Abstract

We carried out a series of long-term creep experiments on clay- and carbonate-rich shale samples from unconventional gas reservoirs to investigate creep over both relatively short-term (4-h) and long-term (4-week) periods. Results from each set of experiments were compared to evaluate the ability to predict the long-term behavior of reservoir rocks using relatively short-term creep experiments. The triaxial deformation experiments were performed in a time-cycling pattern, which included a series of four stages of loading, creep, unloading and recovery experiments conducted over different time spans. The loading conditions (tens of MPa) reflect current reservoir conditions and were far below the strength of the samples. Experiments were conducted on both horizontal and vertical shale samples to address anisotropy introduced by the bedding. A power-law model was fitted to the creep data to predict the long-term behavior of shale samples. Regardless of the applied loading history, results of the experiments show that the shale samples follow a single trend representing their creep behavior through time. We show that the simple power-law model is capable of describing creep over multiple time periods. Additionally, the value of the creep compliance factor is consistent over different creep testing periods and it is possible to characterize the behavior of these samples from relatively short-term (1 day) creep experiments.

Similar content being viewed by others

References

Bayuk I, Ammerman M, Chesnokov E (2007) Elastic moduli of anisotropic clay. Geophysics 72:D107–D117

Bernabe Y (1986) Pore volume and transport properties changes during pressure cycling of several crystalline rocks. Mech Mater 5(3):235–249

Boukharov G, Chanda M, Boukharov N (1995) The three processes of brittle crystalline rock creep. Int J Rock Mech Min Sci Geomech Abstr 32:325–335

Brace W, Paulding B, Scholz C (1966) Dilatancy in the fracture of crystalline rocks. J Geophys Res 71(16):3939–3953

Chaboche JL (1986) Time-independent constitutive theories for cyclic plasticity. Int J Plast 2(2):149–188

Chaboche J (2008) A review of some plasticity and viscoplasticity constitutive theories. Int J Plast 24(10):1642–1693

Chang C, Zoback MD (2010) Viscous creep in room-dried unconsolidated gulf of mexico shale (ii): development of a viscoplasticity model. J Pet Sci Eng 72(1):50–55

Cogan J (1976) Triaxial creep tests of opohonga limestone and ophir shale. Int J Rock Mech Min Sci Geomech Abstr 13:1–10

Croizé D, Renard F, Gratier J-P (2013) Compaction and porosity reduction in carbonates: a review of observations, theory, and experiments. Adv Geophys 54:181–238

Cuisiat F, Grande L, Heg K et al (2002) Laboratory testing of long term fracture permeability in shales. In: SPE/ISRM rock mechanics conference. Society of Petroleum Engineers

Davis NE, Kronenberg AK, Newman J (2008) Plasticity and diffusion creep of dolomite. Tectonophysics 456(3–4):127–146

Fan L, Martin RB, Thompson JW, Atwood K, Robinson JR, Lindsay GJ et al (2011) An integrated approach for understanding oil and gas reserves potential in eagle ford shale formation. In: Canadian unconventional resources conference. Society of Petroleum Engineers

Fan Z, Eichhubl P, Gale JF (2016) Geomechanical analysis of uid injection and seismic fault slip for the mw4. 8 timpson, texas, earthquake sequence. J Geophys Res Solid Earth 121(4):2798–2812

Ferrari A, Laloui L (2013) Advances in the testing of the hydro-mechanical behaviour of shales. In: Multiphysical testing of soils and shales. Springer, Berlin, pp 57–68

Fujii Y, Kiyama T, Ishijima Y, Kodama J (1999) Circumferential strain behavior during creep tests of brittle rocks. Int J Rock Mech Min Sci 36(3):323–337

Gasc-Barbier M, Chanchole S, Berest P (2004) Creep behavior of bure clayey rock. Appl Clay Sci 26(1):449–458

Goodman RE (1989) Introduction to rock mechanics, vol 2. Wiley, New York

Gratier JP, Guiguet R, Renard F, Jenatton L, Bernard D (2009) A pressure solution creep law for quartz from indentation experiments. J Geophys Res Solid Earth 114:B3

Hammes U, Hamlin HS, Ewing TE (2011) Geologic analysis of the upper jurassic Haynesville shale in east texas and west louisiana. AAPG Bull 95(10):1643–1666

Hatzor YH, Palchik V (1998) A microstructure-based failure criterion for Aminadav dolomites. Int J Rock Mech Min Sci 35(6):797–805

Horsrud P, Snsteb E, Be R (1998) Mechanical and petrophysical properties of North Sea shales. Int J Rock Mech Min Sci 35(8):1009–1020

Hyde T, Sun W, Hyde C (2013) An overview of small specimen creep testing. In: Altenbach H, Kruch S (eds) Advanced materials modelling for structures. Springer, Berlin, pp 201–216

Kennedy LA, White JC (2001) Low-temperature recrystallization in calcite: mechanisms and consequences. Geology 29(11):1027–1030

