Abstract

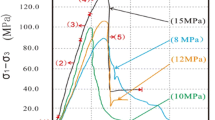

An extensive uniaxial and triaxial compression testing programme was performed on Indiana Limestone to assess its behaviour across the brittle–ductile transition. Particular attention has been paid to the post-yield evolution of strength and dilatancy. Specimens tested at σ 3 = 30 MPa displayed a fully ductile failure mechanism, whereas specimens tested at σ 3 = 15 MPa and σ 3 = 20 MPa displayed transitional mechanisms, which were neither fully brittle nor fully ductile. Based on an examination of failure localization and dilatancy characteristics, the stress at which crack volumetric strain begins to increase was found to be an indicator of individual specimen ductility. In contrast to less porous rocks, the reversal of total volumetric strain did not coincide with the onset of axial strain nonlinearity under unconfined conditions. With respect to post-yield strength, a major change in the rate of friction mobilization relative to plastic shear strain was observed across the brittle–ductile transition. The dilatancy of the specimens was also found to undergo a major change, with the plastic shear strains to mobilization of peak dilatancy in the ductile regime being approximately one order of magnitude higher than in the brittle regime.

Similar content being viewed by others

References

Alejano LR, Alonso E (2005) Considerations of the dilatancy angle in rocks and rock masses. Int J Rock Mech Min Sci 42(4):481–507

Arzúa J, Alejano LR (2013) Dilation in granite during servo-controlled triaxial strength tests. Int J Rock Mech Min Sci 61:43–56

Aydin A, Johnson AM (1978) Development of faults as zones of deformation bands and as slip surfaces in sandstone. Pure Appl Geophys 116(4–5):931–942

Bewick RP, Amann F, Kaiser PK, Martin CD (2015) Interpretation of UCS test results for engineering design. In: 13th ISRM international congress of rock mechanics. International Society for Rock Mechanics

Boutéca M, Sarda JP, Schneider F (1996) Subsidence induced by the production of fluids. Oil Gas Sci Technol 51(3):349–379

Brace WF, Paulding BW, Scholz C (1966) Dilatancy in the fracture of crystalline rocks. J Geophys Res 71(16):3939–3953

Chandler NA (2013) Quantifying long-term strength and rock damage properties from plots of shear strain versus volume strain. Int J Rock Mech Min Sci 59:105–110

Cipullo A, White W, Lee IK (1985) Computer controlled volumetric strain measurements in metadolerite. Bull Int Assoc Eng Geol (Bull Assoc Int Géol Ing 32(1):55–65

Cook NGW (1970) An experiment proving that dilatancy is a pervasive volumetric property of brittle rock loaded to failure. Rock Mech 2(4):181–188

Crouch SL (1970) Experimental determination of volumetric strains in failed rock. Int J Rock Mech Min Sci Geomech Abstr 7(6):589–603

Diederichs MS (2003) Manuel Rocha medal recipient: rock fracture and collapse under low confinement conditions. Rock Mech Rock Eng 36(5):339–381

Diederichs MS (2007) The 2003 Canadian Geotechnical Colloquium: mechanistic interpretation and practical application of damage and spalling prediction criteria for deep tunnelling. Can Geotech J 44(9):1082–1116

Diederichs MS, Martin CD (2010) Measurement of spalling parameters from laboratory testing. In: Rock mechanics and environmental engineering. Proceedings of the European rock mechanics symposium, pp 323–326

Doglioni C, Barba S, Carminati E, Riguzzi F (2011) Role of the brittle–ductile transition on fault activation. Phys Earth Planet Inter 184(3):160–171

Dunham RJ (1962) Classification of carbonate rocks according to depositional texture. Am Assoc Pet Geol Mem 1:108–121

Elliott GM, Brown ET (1985) Yield of a soft, high porosity rock. Geotechnique 35(4):413–423

Evans B, Fredrich JT, Wong TF (1990) The brittle–ductile transition in rocks: recent experimental and theoretical progress. Brittle–Ductile Trans Rocks Geophys Monogr Ser 56:1–20

Fisher QJ, Casey M, Clennell MB, Knipe RJ (1999) Mechanical compaction of deeply buried sandstones of the North Sea. Mar Pet Geol 16(7):605–618

Griggs DT, Turner FJ, Heard HC (1960) Deformation of rocks at 500° to 800° C. Geol Soc Am Mem 79:39–104

