Abstract

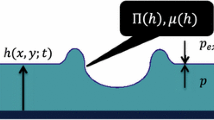

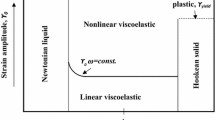

A molecularly thin lubricant layer (of the order of 1–2 nm thick) has been shown to provide bearing forces at the interface between contacting solid surfaces under light loads and high shear rates. This phenomenon is important, for example, in the head-disk contact in magnetic storage hard disk drives to ensure that some of the contact is sustained by the lubricant layer and thus avoiding damage of the solid surfaces. The magnitude of the normal and tangential bearing forces that the lubricant layer can provide depends on temperature, viscosity of the lubricant, sliding velocity and radius of gyration of the lubricant molecules. This study shows that viscosity has the greatest effect on the load bearing capacity of the molecularly thin lubricant. Thus, by controlling the flash temperature and the ratio of molecularly thin lubricant-to-bulk viscosity, the bearing load carrying capacity of the layer can be controlled. This would allow for the contact to be sustained within the mobile lubricant layer, avoiding solid contact so as to protect the diamond-like carbon coating, and thus reduce wear and potential catastrophic failures.

Similar content being viewed by others

References

Archard JF (1958) The temperature of rubbing surfaces. Wear 2:438–455

Cho YK, Cai L, Granick S (1997) Molecular tribology of lubricants and additives. Tribol Int 30(12):889–894

Demirel AL, Granick S (1998) Transition from static to kinetic friction in a model lubricated system. J Chem Phys 109(16):6889–6897

Deolalikar N, Sadeghi F (2008) Numerical modeling of mixed lubrication and flash temperature in EHL elliptical contacts. J Tribol. doi:10.1115/1.2805429

DeVor RE, Chang TH, Sutherland JW (1992) Statistical quality design and control: contemporary concepts and methods. Prentice-Hall, Upper Saddle River

Fisher LR, Israelachvili JN (1979) Direct experimental verification of the Kelvin equation for capillary condensation. Nature 277:548–549

Fukuzawa K, Hayakawa K, Matsumura N, Itoh S, Zhang H (2009) Simultaneously measuring lateral and vertical forces with accurate gap control for clarifying lubrication phenomena at nanometer gap. Tribol Lett 37(3):497–505

Greenwood JA, Williamson JB (1966) Contact of nominally flat surfaces. Proc R Soc. doi:10.1098/rspa.1966.0242

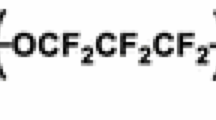

Guo XC, Marchon B, Wang RH, Mate CM, Dai Q, Waltman RJ, Deng H, Pocker D, Xiao QF, Saito Y, Ohtani T (2012) A multidentate lubricant for use in hard disk drives at sub-nanometer thickness. J Appl Phys 111:024503

Hiroshi T, Tagawa N (2012) Adhesion and friction properties of molecularly thin perfluoropolyether liquid films on solid surfaces. Langmuir 28:3814–3820

Karis TE (2009) Lubricants for the disk drive industry. In: Rudnick L (ed) Lubricant additives: chemistry and applications, 2nd edn. CRC Press, FL, pp 523–584

Kogut L, Etsion I (2004) A static friction model for elastic-plastic contacting rough surfaces. J Tribol T ASME 126:34–40

Kunkel GH, Lou H, Macken D, Stoebe TW (2014) Resistance temperature sensors for head-media and asperity detection. Patent No: US 8,737,009 B2

Lee SC, Polycarpou AA (2005) Microtribodynamics of pseudo-contacting head–disk interfaces intended for 1 Tbit/in2. IEEE Trans Magn 41(2):812–818

Lee SC, Strom BD (2008) Characterization of thermally actuated pole tip protrusion for head-media spacing adjustment in hard disk drives. J Tribol-T ASME 130(2):022001

Marchon B, Saito Y (2009) Lubricant design attributes for subnanometer head-disk clearance. IEEE Trans Magn 45(2):872–876

Martini A, Hsu HY, Patankar NA, Lichter S (2008) Slip at high shear rates. Phys Rev Lett. doi:10.1103/PhysRevLett.100.206001

Mate CM, Lorenz MR, Novotny V, Sanders IL, Lin LJ (1989) Tribological studies of storage media by atomic force microscopy. IEEE GA–7

Muller VM, Yushchencko VS, Derjaguin BV (1980) On the influence of molecular forces on the deformation of an elastic sphere and its sticking to a rigid plane. J Coll Interface Sci 77(1):91–101

Persson BNJ (1997) Molecular tribology of lubricants and additives. Tribol Int 30(12):889–894

Rong J, Thomas L, Chong TC (2008) TOF-SIMS analysis for thermal effect study of hard disk lubricant. Appl Surface Sci 255(4):1490–1493

