Abstract

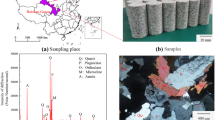

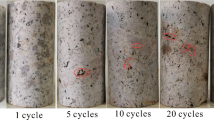

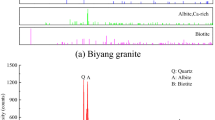

The optimal development of hot dry rock (HDR) geothermal is deep HDR geothermal. Because of different diagenesis environments, the mineral composition and micro-structure of deep granite are quite different than those of shallow granite. To reveal the characteristics of deep granite and guide HDR geothermal development, the difference in thermal and mechanical properties between the granite in Luya Mountain, Shanxi Province, China (coarse-grained granite) and the granite in Shandong Province, China (fine-grained granite) under high-temperature (100–400 ℃) triaxial stress was studied. The results show that the thermal expansion coefficient of the coarse-grained granite increases linearly with increasing temperature, and the thermal expansion coefficient of the coarse-grained granite is 1.52 times that of the fine-grained granite on average, and the difference reaches a maximum at 400 ℃. The elastic modulus of the coarse-grained granite increases slowly first and then decreases sharply with increasing temperature, and its threshold temperature varies with temperature at approximately 300 ℃. The elastic modulus of the fine-grained granite is 1.4–2.6 times that of the coarse-grained granite, and the difference increases with increasing temperature and confining pressure. According to the failure test under triaxial stress (confining pressure (σc) = 25 MPa) and at 400 ℃, for the coarse-grained granite, the peak strength, elastic modulus and its threshold temperature change with temperature are smaller, the peak strain is larger and the elasto-plastic transition occurs easier than those for the fine-grained granite. Micro-observation shows that the larger crystal particles and the extreme heterogeneity of the coarse-grained granite lead to larger thermal deformation and greater deterioration of the mechanical properties, compared with those of the fine-grained granite, further leading to higher permeability of the coarse-grained granite under high temperature and high pressure. The existence of coarse-grained granite provides a good geological foundation for high-efficiency, low-cost and large-scale construction of artificial reservoirs in the process of HDR geothermal development.

Similar content being viewed by others

References

Ballou LB (1979) Geological disposal investigations in granite at the Nevada test site. Lawrence Livermore National Laboratory, Livermore

Bauer SJ, Johnson B (1979) Effects of slow uniform heating on the Westerly and charcoal granites. In: proceedings of the 20th symposium on rock mechanics, Austin, TX, New York: ASCE, 7–18

Bauer SJ, Friedman M, Handin J (1981) Effects of water saturation on strength and ductility of three igneous rocks at effective pressure to 50MPa and temperatures to partial melting. In: proceedings of the 22nd symposium on rock mechanics, Cambridge, MA, 79–84

Brown DW, Duchane DV, Heiken G, Hriscu VT (2012) Mining the earth’s heat: hot dry rock geothermal energy. Springer, Berlin

Chen WM, Ying TZ, Chen YZ et al (1999) Thermal expansion of fluosilicate glass-ceramics. J Inorg Mater 14(2):271–274

Chen YL, SR W, J N et al (2017) An experimental study of the mechanical properties of granite after high temperature exposure based on mineral characteristics. ENG GEOL 220:234–242

Chen SW, Yang CH, Wang GB (2017) Evolution of thermal damage and permeability of Beishan granite. Appl Therm Eng 110:1533–1542

Clark SP Jr (1966) Handbook of physical constants. Geological Society of America, New York

Cooper HW, Simmons G (1977) The effect of cracks on the thermal expansion of rocks. Earth Planet Sci Lett 36(3):404–412

Dmitriyev AP, Kuzyayev LS, Protasov YI et al (1972) Physical properties of rock at high temperatures. NASA Technical Translation, Washington

Durham WB, Abey AE (1981a) The effect of pressure and temperature on the thermal properties of salt and a quartz monazite. Lawrence Livermore National Laboratory, Livermore

Durham WB, Abey AE (1981) Thermal conductivity and diffusivity of climax stock quartz monazite at high pressure and temperature. Lawrence Livermore National Laboratory, Livermore

Dwivedi RD, Goel RK, Prasad VVR et al (2008) Thermo-mechanical properties of Indian and other granites. Int J Rock Mech Min Sci 45:303–315

Engineering ToolBox (2003) Coefficients of linear thermal expansion. https://www.engineeringtoolbox.com/linear-expansion-coefficients-d_95.html. Accessed 16 June 2020

