Abstract

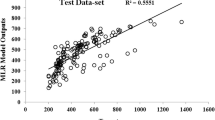

Chitosan/polyethylene oxide (PEO) solution makes electrospun nanofibers with decreased beads and diameters in comparison with lonely chitosan (CS). The aim of this work was to find an artificial neural network (ANN) model for predicting the chitosan/PEO blend electrospun nanofiber diameter. Chitosan/PEO concentration ratio, distance between nozzle tip and collector, applied voltage, and flow rate were considered as input variables, and chitosan/PEO blend electrospun nanofiber diameter was considered as output variable. Scanning electron microscopy images indicated that electrospun nanofiber diameter was approximately 50–185 nm. For increasing validity, k-fold cross validation method was applied to dataset. The ANN technique was used for training and testing via fivefold of dataset. The best results of prediction were obtained via network with three hidden layers including 10, 15, and 5 nodes in each layer, respectively. The mean square error (MSE) and correlation coefficient between the observed and predicted thickness of the nanofibers in the chosen model were about 0.0707 and 0.9630, respectively, indicating the ANN technique validity in the prediction procedure. For the analysis of interactions between the involved electrospinning parameters and nanofiber diameter, 3D graphs in various levels were plotted. In conclusion, the results indicated that using the prediction process via ANN could be relevant in the decision to produce nanofibers with desired shape and diameter via electrospinning.

Similar content being viewed by others

References

Ma Z, Kotaki M, Inai R, Ramakrishna S (2005) Potential of nanofiber matrix as tissue-engineering scaffolds. Tissue Eng 11(1–2):101–109

Fang J, Wang X, Lin T (2011) Functional applications of electrospun nanofibers. In: Tong L (ed) Nanofibers-production, properties and functional applications. InTech–Open Access Publisher, Rijeka, Croatia, pp 287–326

Huang Z-M, Zhang YZ, Kotaki M, Ramakrishna S (2003) A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol 63(15):2223–2253

Deitzel JM, Kleinmeyer J, Harris DEA, Tan NCB (2001) The effect of processing variables on the morphology of electrospun nanofibers and textiles. Polymer 42(1):261–272

Agarwal S, Wendorff JH, Greiner A (2008) Use of electrospinning technique for biomedical applications. Polymer 49(26):5603–5621

Beachley V, Wen X (2009) Effect of electrospinning parameters on the nanofiber diameter and length. Mater Sci Eng C 29(3):663–668

Maleki M, Amani-Tehran M, Latifi M, Mathur S (2014) Drug release profile in core–shell nanofibrous structures: a study on Peppas equation and artificial neural network modeling. Comput Meth Prog Bio 113(1):92–100

Ziabari M, Mottaghitalab V, Haghi AK (2009) Application of direct tracking method for measuring electrospun nanofiber diameter. Braz J Chem Eng 26(1):53–62

Gibson PW, Lee C, Ko F, Reneker D (2007) Application of nanofiber technology to nonwoven thermal insulation. J Eng Fiber Fabr 2(2):32–40

Pham QP, Sharma U, Mikos AG (2006) Electrospinning of polymeric nanofibers for tissue engineering applications: a review. Tissue Eng 12(5):1197–1211

Naghibzadeh M, Adabi M (2014) Evaluation of effective electrospinning parameters controlling gelatin nanofibers diameter via modelling artificial neural networks. Fiber Polym 15(4):767–777

Ribeiro C, Sencadas V, Ribelles JLG, Lanceros-Méndez S (2010) Influence of processing conditions on polymorphism and nanofiber morphology of electroactive poly (vinylidene fluoride) electrospun membranes. Soft Mater 8(3):274–287

Rošic R, Pelipenko J, Kocbek P, Baumgartner S, Bešter-Rogač M, Kristl J (2012) The role of rheology of polymer solutions in predicting nanofiber formation by electrospinning. Eur Polym J 48(8):1374–1384

Yördem OS, Papila M, Menceloğlu YZ (2008) Effects of electrospinning parameters on polyacrylonitrile nanofiber diameter: an investigation by response surface methodology. Mater Des 29(1):34–44

Vasita R, Katti DS (2006) Nanofibers and their applications in tissue engineering. Int J Nanomed 1(1):15

Gibson P, Schreuder-Gibson H, Rivin D (2001) Transport properties of porous membranes based on electrospun nanofibers. Colloids Surf A 187:469–481

Khanlou HM, Sadollah A, Ang BC, Kim JH, Talebian S, Ghadimi A (2014) Prediction and optimization of electrospinning parameters for polymethyl methacrylate nanofiber fabrication using response surface methodology and artificial neural networks. Neural Comput Appl 25(3–4):767–777

Qu J, Wang D, Wang H, Dong Y, Zhang F, Zuo B, Zhang H (2013) Electrospun silk fibroin nanofibers in different diameters support neurite outgrowth and promote astrocyte migration. J Biomed Mater Res A 101(9):2667–2678

Kanafchian M, Valizadeh M, Haghi AK (2011) Prediction of nanofiber diameter for improvements in incorporation of multilayer electrospun nanofibers. Korean J Chem Eng 28(3):751–755

Thompson CJ, Chase GG, Yarin AL, Reneker DH (2007) Effects of parameters on nanofiber diameter determined from electrospinning model. Polymer 48(23):6913–6922

Faridi-Majidi R, Ziyadi H, Naderi N, Amani A (2012) Use of artificial neural networks to determine parameters controlling the nanofibers diameter in electrospinning of nylon-6, 6. J Appl Polym Sci 124(2):1589–1597