Hajiabdolmajid V, Kaiser PK, Martin CD (2002) Modelling brittle failure of rock. Int J Rock Mech Min Sci 39(6):731–741

Hart DJ, Wang HF (1995) Laboratory measurements of a complete set of poroelastic moduli for Berea sandstone and Indiana limestone. J Geophys Res Solid Earth (1978–2012) 100(B9):17741–17751

Hill R (1950) The mathematical theory of plasticity. Oxford University Press, London

Hill JR (2013) Indiana limestone. Retrieved 08/01/2013 from http://igs.indiana.edu/MineralResources/Limestone.cfm

Hoagland RG, Hahn GT, Rosenfield AR (1973) Influence of microstructure on fracture propagation in rock. Rock Mechanics 5(2):77–106

Hoek E, Martin CD (2014) Fracture initiation and propagation in intact rock—a review. J Rock Mech Geotech Eng 6(4):287–300

Hoek E, Carranza-Torres C, Corkum B (2002) Hoek–Brown failure criterion-2002 edition. Proc NARMS-TAC 1:267–273

Hudson JA, Brown ET, Fairhurst C (1971) Optimizing the control of rock failure in servo-controlled laboratory tests. Rock Mech 3(4):217–224

Imber J, Holdsworth RE, Butler CA, Strachan RA (2001) A reappraisal of the Sibson-Scholz fault zone model: the nature of the frictional to viscous (“ brittle–ductile”) transition along a long-lived, crustal-scale fault, Outer Hebrides, Scotland. Tectonics 20(5):601–624

ISRM (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. In: Ulusay R, Hudson JA (eds) Prepared by the commission on testing methods. ISRM, Ankara

Jamison WR, Stearns DW (1982) Tectonic deformation of Wingate Sandstone, Colorado National Monument. AAPG Bull 66(12):2584–2608

Ji Y, Baud P, Vajdova V, Wong TF (2012) Characterization of pore geometry of Indiana limestone in relation to mechanical compaction. Oil Gas Sci Technol (Rev IFP Energ Nouv 67(5):753–775

Kaiser PK, Kim BH (2015) Characterization of strength of intact brittle rock considering confinement-dependent failure processes. Rock Mech Rock Eng 48(1):107–119

Kovari K, Tisa A, Attinger RO (1983) The concept of “continuous failure state” triaxial tests. Rock Mech Rock Eng 16(2):117–131

Labrie D, Conlon B (2008) Hydraulic and poroelastic properties of porous rocks and concrete materials. In: Proceedings of the 42nd US rock mechanics symposium (USRMS). American Rock Mechanics Association, Paper 08-182

Lajtai EZ (1998) Microscopic fracture processes in a granite. Rock Mech Rock Eng 31(4):237–250

Langford JC, Diederichs MS (2015) Quantifying uncertainty in Hoek–Brown intact strength envelopes. Int J Rock Mech Min Sci 74:91–102

Makowitz A, Milliken KL (2003) Quantification of brittle deformation in burial compaction, Frio and Mount Simon Formation sandstones. J Sediment Res 73(6):1007–1021

Martin CD (1997) Seventeenth Canadian geotechnical colloquium: the effect of cohesion loss and stress path on brittle rock strength. Can Geotech J 34(5):698–725

Martin CD, Chandler NA (1994) The progressive fracture of Lac du Bonnet granite. Int J Rock Mech Min Sci Geomech Abstr 31(6):643–659

Medhurst TP (1996) Estimation of the in situ strength and deformability of coal for engineering design. PhD thesis, University of Queensland, Australia

Mogi K (1966) Pressure dependence of rock strength and transition from brittle fracture to ductile flow. Bull Earthq Res Inst Tokyo Univ 44:215–232

Nagel NB (2001) Compaction and subsidence issues within the petroleum industry: from Wilmington to Ekofisk and beyond. Phys Chem Earth Part A 26(1):3–14

Ofoegbu GI, Curran JH (1992) Deformability of intact rock. Int J Rock Mech Min Sci Geomech Abstr 29(1):35–48

Passchier CW, Trouw RA (2005) Microtectonics, 2nd edn. Springer, Berlin

Paterson MS, Wong TF (2005) Experimental rock deformation-the brittle field. Springer, Berlin

Peck L, Barton CC, Gordon RB (1985) Microstructure and the resistance of rock to tensile fracture. J Geophys Res Solid Earth (1978–2012) 90(B13):11533–11546