Feng ZJ, Zhao YS, Zhang Y et al (2018) Real-time permeability evolution of thermally cracked granite at triaxial stresses. Appl Therm Eng 133:194–200

Friedman M, Handin J, Higgs NG et al (1979) Strength and ductility of four dry igneous rocks at low pressures, and temperatures to partial melting. In: proceedings of the 20th symposium on rock mechanics, Austin, TX, New York: ASCE, 35–50

Gautam PK, Verma AK, Sharma P et al (2018) Evolution of thermal damage threshold of Jalore granite. Rock Mech Rock Eng 51:2949–2956

Goldemberg J (2000) World energy assessment: energy and the challenge of sustainability. United Nations Development Programme, NY

Hanley EJ, Dewitt DP, Roy RF (1978) The thermal diffusivity of eight well characterised rocks for the temperature range 300–1000 K. Eng Geol 12:31–47

Heard HC (1980) Thermal expansion and inferred permeability of climax quartz monazite to 300 ℃ and 27.6MPa. Int J Rock Mech Min Sci Geomech Abstr 17:289–296

Helmut GF, Winkler (1955) Struktur und Eigenschaften der Kristalle. Springer Verlag, Berlin

Heuze FE (1983) High-temperature mechanical, physical and thermal properties of granitic rocks—a review. Int J Rock Mech Min Sci Geomech Abstr 20:3–10

Homand-Etienne H, Houpert R (1989) Thermally induced micro-cracking in granites: characterization and analysis. Int J Rock Mech Min Sci Geomech Abstr 26:125–134

Jiang GH, Zuo JP, Li LY et al (2018) The evolution of cracks in Maluanshan granite subjected to different temperature processing. Rock Mech Rock Eng 51:1683–1695

Jin FL, Park SJ (2008) Impact-strength improvement of epoxy resins reinforced with a biodegradable polymer. Mater Sci Eng A 478:402–405

Klet RD (1974) Deep rock nuclear waste disposal test: design and operation. Sandia National Laboratory, Albuquerque

Konecny P, Kozusnikova A, Goel RK et al (2005) A comparative study of influence of temperature on granites from India and Czech Republic. In: proceedings of EUROCK 2005, Brno, Czech Republic 265–267

Kozusnikova A, Konecny P (2011) Influence of temperature on the permeability of rocks. Geotechnique 61:1081–1085

Lindroth DP, Krawza WG (1971) Heat content and specific heat of six rock types at temperatures to 1000 °C. US Bureau of Mines, Washington

Liu S, Xu JY (2015) An experimental study on the physico-mechanical properties of two post-high-temperature rocks. Eng Geol 185:63–70

Ma JL (2008) Foundation of inorganic materials science. Chongqing University Press, Chongqing (in Chinese)

McLaren JR, Titchel I (1981) Physical properties of granite relevant to near field conditions in a nuclear waste depository. AERE, Harwell

Myer LR (1981) Laboratory investigations of thermomechanical properties of Stripa granite. Lawrence Berkeley National Laboratory, Berkeley

Page L, Heard HC (1981) Elastic moduli, thermal expansion, and inferred permeability of climax quartz monazite and Sudbury Gabbro to 500 °C and 55 MPa. Lawrence Livermore National Laboratory, Livermore

Richter D, Simmons G (1974) Thermal expansion behavior of igneous rocks. Int J Rock Mech Min Sci Geomech Abstr 11:403–411

Scenario N, East M (2014) World energy outlook 2014 factsheet. International Energy Agency, Paris

Tullis J, Yund RA (1977) Experimental deformation of dry westerly granite. J Geophys Res 82:5705–5718

Wan ZJ, Zhao YS, Dong FK et al (2008) Experimental study on mechanical characteristics of granite under high temperature and triaxial stresses. Chin J Rock Mechan Eng 27:72–77 (in Chinese)

Wang SZ, Zang XS (1991) Modern materials research method. Beijing University of aeronautics and astronautics press, Beijing (in Chinese)

Wang HF, Bonner BP, Carlson SR et al (1989) Thermal stress cracking in granite. J Geophys Res 94(B2):1745–1758

Whitney DL, Broz M, Cook RF (2007) Hardness, toughness, and modulus of some common metamorphic minerals. Am Mineral 92(2–3):281–288

Wong TF, Brace WF (1979) Thermal expansion of rocks: some measurements at high pressure. Tectonophysics 57(2–4):95–117

