Abstract

In this study, the application of characteristic impedance in estimating specific energy and average fragment size of rocks was investigated during rock breakage at high strain rates. To achieve this, rock specimen was prepared in accordance with recommendations of the International Society for Rock Mechanics and broken at high strain rates using the split Hopkinson’s pressure bar system. Results reveal that although strain rate is well related to specific energy and average fragment size of broken rocks, the product of characteristic impedance and strain rate is more reliable for estimating the forementioned parameters. In addition, strain rate and dissipated energy generally increase at higher incident energies while the average fragment size of broken rocks reduces at higher strain rates. Based on these findings, more studies on indirect estimation of energy requirement for rock breakage to desired average fragment sizes is recommended from the product of characteristic impedance and strain rate.

Highlights

-

Rock classification and rate parameters are crucial for estimating breakage characteristics of rocks at high strain rates.

-

Novel application of the product of characteristic impedance and strain rate is proposed for estimating breakage characteristics of rocks at high strain rates.

-

The product of characteristic impedance and strain rate is more reliable for estimating specific energy and average fragment size from impulse rock breakage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The mining industry consumes a significant portion of the global energy produced per annum. For instance, 11% of the annual energy produced in 2009 was used for mining-related activities in Canada (Natural Resources Canada 2011). Similarly, an average of 6.2% of global energy produced in 2015 was consumed solely by the mining industry (Holmberg et al. 2017). Further investigations revealed that majority of the energy consumed by the mining industry is used during rock breakage (Tschugg et al. 2017; Zhang and Ouchterlony 2022; Pressacco et al. 2022). Rock breakage processes in the mining industry comprise rock drilling, blasting, crushing, and grinding. Unfortunately, the energy efficiency of rock breaking processes is very low. For instance, the energy efficiency of percussive drilling and blasting are about 10% and 6%, respectively (Carrol 1985; Ouchterlony et al. 2003; Sanchidrian et al. 2007). Similarly, the energy efficiency of rock crushing and ball/rod milling are 3–5% and 1%, respectively (Prasher 1987; Chi et al. 1996; Alvarado et al. 1998; Fuerstenau and Abouzeid 2002; Zhang and Ouchterlony 2022). The effects of low energy efficiency of rock breakage processes comprise huge energy losses and increased cost of production compared to energy-optimized processes of rock breakage.

To improve the energy efficiency of comminution processes, studies on non-mechanical pre-treatment of rocks have been conducted with the aim of weakening mineral bonds in rocks prior to impact. Popular pre-treatment methods comprise thermal, magnetic, and electrical methods (Somani et al. 2017; Klein et al. 2018; Pressacco et al. 2022). In addition, comminution equipment with improved energy efficiency have also been proposed, for instance Pothina et al. (2007). However, some drawbacks have remained unresolved. Although it can be argued that pre-treatment processes reduce rock strengths, thereby reducing energy required for breaking rocks, pre-treatment processes also require energy. In some instance, the energy requirement of pre-treatment processes could lead to marginal improvements in overall energy efficiency of rock breakage processes. Similarly, utilization of constant incident energies by comminution equipment with improved energy efficiency ignores effects of variation in mechanical properties of rock boulders from different sections of an outcrop. This results in production of increased volume of fines in weaker rock sections while larger fragment sizes are produced from stronger rock sections. Increased production of fines during rock breakage could result in ore loss due to difficulty in mineral extraction from fines (< 50 microns diameter) and limited utilization of quarry-dust (< 4.75 mm diameter) as aggregates (Wills and Napier-Munn 2006; Luukkanen et al. 2022; Zhang et al. 2022; ASTM D 2487 2017). On the other hand, increased production of larger fragment sizes reduces energy efficiency of rock breakage processes through additional energy requirement for secondary rock breakage processes to achieve desired fragment size. To reduce ore loss during comminution as well as prevent energy wastage during secondary/tertiary rock breakage processes, estimation of specific energy for achieving desired fragment sizes in variable rock/ore mass is of great importance. It is therefore important to classify variable rock sections based on their mechanical properties prior to impact.

In the field of rock mechanics, popular methods of rock mass classification (RMC) comprise rock quality designation (Deere 1967), rock mass rating (Bieniawski 1973), tunneling quality index (Barton et al. 1974), rock mass index (Palmstrom 1996), and geological strength index (Hoek et al. 1995; Wang and Aladejare 2016). The fore-listed RMCs provide useful information for evaluating rock mass competence in hosting engineering structures and their support requirement(s). Similarly, some rock mass parameters have been used to estimate blastability index and fragmentation with acceptable reliability. For instance, rock mass description, joint plane spacing, joint plane orientation, specific gravity and Mohs hardness (see Cunningham 1983, 1987; Lilly 1986, 1992; Nourian and Moomivand 2020; Moomivand and Vandyousefi 2020; Azizi and Moomivand 2021). However, a major drawback of the forementioned RMC systems comprise providing little information on energy requirement for producing desired fragment sizes during rock breakage. To address these, RMC using sonic wave velocity was proposed as a quantitative, non-destructive method for estimating static mechanical properties of rocks (Rawlings and Barton 1995; Zhao and Wu 2000; Nourani et al. 2017; Chawre 2018). Studies have shown that uniaxial compressive strengths of rocks can be estimated from transmitted sonic wave velocities with acceptable reliability (Lama and Vutukuri 1978; Yasar & Erdogan 2004; Karakus et al. 2005; Khandelwal & Singh 2009; Diamantis et al. 2009; Yagiz 2011; Mohamed et al. 2018; Wang et al. 2020; Arman 2021). This is logical because transmitted sonic wave velocities are sensitive to variable inherent cracks in rocks, which form points of crack initiation during loading processes (Griffth 1924; Irwin 1948; Shockey et al. 1974; Pyrak-Nolte et al. 1990; Rokhlin and Wang 1991; Zhao and Cai 2001; Zhao et al. 2006; Li et al. 2013; Moomivand et al. 2022). In fact, the ISRM recommends grouping rocks based on their ultrasonic wave velocity before dynamic tests using the slit Hopkinson’s pressure bar (see Ulusay 2015). However, different rocks with varying mechanical and inherent cracks could have the same wave velocity (Butel et al. 2014; Zhang et al. 2020). This has limited application of sonic wave RMC to comparative evaluations between different sections of rock mass, as opposed to absolute sonic wave values for strength and breakage properties of rocks.

