Abstract

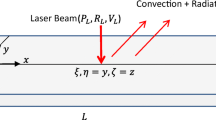

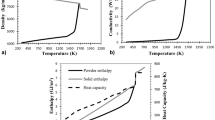

An important goal for the additive manufacturing (AM) community is to predict the material-dependent effective mechanical properties of a build-up specimen. In this work three coupled simulations to calculate the mechanical properties of laser-power bed fusion (L-PBF) processed IN718 are used. These values are compared to experimental data from literature. In the future, this approach is going be used for newly designed materials to estimate the expected mechanical properties and the resulting microstructure (As an extra step, the thermophysical properties of the new alloy have to be calculated in advance). The simulation chain to solve this challenge involves the simulation of the melt pool behaviour during the L‑PBF process to obtain the solidification conditions. These are required to then calculate the microstructural growth behaviour with the phase-field method. The resulting microstructure is homogenized to obtain the final effective mechanical properties of the L‑PBF processed material. The simulation results are compared with according results from experiments at each step to verify the approach and each simulation result.

Zusammenfassung

Ein wichtiges Ziel im Bereich der Additiven Fertigung (AM) ist die Vorhersage der effektiven mechanischen Eigenschaften der gefertigten Bauteile.

In dieser Arbeit wird eine dreigliedrige Simulationskette vorgestellt. mit deren Hilfe die mechanischen Eigenschaften von mittles Laser Powder Bed Fusion (LPBF) bearbeitetem Inconel718 vorhergesagt und mit Literaturewerten verglichen werden. Zukünftig soll der präsentierte Ansatz dazu dienen neue, bisher noch nicht additiv verarbeitete/qualifizierte Materialien vorab zu untersuchen und Aussagen über die entstehende Mikrostruktur und die zu erwartenden mechanischen Eigenschaften zu treffen. (Für unbekannte Materialen müssen die thermophysikalischen Eigenschafte vorab noch berechnet werden, z. B. mit ThermoCalc).

Die erste Simulation löst das thermische Problem beim LPBF, und das Ergebnis sind die örtlich- und zeitlich aufgelösten Erstarrungsbedingungen, welche wiederum eine Eingangsgröße für die zweite Simulation sind. Bei dieser wird mittels der Phasenfeldmethode die Erstarrungsphase aufgelöst nachmodelliert, um eine 3D Mikrostruktur zu erhalten. Im dritten Schritt wird diese homogenisiert, und aus den Phaseneigeschaften werden die mechanischen Eigenschaften des LPBF prozessierten IN718 berechnet. Jeder Simulationsschritt wird anhand von experimentell gewonnenen Daten überprüft.

Similar content being viewed by others

References

Zielinski, J.; Düchting, J.; Schleifenbaum, J. H.: Measurement of the Effective Absorption of Laser Radiation for Different States Relevant in the SLM Process on the Example of Ti6Al4V, DDMC 2018 : Fraunhofer Direct Digital Manufacturing Conference proceedings, Direct Digital Manufacturing Conference, Berlin, March 14–15, 2018, Fraunhofer Generativ, 2018

Philo, A.M.; Mehraban, S.; Holmes, M.; et al.: A pragmatic continuum level model for the prediction of the onset of keyholing in laser powder bed fusion, The International Journal of Advanced Manufacturing Technology, 101 (2019), pp 697–714, https://doi.org/10.1007/s00170-018-2770-7

Boussinot, G.; Apel, A.; Zielinski, J.; Hecht, J.; Schleifenbaum, J. H.: Strongly Out-of-Equilibrium Columnar Solidification During Laser Powder-Bed Fusion in Additive Manufacturing, PHYSICAL REVIEW APPLIED, 11 (2019), p 014025, https://doi.org/10.1103/PhysRevApplied.11.014025

Laschet, G.; Apel, M.: Thermo-elastic homogenization of a 3‑D steel microstructure simulated by the phase field method, Steel Res. Int., 81 (2010), p 637

Laschet, G.; Kashko, T.; Benke, S.; Öte, M.; Bobzin, K: Prediction of effective properties, in Schmitz, G. J.; Prahl, U. (Eds): Integrated Compuational Materials Engineering—Concepts and Application of a Modular Platform, Weinheim, Germandy: Wiley-VCH, 2012, pp 81–115

Martin, G.; Ochoa, N.; Sai, K.; Hervé-Luanco, E.; Cailletaud, G: A multicale model for the elastoviscoplastic behaviour of directionally solidified alloys: application to FE structural computations, Int. Jnl. Solids Struct., 51 (2014), p 1175

Kumara, C.; Deng, D.; Moverare, J.; Nylen, P.: “Modelling of anisotropic elastic properties in alloy 718 build by electron beam melting”, Mater. Scien. & Technology, 34 (2018), p 529

Song, J.; Gao, Z.; Zhang, L.; Wu, W.; He, B.; Lu, L.: “rediction on elastic properties of Nb-doped Ni systems, Molecular Simulation, 45 (2019), p 935

Hermann, W.; Sockel, H.; Han, J.; Bertram, A.: Elastic properties and determination of elastic constants of Nickel-base superalloys by a free-free beam technique, Proc. of Superalloys, 1996, pp 229–238a, https://doi.org/10.7449/1996/Superalloys_1996_229_238

Tegze, G.; Tóth, G. I.; Gránásy, L.: Faceting and Branching in 2D Crystal Growth, Phys. Rev. Lett., 106 (2011), p 195502

Ghosh, S.; Ofori-Opoku, N.; Guyer, J. E.: Simulation and analysis of γ‑Ni cellular growth during laser powder deposition of Ni-based superalloys, Comp. Mat. Sc., 144 (2018), p 256

Gong, X.; Wang, X.; Jones, Z.: Characterization of Microstructure and Mechanical Property of Inconel 718 from Selective Laser Melting, Conference Paper, ASME 2015, International Manufacturing Science and Engineering Conference, Houston, Texas USA, 2015

Eiken, J.; Böttger, B.; Steinbach, I.: Multiphase-field approach for multicomponent alloys with extrapolation scheme for numerical application, Phys. Rev. E, 73 (2006), p 066122

Acknowledgements

We acknowledge funding by the German Federal Ministry of Education and Research in the framework of the “Forschungscampus Digital Photonic Production: DPP Direct,” FKZ Grant No. 13N13709.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zielinski, J., Boussinot, G., Laschet, G. et al. From Melt Pool to Microstructure to Mechanical Properties: A Simulative Approach to L-PBF Processed Material Behaviour. Berg Huettenmaenn Monatsh 165, 175–180 (2020). https://doi.org/10.1007/s00501-020-00965-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00501-020-00965-4

Keywords

- Simulation

- Solidification conditions

- Phase field method

- Homogenization

- Effective elastic properties

- Laser Powder Bed Fusion

- Inconel718