Abstract

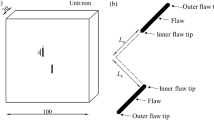

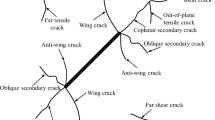

Flaws play a critical role in mastering the mechanical responses and failure behaviors of rock masses in practical engineering. In this study, a series of compressive–shear tests were performed on sandstone samples containing a single flaw to systemically investigate the effect of flaw geometrical parameters and die angle on the cracking process using digital image correlation (DIC) analysis. The results indicate that the peak force of specimens is significantly affected by the geometrical parameters of the pre-existing flaw and the die angle. The peak compressive–shear force decreases with increasing flaw length, width, inclination angle and die angle except for the flawed specimen with the die angle of 15°. Aided by DIC analysis, it is found that the initiation of the anti-wing cracks and secondary cracks lags behind the wing cracks. The crack initiation and propagation of wing crack are dominated by the tensile strain, while the crack initiation mechanism of the anti-wing crack and secondary crack is mixed tensile–shear dominated. A novel crack dominant parameter (CDP) is proposed to quantitatively analyze the effect of the maximum principal strain and shear strain at the aforementioned key points. The crack behaviors are dominated by tensile stress, mixed tensile–shear stress and shear stress when CDP > 2, 0 < CDP < 2 and CDP < 0, respectively. With increasing flaw length, width and die angle, it became easier for the flawed specimen to coalesce along the shearing plane and the corresponding final failure mode became concise with a lower degree of fragmentation. The findings of this paper would facilitate a better understanding of the failure behavior of rock masses containing flaws under compressive–shear loads.

Highlights

-

The mechanical properties of flawed rocks are significantly influenced by the geometrical parameters of pre-existing flaw and die angle.

-

The novel crack dominant parameter (CDP) is proposed to quantitatively analyze the crack initiation behaviors of flawed rocks around the flaw tips.

-

The final failure modes of the flawed rocks are associated with the geometrical parameters of pre-existing flaw and die angle, which become concise with increasing flaw length, width and die angle.

Similar content being viewed by others

References

Aliabadian Z, Zhao GF, Russell AR (2019) Crack development in transversely isotropic sandstone discs subjected to Brazilian tests observed using digital image correlation. Int J Rock Mech Min Sci 119:211–221. https://doi.org/10.1016/j.ijrmms.2019.04.004

Bobet A (2000) The initiation of secondary cracks in compression. Eng Fract Mech 66:187–219. https://doi.org/10.1016/S0013-7944(00)00009-6

Bobet A, Einstein HH (1998) Fracture coalescence in rock-type materials under uniaxial and biaxial compression. Int J Rock Mech Min Sci 35:863–888. https://doi.org/10.1016/S0148-9062(98)00005-9

Brideau MA, Yan M, Stead D (2009) The role of tectonic damage and brittle rock fracture in the development of large rock slope failures. Geomorphology 103:30–49. https://doi.org/10.1016/j.geomorph.2008.04.010

Cao RH, Cao P, Lin H et al (2018) Failure characteristics of intermittent fissures under a compressive–shear test: experimental and numerical analyses. Theor Appl Fract Mech 96:740–757. https://doi.org/10.1016/j.tafmec.2017.11.002

Daphalapurkar NP, Ramesh KT, Graham-Brady L, Molinari JF (2011) Predicting variability in the dynamic failure strength of brittle materials considering pre-existing flaws. J Mech Phys Solids 59:297–319. https://doi.org/10.1016/j.jmps.2010.10.006

Dong T, Cao P, Lin Q et al (2020) Size effect on mechanical properties of rock-like materials with three joints. Geotech Geol Eng 38:4073–4089. https://doi.org/10.1007/s10706-020-01279-5

Elmo D, Stead D (2010) An integrated numerical modelling-discrete fracture network approach applied to the characterisation of rock mass strength of naturally fractured pillars. Rock Mech Rock Eng 43:3–19. https://doi.org/10.1007/s00603-009-0027-3

Fan X, Kulatilake PHSW, Chen X (2015) Mechanical behavior of rock-like jointed blocks with multi-non-persistent joints under uniaxial loading: a particle mechanics approach. Eng Geol 190:17–32

Fan W, Yang H, Jiang X, Cao P (2021) Experimental and numerical investigation on crack mechanism of folded flawed rock-like material under uniaxial compression. Eng Geol 291:106210. https://doi.org/10.1016/j.enggeo.2021.106210