The concept of characteristic impedance, which refers to the product of density and sonic wave velocity was earlier used, for example by Lundberg (1976). Recently, Zhang (2016) proposed that characteristic impedance may be used to classify and evaluate rock masses. The utilization of characteristic impedance enables differentiation of varying rocks with the same sonic wave velocity by virtue of variations in their density. An extensive review of previous studies on a wide range of rocks revealed that characteristic impedance is well related to the uniaxial compressive strength, tensile strength, shear strength, mode-I fracture toughness, Young’s modulus and Poisson’s ratio (Zhang et al. 2020). Sequel to identified relations between characteristic impedance and mechanical properties of rocks, Zhang et al. (2020) recommended classifying rocks based on their characteristic impedance. Aladejare et al. (2022) also proposed soft computing models for estimating characteristic impedance of rocks from their physical and mechanical properties with acceptable reliabilities.

The forementioned studies have shown that characteristic impedance is well related to several mechanical properties of rocks. However, studies on relations between characteristic impedance, specific energy, and average fragment size during rock breakage at high strain rates has not been attempted at the time of this study. If the average fragment size can be predicted during rock breakage at high strain rates, ore loss associated with production of unwanted fragment sizes may be controlled. It is to note that ore loss from production of unwanted fragment size during rock breakage constitutes a critical and constantly improving aspect of rock breakage. Following global depleting ore reserves to meet growing population needs, repeated rock breakage using conventional methods are likely to result in increased ore loss and global depletion of scarce minerals. Therefore, studies on methods of reducing ore loss during rock breakage are of great importance, especially as regard globally scarce minerals e.g., antimony, molybdenum and zinc which may be exhausted within few decades (Henckens et al. 2016; Zhang et al. 2021).

To reduce ore loss and increase energy efficiency during rock breakage, specific energy for breaking varying rock sections into desired fragment sizes must be estimated. Following identified relations between characteristic impedance and mechanical rock properties in literature, indirect estimation of mechanical properties from characteristic impedance of rocks is logical. In addition, effects of strain rate during rock breakage must be considered following strong rate dependence of rock breakage during dynamic loading (Lajtai et al. 1991; Zhang et al. 1999, 2000; Dai et al. 2009; Dai and Xia 2013; Ma et al. 2010, 2011; Li et al. 2013; Meng et al. 2016; Mishra et al. 2018). Currently, most crushers and mills repeatedly apply similar input energies to break varying rock sections. The downside of this approach is negligence of variations in mechanical properties of several sections within rock mass(es) (Aladejare 2016; Xia et al. 2008; Dai and Xia 2010; Zhang et al. 2020; Guan et al. 2021). This generally results in the production of larger fragments in stronger rock sections and smaller fragments in weaker rock sections of rock mass. To address this, relations among characteristic impedance, specific energy, strain rate and fragmentation results were investigated.

2 Location and Geology of Study Area

The study area is located in Elijarvi of Keminmaa municipality in Kemi, Finland. Specimen used for this study were sampled about 10 km northeast of Kemi city center, 31 km southeast of Tornio city center, and 106 km northwest of Oulu city center (see Fig. 1). Geologically, the study area is located within the ‘Kemi layered intrusion’ which forms a significant section of the Fennoscandian layered intrusion (Mikkola 1949; Alapieti and Huhtelin 2005). The surface section of the Kemi layered intrusion is 15 km long and 0.2–2 km wide while the lower sections are funnel shaped with thickening towards the middle and thinning towards the edges (Huhtelin 2015). However, tectonic movements during the Svecokarelidic orogeny tilted the funnel shaped intrusion to form a \({70}^{0}\) northwest dipping body (Alapieti and Huhtelin 2005). The age of the chromite intrusion is estimated to be about 2.44 ± 0.16 Ga from Pb–Pb isotope dating (Manhes et al. 1980). Major lithologic units in the study area comprise chromite cumulates which lie on the Archean basement complex and grade upwards to pyroxenetic and peridotitic cumulates, gabbroic cumulates, mafic subvolcanics, dolomite, quartzite, and phyllite, respectively (Alapieti and Huhtelin 2005). Specimen used in this study was drilled from the peridotitic cumulates of the Kemi layered intrusion (see Fig. 1).

