L, Wang R, Ruan S, Yang P, Fang Z (2023) Strengthening mechanism of granulated blast-furnace slag on the uniaxial compressive strength of modified magnesium slag-based cemented backfilling material. Process Saf Environ 174:722–733

Acknowledgements

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (No. 52325905) and the Open Research Fund of State Key Laboratory of Geomechanics and Geotechnical Engineering, Institute of Rock and Soil Mechanics, Chinese Academy of Sciences (No. Z020005).

Author information

Authors and Affiliations

Contributions

JX conceptualization, methodology, writing-original draft, and writing-review and editing; QJ conceptualization, resources, supervision, and funding acquisition; SL resources, supervision, and data curation; PC resources, formal analysis; HZ resources, formal analysis.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest concerning the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xin, J., Jiang, Q., Li, S. et al. Fracturing and Energy Evolution of Rock Around Prefabricated Rectangular and Circular Tunnels Under Shearing Load: A Comparative Analysis. Rock Mech Rock Eng 56, 9057–9084 (2023). https://doi.org/10.1007/s00603-023-03532-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-023-03532-8