Abstract

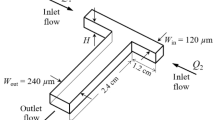

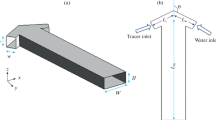

To understand the fluidic and mixing performances of passive micromixer, this paper numerically studies the influences of microchannel cross-sectional dimensions on the pressure drop and local mixing efficiency of T-shaped micromixer with three different cross-sectional shapes of rectangle, ellipse and isosceles triangle. Furthermore, a new dimensionless parameter is introduced to characterize the comprehensive fluidic and mixing performances of the main mixing channel and the whole T-shaped micromixer. It is found that both the fluidic and mixing performances of the T-shaped micromixer are sensitive to the cross-sectional dimensions of the microchannel. Among all the T-shaped micromixers with different microchannel cross-sectional shapes and different microchannel cross-sectional dimensions studied in this paper, the micromixer with elliptical-shaped microchannel having the dual axis length ratio of 0.5 is the optimal structure with the best comprehensive fluidic and mixing performances. The findings in present work are important for the design of the micromixer with desirable fluidic and mixing performances.

Similar content being viewed by others

References

Cai G, Xue L, Zhang H, Lin J (2017) A review on micromixers. Micromachines 8(9):274

Chen P (2013) An evaluation of a real-time passive micromixer to the performance of a continuous flow type microfluidic reactor. BioChip J 7(3):227–233

Chen X, Li T (2016) A novel design for passive misscromixers based on topology optimization method. Biomed Microdevices 18(4):57

Chen X, Zhang S (2018) 3D micromixers based on Koch fractal principle. Microsyst Technol 24:2627–2636

Chen X, Li T, Hu Z (2017) A novel research on serpentine microchannels of passive micromixers. Microsyst Technol 23:2649–2656

Fletcher PDI, Haswell SJ, Zhang X (2003) Monitoring of chemical reactions within microreactors using an inverted Raman microscopic spectrometer. Electrophorisis 24:3239–3245

Gunnasegaran P, Mohammed H, Shuaib N, Saidur R (2010) The effect of geometrical parameters on heat transfer characteristics of microchannels heat sink with different shapes. Int Commun Heat Mass Transf 37(8):1078–1086

Haghighinia A, Movahedirad S (2019) Mass transfer in a novel passive micro-mixer: flow tortuosity effects. Anal Chim Acta 1098:75–85

Jeon W, Shin C (2009) Design and simulation of passive mixing in microfluidic systems with geometric variations. Chem Eng J 152:575–582

Jing D, He L (2019) Numerical studies on the hydraulic and thermal performances of microchannels with different cross-sectional shapes. Int J Heat Mass Transf 143:118604

Jing D, Yi S (2019) Electroosmotic flow in treelike branching microchannel network. Fractals 27(6):1950095

Jing D, Song J, Sui Y (2020) Hydraulic and thermal performances of laminar flow in fractal treelike branching microchannel network with wall velocity slip. Fractals. https://doi.org/10.1142/S0218348X2050022X

Kandlikar SG, Garimella S, Li DQ, Colin S, King MR (2006) Heat transfer and fluid flow in minichannels and microchannels. Elsevier, Oxford

Kwang W, Lee K, Furlani Edward P (2012) Design of pressure-driven microfluidic networks using electric circuit analogy. Lab Chip 12(3):515–545

Lee C, Wang W, Liu Ch, Fu L (2016) Passive mixers in microfluidic systems: a review. Chem Eng J 288:146–160

Liu Z, Lu Y, Wang J, Luo G (2012) Mixing characterization and scaling-up analysis of asymmetrical T-shaped micromixer: experiment and CFD simulation. Chem Eng J 181–182:597–606

Mortensen N, Okkels F, Bruus H (2005) Reexamination of Hagen-Poiseuille flow: shape dependence of the hydraulic resistance in microchannels. Phys Rev E 71:057301

Morteza B, Mohsen Nazemi A, Azam U (2020) Active and passive micromixers: a comprehensive review. Chem Eng Process Process Intensif 147:107771

Mubashshir Ahmad A, Wang Y (2008) Parametric study on mixing of two fluids in a three-dimensional serpentine microchannel. Chem Eng J 146(3):439–448

Phillips Reid H, Jain R, Browning Y, Shah R, Kauffman P, Dinh D, Lutz Barry R (2016) Flow control using audio tones in resonant microfluidic networks: towards cell-phone controlled lab-on-a-chip devices. Lab Chip 16(17):3260–3267

Rismanian M, Mohammad S, Navid K (2019) A new non-dimensional parameter to obtain the minimum mixing length in tree-like concentration gradient generators. Chem Eng Sci 195:120–126

Shah RK, London AL (1978) Laminar flow forced convection in ducts. Academic Press, Cambridge

Su T, Cheng K, Wang J, Xu Zh, Dai W (2019) A fast design method for passive micromixer with angled bend. Microsyst Technol 25(11):4391–4397

Tsougeni K, Papadakis G, Gianneli M, Grammoustianou A, Constantoudis V, Dupuy B, Petrou PS, Kakabakos SE, Tserepi A, Gizeli E, Gogolides E (2016) Plasma nanotextured polymeric lab-on-a-chip for highly efficient bacteria capture and lysis. Lab Chip 16(1):122–131

Veldurthi N, Bodas D, Chandel S, Tejashree B (2019) Geometrically similar rectangular passive micromixers and the scaling validity on mixing efficiency and pressure drops. J Mech Eng 69(1):69–84

Acknowledgement

The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (No. 51505292).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhan, X., Jing, D. Influence of geometric parameters on the fluidic and mixing characteristics of T-shaped micromixer. Microsyst Technol 26, 2989–2996 (2020). https://doi.org/10.1007/s00542-020-04857-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-020-04857-y