Geological map showing sampled section of the Kemi intrusion, Northern Ostrobothnia, Finland (Modified from Alapieti and Huhtelin 2005). Insert: Location map of the study area

3 Method of Study

In this study, peridotites were sampled in situ using a 50 mm core drill (see Fig. 1). The cored specimens were trimmed to length and diameter ratio of 1:1 in accordance with recommendations for dynamic rock testing by the International Society for Rock Mechanics (Ulusay 2015). To ensure prepared specimen faces are smooth and devoid of edge breakouts, low feed speeds were used to trim specimen. In addition, a 400-grit sandpaper was used to polish trimmed faces of specimen to remove un-avoidable rough edges during core trimming processes. The mass and dimension (length and radius) of prepared specimens were then measured using an electronic scale and caliper from which computations of density and volume was conducted (see Eqs. 1 and 2), respectively. Similarly, ultrasonic wave velocity of prepared specimen was measured using a PunditLab+ digital ultrasonic tester. To achieve this, a film of coupling gel was smeared evenly on both ends of trimmed specimen faces to enable transmission of sonic waves. This was then followed by placement of two 250 kHz transducers comprising a transmitter and receiver, which were connected to the PunditLab+ device. Using direct pitch and catch method, the time for transmitted sonic waves to reach the receiver was measured and used to compute the sonic wave velocity from specimen length. The characteristic impedance ¨Z¨ of each specimen as defined by Lundberg (1976), Zhang (2016) and Zhang et al. (2020) was computed using Eq. 1:

where \(Z\) denotes characteristic impedance, \(\rho\) denotes density, and \(V\) denotes sonic velocity as primary wave velocity

The dynamic properties of prepared specimen were measured using the split Hopkinson’s pressure bar device at Oulu mining school, Finland (see Fig. 2).

The striker bar was propelled by nitrogen gas from the SHPB barrel when the trigger was pulled. To investigate fracture properties of prepared specimen at different impact velocities, striker-bar velocities in the range of 11–21 m/s were applied. Generated stress waves from impact of striker-bar was transmitted through the incident bar to the specimen, transmission bar, momentum bar and momentum trap, respectively. The incident, reflected and transmitted waves from each impact were measured as electric signals with the aid of strain gauges attached to the incident and transmission bars. To achieve this, A Rigol DS1204D oscilloscope was used to amplify, and record measured electric signals (see Fig. 2). To minimizing effects of inertia and stress gradient across the specimen, incident stress from the striker bar was slowed down using a 2 mm pure copper disk, taped to the incident bar. In addition, the lengths of incident and transmission bars of the SHPB were varied between 2 m and 1.5 m, respectively, to ensure stress equilibrium at both ends of loaded specimen before fracture.

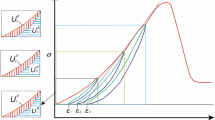

Measured signals from the oscilloscope were transferred to a workstation where dynamic compressive strength, strain, and strain rates were estimated using one-dimension stress wave theory (see Eqs. 2, 3, 4). Similarly, energy transformations during impact loading of samples were estimated according to the recommendation by Lundberg (1976) and presented in Eqs. 5, 6, 7, 8:

where σ is the uniaxial dynamic compressive stress, Ls is the length of specimen, C is the one-dimension elastic bar wave speed, and t is the time, E is the elastic modulus of the bars, A is the cross-sectional area of the bar. \({\varepsilon }_{i}\mathrm{is\, the\, incident \,strain},\) \({\varepsilon }_{r}\) is the reflected strain and \({\varepsilon }_{t}\) is the transmitted strain.

where \({W}_{\mathrm{I}}\) is the incident energy, \({W}_{\mathrm{R}}\) is the reflected energy, \({W}_{\mathrm{T}}\) is the transmitted energy

The energy dissipation, which denotes the amount of energy consumed in the rock specimen, was estimated in accordance with the laws of thermodynamics (see Eq. 8):

where WA is the dissipated energy, WI denotes the incident energy, WR denotes the reflected energy and WT denotes the transmitted energy.

Similarly, specific energy \({W}_{f}\) refers to the amount of energy (Mega Joules) dissipated in a unit volume (m3) of rock mass during impact loading. Mathematically, \({W}_{f}\) is expressed as the ratio of dissipated energy to volume of loaded specimen (see Eq. 9):

To evaluate effects of impact velocity and characteristic impedance on fragmentation results, broken fragments were classified based on their diameter using a RC-TAP RX-29 sieve shaker. Retained fragments in each sieve were used to estimate the average fragment size of broken fragments (see Eq. 10). (See Hong et al. 2009; Weng et al. 2019):

where \({W}_{\mathrm{b}}\) is the weight of broken fragments in each sieve, \(\overline{d }\) is the mean of two consecutive sieve diameters, and AFS is the average fragment size.

4 Results

In this section, results from physical, mechanical and fragmentation properties of Kemi peridotites at different impact velocities are presented. Parameters used to evaluate the physical properties of Kemi peridotites comprise density and sonic wave velocity that were measured in the laboratory. Accordingly, characteristic impedance was estimated from the product of density and wave velocity as suggested by Lundberg (1976). Parameters used to evaluate the mechanical properties of prepared specimen comprise dynamic compressive strength, strain, strain rate, and specific energy (see Table 1). In addition, the fragment size distribution of broken specimen was evaluated, and results are presented in Table 2.

