Abstract

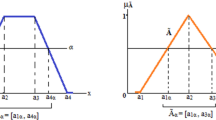

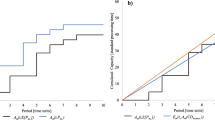

Thus far in the available literature, capability-based distributed layout (CBDL) design approaches were only developed under certain environments. Indeed, uncertainties embedded in the machine unavailability (or random machine breakdowns), product demands, and process flow data were not considered by the previous studies to achieve a robust CBDL design. However, many real-life facility layout design applications may involve different types of uncertainties simultaneously, like fuzziness and stochasticity. Based on this motivation, for the first time in the literature, this paper introduces a novel robust capability-based distributed layout (R-CBDL) design problem under a mixed fuzzy-stochastic environment. First, a new fuzzy-stochastic optimization model of the R-CBDL design problem is developed by considering the random machine breakdowns and fuzzy demand/process flow data. Then, a hybrid solution approach based on a chance-constrained stochastic programming technique with a well-known interactive fuzzy resolution method is proposed. Thus, the random machine breakdowns and fuzzy part flow rates among different machining capabilities could be easily handled via the proposed approach. Fortunately, the proposed approach can also generate various risky and risk-free robust layout design alternatives under different probabilistic scenarios and uncertainty levels (α-cuts) according to the facility designer’s risk attitude. To show the validity and applicability of the proposed R-CBDL problem and hybrid solution approach, an extensive computational study with comparative analysis is first presented based on an illustrative numerical example under different machine capability overlap cases and probability distributions. Then, the performance of the proposed approach is also tested on a real-life cellular manufacturing system of a company. The computational experiments have shown that the proposed approach can accomplish more efficient robust layout design alternatives with on average 24.5% better total expected layout score when compared to the existing cellular layout of the manufacturing company.

Similar content being viewed by others

Data availability

Data are available on request from the authors.

Code availability

In case of this paper is accepted, the data and codes needed for replication of our results will be available on request from the authors.

References

Aiello G, Enea M (2001) Fuzzy approach to the robust facility layout in uncertain production environments. Int J Prod Res 39(18):4089–4101

Amri SK, Darmoul S, Gabouj SH, Pierreval H (2016) Risk issues in facility layout design. In: Proceedings of the 2016 international conference on industrial engineering and operations management ICIEOM, Kuala Lumpur, Malaysia, pp 1253–1264

Baykasoğlu A, Gindy NN (2000) MOCACEF 1.0: multiple objective capability based approach to form part-machine groups for cellular manufacturing applications. Int J Prod Res 38(5):1133–1161

Baykasoğlu A, Göçken M (2010) Capability-based distributed layout and its simulation based analyses. J Intell Manuf 21(4):471–485

Baykasoğlu A, Subulan K (2019) A fuzzy-stochastic optimization model for the intermodal fleet management problem of an international transportation company. Transp Plan Technol 42(8):777–824

Baykasoğlu A, Subulan K (2020) Capability-based distributed layout formation with or without demand and process flow information. Appl Soft Comput 94:1–16

Baykasoğlu A, Subulan K, Hamzadayı A (2022) Capability-based machine layout with a matheuristic-based approach. Expert Syst Appl 198:116900

Baykasoğlu A (2003) Capability-based distributed layout approach for virtual manufacturing cells. Int J Prod Res 41(11):2597–2618

Benjaafar S, Heragu SS, Irani SA (2002) Next generation factory layouts: research challenges and recent progress. Interfaces 32(6):58–76

Benjaafar S, Sheikhzadeh M (2000) Design of flexible plant layouts. IIE Trans 32:309–322

Bisschop J, Roelofs M (2006) AIMMS-the user’s guide. Paragon, The Netherlands

Celik M, Efeoglu B, Sural H (2016) A performance measurement framework and solution approach for the integrated facility layout problem with uncertain demand. In: 14th international material handling research colloquium proceedings. Karlsruhe, Baden-Württemberg, Germany

Charnes A, Cooper WW (1959) Chance-constrained programming. Manage Sci 6(1):73–79

Drira A, Pierreval H, Hajri-Gabouj S (2013) Design of a robust layout with information uncertainty increasing over time: a fuzzy evolutionary approach. Eng Appl Artif Intell 26(3):1052–1060

Ertay T, Ruan D, Tuzkaya UR (2006) Integrating data envelopment analysis and analytic hierarchy for the facility layout design in manufacturing systems. Inf Sci 176(3):237–262

Esmikhani S, Kazemipoor H, Sobhani FM, Molana SMH (2022) Solving fuzzy robust facility layout problem equipped with cranes using MPS algorithm and modified NSGA-II. Expert Syst Appl 210:118402

Fazlelahi FZ, Pournader M, Gharakhani M, Sadjadi SJ (2016) A robust approach to design a single facility layout plan in dynamic manufacturing environments using a permutation-based genetic algorithm. Proc Inst Mech Eng 230(12):2264–2274