Gao FQ, Kang HP (2016) Effects of pre-existing discontinuities on the residual strength of rock mass—insight from a discrete element method simulation. J Struct Geol 85:40–50. https://doi.org/10.1016/j.jsg.2016.02.010

Gehle C, Kutter HK (2003) Breakage and shear behaviour of intermittent rock joints. Int J Rock Mech Min Sci 40:687–700. https://doi.org/10.1016/S1365-1609(03)00060-1

Gerolymatou E, Triantafyllidis T (2016) Shearing of materials with intermittent joints. Rock Mech Rock Eng 49:2689–2700. https://doi.org/10.1007/s00603-016-0956-6

Haeri H, Shahriar K, Marji MF, Moarefvand P (2014) Experimental and numerical study of crack propagation and coalescence in pre-cracked rock-like disks. Int J Rock Mech Min Sci 67:20–28. https://doi.org/10.1016/j.ijrmms.2014.01.008

Han Z, Li D, Zhou T et al (2020) Experimental study of stress wave propagation and energy characteristics across rock specimens containing cemented mortar joint with various thicknesses. Int J Rock Mech Min Sci 131:104352. https://doi.org/10.1016/j.ijrmms.2020.104352

Harthong B, Scholtès L, Donzé FV (2012) Strength characterization of rock masses, using a coupled DEM-DFN model. Geophys J Int 191:467–480. https://doi.org/10.1111/j.1365-246X.2012.05642.x

Huang J, Chen G, Zhao Y, Wang R (1990) An experimental study of the strain field development prior to failure of a marble plate under compression. Tectonophysics 175:269–284. https://doi.org/10.1016/0040-1951(90)90142-U

Huang YH, Yang SQ, Zhao J (2016) Three-dimensional numerical simulation on triaxial failure mechanical behavior of rock-like specimen containing two unparallel fissures. Rock Mech Rock Eng 49:4711–4729. https://doi.org/10.1007/s00603-016-1081-2

Huang D, Guo YQ, Cen DF et al (2020) Experimental investigation on shear mechanical behavior of sandstone containing a pre-existing flaw under unloading normal stress with constant shear stress. Rock Mech Rock Eng 53:3779–3792. https://doi.org/10.1007/s00603-020-02136-w

Jaeger JC, Cook NGW, Zimmerman RW (2007) Fundamentals of rock mechanics. Wiley, Hoboken

Janeiro RP, Einstein HH (2010) Experimental study of the cracking behavior of specimens containing inclusions (under uniaxial compression). Int J Fract 164:83–102. https://doi.org/10.1007/s10704-010-9457-x

Kong P, Jiang L, Shu J et al (2019) Effect of fracture heterogeneity on rock mass stability in a highly heterogeneous underground roadway. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-019-01887-5

Lee H, Jeon S (2011) An experimental and numerical study of fracture coalescence in pre-cracked specimens under uniaxial compression. Int J Solids Struct 48:979–999. https://doi.org/10.1016/j.ijsolstr.2010.12.001

Li H, Wong LNY (2012) Influence of flaw inclination angle and loading condition on crack initiation and propagation. Int J Solids Struct 49:2482–2499. https://doi.org/10.1016/j.ijsolstr.2012.05.012

Li YP, Chen LZ, Wang YH (2005) Experimental research on pre-cracked marble under compression. Int J Solids Struct 42:2505–2516. https://doi.org/10.1016/j.ijsolstr.2004.09.033

Lin H, Yang H, Wang Y et al (2019) Determination of the stress field and crack initiation angle of an open flaw tip under uniaxial compression. Theor Appl Fract Mech 104:102358. https://doi.org/10.1016/j.tafmec.2019.102358

Liu L, Li H, Li X et al (2020) Underlying mechanisms of crack initiation for granitic rocks containing a single pre-existing flaw: insights from digital image correlation (DIC) analysis. Rock Mech Rock Eng 54:857–873. https://doi.org/10.1007/s00603-020-02286-x

Ma K, Liu GY (2022) Three‑dimensional discontinuous deformation analysis of failure mechanisms and movement characteristics of slope rockfalls. Rock Mech Rock Eng 55:275–296. https://doi.org/10.1007/s00603-021-02656-z

Maji AK, Shah SP (1989) Application of acoustic emission and laser holography to study microfracture in concrete. In: Lew HS (ed) Nondestructive testing. Michigan, American Concrete Institute, pp 83–110

McCormick N, Lord J (2010) Digital image correlation. Mater Today 13:52–54. https://doi.org/10.1016/S1369-7021(10)70235-2