Khan AS, Farrokh B (2006) Thermo-mechanical response of nylon 101 under uniaxial and multi-axial loadings: Part I, experimental results over wide ranges of temperatures and strain rates. Int J Plast 22(8):1506–1529

Kias E, Maharidge R, Hurt R et al (2015) Mechanical versus mineralogical brittleness indices across various shale plays. In: SPE annual technical conference and exhibition. Society of Petroleum Engineers

Krempl E, McMahon J, Yao D (1986) Viscoplasticity based on overstress with a differential growth law for the equilibrium stress. Mech Mater 5(1):35–48

Kubetsky V, Eristov V (1970) In situ investigations of creep in rock for the design of pressure tunnel linings. British Geotechnical Society, pp 83–91

Kwon O, Kronenberg AK, Gangi AF, Johnson B, Herbert BE (2004) Permeability of illite-bearing shale: 1: Anisotropy and effects of clay content and loading. J Geophys Res Solid Earth 109(10):B10205-1

Lakes RS (2009) Viscoelastic materials. Cambridge University Press, Cambridge

Li W, Jin C, Salviato M, Cusatis G et al (2015) Modeling of failure behavior of anisotropic shale using lattice discrete particle model. In: 49th US rock mechanics/geomechanics symposium. American Rock Mechanics Association

Lockner D, Byerlee J (1977) Acoustic emission and creep in rock at high conning pressure and differential stress. Bull Seismol Soc Am 67(2):247–258

Lund Snee JE, Zoback MD (2016) State of stress in texas: implications for induced seismicity. Geophys Res Lett 43(19):10-208

Moore DE, Lockner DA (2004) Crystallographic controls on the frictional behavior of dry and water-saturated sheet structure minerals. J Geophys Res Solid Earth 109(B3). https://doi.org/10.1029/2003JB002582

Mullen J et al (2010) Petrophysical characterization of the eagle ford shale in south Texas. In: Canadian unconventional resources and international petroleum conference. Society of Petroleum Engineers

Murray RC (1960) Origin of porosity in carbonate rocks. J Sediment Res 30:59–84

Paterson MS, Wong TF (2005) Experimental rock deformation-the brittle field. Springer, The Netherlands

Pope C et al (2009) Haynesville shale-one operator's approach to well completions in this evolving play. In: SPE Annual Technical Conference and Exhibition. Society of Petroleum Engineers

Putnis A, Putnis CV (2007) The mechanism of reequilibration of solids in the presence of a fluid phase. J Solid State Chem 180(5):1783–1786

Rassouli F, Moosavi M, Jafari M et al (2009) The application of impression test in creep behavior of mudstone. In: ISRM regional symposium-eurock 2009. International Society for Rock Mechanics

Raufaste C et al (2011) The mechanism of porosity formation during solvent-mediated phase transformations. Proc R Soc London A: Math Phys Eng Sci 467(2129):1408–1426

Ruggles M, Krempl E (1990) The interaction of cyclic hardening and ratchetting for AISI type 304 stainless steel at room temperature—I. Experiments. J Mech Phys Solids 38(4):575–585

Ruiz-Agudo E, Putnis CV, Putnis A (2014) Coupled dissolution and precipitation at mineral-fluid interfaces. Chem Geol 383:132–146

Rutter E (1972) On the creep testing of rocks at constant stress and constant force. Int J Rock Mech Min Sci Geomech Abstr 9:191–195

Rybacki E, Reinicke A, Meier T, Makasi M, Dresen G (2015) What controls the mechanical properties of shale rocks?—Part I: strength and Young’s modulus. J Pet Sci Eng 135:702–722

Sone H (2012) Mechanical properties of shale gas reservoir rocks, and its relation to the in situ stress variation observed in shale gas reservoirs, Ph.D. thesis, Stanford University

Sone H, Zoback MD (2013) Mechanical properties of shale-gas reservoir rocks Part 1: static and dynamic elastic properties and anisotropy. Geophysics 75:D381–D392

Sone H, Zoback MD (2014a) Time-dependent deformation of shale gas reservoir rocks and its long-term effect on the in situ state of stress. Int J Rock Mech Min Sci 69:120–132

Sone H, Zoback MD (2014b) Viscous relaxation model for predicting least principal stress magnitudes in sedimentary rocks. J Pet Sci Eng 124:416–431

Spain DR, Anderson GA (2010) Controls on reservoir quality and productivity in the Haynesville shale, vol 60. Gulf coast association of geological societies transactions, Northwestern gulf of mexico basin, pp 657–668

Thompson J, Fan L, Grant D, Martin RB, Kanneganti KT, Lindsay GJ et al (2011) An overview of horizontal-well completions in the Haynesville shale. J Can Pet Technol 50(06):22–35

Van Oort E (2003) On the physical and chemical stability of shales. J Pet Sci Eng 38(3):213–235

Wawersik W, Brace W (1971) Post-failure behavior of a granite and diabase. Rock Mech 3(2):61–85

