Abstract

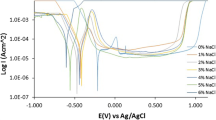

This work aims to investigate the relation between PREN of ferrite and austenite and the pitting potential of UNS S31803 DSS. Samples were solution-treated between 1040 °C and 1150 °C generating different phase fractions and, consequently, different alloy element contents. ThermoCalc® thermodynamic simulations were performed to predict the chemical composition of each phase allowing the PREN calculations. Besides, potentiodynamic polarization tests were conducted in 0.6 M NaCl solution at 70 °C to correlate pitting potential (Epit) and PREN. Thermodynamic simulation reveals that PREN for ferrite is higher than austenite between 975 °C and 1300 °C. Nevertheless, the electrochemical results show a slight reduction of pitting potential with increasing ferrite content, probably related to the reduction of Cr and Mo contents in this phase. Pits were found preferably in ferrite and in ferrite/austenite interfaces. This behavior suggests that, even with only a slight reduction of pitting potential and, consequently, a discrete corrosion resistance reduction, ferrite is more susceptible to pitting. No pits were found in austenite, suggesting that higher N contents are fundamental to maintain the corrosion resistance of this phase.

Zusammenfassung

Dieser Beitrag zielt darauf ab, die Beziehung zwischen PREN von Ferrit und Austenit und dem Lochfraßpotenzial von UNS S31803 DSS zu untersuchen. Die Proben wurden zwischen 1040 °C und 1150 °C lösungsgeglüht und erzeugten unterschiedliche Phasenanteile und damit unterschiedliche Legierungselementgehalte. ThermoCalc® thermodynamische Simulationen wurden durchgeführt, um die chemische Zusammensetzung jeder Phase vorherzusagen und die PREN-Berechnungen durchzuführen. Außerdem wurden potentiodynamische Polarisationstests in 0,6 M NaCl-Lösung bei 70 °C durchgeführt, um das Lochfraßpotenzial (Epit) und PREN zu korrelieren. Die thermodynamische Simulation zeigt, dass PREN für Ferrit zwischen 975 °C und 1300 °C höher als Austenit ist. Dennoch zeigen die elektrochemischen Ergebnisse eine leichte Reduzierung des Lochfraßpotentials mit steigendem Ferritgehalt, wahrscheinlich im Zusammenhang mit der Reduzierung des Cr- und Mo-Gehalts in dieser Phase. Korrosionsangriffe wurden vorzugsweise in Ferrit und in Ferrit/Austenit-Grenzflächen gefunden. Dieses Verhalten deutet darauf hin, dass Ferrit selbst bei nur geringer Reduzierung des Lochfraßpotenzials und damit einer diskreten Reduzierung der Korrosionsbeständigkeit anfälliger für Lochfraß ist. Es wurden keinKorrosionsangriff im Austenit gefunden, was darauf hindeutet, dass höhere N-Gehalte von grundlegender Bedeutung sind, um die Korrosionsbeständigkeit dieser Phase aufrechtzuerhalten.

Similar content being viewed by others

References

Solomon, H. S.; Devine, T. M.: Duplex Stainless Steels: A tale of two phases Proceedings, Conference Duplex Stainless Steels, ASM Metals Park, Ohio, 1984, p. 693

Nilsson, J. O.: Super Duplex Stainless Steel, Materials Science and Technology, 8 (1992), p. 685

Vannevik, H.: Effect of elemental partitioning on pitting resistance of high nitrogen duplex stainless steels, ISIJ international, 36 (1996) p 807

International Organization for Standardization. ISO15156‑3, Petroleum and natural gas industries—Materials for use in H2Scontaining environments in oil and gas production—Part 3: Cracking-resistant CRAs (corrosion resistant alloys) and other alloys, 2015

Iris Alvarez-Armas (Ed), Suzanne Degallaix-Moreuil (Ed), Duplex Stainless Steels, ISBN: 978-1-848-21137-7 November 2009 Wiley-ISTE p. 51

J.A. Sedriks. Corrosion of stainless steels, John Wiley, New York (1996).

Garfias-Mesias, L. F.: Understanding why PREN alone cannot be used to select duplex stainless steels, Proceedings, Nace International Conference, Dallas, 2005

Magnabosco, R.; Alonso-Falleiros, N.: Pit Morphology and its Relation to Microstructure of 850 °C Aged Duplex Stainless Steel, Corrosion, 2005 (February 2005), p.130. https://doi.org/10.5006/1.3278167

Lothongkum, G.; Wongpanya, P.; Morito, S.; Furuhara, T.; Maki, T.: Effect of nitrogen on corrosion behavior of 28Cr-7Ni duplex and microduplex stainless steels in air-saturated 3.5wt% NaCl solution, Corrosion Science, 48 (2006), p. 137

Acknowledgements

The authors thank CNPq-Brasil for grant 301458/2016‑2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Caluscio Dos Santos, D., Monfrinatti Macarrão, I. & Magnabosco, R. Relation Between Pitting Potential and PREN Values for Ferrite and Austenite in Duplex Stainless Steels. Berg Huettenmaenn Monatsh 165, 46–50 (2020). https://doi.org/10.1007/s00501-019-00925-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00501-019-00925-7