Xi BP, Zhao YS (2010) Experimental research on mechanical properties of water-cooled granite under high temperature within 600 ℃. Chin J Rock Mechan Eng 29:892–898 (in Chinese)

Xiuer P (1984) Thermal stress and thermal fatigue. National defense industry press, Beijing (in Chinese)

Yang KG, Yuan YM (2009) Foundation of Geology. China University of Geosciences press, Wuhan (in Chinese)

Yang SQ, Ranjith PG, Jing HW et al (2017) An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high temperature treatments. Geothermics 65:180–197

Yin WT, Zhao YS, Feng ZJ (2019) Experimental research on the rupture characteristics of fractures subsequently filled by magma and hydrothermal fluid in hot dry rock. Renew Energ 139:71–79

You MQ, Su CD (2003) Heterogeneity of rock and the definition of Yong’s modulus. Chin J Rock Mechan Eng 22(5):757–761 (in Chinese)

Yuan JQ, Zhu SQ, Zhai YS (1985) Geology of ore deposits. Geological publishing house, Beijing (in Chinese)

Zhang FZ, Xu RN, Jiang PX (2016) Thermodynamic analysis of enhanced geothermal systems using impure CO2 as the geofluid. Appl Therm Eng 37:1277–1285

Zhao YS, Wan ZJ, Kang JR (2004) Introduction of geothermal extraction of hot dry rock. Science press, Beijing (in Chinese)

Zhao YS, Meng QR, Kang TH et al (2008) Micro-CT experimental technology and Meso-Investigation on thermal fracturing characteristics of granite. Chin J Rock Mechan Eng 27:28–34 (in Chinese)

Zhao YS, Wan ZJ, Feng ZJ et al (2012) Triaxial compression system for rock testing under high temperature and high pressure. Int J Rock Mech Min Sci 52:132–138

Zhao YS, Feng ZJ, Xi BP et al (2015) Deformation and instability failure of borehole at high temperature and high pressure in hot dry rock exploitation. Renew Energ 77:159–165

Zhao YS, Feng ZJ, Zhao Y et al (2017) Experimental investigation on thermal cracking, permeability under HTHP and application for geothermal mining of HDR. ENERGY 132:305–314

Zhou H, Liu H, Hu D, Yang F, Lu J, Zhang F (2016) Anisotropies in mechanical behavior, thermal expansion and P-wave velocity of sandstone with bedding planes. Rock Mech Rock Eng 49(11):4497–4504

Zhu HH, Yan ZG, Deng T et al (2006) Testing study on mechanical properties of tuff, granite and breccia after high temperature. Chinese J Rock Mech Eng 25(1):945–951 (950 in Chinese)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant nos. U1810104, 11772213) and the Program for the Outstanding Innovative Teams of Higher Learning Institutions of Shanxi.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: The Derivation Process of Thermal Stress

Appendix: The Derivation Process of Thermal Stress

Assuming that the axial length of a mineral crystal particle is L, the thermal expansion coefficient is α, and the temperature difference is ΔT, then the axial elongation l of the mineral crystal particle is as follows:

The elongation per unit length (i.e., the strain (ε)) is as follows:

If the mineral crystal particle is constrained, a compressive stress corresponding to the strain in formula (2) will be generated. Assuming that the elastic modulus of the mineral crystal particle is E, the axial stress (i.e., the thermal stress (σ)) of the mineral crystal particle is as follows (Wong et al. 1979; Wang et al. 1989):

Then analyse the combination of different types of mineral crystal particle. Assume that E1, α1, E2 and α2 are the elastic moduli and thermal expansion coefficients of two adjacent mineral particles, respectively, the interface area is A, and that ΔT is the temperature difference. For simplicity, this paper also assumes that the mineral particles only generate stress and strain in the direction perpendicular to the interface (i.e., under one-dimensional stress state). Assuming that the stress and strain of the two mineral particles are σ1, ε1, σ2 and ε2, respectively, the relationship between stress and strain is as follows:

Considering the axial force balance and boundary conditions, the following equations hold:

According to formulas (4), (5) and (6), the thermal stresses of the two mineral crystal particles are obtained as follows:

Rights and permissions

About this article

Cite this article

Yin, W., Feng, Z. & Zhao, Y. Effect of Grain Size on the Mechanical Behaviour of Granite Under High Temperature and Triaxial Stresses. Rock Mech Rock Eng 54, 745–758 (2021). https://doi.org/10.1007/s00603-020-02303-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-020-02303-z