Abstract

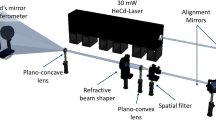

Deep X-ray lithography is a preferred fabrication approach for those micro devices that depend on smooth and vertical sidewalls of comparatively deep structures rather than extreme lateral resolution. The structure quality obtained depends on, and is limited by, the quality of the X-ray mask applied. A critical component of the mask is its absorber patterns. They get fabricated by electroplating into voids of a polymer template. These templates must usually be at least 3 μm deep and exhibit smooth and vertical sidewalls with a lateral resolution of micrometers and possibly below. Primary patterning of the templates is very demanding. Best results are obtained when dedicated electron beam writers with acceleration voltages of 100 kV and above are applied. This, however, limits access to patterning infrastructure and substantially drives delivery timeline and cost, making mask absorber template patterning a bottleneck of the entire process sequence. We propose, evaluate and optimize an alternative absorber patterning approach based on direct laser writing. An ultraviolet laser with 355 nm wavelength and 250 mW beam power by Heidelberg Instruments is applied to expose 2.9 μm thick, chemically amplified, high contrast, negative tone resist mrx-5. Exposure parameters analyzed include the dose and focal settings. Experiments are carried out on bare silicon wafers as well as on chrome-gold and on titanium oxide plating bases. For all cases, results with and without an additional antireflective coating of 200 nm AZ BAR-Li are studied. Aspects of the resist template structure quality analyzed include the sidewall verticality and its smoothness and defects, resist adhesion to the substrate, minimum feature size and structure accuracy, as well as irregularities due to stitching of partial layouts. In an optimized process, a dose of 14 mW on oxidized titanium and BAR-Li was used. We were able to demonstrate 1.5 μm minimum feature size of isolated structures and structural details of about 1 μm. The sidewalls are vertical and exhibit a roughness of dozens of nanometers. When an antireflective coating is used, chamfers are observed at the resist bottom. The structure accuracy occasionally deviates from the original layout by 200–300 nm, particularly at stitching singularities or towards the end of resist walls. The described absorber template patterning process delivers a resolution that much extends beyond previous UV patterning approaches. The structure accuracy, however, is inferior to electron beam written samples. Given the cost and timeline benefit, results of the study will allow users to identify which primary patterning approach is best suited for their micro devices.

Similar content being viewed by others

Notes

Manuscript currently under preparation: Achenbach S, Schulz J, Mohr J, Wells G. Alternative Fabrication Approaches for increased Quality and Availability of Masks for Deep X-Ray Lithography.

Performance data is available from the DWL 66FS data sheet (2008). Heidelberg Instruments Mikrotechnik GmbH, Heidelberg, Germany. http://www.himt.de.

Further details on LIC stripes are available from the Heidelberg Instruments User Guide, Heidelberg Instruments Mikrotechnik GmbH, Heidelberg, Germany.

The mr-x resist has been developed through funding of the German Ministry of Education and Research within the INNOLIGA-Project under contract 16SV3522 and is commercialized by micro resist technology GmbH, Berlin, Germany.

Further information on the antireflective coating is available from the AZ-BARLi Bottom Antireflective Coating Product Data Sheet. Developed by Clariant AG and distributed by Microchemicals GmbH, Ulm, Germany. http://www.microchemicals.com.

References

Achenbach S (1996) Genauigkeitsbegrenzende Effekte bei der Übertragung von Mikrostrukturen in große Resistdicken mittels Röntgentiefenlithographie mit Synchrotronstrahlung. Dissertation (in German), University of Karlsruhe, Karlsruhe, Germany

Achenbach S, Börner M, Kinuta S, Bacher W, Mohr J, Saile V, Saotome Y (2007) Structure quality in deep XRL applying commercial polyimide-based masks. Microsyst Technol 13(3–4):349–354

Becker EW, Ehrfeld W, Hagmann P, Maner A, Münchmeyer D (1986) Fabrication of microstructures with high aspect ratios and great structural heights by synchrotron radiation lithography, galvanoforming, and plastic moulding (LIGA process). Microelectron Eng 4(1):36–56

Desta Y, Göttert J (2009) X-ray masks for LIGA microfabrication. Advanced micro and nanosystems, vol 7. LIGA and its applications. Wiley VCH, Weinheim, pp 11–50. ISBN 978-3-527-31698-4

Klymyshyn D, Börner M, Haluzan D, Gono Santosa E, Schaffer M, Achenbach S, Mohr J (2010) Vertical high-Q RF-MEMS devices for reactive lumped element circuits. IEEE Trans Microw Theory Tech 58(11):2976–2986

Lorenz H, Despont M, Fahrni N, LaBianca N, Renaud P, Vettiger P (1997) SU-8: a low-cost negative resist for MEMS. J Micromech Microeng 7:121–124

Meyer P, Saile V, Schulz J, Klein O, Arendt M (2008) Launching into a golden age: gears (mm parts) made by the deep X-ray LIG(A) process. Int J Technol Transfer Commer 7(4):1–9

Mohr J, Göttert J, Müller A, Ruther P, Wengeling K (1997) Micro-optical and opto-mechanical systems fabricated by the LIGA technique. Proc SPIE Int Soc Opt Eng 3008:273–278

Reichmanis E, Houlihan FM, Nalamasu O, Neenan TX (1994) Chemically amplified resists: chemistry and processes. Adv Func Mater 4(2):83–93

Scheunemann HU, Loechel B, Jian L, Schondelmaier D, Desta Y, Göttert J (2003) Cost effective masks for deep X-ray lithography. Proc SPIE Int Soc Opt Eng 5116:775–781

Schomburg WK, Baving H, Bley P (1991) Ti- and Be- X-ray masks with alignment windows for the LIGA process. Microelectron Eng 13:323–326

Acknowledgements

This work was partly carried out with the support of the Karlsruhe Nano Micro Facility (KNMF, http://www.knmf.kit.edu), a Helmholtz Research Infrastructure at Karlsruhe Institute of Technology (KIT, http://www.kit.edu). Research described in this paper was partly supported by the Karlsruhe Institute of Technology (KIT, http://www.kit.edu). This paper is based on contributions from the Karlsruhe Institute of Technology, Institute of Microstructure Technology, and from the Canadian Light Source, Synchrotron Laboratory for Micro and Nano Devices.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Achenbach, S., Hengsbach, S., Schulz, J. et al. Optimization of laser writer-based UV lithography with high magnification optics to pattern X-ray lithography mask templates. Microsyst Technol 25, 2975–2983 (2019). https://doi.org/10.1007/s00542-018-4161-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-018-4161-2