Robinson LH (1959) The effect of pore and confining pressure on the failure process in sedimentary rock. In: Proceedings of the 3rd US symposium on rock mechanics (USRMS). American Rock Mechanics Association

Rummel F, Fairhurst C (1970) Determination of the post-failure behavior of brittle rock using a servo-controlled testing machine. Rock Mech 2(4):189–204

Schmidt RA, Huddle CW (1977) Effect of confining pressure on fracture toughness of Indiana limestone. Int J Rock Mech Min Sci Geomech Abstr 14(5):289–293

Scholz CH (1988) The brittle-plastic transition and the depth of seismic faulting. Geol Rundsch 77(1):319–328

Simpson C (1985) Deformation of granitic rocks across the brittle–ductile transition. J Struct Geol 7(5):503–511

Singh AB (1997) Study of rock fracture by permeability method. J Geotechn Geoenviron Eng 123(7):601–608

Thomas AM, Bürgmann R, Shelly DR, Beeler NM, Rudolph ML (2012) Tidal triggering of low frequency earthquakes near Parkfield, California: implications for fault mechanics within the brittle‐ductile transition. J Geophys Res Solid Earth (1978–2012) 117(B5)

Turner FJ, Griggs DT, Heard H (1954) Experimental deformation of calcite crystals. Geol Soc Am Bull 65(9):883–934

Underhill JR, Woodcock NH (1987) Faulting mechanisms in high-porosity sandstones; new red sandstone, Arran, Scotland. Geol Soc Lond Spec Publ 29(1):91–105

Vajdova V, Baud P, Wong TF (2004) Compaction, dilatancy, and failure in porous carbonate rocks. J Geophys Res Solid Earth (1978–2012) 109(B5)

Vajdova V, Baud P, Wu L, Wong TF (2012) Micromechanics of inelastic compaction in two allochemical limestones. J Struct Geol 43:100–117

Vermeer PA, De Borst R (1984) Non-associated plasticity for soils, concrete and rock. HERON 29(3):1984

Walton G, Diederichs MS (2015a) A mine shaft case study on the accurate prediction of yield and displacements in stressed ground using lab-derived material properties. Tunn Undergr Space Technol 49:98–113

Walton G, Diederichs MS (2015b) A new model for the dilation of brittle rocks based on laboratory compression test data with separate treatment of dilatancy mobilization and decay. Geotech Geol Eng 33(3):661–679

Walton G, Arzua J, Alejano LR, Diederichs MS (2014a) A laboratory-testing-based study on the strength, deformability, and dilatancy of carbonate rocks at low confinement. Rock Mech Rock Eng 48(3):941–958

Walton G, Diederichs MS, Alejano LR, Arzúa J (2014b) Verification of a laboratory-based dilation model for in situ conditions using continuum models. J Rock Mech Geotech Eng 6(6):522–534

Walton G, Diederichs M, Punkkinen A, Whitmore J (2016) Back analysis of a pillar monitoring experiment at 2.4 km depth in the Sudbury Basin, Canada. Int J Rock Mech Min Sci 85(1):33–51

Wawersik WR (1975) Technique and apparatus for strain measurements on rock in constant confining pressure experiments. Rock Mech 7(4):231–241

Wawersik WR, Brace WF (1971) Post-failure behavior of a granite and diabase. Rock Mech 3(2):61–85

Wawersik WR, Fairhurst C (1970) A study of brittle rock fracture in laboratory compression experiments. Int J of Rock Mech Min Sci Geomech Abstr 7(5):561–575

Wong TF, Baud P (2012) The brittle–ductile transition in porous rock: a review. J Struct Geol 44:25–53

Zhao XG, Cai M (2010) A mobilized dilation angle model for rocks. Int J Rock Mech Min Sci 47(3):368–384

Zheng Z, Cook NG, Myer LR (1989) Stress induced microcrack geometry at failure in unconfined and confined axial compressive tests. In: Proceedings of the 30th US symposium on rock mechanics (USRMS). American Rock Mechanics Association

Acknowledgements

The authors would like to acknowledge the help of Sean Cowie in developing the brittle damage schematic used in this paper.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Walton, G., Hedayat, A., Kim, E. et al. Post-yield Strength and Dilatancy Evolution Across the Brittle–Ductile Transition in Indiana Limestone. Rock Mech Rock Eng 50, 1691–1710 (2017). https://doi.org/10.1007/s00603-017-1195-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-017-1195-1