Abstract

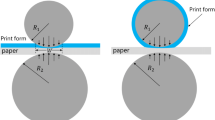

We considered the effect of the upper roller on plate-to-roll gravure offset printing. The x and y velocities of a liquid droplet due to cycloid movement are considered in a numerical model. The phase-field method is used for the interface dynamics of the two-phase fluids (gas and liquid). The liquid transfer ratio is simulated by changing the radius of the roller, the angular velocity of the roller, the contact angle between the liquid and contact surface, and the viscosity and surface tension, which primarily affect gravure offset printing. We developed a plate-to-roll model on basis of a cycloid motion. To validate the proposed model, simulation results of transfer ratio are compared with results reported in the literature for models based on the plate-to-plate configuration. The proposed plate-to-roll model shows good agreement with the plate-to-plate model. As one of our main results, we found that slip displacement occurs during plate-to-roll gravure offset printing. Effects of various parameters acting on the conventional plate to plate model are also studied in our plate-to-roll simulations.

Similar content being viewed by others

References

Ahmed DH, Sung HJ, Kim DS (2011) Simulation of non-Newtonian ink transfer between two separating plates for gravure-offset printing. Int J Heat Fluid Flow 32:298–307

Hagberg J, Pudas M, Leppävuori S, Elsey K, Logan A (2001) Gravure offset printing development for fine line thick film circuits. Microelectron Int 18:32–35

Hahne P, Hirth E, Reis IE, Schwichtenberg K, Richtering W, Horn FM, Eggenweiler U (2001) Progress in thick-film pad printing technique for solar cells. Sol Energy Mater Sol Cells 65:399–407

Huang WX, Lee SH, Sung HJ, Lee TM, Kim DS (2008) Simulation of liquid transfer between separating walls for modeling micro-gravure-offset printing. Int J Heat Fluid Flow 29:1436–1446

Kang HW, Sung HJ, Lee TM, Kim DS, Kim CJ (2009) Liquid transfer between two separating plates for micro-gravure-offset printing. J Micromech Microeng 19:15–25

Lee S, Na Y (2010) Analysis on the ink transfer mechanism in R2R application. J Mech Sci Technol 24:293–296

Mikami Y, Nagae Y, Mori Y, Kuwabara K, Saito T, Hayanma H, Asada H, Akimoto Y, Kobayashi M, Okazaki S, Asaka K, Matsui H, Nakamura K, Kaneko E (1994) A new patterning process concept for large-area transistor circuit fabrication without using an optical mask aligner. IEEE Trans Electron Devices 41:306–314

Odiotti ME, Colaprico V (1991) Gravure process and technology. Gravure Association of America, New York

Park SS, Jeon Y, Cho M, Bai C, Lee D, Shim J (2012) The FEM based liquid transfer model in gravure offset printing using phase field method. Microsyst Technol 18:2027–2034

Powell CA, Savage MD, Guthrie JT (2002) Computational simulation of the printing of Newtonian liquid from a trapezoidal cavity. Int J Numer Methods Heat Fluid Flow 12:338–355

Pudas M, Hagberg J, Leppävuori S (2002) The absorption ink transfer mechanism of gravure offset printing for electronic circuitry. IEEE Trans Electron Packag Manuf 25:335–343

Pudas M, Hagberg J, Leppävuori S, Elsey K, Logan A (2004a) Methods for the evaluation of fine-line offset gravure printing inks for ceramics. Color Technol 120:119–126

Pudas M, Hagberg J, Leppävuori S (2004b) Printing parameters and ink components affecting ultra-fine-line gravure-offset printing for electronics applications. J Eur Ceram Soc 24:2943–2950

Sankaran AK, Rothstein JP (2012) Effect of viscoelasticity on liquid transfer during gravure printing. J Non Newton Fluid Mech 175–176:64–75

Yue P, Feng JJ, Liu C, Shen J (2004) A diffuse-interface method for simulating two-phase flows of complex fluids. J Fluid Mech 515:293–317

Author information

Authors and Affiliations

Corresponding authors

Additional information

Yongsik Kim and Sangshin Park contributed equally to this work.

Rights and permissions

About this article

Cite this article

Kim, Y., Park, S., Shin, K. et al. Effect of cycloid movement on plate-to-roll gravure offset printing. Microsyst Technol 22, 357–365 (2016). https://doi.org/10.1007/s00542-015-2452-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-015-2452-4