Results show that density and sonic wave velocity of Kemi peridotites varies in the range of 2.79–3.16 \({\mathrm{g}/\mathrm{cm}}^{3}\) and 4255–5797 m \({\mathrm{s}}^{-1}\), respectively. In addition, estimation of characteristic impedance from density and P-wave velocity reveal that characteristic impedance of Kemi peridotites varies in the range of 12.95–16.23 \({\mathrm{x }10}^{6}\mathrm{Kg}/\mathrm{s }\cdot {\mathrm{m}}^{2}\). Based on the experiment design, the dynamic compressive strength, strain, and strain rate of Kemi peridotites varied between 40.68 and 161.7\(\mathrm{MPa}\), 0.007 and 0.091, and 57.51 and 242.3 \({\mathrm{s}}^{-1}\), respectively. On the other hand, investigation on energy transformation during rock breakage showed that incident energy, dissipated energy and specific energy varied between 176.75 and 1083.66\(\mathrm{J}\), 35.18 and 261.5\(\mathrm{J}\), and 0.35 and 2.64 \(\mathrm{M}{\mathrm{J}/\mathrm{m}}^{3}\), respectively. At the aforementioned strain rates, the average fragment size of Kemi peridotites varied in the range of 6.98–16.63\(\mathrm{mm}\).

Based on experiment results, relations between incident energy, strain rate, dissipated energy and average fragment size were investigated (see Fig. 3). In addition, the performance of strain rate and the product of characteristic impedance and strain rate in estimating specific energy and average fragment size during rock breakage were investigated (see Figs. 4 and 5).

Following relations between incident energy and strain rate as well as the performance of the product of characteristic impedance and strain rate in estimating specific energy during rock breakage (see Figs. 3A and 4B), a multiple regression (MR) model for estimating specific energy requirement was developed using MR function of Microsoft Excel software (see Eq. 11). Accordingly, the performance of the multiple regression model in estimating specific energy was evaluated (see Fig. 6).

5 Discussion

Results show that strain rate, dissipated energy, and specific energy generally increase when higher incident energies are applied during rock breakage. However, the average fragment size of broken specimen reduced at higher strain rates. These findings are logical and in line with available knowledge on rock breakage at high strain rates (Lajtai et al. 1991; Zhang et al. 1999, 2000; Dai et al. 2009; Ma et al. 2010, 2011; Dai and Xia 2013; Li et al. 2013; Meng et al. 2016; Mishra et al. 2018). Further evaluation of the performance of strain rate and the product of characteristic impedance and strain rate in estimating specific energy and average fragment size during rock breakage was conducted. Based on the regression coefficient, results indicate that the product of characteristic impedance and strain rate is generally more reliable for estimating specific energy and average fragment size during impulse rock breakage.

To illustrate reasons for improved reliability of the product of characteristic impedance and strain rate in estimating specific energy and average fragment size during rock breakage, knowledge on rock response to dynamic stress and energy transformation at laboratory scale are essential. To this effect, two classic assumptions on brittle material response to dynamic stress are considered. The first comprise the assumption of thermodynamic equilibrium, where rock breakage is attributed to energy transformation from one state to another while the second comprise the assumption that microcracks in brittle materials constitute potential points of activation, growth, and coalescence of fractures during loading processes (Shockey et al. 1974; Lundberg 1976; Grady 1980; Margolin and Adams 1982; Grady and Kipp 1987). Energy transformation during rock breakage comprise energy consumed in creating fractures from microcracks, heat energy, acoustic energy, electromagnetic energy, kinetic and rotation energy of flying fragments (Zhang 2016). Although the forementioned energy transformations occur during rock breakage, energy measurements in this study were constrained to incident and dissipated energy due to limitation of measuring equipment. Assuming rock specimens are identical and dissipated energy denotes the total transformed energy during rock breakage, it is logical to assume that increase in incident energy results to increased strain rate and energy dissipation. This is in line with the first assumption on thermodynamic equilibrium. Similarly, higher strain rates often result in reduced average fragment sizes of broken specimen. Results presented in Figs. 4 and 5 of this study agree with this assumption. Although the forementioned conditions are more obvious when identical rock specimens are considered, it is to note that rocks are highly variable materials. Accordingly, rocks with higher volume of inherent cracks are generally assumed to be weaker than identical rock facies with fewer microcracks. This is because microcracks constitute free faces for potential nucleation and coalescence of inherent cracks in accordance with the second assumption on rock breakage.

Despite the role of inherent cracks during rock breakage, their application in estimating specific energy and average fragment sizes during impulse rock breakage have not been fully explored. This can be attributed to cost of high precision non-destructive imagery (e.g., X-ray tomology) and difficulty in field imagery of inherent cracks in rock mass. In addition, some difficulty abounds in predicting specific inherent cracks(s) to be activated and their effects on fragmentation results. However, measurements of constant p-wave velocities in rocks could be used to relatively evaluate the abundance of inherent cracks in rocks. This is because reflection and refraction of waves at interfaces of inherent cracks results to reduced velocity of transmitted waves when compared with specimen devoid of inherent cracks. Similarly, increased inherent cracks in rocks, e.g., voids in sedimentary rocks could result to slight variations in rock density when compared with similar rocks which are devoid of inherent cracks. Therefore, it is logical to assume that characteristic impedance provides a relative index for evaluating inherent cracks in rocks.

