Abstract

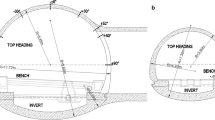

Measurements indicate that the development of cracking is a key feature relating to the strength and collapse of a columnar jointed rock mass. In this context, a new support design method utilising rock cracking indices for columnar jointed rock mass under high stress is proposed to restrain the development of cracking in the surrounding rock mass. The method involves limiting the cracking evolution of the surrounding rock mass by designing the appropriate parameters and time of installation of the support system. Two indices are suggested: the allowable depth of the excavation damaged zone (EDZ); and the allowable damage extent of the rock mass in the EDZ. The method involves limiting the evolution of cracking in the surrounding rock mass by designing the parameters and time of installation of the support system. The support system should have a suitable stiffness and installation time so as to restrain the evolution of the depth and damage extent of the EDZ within the surrounding rock. Therefore, the depth and damage extent of the EDZ, as well as the axial stress in the anchor bolts, are calculated at different distances between the support location and the tunnel working face to find the appropriate stiffness and installation time of the support system. The method has been successfully adopted to determine the thickness of shotcrete, the arrangement and installation time of rockbolts, and other parameters, for five large diversion tunnels at the Baihetan hydropower station, China, which were excavated in columnar jointed rock masses.

Similar content being viewed by others

References

Al Hallak R (2000) Experimental study of the stability of a tunnel face reinforced by bolts. Geotech Aspect Underground Constr Soft Ground, Balkema, Rotterdam, pp 65–68

Alejano LR, Alonso E, Rodríguez-Dono A et al (2010) Application of the convergence-confinement method to tunnels in rock masses exhibiting Hoek-Brown strain-softening behaviour. Int J Rock Mech Min Sci 47(1):150–160

Barton N, Løset F, Lien R et al (1981) Application of Q-system in design decisions concerning dimensions and appropriate support for underground installations. Subsurf Space 2:553–561

Bernaud D, Maghous S, De Buhan P et al (2009) A numerical approach for design of bolt-supported tunnels regarded as homogenized structures. Tunn Undergr Space Technol 24(5):533–546

Bhawani S, Viladkar MN, Samadhiya NK et al (1995) A semi-empirical method for the design of support systems in underground openings. Tunn Undergr Space Technol 10(3):375–383

Cai M, Kaiser PK (2005) Assessment of excavation damaged zone using a micromechanics model. Tunn Undergr Space Technol 20(4):301–310

Cai M, Kaiser PK, Tasaka Y et al (2004) Generalized crack initiation and crack damage stress thresholds of brittle rock masses near underground excavations. Int J Rock Mech Min Sci 41(5):833–847

Carranza-Torres C, Fairhurst C (2000) Application of convergence-confinement method of tunnel design to rock masses that satisfy the Hoek-Brown failure criterion. Tunn Undergr Space Technol 15(2):187–213

Chen BR, Feng XT, Zeng X et al (2011) Real-time microseismic monitoring and its characteristic analysis during TBM tunneling in deep-buried tunnel. Chin J Rock Mech Eng 30(2):275–283

Claudio O, Gunnar O (2004) Quality in tunnelling: ITA-AITES working group 16 final report. Tunn Undergr Space Technol 19(3):239–272

De Buhan P, Bourgeois E, Hassen G (2008) Numerical simulation of bolt supported tunnels by means of a multiphase model conceived as an improved homogenization procedure. Int J Numer Anal Methods 32(13):1597–1615

Feder G, Arwanitakis M (1976) Zur Gebirgsmechanik ausbruchsnaher Bereichetiefliegender Hohlraumbauten. BHM 121(4):103–117

Feng XT, Zhang CQ, Li SJ et al (2013) Dynamic design method for deep tunnels at hard rocks. Science Press, Beijing

Golshani A, Okui Y, Oda M et al (2006) A micromechanical model for brittle failure of rock and its relation to crack growth observed in triaxial compression tests of granite. Mech Mater 38(4):287–303

Gong QM, Zhao J, Jiang YS (2007) In situ TBM penetration tests and rock mass boreability analysis in hard rock tunnels. Tunn Undergr Space Technol 22(3):303–316

Hahn T, Holmgren J (1979) Adhesion of shotcrete to various types of rock surfaces and its influence on the strengthening function of shotcrete when applied on hard jointed rock. In: Proceedings, 4th international congress on rock mechanics, International Society for rock mechanics, vol 1, Montreux, Switzerland, pp 431–440

Hajiabdolmajid V, Kaiser PK, Martin CD (2002) Modelling brittle failure of rock. Int J Rock Mech Min Sci 39(6):731–741

