Abstract

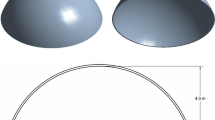

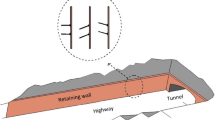

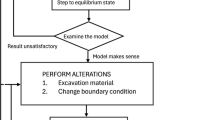

The current research scrutinizes the effects of axial loading width and immediate roof thickness on the failure mechanism of a notched roof in room and pillar mining by experimental test and numerical simulation. Gypsum specimens with dimensions of 150 mm × 150 mm × 50 mm containing two rooms and a middle immediate roof (with and without the presence of an edge notch) were prepared for this purpose. The immediate roof has three different thicknesses, i.e., 30 mm, 45 mm, and 60 mm. The length of the edge notches was 1 cm, and their angles were 45°, 90°, and 135°. The upper room was loaded under axial loading with a width of 50 mm. A total of 12 physical specimens were tested. Concurrent with experimental tests, 36 numerical models were simulated. The model geometry was similar to the experimental one, but the upper room was loaded under three different axial loadings, i.e., 10 mm, 30 mm, and 50 mm. The results show that the notch angle, roof thickness, and loading width affect the failure pattern and compressive strength of models. The immediate-edged roof with an angle of 45 has a critical condition compared to other configurations. Also, models under a loading width of 50 mm have less compressive strength compared to other loading widths. The experimental test and numerical simulation show similar outcomes.

Highlights

-

The effects of axial loading width and immediate roof thickness on the failure mechanism of a notched room by experimental test and numerical simulation are investigated.

-

Gypsum specimens with dimensions of 150 mm × 150 mm × 50 mm containing two rooms and a middle immediate roof (with and without the presence of an edge notch) were prepared.

-

The results show that the notch angle, roof thickness, and loading width affect the failure pattern and compressive strength of models.

-

The immediate-edged roof with an angle of 45 has a critical condition compared to other configurations.

Similar content being viewed by others

References

Brady BHG, Brown ET (2004) Rock mechanics for underground mining. Kluwer Academic Publishers, Dordrecht

Chen S, Guo W, Zhou H, Shen B, Liu J (2014) Field investigation of long-term bearing capacity of strip coal pillars. Int J Rock Mech Min Sci 70:109–114

Constr Build Mater 213:142–155

Esterhuizen GS, Dolinar DR, Ellenberger JL (2011) Pillar strength in underground stone mines in the United States. Int J Rock Mech Min Sci 48:42–50

Feng Q, Jiang B, Wang G, Hu C (2016) Analytical solution for a circular roadway considering the transient effect of excavation unloading. Int J Min Sci Tech 26(4):543–549

Ghasemi E, Ataei M, Shahriar K, Sereshki F, Jalali SE, Ramazanzadeh A (2012) Assessment of roof fall risk during retreat mining in room and pillar coal mines. Int J Rock Mech Min Sci 54:80–89

Ghazvinian A, Sarfarazi V, Schubert W, Blumel M (2012) A study of the failure mechanism of planar non-persistent open joints using PFC2D. Rock Mech Rock Eng 45(5):677–693. https://doi.org/10.1007/s00603-012-0233-2

Golewski GL (2019a) The influence of microcrack width on the mechanical parameters in concrete with the addition of fly ash: consideration of technological and ecological benefits. Constr Build Mater 197:849–861

Golewski GL (2019b) Estimation of the optimum content of fly ash in concrete composite based on the analysis of fracture toughness tests using various measuring systems

Huang Z, Jiang ZQ, Qian ZW, Cao DT (2014) Analytical and experimental study of water seepage propagation behavior in the fault. Acta Geodyn Geomater 11(4):361–371

Huang Z, Li XZ, Li SJ, Zhao K, Zhang R (2018) Investigation of the hydraulic properties of deep fractured rocks around underground excavations using high-pressure injection tests. Eng Geol 245:180–191

Jaiswal A, Shrivastva BK (2009) Numerical simulation of coal pillar strength. Int J Rock Mech Min Sci 46:779–788