Although inherent cracks in rocks form points of fracture initiation during loading, dynamic processes of rock breakage are strongly rate dependent (Zhang et al. 1999, 2000; Dai et al. 2009; Dai and Xia 2013; Ma et al. 2010, 2011; Mishra et al. 2018). That is, application of higher incident energies during rock breakage will likely result to increased strain rates and fragmentation due to higher energy dissipation and vice versa. Therefore, product of characteristic impedance and strain rate during breakage of some peridotitic rocks are assumed to inculcate both classic assumptions on rock response to dynamic stress. This is assumed to be responsible for improved reliability during estimation of specific energy and average size of rocks.

The results from this study are based on laboratory scale experiments and developed equations are useful in theoretical developments on rock response to dynamic stress and fragmentation under dynamic uniaxial compression. However, rock mass behavior under shock wave and dynamic stresses are complicated due to effects of in situ stress and confinement. Similarly, in situ rock mass properties comprising rock mass description, fracture orientation, joint plane spacing, specific gravity, quasi-static uniaxial compressive strength and block size significantly affect average fragment size in empirical rock mass fragmentation models (see Cunningham 1983, 1987; Lilly 1986, 1992; Nourian and Moomivand 2020; Moomivand and Vandyousefi 2020; Azizi and Moomivand 2021; Moomivand et al. 2021). Therefore, the forementioned parameters must be considered in extending theoretical developments in this study to rock mass conditions.

6 Conclusion

The following conclusion can be drawn from this study:

-

i.

Strain rate and dissipated energy generally increase at higher incident energies during rock breakage.

-

ii.

The average fragment size of broken fragments generally reduces at higher strain rates.

-

iii.

The product of characteristic impedance and strain rate is more reliable for estimating specific energy and average fragment size of rocks during impulse loading.

-

iv.

Based on the study findings, more studies on the application of the product of characteristic impedance and strain rate in estimating specific energy and average fragment size during rock breakage is recommended. This could improve energy efficiency as well as reduce ore loss associated with production of undesirable fragment sizes during rock breakage.

Data Availability

The authors declare that experimental data from which computations and conclusions were drawn in this study are available within the paper.

Abbreviations

- \(Z\) :

-

Characteristic impedance, \(\frac{{10}^{6}\mathrm{Kg}}{\mathrm{s}}\cdot {\mathrm{m}}^{2}\)

- \(\rho\) :

-

Density, \({\mathrm{g}/\mathrm{cm}}^{3}\)

- \({V}_{p}\) :

-

P-wave velocity, \({\mathrm{ms}}^{-1}\)

- \(\sigma\) :

-

Uniaxial dynamic compressive stress, \(\mathrm{MPa}\)

- \(A\) :

-

Cross-sectional area of the bar, \({\mathrm{m}}^{2}\)

- \(E\) :

-

Elastic modulus of the bars

- \(C\) :

-

One-dimension elastic bar wave speed, \({\mathrm{ms}}^{-1}\)

- \({A}_{s}\) :

-

Area of specimen, \({\mathrm{m}}^{2}\)

- \({L}_{s}\) :

-

Length of specimen, \(\mathrm{m}\)

- \({\varepsilon }_{i}\) :

-

Incident strain

- \({\varepsilon }_{r}\) :

-

Reflected strain

- \({\varepsilon }_{t}\) :

-

Transmitted strain

- \(\varepsilon\) :

-

Strain

- \({\varepsilon }^{^{\prime}}\) :

-

Strain rate, \({\mathrm{s}}^{-1}\)

- \(t\) :

-

Time, \(\mathrm{s}\)

- \({W}_{I}\) :

-

Incident energy, \(\mathrm{J}\)

- \({W}_{R}\) :

-

Reflected energy, \(\mathrm{J}\)

- \({W}_{T}\) :

-

Transmitted energy, \(\mathrm{J}\)

- \({W}_{a}\) :

-

Dissipated energy, \(\mathrm{J}\)

- \({W}_{f}\) :

-

Specific energy, \(\mathrm{M}{\mathrm{J}/\mathrm{m}}^{3}\)

- \({W}_{fest}\) :

-

Estimated specific energy, \(\mathrm{M}{\mathrm{J}/\mathrm{m}}^{3}\)

- \(AFS\) :

-

Average fragment size, \(\mathrm{mm}\)

- \({W}_{b}\) :

-

Mass of broken fragments in each sieve, \(\mathrm{g}\)

- \(\overline{d }\) :

-

Mean of two consecutive sieve diameters, \(\mathrm{mm}\)

References

Aladejare AE, Ozoji TM, Lawal AI, Zhang Z-X (2022) Soft computing-based models for predicting the characteristic impedance of igneous rock from their physico-mechanical properties. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-022-02836-5

Aladejare AE (2016) Development of Bayesian probabilistic approaches for rock property characterization. Doctoral dissertation, City University of Hong Kong

Alapieti TT, Huhtelin TA (2005) The Kemi intrusion and associated chromite deposit. Field trip guidebook: Early Paleoproterozoic (2.5–2.4) Tornio-Näränkävaara layered intrusion belt and related chrome and platinum group element mineralization, Northern Finland. Ed. by Alapieti & Kärki. Geological survey of Finland. Guide nr. Espoo 51a:13–31