Scarpulla MA, Mate CM (2003) Air shear driven flow of thin perfluoropolyether polymer films. J chem phys 118(7):3368–3375

Seagate technology (2014), What is the normal operating temperature for seagate disk drives? http://knowledge.seagate.com/articles/en_US/FAQ/193771en. Accessed 20 March 2014

Spikes HA, Olver AV (2009) Compression heating and cooling in elastohydrodynamic contacts. Tribol Lett 36(1):69–80

Stanley HM, Etsion I, Bogy DB (1990) Adhesion of contacting rough surfaces in the presence of sub-boundary lubrication. J Tribol 112(1):98–104

Suh AY, Polycarpou AA (2005) Adhesive contact modeling for sub-5-nm ultralow flying magnetic storage head-disk interfaces including roughness effects. J Appl Phys. doi:10.1063/1.1914951

Suh AY, Polycarpou AA (2008) Design optimization of sub-5 nm head–disk interfaces using a two-degree-of-freedom dynamic contact model with friction. Int J Prod Dev 5(3–4):268–291

Suh AY, Mate CM, Payne RN, Polycarpou AA (2006) Experimental and theoretical evaluation of friction at contacting magnetic storage slider-disk interfaces. Tribol Lett 23(3):177–190

Vakis AI, Polycarpou AA (2010) Head-disk interface nanotribology for Tbit/in2 recording densities: near-contact and contact recording. J Phys D Appl Phys. doi:10.1088/0022-3727/43/22/225301

Vakis AI, Polycarpou AA (2012) Modeling sliding contact of rough surfaces with molecularly thin lubricant. Tribol Lett 45(1):37–48

Vakis AI, Polycarpou AA (2013) An advanced rough surface continuum-based contact and sliding model in the presence of molecularly thin lubricant. Tribol Lett 49(1):227–238

Vakis AI, Lee SC, Polycarpou AA (2009) Dynamic head–disk interface instabilities with friction for light contact (surfing) recording. IEEE Trans Magn 45(11):4966–4971

Vakis AI, Eriten M, Polycarpou AA (2011) Modeling bearing and shear forces in molecularly thin lubricants. Tribol Lett 41(3):573–586

Vakis AI, Hadjicostis CN, Polycarpou AA (2012) Three-DOF dynamic model with lubricant contact for thermal fly-height control nanotechnology. J Phys D Appl Phys 45:135402

Wietzel U (1993) Significance of temperature effects for the behavior of thin lubricant films in an oscillating contact. Wear 169(1):59–62

Wood RW (2002) Recording technologies for terabit per square inch systems. IEEE Trans Magn 38(4):1711–1718

Yeo CD, Sullivan M, Lee SC, Polycarpou AA (2008) Friction force measurements and modeling in hard disk drives. IEEE Trans Magn 44(1):157–162

Zhu Y, Granick S (2004) Superlubricity: a paradox about confined fluids resolved. Phys Rev Lett. doi:10.1103/PhysRevLett.93.096101

Acknowledgments

The motivation of this work was through a sponsored research program from Seagate Technology LLC, through Grant No. SRA- 32724.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: The MTL model

According to the MTL model, the expressions for normal (P) and shearing (Q) forces are given by Eqs. 5 and 6 respectively. Where P o and Q o are the maximum experimental normal and shear forces given by Eqs. 7 and 8. The experimental shearing velocity U = 200 μm/s; the radius of spherical shearing probe R = 102 μm (Vakis et al. 2011). Then the critical shear rate is U/κ = 2 × 105/s for κ = 1 nm (Wood 2002).

The fitting coefficients m and n are calculated from Eqs. 9 and 10 and can also be obtained from the logarithmic curves of normal and shear forces vs. shear rate.

The normal and shear stiffnesses are calculated according to Eqs. 11 and 12. Where the shear rate is found from the expression, U/d o and this becomes maximum when the solid–solid gap reaches the bonded lubricant thickness (2κ).

Here d o is the liquid gap. The maximum shear rate is when d o = κ, i.e., h−3σ = 2κ (when the distance between slider and disk becomes twice the bonded lubricant thickness).

Appendix 2: Regression models

The coefficients for predicting the maximum bearing force for the three levels of U are given in Eqs. 14, 15 and 16.

The coefficients for predicting the maximum bearing force for the three levels of μ is given in Eqs. 17, 18 and 19.

Rights and permissions

About this article

Cite this article

Chowdhury, S., Vakis, A.I. & Polycarpou, A.A. Optimization of molecularly thin lubricant to improve bearing capacity at the head-disk interface. Microsyst Technol 21, 1501–1511 (2015). https://doi.org/10.1007/s00542-014-2364-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-014-2364-8