Miao S, Pan PZ, Wu Z et al (2018) Fracture analysis of sandstone with a single filled flaw under uniaxial compression. Eng Fract Mech 204:319–343. https://doi.org/10.1016/j.engfracmech.2018.10.009

Mohammadi HR, Mansouri H, Bahaaddini M, Jalalifar H (2017) Investigation into the effect of fault properties on wave transmission. Int J Numer Anal Methods Geomech 41:1741–1757. https://doi.org/10.1002/nag.2698

Munoz H, Taheri A, Chanda EK (2016) Fracture energy-based brittleness index development and brittleness quantification by pre-peak strength parameters in rock uniaxial compression. Rock Mech Rock Eng 49:4587–4606. https://doi.org/10.1007/s00603-016-1071-4

Niu Y, Zhou XP, Berto F (2020) Evaluation of fracture mode classification in flawed red sandstone under uniaxial compression. Theor Appl Fract Mech 107:102528. https://doi.org/10.1016/j.tafmec.2020.102528

Pan B, Qian K, Xie H, Asundi A (2009) Two-dimensional digital image correlation for in-plane displacement and strain measurement: a review. Meas Sci Technol. https://doi.org/10.1088/0957-0233/20/6/062001

Pan PZ, Miao S, Jiang Q et al (2019) The influence of infilling conditions on flaw surface relative displacement induced cracking behavior in hard rock. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-019-02033-x

Park CH, Bobet A (2009) Crack coalescence in specimens with open and closed flaws: a comparison. Int J Rock Mech Min Sci 46:819–829. https://doi.org/10.1016/j.ijrmms.2009.02.006

Park CH, Bobet A (2010) Crack initiation, propagation and coalescence from frictional flaws in uniaxial compression. Eng Fract Mech 77:2727–2748. https://doi.org/10.1016/j.engfracmech.2010.06.027

Petit J-P, Barquins M (1988) Can natural faults propagate under Mode II conditions? Tectonics 7:1243–1256. https://doi.org/10.1029/TC007i006p01243

Sagong M, Bobet A (2002) Coalescence of multiple flaws in a rock-model material in uniaxial compression. Int J Rock Mech Min Sci 39:229–241. https://doi.org/10.1016/S1365-1609(02)00027-8

Sharafisafa M, Shen L, Xu Q (2018) Characterisation of mechanical behaviour of 3D printed rock-like material with digital image correlation. Int J Rock Mech Min Sci 112:122–138. https://doi.org/10.1016/j.ijrmms.2018.10.012

Sharafisafa M, Shen L, Zheng Y, Xiao J (2019) The effect of flaw filling material on the compressive behaviour of 3D printed rock-like discs. Int J Rock Mech Min Sci 117:105–117. https://doi.org/10.1016/j.ijrmms.2019.03.031

Shen B (1995) The mechanism of fracture coalescence in compression-experimental study and numerical simulation. Eng Fract Mech 51:73–85. https://doi.org/10.1016/0013-7944(94)00201-R

Wang SY, Sloan SW, Sheng DC et al (2014) Numerical study of failure behaviour of pre-cracked rock specimens under conventional triaxial compression. Int J Solids Struct 51:1132–1148. https://doi.org/10.1016/j.ijsolstr.2013.12.012

Wang YT, Zhou XP, Kou MM (2019) Three-dimensional numerical study on the failure characteristics of intermittent fissures under compressive–shear loads. Acta Geotech 14:1161–1193. https://doi.org/10.1007/s11440-018-0709-7

Wong RHC, Chau KT (1998) Crack coalescence in a rock-like material containing two cracks. Int J Rock Mech Min Sci 35:147–164. https://doi.org/10.1016/S0148-9062(97)00303-3

Wong LNY, Einstein HH (2009) Crack coalescence in molded gypsum and carrara marble: part 1. macroscopic observations and interpretation. Rock Mech Rock Eng 42:475–511. https://doi.org/10.1007/s00603-008-0002-4

Wong LNY, Li HQ (2013) Numerical study on coalescence of two pre-existing coplanar flaws in rock. Int J Solids Struct 50:3685–3706. https://doi.org/10.1016/j.ijsolstr.2013.07.010

Wong RHC, Guo YS, Li LY, Chau KT, Zhu WS, Li SC (2006) Anti-wing crack growth from surface flaw in real rock under uniaxial compression. In: Proceedings of the 16th European conference of fracture, Alexandroupolis pp 825–826. https://doi.org/10.1007/1-4020-4972-2_408

Yang SQ, Jing HW (2011) Strength failure and crack coalescence behavior of brittle sandstone samples containing a single fissure under uniaxial compression. Int J Fract 168:227–250. https://doi.org/10.1007/s10704-010-9576-4