Alvarado S, Algüerno J, Auracher H, Casali A (1998) Energy-exergy optimization of comminution. Energy 23:153–158

Arman H (2021) Correlation of P-wave velocity with mechanical and physical properties of limestone with statistical analysis. Sci Rep. https://doi.org/10.1038/s41598-021-03524-0

ASTM D 2487 (2017) Standard practice for classification of soils for engineering purposes (Unified Soil Classification System). Annual book of ASTM standards

Azizi A, Moomivand H (2021) A new approach to represent impact of discontinuity spacing and rock mass description on the median fragment size of blasted rocks using image analysis of rock mass. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-020-02360-4

Barton N, Lien R, Lunde J (1974) Engineering classification of rock masses for the design of tunnel support. Rock Mech 6(4):189–236

Bieniawski ZT (1973) Engineering classification of jointed rock masses. Civ Eng Siviele Ingenieurswese 15:335–343

Butel N, Hossack A, Kizil MS (2014) Prediction of in situ rock strength using sonic velocity. Proceedings of the coal operators’ conference. https://ro.uow.edu.au/coal/502/

Carrol MM (1985) Mechanics of geological materials. Appl Mech Rev 38:1256–1260

Chawre B (2018) Correlations between ultrasonic pulse wave velocities and rock properties of quartz-mica schist. J Rock Mech Geotech Eng 10(3):594–602

Chi G, Fuerstenau MC, Bradt RC, Ghosh A (1996) Improved comminution efficiency through controlled blasting during mining. Int J Miner Process 47:93–101

Cunningham CVB (1983) The Kuz-Ram model for prediction of fragmentation from blasting. In: Holmberg R, Rustan A (eds) Proceedings of 1st international symposium on rock fragmentation by blasting. Tekniska Universitet, Lulea, pp 439–453

Cunningham CVB (1987) Fragmentation estimations and the Kuz–Ram model—four years on. In: Fourney WL, Dick RD (eds) Proceedings of 2nd international symposium on rock fragmentation by blasting, Keystone, CO, 23–26 August 1987. Society of Experimental Mechanics, Bethel, pp 475–487

Dai F, Xia KW (2010) Tensile strength anisotropy of Barre granite. Pure Appl Geophys 167:1419–1432

Dai F, Xia KW (2013) Laboratory measurements of the rate dependence of the fracture toughness anisotropy of Barre granite. Int J Rock Mech Min Sci. https://doi.org/10.1016/j.ijrmms.2012.12.035

Dai F, Xia K, Tang L (2009) Rate dependence of the flexural tensile strength of Laurentian granite. Int J Rock Mech Min Sci. https://doi.org/10.1016/j.ijrmms.2009.05.001

Deere DU (1967) Discussion on rock classification. In: Proceedings of the first congress of the international society for rock mechanics. 156–158

Diamantis K, Gartzos E, Migiros G (2009) Study on uniaxial compressive strength, point load strength index, dynamic and physical properties of serpentinites from Central Greece: test results and empirical relations. Eng Geol 108:199–207. https://doi.org/10.1016/j.enggeo.2009.07.002

Fuerstenau DW, Abouzeid AZM (2002) The energy efficiency of ball milling in comminution. Int J Miner Process 67:161–185

Grady DE (1980) Shock deformation of brittle solids. J Geophy Research 85(9):13–924

Grady DE, Kipp ME (1987) Dynamic rock fragmentation. Int J Rock Mech Min Sci Geomech Abstr 16:293–302

Griffith AA (1924) The theory of rupture. Proc First Int Congress Appl Mech, Delft. 55–63

Guan Z, Chang YC, Wang Y, Aladejare AE, Zhang D, Ching J (2021) Site-specific statistics for geotechnical properties. State-of-the-art review of inherent variability and uncertainty in geotechnical properties and models

Henckens MLCM, Van-Ierland EC, Driessen PPJ, Worrell E (2016) Mineral resources: geological scarcity, market price trends, and future generations. Resour Policy 49:102–111. https://doi.org/10.1016/j.resourpol.2016.04.012

Hoek ET, Kaiser PK, Bawden WF (1995) Support of underground excavations in hard rock. A.A. Balkema, Rotterdam

Holmberg K, Kivikytö-Reponen P, Härkisaari P, Valtonen K, Erdemir A (2017) Global energy consumption due to friction and wear in the mining industry. Tribol Int. https://doi.org/10.1016/j.triboint.2017.05.010

Hong L, Zhou ZL, Yin TB, Liao GY, Ye ZY (2009) Energy consumption in rock fragmentation at intermediate strain rate. J Cent South Univ Technol. https://doi.org/10.1007/s11771−009−0112−5

Huhtelin T (2015) Chapters 3 and 4 The Kemi chromite deposit. Mineral deposits of Finland. Elsevier, Amsterdam

Irwin GR (1948) Fracture dynamics. Fracturing of metals. American Society for Metals, Cleveland, pp 147–166

Karakus M, Kumral M, Kilic O (2005) Predicting elastic properties of intact rocks from index tests using multiple regression modelling. Int J Rock Mech Min Sci. https://doi.org/10.1016/j.ijrmms.2004.08.005

Khandelwal M, Singh TN (2009) Correlating static properties of coal measures rocks with P-wave velocity. Int J Coal Geo 79(2):55–60. https://doi.org/10.1016/j.coal.2009.01.004