Nasouri K, Bahrambeygi H, Rabbi A, Shoushtari AM, Kaflou A (2012) Modeling and optimization of electrospun PAN nanofiber diameter using response surface methodology and artificial neural networks. J Appl Polym Sci 126(1):127–135

Rezaei B, Askari M, Shoushtari AM, Ghani M, Haji A (2012) Application of response surface methodology (RSM) and Artificial Neural Network (ANN) in diameter optimization of thermo regulating nanofibers

Nasouri K, Shoushtari AM, Khamforoush M (2013) Comparison between artificial neural network and response surface methodology in the prediction of the production rate of polyacrylonitrile electrospun nanofibers. Fiber Polym 14(11):1849–1856

Rabbi A, Nasouri K, Bahrambeygi H, Shoushtari AM, Babaei MR (2012) RSM and ANN approaches for modeling and optimizing of electrospun polyurethane nanofibers morphology. Fiber Polym 13(8):1007–1014

Desai KM, Survase SA, Saudagar PS, Lele SS, Singhal RS (2008) Comparison of artificial neural network (ANN) and response surface methodology (RSM) in fermentation media optimization: case study of fermentative production of scleroglucan. Biochem Eng J 41(3):266–273

Bas D, Boyaci IH (2007) Modeling and optimization II: comparison of estimation capabilities of response surface methodology with artificial neural networks in a biochemical reaction. J Food Eng 78(3):846–854

Lou W, Nakai S (2001) Application of artificial neural networks for predicting the thermal inactivation of bacteria: a combined effect of temperature, pH and water activity. Food Res Int 34(7):573–579

Marchitan N, Cojocaru C, Mereuta A, Duca G, Cretescu I, Gonta M (2010) Modeling and optimization of tartaric acid reactive extraction from aqueous solutions: a comparison between response surface methodology and artificial neural network. Sep Purif Technol 75(3):273–285

Montgomery DC, Myers RH (1995) Response surface methodology: process and product optimization using designed experiments. Raymond H Meyers and Douglas C Montgomery A Wiley-Interscience Publications

Datt G (2012) An evolutionary approach: analysis of artificial neural networks. Int J Emerg Technol Adv Eng 2(1):160–164

Jha GK (2007) Artificial neural networks. Indian Agricultural Research Institute, New Delhi

Abraham A (2005) Artificial neural networks. In: Sydenham P, Thorn R (eds) Handbook of measuring system design. Wiley, pp 901–908

Yadav JS, Yadav M, Jain A (2014) Artificial neural network. Int J Sci Res Educ 1(06):108–118

Tu JV (1996) Advantages and disadvantages of using artificial neural networks versus logistic regression for predicting medical outcomes. J Clin Epidemiol 49(11):1225–1231

Aghajani M, Shahverdi AR, Rezayat SM, Amini MA, Amani A (2013) Preparation and optimization of acetaminophen nanosuspension through nanoprecipitation using microfluidic devices: an artificial neural networks study. Pharm Dev Technol 18(3):609–618

Chen XK (2014) Prediction of tensile properties of CNF/epoxy composites using artificial neural network. Trans Tech Publ 898:111–114

Adabi M, Saber R, Naghibzadeh M, Faridbod F, Faridi-Majidi R (2015) Parameters affecting carbon nanofiber electrodes for measurement of cathodic current in electrochemical sensors: an investigation using artificial neural network. RSC Adv 5(99):81243–81252

Kang YO, Yoon IS, Lee SY, Kim DD, Lee SJ, Park WH, Hudson SM (2010) Chitosan-coated poly (vinyl alcohol) nanofibers for wound dressings. J Biomed Mater Res B 92(2):568–576

Geng X, Kwon O-H, Jang J (2005) Electrospinning of chitosan dissolved in concentrated acetic acid solution. Biomaterials 26(27):5427–5432

Sun K, Li ZH (2011) Preparations, properties and applications of chitosan based nanofibers fabricated by electrospinning. Express Polym Lett 5(4):342–361

Karimi MA, Pourhakkak P, Adabi M, Firoozi S, Adabi M, Naghibzadeh M (2015) Using an artificial neural network for the evaluation of the parameters controlling PVA/chitosan electrospun nanofibers diameter. e-Polymers 15(2):127–138

Talebi R, Ghiasi MM, Talebi H, Mohammadyian M, Zendehboudi S, Arabloo M, Bahadori A (2014) Application of soft computing approaches for modeling saturation pressure of reservoir oils. J Nat Gas Sci Eng 20:8–15

Esnaashari SS, Rezaei S, Mirzaei E, Afshari H, Rezayat SM, Faridi-Majidi R (2014) Preparation and characterization of kefiran electrospun nanofibers. Int J Biol Macromol 70:50–56

Jia Y-T, Gong J, Gu X-H, Kim H-Y, Dong J, Shen X-Y (2007) Fabrication and characterization of poly (vinyl alcohol)/chitosan blend nanofibers produced by electrospinning method. Carbohyd Polym 67(3):403–409

Adabi M, Saber R, Faridi-Majidi R, Faridbod F (2015) Performance of electrodes synthesized with polyacrylonitrile-based carbon nanofibers for application in electrochemical sensors and biosensors. Mater Sci Eng, C 48:673–678

Acknowledgments

This project was supported by Tehran University of Medical Sciences (TUMS), Grant No. 93-04-87-27607.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ketabchi, N., Naghibzadeh, M., Adabi, M. et al. Preparation and optimization of chitosan/polyethylene oxide nanofiber diameter using artificial neural networks. Neural Comput & Applic 28, 3131–3143 (2017). https://doi.org/10.1007/s00521-016-2212-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-016-2212-0