Gölcük İ, Durmaz ED, Şahin R (2022) Interval type-2 fuzzy development of FUCOM and activity relationship charts along with MARCOS for facilities layout evaluation. Appl Soft Comput 128:109414

Guo W, Jiang P, Yang M (2022) Unequal area facility layout problem-solving: a real case study on an air-conditioner production shop floor. Int J Prod Res. https://doi.org/10.1080/00207543.2022.2037778

Gupta N, Ali I, Bari A (2003) A compromise solution for multi-objective chance constraint capacitated transportation problem. ProbStat Forum 6:60–67

Hamedi M, Esmaeilian G, Ismail N, Ariffin MKA (2012a) Capability-based virtual cellular manufacturing systems formation in dual-resource constrained settings using Tabu search. Comput Ind Eng 62(4):953–971

Hamedi M, Esmaeilian G, Ismail NB (2012b) Developing capability–based virtual cellular manufacturing systems and comparison with capability–based classical cellular manufacturing systems. Appl Mech Mater 110:3938–3946

Hamedi M, Esmaeilian G (2015) Functional and distributed layouts and their effectiveness on capability-based virtual cellular manufacturing systems performance. In: 2015 International conference on industrial engineering and operations management. IEEE, pp 1–8. Dubai, United Arab Emirates

Hunagund IB, Pillai VM, Kempaiah UN (2020) Design of robust layout for unequal area dynamic facility layout problems with flexible bays structure. J Facil Manag 18(4):361–392

Izadinia N, Eshghi K, Salmani MH (2014) A robust model for multi-floor layout problem. Comput Ind Eng 78:127–134

Jimenez M, Arenas M, Bilbao A, Rodriguez MV (2007) Linear programming with fuzzy parameters: an interactive method resolution. Eur J Oper Res 177:1599–1609

Jimenez M (1996) Ranking fuzzy numbers through the comparison of its expected intervals. Int J Uncert Fuzziness Knowl-Based Syst 4(4):379–388

Jithavech I, Krishnan KK (2010) A simulation-based approach for risk assessment of facility layout designs under stochastic product demands. Int J Adv Manuf Technol 49:27–40

Khajemahalle L, Emami S, Keshteli RN (2021) A hybrid nested partitions and simulated annealing algorithm for dynamic facility layout problem: a robust optimization approach. Inf Syst Oper Res 59(1):74–101

Kulturel-Konak S (2007) Approaches to uncertainties in facility layout problems: perspectives at the beginning of the 21st century. J Intell Manuf 18(2):273–284

Liu B (2004) Uncertainty theory: an introduction to its axiomatic foundations. In: Studies in fuzziness and soft computing. Springer, Heidelberg

Liu B (2007) Uncertainty theory: studies in fuzziness and soft computing. Springer, Berlin

LINDO Systems Inc. (xxxx) LINGO: The Modelling Language and Optimizer https://www.lindo.com/downloads/PDF/LINGO.pdf. Accessed 17 Dec 2021

Meller RD, Gau KY (1996) Facility layout objective functions and robust layouts. Int J Prod Res 34(10):2727–2742

Morinaga E, Iwasaki K, Wakamatsu H, Arai E (2019) Reduction of computational load in robust facility layout planning considering temporal production efficiency. In: IFIP international conference on advances in production management systems. Springer, Cham, pp 189–195. Austin, TX, USA

Morinaga E, Iwasaki K, Wakamatsu H, Arai E (2017) A robust facility layout planning method considering temporal efficiency. In: IFIP International conference on advances in production management systems. Springer, Cham, pp 168–175. Hamburg, Germany

Moslemipour G, Lee TS, Loong YT (2018) Solving stochastic dynamic facility layout problems using proposed hybrid AC-CS-SA meta-heuristic algorithm. Int J Ind Syst Eng 28(1):1–31

Moslemipour G, Lee TS, Rilling D (2012) A review of intelligent approaches for designing dynamic and robust layouts in flexible manufacturing systems. Int J Adv Manuf Technol 60:11–27

Moslemipour G, Lee TS, Loong YT (2017) Performance analysis of intelligent robust facility layout design. Chin J Mech Eng 30(2):407–418

Neghabi H, Eshghi K, Salmani MH (2014) A new model for robust facility layout problem. Inf Sci 278:498–509

Nematian J (2014) A robust single row facility layout problem with fuzzy random variables. Int J Adv Manuf Technol 72:255–267

Pagone E, Haddad Y, Barsotti L, Dini G, Salonitis K (2023) A stochastic evaluation framework to improve the robustness of manufacturing systems. Int J Comput Integr Manuf. https://doi.org/10.1080/0951192X.2022.2162592

Peng Y, Zeng T, Fan L, Han Y, Xia B (2018) An improved genetic algorithm based robust approach for stochastic dynamic facility layout problem. Discret Dyn Nat Soc 2018:1529058

Pérez-Gosende P, Mula J, Díaz-Madroñero M (2023) A bottom-up multi-objective optimization approach to dynamic facility layout planning. Int J Prod Res. https://doi.org/10.1080/00207543.2023.2168308

