Abstract

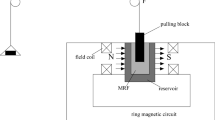

In this paper we proposed a platform for measuring shear force of magnetorheological (MR) fluid by which the relationship of yield stress and magnetic flux density of specific materials can be determined. The device consisted of a rotatable center tube placed in a frame body and the magnetic field was provided by two blocks of permanent magnets placed oppositely outside the frame body. The magnitude and direction of the magnetic flux were manipulated by changing the distance of the two permanent magnets from the frame body and rotating the center tube, respectively. For determining the magnetic field of the device, we adopted an effective method by fitting the finite element method result to the measured one and then rebuilt the absent components to approximate the magnetic field, which was hardly to be measured as different device setup were required. With the proposed platform and analytical methods, the drawing shear force and the corresponding yield stress contributed by MR fluid in respect to the magnitude and direction of given magnetic flux density could be evaluated effectively for specific designing purposes without the requirement of a large, complex, and expensive instrument.

Similar content being viewed by others

References

Bucchi F, Forte P, Frendo F, Squarcini R (2013) A magnetorheological clutch for efficient automotive auxiliary device actuation. Frattura ed Integrità Strutturale 7(23):62–74

Bucchi F, Forte P, Frendo F, Musolino A, Rizzo R (2014) A fail-safe magnetorheological clutch excited by permanent magnets for the disengagement of automotive auxiliaries. J Intell Mater Syst Struct 25(16):2102–2114

Carlson JD, Catanzarite DM, Clair SKA (1996) Commercial magneto-rheological fluid devices. Int J Mod Phys B 10(23n24):2857–2865

Fernández MA, Chang JY, Huang CY (2018) Development of a passive magnetorheological fluid clutch with field-blocking mechanism. IEEE Trans Magn 54(11):1–5

Hans ML, Claus G, Kieburg C (2011) Wall materials and roughness effects on transmittable shear stress of magnetorheological fluids in plate-plate magnetorheometry. Rheol Acta 50(2):141–157

Jolly MR, Bender JW, Carlson JD (1999) Properties and applications of commercial magnetorheological fluids. J Intell Mater Syst Struct 10(1):5–13

Jonkkari I, Kostamo E, Kostamo J, Syrjala S, Pietola M (2012) Effect of the plate surface characteristics and gap height on yield stresses of a magnetorheological fluid. Smart Mater Struct 21(7):075030

Kciuk M, Turczyn R (2006) Properties and application of magnetorheological fluids. J Achiev Mater Manuf Eng 18(1–2):127–130

Lemaire E, Bossis G (1991) Yield stress and wall effects in magnetic colloidal suspensions. J Phys D Appl Phys 24(8):1473–1477

LORD (2008) MRF-140CG technical Data (http://www.lordmrstore.com/lord-mr-products/mrf-140cg-magneto-rheological-fluid)

Nishida T, Okatani Y, Tadakuma K (2016) Development of universal robot gripper using MR α fluid. Int J Humanoid Rob 13(04):1650017

Olabi AG, Grunwald A (2007) Design and application of magnetorheological fluid. Mater Des 28(10):2658–2664

Plunkett KF, Imam MA, Rath B, Conrad H (2013) Resistance of a commercial magnetorheological fluid to penetration. J Phys: Conf Ser 412(1):012023

Song Y, Guo S, Yin X, Zhang L, Wang Y, Hirata H, Ishihara H (2018) Design and performance evaluation of a haptic interface based on MR fluids for endovascular tele-surgery. Microsyst Technol 24(2):909–918

Spaggiari A (2013) Properties and applications of Magnetorheological fluids. Frattura ed Integrità Strutturale 7(23):57–61

Tang X, Zhang X, Tao R, Rong Y (2000) Structure-enhanced yield stress of magnetorheological fluids. J Appl Phys 87(5):2634–2638

Tsugami Y, Barbié T, Tadakuma K, Nishida T (2017) Development of universal parallel gripper using reformed magnetorheological fluid. In: 2017 11th Asian control conference (ASCC), pp 778–783

Wang J, Meng G (2001) Magnetorheological fluid devices: principles, characteristics and applications in mechanical engineering. Proc Inst Mech Eng Part L J Mater Des Appl 215(3):165–174

Semancik JR (1997) Yield stress measurements using controlled stress rheometry. TA Instrument, New Castle

Yang B, Chen T, Meng G, Feng Z, Jiang J, Zhang S, Zhou Q (2013) Design of a safety escape device based on magnetorheological fluid and permanent magnet. J Intell Mater Syst Struct 24(1):49–60

Acknowledgements

The authors appreciate the support from Ministry of Science and Technology of Taiwan under the Grants 107-2218-E-007-036 and 107-2218-E-007-006 for the work described herein.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, PH., Chang, JY. Design of a yield stress characterizing platform for magnetorheological fluid magnetized by permanent magnets. Microsyst Technol 26, 3427–3434 (2020). https://doi.org/10.1007/s00542-020-04900-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-020-04900-y