Yang SQ, Jiang YZ, Xu WY, Chen XQ (2008) Experimental investigation on strength and failure behavior of pre-cracked marble under conventional triaxial compression. Int J Solids Struct 45:4796–4819. https://doi.org/10.1016/j.ijsolstr.2008.04.023

Yang XX, Kulatilake PHSW, Asce F et al (2015) Particle flow modeling of rock blocks with nonpersistent open joints under uniaxial compression. Int J Geomech 16:1–17. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000649

Zhang XP, Wong LNY (2013) Crack initiation, propagation and coalescence in rock-like material containing two flaws: a numerical study based on bonded-particle model approach. Rock Mech Rock Eng 46:1001–1021. https://doi.org/10.1007/s00603-012-0323-1

Zhang XP, Liu Q, Wu S, Tang X (2015) Crack coalescence between two non-parallel flaws in rock-like material under uniaxial compression. Eng Geol 199:74–90. https://doi.org/10.1016/j.enggeo.2015.10.007

Zhang K, Cao P, Ma G et al (2016) Strength, fragmentation and fractal properties of mixed flaws. Acta Geotech 11:901–912. https://doi.org/10.1007/s11440-015-0403-y

Zhang Y, Jiang Y, Asahina D, Wang C (2020) Experimental and numerical investigation on shear failure behavior of rock-like samples containing multiple non-persistent joints. Rock Mech Rock Eng 53:4717–4744. https://doi.org/10.1007/s00603-020-02186-0

Zhao C, Niu J, Zhang Q et al (2019) Failure characteristics of rock-like materials with single flaws under uniaxial compression. Bull Eng Geol Environ 78:593–603. https://doi.org/10.1007/s10064-018-1379-2

Zhong Z, Huang D, Zhang Y, Ma G (2020) Experimental study on the effects of unloading normal stress on shear mechanical behaviour of sandstone containing a parallel fissure pair. Rock Mech Rock Eng 53:1647–1663. https://doi.org/10.1007/s00603-019-01997-0

Zhou C, Xu C, Karakus M, Shen J (2019a) A particle mechanics approach for the dynamic strength model of the jointed rock mass considering the joint orientation. Int J Numer Anal Methods Geomech 43:2797–2815. https://doi.org/10.1002/nag.3002

Zhou T, Zhu JB, Ju Y, Xie HP (2019b) Volumetric fracturing behavior of 3D printed artificial rocks containing single and double 3D internal flaws under static uniaxial compression. Eng Fract Mech 205:190–204. https://doi.org/10.1016/j.engfracmech.2018.11.030

Zhou T, Zhu J, Xie H (2020a) Mechanical and volumetric fracturing behaviour of three-dimensional printing rock-like samples under dynamic loading. Rock Mech Rock Eng 53:2855–2864. https://doi.org/10.1007/s00603-020-02084-5

Zhou Z, Cai X, Li X et al (2020b) Dynamic response and energy evolution of sandstone under coupled static-dynamic compression: insights from experimental study into deep rock engineering applications. Rock Mech Rock Eng 53:1305–1331. https://doi.org/10.1007/s00603-019-01980-9

Zhou C, Xie H, Zhu J et al (2022a) Mechanical and fracture behaviors of brittle material with a circular inclusion: insight from infilling composition. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-022-02799-7

Zhou C, Xie H, Zhu J, Zhou T (2022b) Failure criterion considering high temperature treatment for rocks from a micromechanical perspective. Theor Appl Fract Mech 118:103226. https://doi.org/10.1016/j.tafmec.2021.103226

Zhu JB, Zhou T, Liao ZY et al (2018) Replication of internal defects and investigation of mechanical and fracture behaviour of rock using 3D printing and 3D numerical methods in combination with X-ray computerized tomography. Int J Rock Mech Min Sci 106:198–212. https://doi.org/10.1016/j.ijrmms.2018.04.022

Acknowledgements

The work was financially supported by the Program for Guangdong Introducing Innovative and Entrepreneurial Teams (No. 2019ZT08G315), the National Natural Science Foundation of China (No. 52004161, 52004162) and the Shenzhen Natural Science Foundation (JCYJ20210324093400001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, T., Chen, J., Xie, H. et al. Failure and Mechanical Behaviors of Sandstone Containing a Pre-existing Flaw Under Compressive–shear Loads: Insight from a Digital Image Correlation (DIC) Analysis. Rock Mech Rock Eng 55, 4237–4256 (2022). https://doi.org/10.1007/s00603-022-02861-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-022-02861-4