Pillai VM, Hunagund LB, Krishnan KK (2011) Design of robust layout for dynamic plant layout problems. Comput Ind Eng 61(3):813–823

Pourvaziri H, Salimpour S, Niaki STA, Azab A (2022) Robust facility layout design for flexible manufacturing: a doe-based heuristic. Int J Prod Res 60(18):5633–5654

Rosenblatt MJ, Lee HL (1987) A robustness approach to facilities design. Int J Prod Res 25(4):479–486

Şahinkoç M, Bilge U (2018) Facility layout problem with QAP formulation under scenario-based uncertainty. Inf Syst Oper Res 56(4):406–427

Salmani MH, Eshghi K, Neghabi H (2015) A bi-objective MIP model for facility layout problem in uncertain environment. Int J Adv Manuf Technol 81(9):1563–1575

Shafigh F, Defersha FM, Moussa SE (2017) A linear programming embedded simulated annealing in the design of distributed layout with production planning and systems reconfiguration. Int J Adv Manuf Technol 88:1119–1140

Shafigh F, Defersha FM, Moussa SE (2015) A mathematical model for the design of distributed layout by considering production planning and system reconfiguration over multiple time periods. J Ind Eng Int 11(3):283–295

Subulan K (2020) An interval-stochastic programming based approach for a fully uncertain multi-objective and multi-mode resource investment project scheduling problem with an application to ERP project implementation. Expert Syst Appl 149:113189

Subulan K, Çakır G (2022) Constraint programming-based transformation approach for a mixed fuzzy-stochastic resource investment project scheduling problem. Soft Comput 26:2523–2560

Subulan K, Varol B, Baykasoğlu A (2023) Unequal-area capability-based facility layout design problem with a heuristic decomposition-based iterative mathematical programming approach. Expert Syst Appl 214:119199

Targhi NS, Sabzehparvar M, Ebrahimnezhad S (2019) A mathematical model for robust facility layout problem in 3D space with possibility of floors. In: 2019 15th Iran international industrial engineering conference. IEEE, pp 158–164. Yazd, Iran

Vitayasak S, Pongcharoen P, Hicks C (2019) Robust machine layout design under dynamic environment: dynamic customer demand and machine maintenance. Expert Syst Appl 3:100015

Vitayasak S, Pongcharoen P (2016) Application of genetic algorithm for quantifying the affect of breakdown maintenance on machine layout. In: International workshop on multi-disciplinary trends in artificial intelligence. Springer, Cham, pp 208–218. Chiang Mai, Thailand

Vitayasak S, Pongcharoen P, Hicks C (2017) A tool for solving stochastic dynamic facility layout problems with stochastic demand using either a genetic algorithm or modified backtracking search algorithm. Int J Prod Econ 190:146–157

Vitayasak S, Pongcharoen P (2015a) Genetic algorithm based robust layout design by considering various demand variations. In: International conference in swarm intelligence. Springer, Cham, pp 257–265. Beijing, China

Vitayasak S, Pongcharoen P (2015) Re-layout and robust machine layout design under stochastic demand. Appl Mech Mater 789:1252–1257

Xiao X, Hu Y, Wang W, Ren W (2019) A robust optimization approach for unequal-area dynamic facility layout with demand uncertainty. Procedia CIRP 81:594–599

Yang Z, Lu W (2023) Facility layout design for modular construction manufacturing: a comparison based on simulation and optimization. Autom Constr 147:104713

Zha S, Guo Y, Huang S, Wang F, Huang X (2017) Robust facility layout design under uncertain product demands. Procedia CIRP 63:354–359

Zha S, Yu G, Shaohua H, Qi W, Pengzhou T (2020) A hybrid optimization approach for unequal-sized dynamic facility layout problems under fuzzy random demands. Proc Inst Mech Eng 234(3):382–399

Zhao Y, Wallace SW (2015) A heuristic for the single-product capacitated facility layout problem with random demand. EURO J Transp Log 4:379–398

Zolfi K, Jouzdani J, Shirouyehzad H (2023) A novel memory-based simulated annealing algorithm to solve multi-line facility layout problem. Dec Sci Lett 12:69–88

Funding

No funds, grants, or other support was received.

Author information

Authors and Affiliations

Contributions

K.S. conceived the study, participated in the design of the solution algorithms and implementation of the mathematical models, carried out computational experiments, analyzed experimental results, and wrote the paper with the other authors. B.V. participated in the design of the study and initial versions of the manuscript and analyzed the computational results. A.B. participated throughout the preparation of the paper. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

Authors have no conflicts of interest to declare that are relevant to the content of this article.

Ethical approval

No human participants or animals have been involved in this study.

Informed consent

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Subulan, K., Varol, B. & Baykasoğlu, A. Designing robust capability-based distributed machine layouts with random machine availability and fuzzy demand/process flow information. Soft Comput 28, 4359–4397 (2024). https://doi.org/10.1007/s00500-023-08756-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-023-08756-y