Klein B, Wang C, Nadolski S (2018) Energy-efficient comminution: best practices and future research needs. In: Awuah-Offei K (ed) Energy efficiency in the minerals. Industry green energy and technology. Springer, Cham, pp 197–211

Lajtai EZ (1991) Time-dependent behaviour of the rock mass. Geotech Geol Eng 9:109–124

Lama RD, Vutukuri VS (1978) Handbook on mechanical properties of rocks, vol II. Trans Tech Publications, Germany

Li JC, Wu W, Li HB, Zhu JB, Zhao J (2013) A thin-layer interface model for wave propagation through filled rock joints. J Appl Geophys 91:31–38

Lilly PA (1986) An empirical method of assessing rock mass blastability. In: Davidson JR (ed) Proc large open pit mine conf, Newman, West Austr

Lilly PA (1992) The use of blastability index in the design of blasts for open pit mines. In: Szwedzicki T, Baird GR, Little TN (eds) Proc West Austr conf min geomech, 421–426

Lundberg B (1976) A split Hopkinson bar study of energy absorption in dynamic rock fragmentation. Int J Rock Mech Min Sci Geomech Abstr 13:187–197

Luukkanen S, Tanhua A, Zhang Z, Canales RM, Auranen I (2022) Towards waterless operations from mine to mill. Min Eng. https://doi.org/10.1016/j.mineng.2022.107793

Ma GW, Wang XJ, Li QM (2010) Modeling strain rate effect of heterogeneous materials using SPH method. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-010-0089-2

Ma GW, Wang XJ, Ren F (2011) Numerical simulation of compressive failure of heterogeneous rock-like materials using SPH method. Int J Rock Mech Min Sci 48:3. https://doi.org/10.1016/j.ijrmms.2011.02.001

Manhes G, Allegre CJ, Dupre B, Hamelin B (1980) Lead isotope study of basic-ultrabasic layered complexes: speculation about the age of the earth and primitive mantle characteristics: earth Planet. Sci Lettr 47:370–382

Margolin LG, Adams TF (1982) Numerical simulation of fracture: Proc 23rd Symp Rock Mech, Berkeley. AIME, New York

Meng Q, Zhang M, Han L, Pu H, Nie T (2016) Effects of acoustic emission and energy evolution of rock specimens under the uniaxial cyclic loading and unloading compression. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-016-1077-y

Mikkola A (1949) On the geology of the area north of the Gulf of Bothnia. Comm Gèol Finlande Bull 146:64

Mishra S, Meena H, Parashar V, Khetwal A, Chakraborty T, Matsagar V, Chandel P, Singh M (2018) High strain rate response of rocks under dynamic loading using split hopkinson pressure bar. Geotech Geol Eng 36:531–549. https://doi.org/10.1007/s10706-017-0345-2

Mohamed A, Thameur M, Chedly A (2018) Ultrasonic velocity as a tool for physical and mechanical parameters prediction within geo-materials: application on cement mortar. Russ J Nondestruct Test. https://doi.org/10.1134/S1061830918050091

Moomivand H, Vandyousefi H (2020) Development of a new empirical fragmentation model using rock mass properties, blasthole parameters, and powder factor. Arab J Geosci. https://doi.org/10.1007/s12517-020-06110-2

Moomivand HD, Maarefvand P, Moomivand H (2021) A new empirical approach to assess wave velocities and dynamic elastic properties of several models of jointed rock before and after grouting. Rock Mech Rock Eng 54(4):6439–6455. https://doi.org/10.1007/s00603-021-02625-6

Moomivand H, Moomivand H, Nikrouz R, Azad R (2022) Development of a new empirical relation to assess P-wave velocity anisotropy of rocks. Geotech Geol Eng 40:1537–1550. https://doi.org/10.1007/s10706-021-01983-w

Natural Resources Canada (2011) Energy efficiency trend in Canada, 1990 to 2009. http://oee.rncan.gc.ca/publications/statistics/trends11/chapter5.cfm?attr=0. Accessed 26 Sept 2022

Nourani MH, Moghadder MT, Safari M (2017) Classification and assessment of rock mass parameters in Choghart iron mine using P-wave velocity. J Rock Mech Geotech Eng 9(2):318–328

Nourian A, Moomivand H (2020) Development of a new model to predict uniformity index of fragment size distribution based on the blasthole parameters and blastability index. J Min Sci 56(1):47–58. https://doi.org/10.1134/S1062739120016478

Ouchterlony F, Nyberg U, Olsson M (2003) The energy balance of production blasts at Nordkalk’s Klinthagen quarry. In: Holmberg R (ed) Proceedings of the second world conference

Palmström A (1996) Characterizing rock masses by the RMi for use in practical rock engineering: part 1: the development of the rock mass index (RMi). Tunn Undergr Space Technol 11(2):175–188

Pothina R, Kecojevic V, Klima MS, Komljenovic D (2007) Gyratory crusher model and impact parameters related to energy consumption. Min Metallg Expl. https://doi.org/10.1007/BF03403212

Prasher CL (1987) Crushing and grinding process handbook. Wiley, Chichester

Pressacco M, Kangas JJJ, Saksala T (2022) Numerical modelling of microwave heating assisted rock fracture. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-021-02685-8

Pyrak-Nolte LJ, Myer LR, Cook NGW (1990) Transmission of seismic waves across single natural fractures. J Geophys Res 95:8617–8638