Yang Y, Zoback M (2016) Viscoplastic deformation of the Bakken and adjacent formations and its relation to hydraulic fracture growth. Rock Mech Rock Eng 49(2):689–698

Yang Y, Sone H, Zoback M et al (2015) Fracture gradient prediction using the viscous relaxation model and its relation to out-of-zone microseismicity. In: SPE annual technical conference and exhibition. Society of Petroleum Engineers

Yoshida F (1990) Uniaxial and biaxial creep-ratcheting behavior of SUS304 stainless steel at room temperature. Int J Press Vessels Pip 44(2):207–223

Zhang CL, Rothfuchs T, Su K, Hoteit N (2007) Experimental study of the thermo-hydro- mechanical behaviour of indurated clays. Phys Chem Earth A/B/C 32(8):957–965

Zhu W, Baud P, Wong TF (2010) Micromechanics of cataclastic pore collapse in limestone. J Geophys Res Solid Earth 115(B4). https://doi.org/10.1029/2009JB006610

Acknowledgements

We thank ConocoPhillips and BP for providing the samples we used in this study and Carl Zeiss Microscopy for providing the imaging tools. We also thank the reviewers for the constructive comments, which helped to improve the manuscript. Financial support for Fatemeh Rassouli was provided by Stanford Rock and Borehole Geophysics (SRB) industrial consortium.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Seasoning Effect

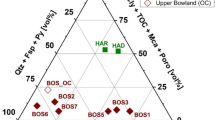

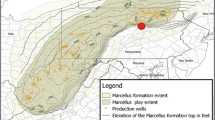

To study the behavior of the first creep cycles reported in Figs. 2, 3 and 14, we conducted a series of cyclic experiments on six different samples from Haynesville and Eagle Ford formations. The majority of the samples had a high amount of carbonate content. The mineral compositions of these samples are compared to the four samples described in the text in Fig. 15.

These experiments followed the seasoning process of the samples discussed in studies by Brace et al. (1966), Bernabe (1986) and Wawersik and Brace (1971), where the sample is first loaded to allow for the sample to come into a consistent position in the loading frame. The main goal of running these experiments was to compare the behavior of the first creep cycle to the rest of the cyclic stages in our protocol. This initial loading step allows slight variations in response, resulting from small heterogeneities in the sample associated with recovery, sample preparation, and loading to be removed. After the seasoning cycle, the sample behaves more like the material in situ.

Here, we examined the seasoning process tests following the loading pattern used for time-cycling experiments (Fig. 16), which consists of four cycles of loading, creep, unloading and recovery stages. The time span of the first three creep stages was equal to 3 h, while the final loading stage lasted for 1 day. Similar to the time-cycling creep tests, both the confining pressure and differential creep stresses were kept constant at 40 MPa. The differential stress value was reduced to 2 MPa at the unloading steps.

The power-law parameters calculated for these experiments are shown in Fig. 17. As we expected, the n values for the first creep step of all these experiments (marked with red circles) are outliers, while the results for the other three steps are more uniform. This confirms our conclusion in Sect. 4.3 that to get a better prediction of the time-dependent behavior of the rocks within short periods of time, samples should be tested in a two-cycle pattern. The first few-hour cycle is to make the sample closer to the in situ state conditions, and the second creep cycle to calculate the n and B values for the viscoplastic behavior predictions.

Appendix 2

Total strains of all the samples using the method described in Sect. 4.1 are shown in Fig. 18. As mentioned before, regardless of the loading history, samples follow one time-dependent deformation trend.

Appendix 3

Ultrasonic velocity measurements were conducted during the creep experiments presented in this study. These values were calculated from the recorded travel time of ultrasonic waves generated by piezoelectric crystals attached to the inner surface of the core holders. The resolution of the recorded ultrasonic waves is 0.04 μs at room temperature.

P-wave and cross-polarized S-wave velocities were measured and used to calculate vertical and horizontal Poisson’s ratio and E values shown in Figs. 19 and 20 from the following equations:

where E, K and μ are elastic, volumetric and shear moduli, respectively; Vs and Vp are S-wave and P-wave velocities; and ρ is bulk density.

Both horizontal samples have higher dynamic E values and Poisson’s ratio, which is in agreement with what we discussed above. The higher amount of Poisson’s ratio shows that the horizontal samples are more expandable because of bedding planes parallel to the loading axis.

The small difference between the values calculated from horizontal and vertical S-waves depends on the position of the core holders with respect to the bedding planes. Since in these experiments we were not interested in S-wave anisotropy, we did not choose the orientation of piezoelectric crystals with respect to the orientation of bedding planes in the samples.

Rights and permissions

About this article

Cite this article

Rassouli, F.S., Zoback, M.D. Comparison of Short-Term and Long-Term Creep Experiments in Shales and Carbonates from Unconventional Gas Reservoirs. Rock Mech Rock Eng 51, 1995–2014 (2018). https://doi.org/10.1007/s00603-018-1444-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-018-1444-y