Hao XJ, Feng XT, Yang CX et al (2015) Analysis of time-dependent EDZ development of columnar jointed rock mass in the Baihetan diversion tunnel. Rock Mech Rock Eng 48(9):1–24

Hirohisa K, Hideto M (2003) Centrifuge model test of tunnel face reinforcement by bolting. Tunn Undergr Space Technol 18:205–212

Hoek E, Martin CD (2014) Fracture initiation and propagation in intact rock—a review. J Rock Mech Geotech Eng 6(4):287–300

Horii H, Nemat-Nasser S (1986) Brittle failure in compression: splitting, faulting and brittle-ductile transition. Philos Trans R Soc Lond A: Math, Phys Eng Sci 319(1549):337–374

Jalalifar H, Mojedifar S, Sahebi AA (2014) Prediction of rock mass rating using fuzzy logic and multi-variable RMR regression model. Int J Rock Mech Min Sci 24(2):237–244

Jiang Q, Feng XT, Chen J, Huang K, Jiang YL (2013) Estimating in situ rock stress from spalling veins: a case study. Eng Geol 152(1):38–47

Jiang Q, Feng XT, Yossef HH et al (2014) Mechanical anisotropy of columnar jointed basalts: an example from the Baihetan hydropower station, China. Eng Geol 175:35–45

Kalman K (2003a) History of the sprayed shotcrete lining method—part I: milestones up to the 1960s. Tunn Undergr Space Technol 18(1):57–69

Kalman K (2003b) History of the sprayed shotcrete lining method—part II: milestones up to the 1960s. Tunn Undergr Space Technol 18(1):71–83

Kulatilake PHSW, Park J, Um J (2004) Estimation of rock mass strength and deformability in 3-D for a 30 m cube at a depth of 485 m at Äspö hard rock laboratory. Geotech Geol Eng 22(3):313–330

Li SJ, Feng XT, Li ZH et al (2012a) In situ monitoring of rockburst nucleation and evolution in the deeply buried tunnels of Jinping II hydropower station. Eng Geol 137(1):85–96

Li SJ, Feng XT, Li ZH et al (2012b) Evolution of fractures in the excavation damaged zone of a deeply buried tunnel during TBM construction. Int J Rock Mech Min Sci 55(10):125–138

Li SJ, Feng XT, Hudson JA (2013a) ISRM suggested method for measuring rock mass displacement using a sliding micrometer. Rock Mech Rock Eng 46(3):645–653

Li SJ, Feng XT, Wang CY et al (2013b) ISRM suggested method for rock fractures observations using a borehole digital optical televiewer. Rock Mech Rock Eng 46(3):635–644

Martin CD (1993) The strength of massive Lac du Bonnet granite around underground opening. Ph.D. thesis, University of Manitoba, 1993

Martin CD, Read RS, Martino JB (1997) Observations of brittle failure around a circular test tunnel. Int J Rock Mech Min Sci 34(7):1065–1073

Martin CD, Christiansson R, Söderhäll J (2001) Rock stability considerations for sitting and constructing a KBS-3 repository. Based on experiences from Äspö HRL, AECL’s URL, tunneling and mining, SKB TR0138, Svensk Kärnbränslehantering AB

Martino JB, Chandler NA (2004) Excavation-induced damage studies at the underground research laboratory. Int J Rock Mech Min Sci 41(8):1413–1416

Pacher F (1964) Deformations messungen im Versuchsstollen als Mittel zurErforschung des Gebirgsverhaltens und zur Bemessung des Ausbaues, Felsmechanik, pp 149–161

Pan PZ, Yan F, Feng XT (2012) Modeling the cracking process of rocks from continuity to discontinuity using a cellular automaton. Comput Geosci 42:87–99

Wu FQ, Hu X, Gong M et al (2010) Unloading deformation during layered excavation for the underground powerhouse of Jinping I Hydropower Station, southwest China. Bull Eng Geol Environ 69(3):343–351

Acknowledgments

Financial support from the National Natural Science Foundation of China under Grant Nos. 11232014 and 41372315 are gratefully acknowledged. In particular, the authors also wish to thank Prof. Q.X. Fan, Prof. Z.B. Wu and Prof. Y.L. Fan for their kind help in the field investigation and the technical support from China Three Gorges Project Corporation. The authors would also like to acknowledge two anonymous reviewers for their helpful suggestions and comments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, XT., Hao, XJ., Jiang, Q. et al. Rock Cracking Indices for Improved Tunnel Support Design: A Case Study for Columnar Jointed Rock Masses. Rock Mech Rock Eng 49, 2115–2130 (2016). https://doi.org/10.1007/s00603-015-0903-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-015-0903-y