Rawlings C, Barton N (1995) The relationship between Q and RMR classification in rock engineering. In: Fujill T (ed) Proceedings of the 8th international congress on rock mechanics. Minato-Kutokyo Press, Akasaka, pp 29–31

Rokhlin SI, Wang YJ (1991) Analysis of boundary conditions for elastic wave interaction with an interface between two solids. J Acoust Soc Am 89:503–515

Sanchidrián JA, Pablo S, López LM (2007) Energy components in rock blasting. Int J Rock Mech Min Sci 44:130–147

Shockey DA, Curran DR, Seaman L, Rosenberg JT, Petersen CF (1974) Fragmentation of rock under dynamic Loads. Int J Rock Mech Min Sci Geomech Abstr 11:303–317

Somani A, Nandi TK, Pal SK, Majumder AK (2017) Pre-treatment of rocks prior to comminution—a critical review of present practices. Int J Min Sci Technol 27(2):339–348

Tschugg J, Öfner W, Flachberger H (2017) Comparative laboratory studies of conventional and electrodynamic fragmentation of an industrial mineral. BHM 162(8):319–325. https://doi.org/10.1007/s00501-017-0638-z

Ulusay R (2015) The ISRM suggested methods for rock characterization, testing and monitoring: 2007–2014. Springer, Cham Heidelberg New York Dordrecht London

Wang Y, Aladejare AE (2016) Evaluating variability and uncertainty of geological strength index at a specific site. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-016-0957-5

Wang M, Li Z, Shao X (2020) Ultrasonic velocity, attenuation, and mechanical behavior of Longmaxi bedded shale under uniaxial compressive tests. Arab J Geosci. https://doi.org/10.1007/s12517-020-05991-7

Weng L, Wu Z, Liu Q, Wang Z (2019) Energy dissipation and dynamic fragmentation of dry and water-saturated siltstones under sub-zero temperatures. Eng Frac Mech. https://doi.org/10.1016/j.engfracmech.2019.106659

Wills BA, Napier-Munn TJ (2006) Wills mineral processing technology: an introduction to the practical aspects of ore treatment and mineral recovery. Butterworth-Heinemann, Oxford

Xia K, Nasseri MHB, Mohanty B, Lu F, Chen R, Luo SN (2008) Effects of micro-structures on dynamic compression of Barre granite. Int J Rock Mech Min Sci 45:879–887. https://doi.org/10.1016/j.ijrmms.2007.09.013

Yagiz S (2011) P-wave velocity test for assessment of geotechnical properties of some rock materials. Bull Mat Sci 34(4):947

Yasar E, Erdogan Y (2004) Correlating sound velocity with the density, compressive strength and Young’s modulus of carbonate rocks. Int J Rock Mech Min Sci 41(5):871–875. https://doi.org/10.1016/j.ijrmms.2004.01.012

Zhang Z-X (2016) Rock fracture and blasting: theory and applications. Butterworth-Heinemann, Oxford

Zhang ZX, Ouchterlony F (2022) Energy requirement for rock breakage in laboratory experiments and engineering operations: a review. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-021-02687-6

Zhang ZX, Kou SQ, Yu J, Yu Y, Jiang LG, Lindqvist PA (1999) Effects of loading rate on rock fracture. Int J Rock Mech Min Sci 36:597–611

Zhang ZX, Kou SQ, Jiang LG, Lindqvist PA (2000) Effects of loading rate on rock fracture: fracture characteristics and energy partitioning. Int J Rock Mech Min Sci. https://doi.org/10.1016/S1365-1609(00)00008-3

Zhang Z-X, Hou DF, Aladejare AE (2020) Empirical equations between characteristic impedance and mechanical properties of rocks. J Rock Mech Geotech Eng 12(5):975–983

Zhang Z-X, Hou DF, Aladejare AE, Ozoji TM, Qiao Y (2021) World mineral loss and possibility to increase ore recovery ratio in mining production. Int J Min Recl Env 35(9):670–691. https://doi.org/10.1080/17480930.2021.1949878

Zhang ZX, Sanchidrián JA, Ouchterlony F, Luukkanen S (2022) Reduction of fragment size from mining to mineral processing—a review. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-022-03068-3

Zhao J, Cai J (2001) Transmission of elastic P-waves across single fractures with a nonlinear normal deformational behavior. Rock Mech Rock Eng 34:3–22. https://doi.org/10.1007/s006030170023

Zhao MJ, Wu DL (2000) Ultrasonic classification and strength prediction of engineering rock mass. Chin J Rock Mech Eng 19(1):89–92 ((in Chinese))

Zhao J, Zhao XB, Cai JG (2006) A further study of P-wave attenuation across parallel fractures with linear deformational behaviour. Int J Rock Mech Min Sci 43(5):76–788

Acknowledgements

The authors are grateful to the Renlund Foundation for sponsoring this study.

Funding

Open Access funding provided by University of Oulu including Oulu University Hospital.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ozoji, T., Zhang, ZX., Adeyemi, A. et al. Effect of Characteristic Impedance in Estimating Specific Energy and Average Fragment Size at High Strain Rates of Some Peridotitic Rock Materials at Laboratory Scale. Rock Mech Rock Eng 56, 5693–5704 (2023). https://doi.org/10.1007/s00603-023-03359-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-023-03359-3