Kang H, Zhang X, Si L, Wu Y, Gao F (2010) In-situ stress measurements and stress distribution characteristics in underground coal mines in China. Eng Geol 116(3–4):333–345

Klemetti TM, Sears MM, Tulu IB (2017) Design concerns of room and pillar retreat panels. Int J Min Sci Technol 27(1):29–35

Li HL, Bai HB, Yang J, Cheng Y (2013) Water injection test and numerical analysis of the mining-induced failure depth of floor. Electron J Geotech Eng 18(1):849–857

Li Y, Tang DZ, Xu H, Yu TX (2014) In-situ stress distribution and its implication on coalbed methane development in Liulin area, eastern Ordos basin. China J Petrol Sci Eng 122:488–496

Li A, Liu Y, Mou L (2015) Impact of the panel width and overburden depth on floor damage depth in no. 5 coal seam of Taiyuan group in Chenghe Mining Area. Electron J Geotech Eng 20(6):1603–1617

Li YW, Jia D, Wang M, Liu J, Fu CK, Yang XL, Ai C (2016) Hydraulic fracturing model featuring initiation beyond the wellbore wall for directional well in coal bed. J Geophys Eng 13(4):536–548

Liu XS, Tan YL, Ning JG, Tian CL, Wang J (2015) The height of water-conducting fractured zones in longwall mining of shallow coal seams. Geotech Geol Eng 33(3):693–700

Liu SL, Liu WT, Shen JJ (2017a) Stress evolution law and failure characteristics of mining floor rock mass above confined water. Ksce J Civ Eng 21(7):2665–2672

Liu WT, Song WC, Mu DR, Zhao JY (2017b) Section observation system on floor mining damage zone and its application. J Cent S Univ Sci Tech 48(10):2808–2816

Liu WT, Du YH, Liu YB, Pang LF (2019) Failure characteristics of floor mining-induced damage under deep different dip angles of coal seam. Geotech Geol Eng 37(2):985–994

Mark C, Karabin G, Zelanko JC, Hoch MT, Chase F (2002) Evaluatıon of pillar recovery in southern West Virginia. In: Peng SS, Mark C, Khair AW, Heasley KA (eds) Proceedings of the 21st International Conference on Ground Control in Mining, August 6–8, West Virginia University, Morgantown, pp 81–89

Martin CD, Maybe WG (2000) The strength of hard-rock pillars. Int J Rock Mech Min Sci 37:1239–1246

Meng XX, Liu WT, Zhao JY, Ding XY (2019) In situ investigation and numerical simulation of the failure depth of an inclined coal seam floor: a case study. Mine Water Environ 38(3):686–694

Mohan GM, Sheorey PR, Kushwaha A (2001) Numerical estimation of pillar strength in coal mines. Int J Rock Mech Min Sci 38:1185–1192

Mortazavi A, Hassani FP, Shabani M (2009) A numerical investigation of rock pillar failure mechanism in underground openings. Comput Geotech 36(5):691–697

Nazarov LA, Nazarova LA, Freidin AM (2006) Estimating the long-term pillar safety for room-and-pillar ore mining. J Min Sci 42(6):530–539

Potyondy DO (2015) The bonded-particle model as a tool for rock mechanics research and application: current trends and future directions. Geosyst Eng 18(1):1–28. https://doi.org/10.1080/12269328.2014.998346

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364

Potyondy DO (2012) A flat-jointed bonded-particle material for hard rock. Paper presented at the 46th U.S. Rock Mechanics/Geomechanics Symposium, Chicago, USA

Potyondy DO (2017) Simulating perforation damage with a flat-jointed bonded-particle material. Paper presented at the 51st US Rock Mechanics/Geomechanics Symposium, San Francisco, California, USA

Poulsen BA (2010) Coal pillar load calculation by pressure arch theory and near field extraction ratio. Int J Rock Mech Min Sci 47:1158–1165

Reed G, Mctyer K, Frith R (2017) An assessment of coal pillar system stability criteria based on a mechanistic evaluation of the interaction between coal pillars and the overburden. Int J Min Sci Technol 27(1):9–15

Simsir F (2015) Underground mining methods. DEU Publications, Izmir

Singh R, Sheorey PR, Singh DP (2002) Stability of the parting between coal pillar workings in level contiguous seams. Int J Rock Mech Min Sci 39:9–39

Skrzypkowski K (2019) The influence of room and pillar method geometry on the deposit utilization rate and rock bolt load. Energies 12:4770. https://doi.org/10.3390/en12244770

Skrzypkowski K (2020) Decreasing mining losses for the room and pillar method by replacing the inter-room pillars by the construction of wooden cribs filled with waste rocks. Energies 13:3564. https://doi.org/10.3390/en13143564

Skrzypkowski K, Korzeniowski W, Zagórski K, Zagórska A (2020) Adjustment of the yielding system of mechanical rock bolts for room and pillar mining method in stratified rock mass. Energies 13:2082. https://doi.org/10.3390/en13082082

Tesarik DR, Seymour JB, Yanske TR (2009) Long-term stabi lity of a backfilled room-and-pillar test section at the Buick Mine, Missouri, USA. Int J Rock Mech Min Sci 46:1182–1196

Tuncay E (2009) Rock rupture phenomenon and pillar failure in tuffs in the Cappadocia region (Turkey). Int J Rock Mech Min Sci 46:1253–1266

Wang Y, Yang HN, Han JQ, Zhu C (2022a) Effect of rock bridge length on fracture and damage modelling in granite containing hole and fissures under cyclic uniaxial increasing-amplitude decreasing-frequency (CUIADF) loads. Int J Fatig 2:106741

Wang Y, Zhu C, Song ZY, Gong S (2022b) Macro-meso failure characteristics of circular cavity-contained granite under unconventional cyclic loads: a lab-scale testing. Measurement 188:110608

Wei G (2014) Study on the width of the non-elastic zone in inclined coal pillar for strip mining. Int J Rock Mech Min Sci 72:304–310

Xu ZM, Sun YJ, Gong SY, Zhu ZK (2012) Monitoring and numerical simulation of formation of water inrush pathway caused by coal mining above confined water with high pressure. Chin J Rock Mech Eng 31(8):1698–1704

Yaylaci M (2016) The investigation crack problem through numerical analysis. Struct Eng Mech 57(6):1143–1156. https://doi.org/10.12989/sem.2016.57.6.1143

Yaylaci M (2017) Comparison between numerical and analytical solutions for the receding contact problem. Sigma J Eng Nat Sci 35(2):333–346

Zhang PS, Wu JW, Liu CD (2006) Coal mining activities floor destruction rule of dynamic observation. J Rock Mech Engn 25(1):3009–3013

Zhang J, Jiang F, Zhu S, Zhang L (2016) Width design for gobs and isolated coal pillars based on overall burst-instability prevention in coal mines. J Rock Mech Geotech Eng 8:551–558

Zhao JL, Tang DZ, Xu H, Li Y, Li S, Tao S, Lin WJ, Liu ZX (2016) Characteristic of in situ stress and its control on the coalbed methane reservoir permeability in the eastern margin of the Ordos Basin, China. Rock Mech Rock Eng 49(8):3307–3322

Zhu WSY, Zhang TT (2018) Permeability of the coal seam floor rock mass in a deep mine based on in-situ water injection tests. Mine Water Environ 37(4):724–733

Acknowledgements

This work was financially supported by National Natural Science Foundation of China (Grant No. 51608117), Key Specialized Research and Development Breakthrough Program in Henan province (Grant No. 192102210051) and High foreign country expert project in Henan province (Grant No. HNGD2022040).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fu, J., Haeri, H., Sarfarazi, V. et al. Effects of Axial Loading Width and Immediate Roof Thickness on the Failure Mechanism of a Notched Roof in Room and Pillar Mining: Experimental Test and Numerical Simulation. Rock Mech Rock Eng 56, 719–745 (2023). https://doi.org/10.1007/s00603-022-03082-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-022-03082-5