Abstract

An accurate local thermal sensation model is indispensable for the effective development of personalized conditioning systems in office environments. The output of such a model relies on the accurate prediction of local skin temperatures, which in turn depend on reliable input data of the local clothing thermal resistance and clothing area factor. However, for typical office clothing ensembles, only few local datasets are available in the literature. In this study, the dry thermal resistance was measured for 23 typical office clothing ensembles according to EN-ISO 15831 on a sweating agile manikin. For 6 ensembles, the effects of different air speeds and body movement were also included. Local clothing area factors were estimated based on 3D scans. Local differences can be found between the measured local insulation values and local area factors of this study and the data of other studies. These differences are likely due to the garment fit on the manikin and reveal the necessity of reporting clothing fit parameters (e.g., ease allowance) in the publications. The increased air speed and added body movement mostly decreased the local clothing insulation. However, the reduction is different for all body parts, and therefore cannot be generalized. This study also provides a correlation between the local clothing insulation and the ease allowance for body parts covered with a single layer of clothing. In conclusion, the need for well-documented measurements is emphasized to get reproducible results and to choose accurate clothing parameters for thermo-physiological and thermal sensation modeling.

Similar content being viewed by others

Introduction

Most adults spend the major part of the day at work, typically in an office building. To enable workers at office buildings to perform at their best and stay healthy, it is necessary that the indoor environment meets their individual needs (Seppänen et al. 2006; Urlaub et al. 2013). However, office buildings also have to be energy efficient to adhere to modern standards. Hence, researchers and building engineers aim to design the buildings’ heating, ventilation, and air conditioning systems to be energy efficient, while also providing a thermally comfortable environment to all occupants. To achieve this goal, personalized heating and cooling systems are being developed (Arens et al. 1991; Melikov et al. 1994; Foda and Sirén 2012; Veselý and Zeiler 2014; Parkinson et al. 2015). To test the thermal comfort provided by these systems, a large number of human subjects are usually required, which increases the studies’ cost and length. This situation could be improved by using local thermal sensation and coupled thermal comfort models for preselecting promising designs. To achieve a high predictability, these models require reliable input data of the local clothing thermal resistance and clothing area factor. However, Veselá et al. (2017) show that the available data is limited for typical office clothing ensembles. Furthermore, few studies were performed on the local effect of increased air speeds and body movement on the dry thermal resistance.

Studies published on local clothing insulation values are for example Lee et al. (2013), Lu et al. (2015), Nelson et al. (2005), and Havenith et al. (2012). In Lee et al. (2013), measurements were carried out on a thermal manikin seated on a chair with different clothing sets. Their study contained a large variety of ensembles, but the effect of air speed and body movement were not included. Lu et al. (2015) studied the effect of air speed and body movement for dry local clothing insulation, but only two clothing ensembles are usable for office settings. A different approach is found in Nelson et al. (2005), where local insulation values were recalculated from the global values published by McCullough et al. (1985, 1989). Their study includes a large variety of single garments that can be combined to whole-body ensembles as needed. However, local effects of overlaying clothing items were not considered in this approach. Havenith et al. (2012) presented empirical equations based on the seasonal dressing customs of Europeans according to the outdoor air temperature to determine the local clothing insulation for seven body parts. This approach gives a rough estimation on the clothing insulation worn in a specific season of the year but does not include the properties of the worn garments, such as the clothing material or fit, and neglects the parameters of the indoor environment.

In conclusion, current literature does not provide enough clothing insulation values for a variety of typical office clothing ensembles under different air speeds and with body movement. To close this gap, we measured the local dry thermal resistance of eight body parts at three different air speeds and including body movement of a large variety of typical office clothing ensembles using a sweating agile manikin and a sweating foot manikin at Empa, Switzerland. Additionally, the local clothing area factors were estimated based on 3D scans of the clothing items. This paper presents the results of the measurements and discusses the effect of air speed, body movement and garment fit on the local thermal properties of the clothing ensembles.

Methods

Measuring equipment

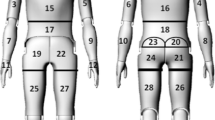

The local dry thermal resistance (IT,i) of the office clothing ensembles was measured using the sweating agile manikin (SAM) (Richards and Mattle 2001) at Empa, Switzerland. The manikin consists of 22 shell elements, which are made from thin-walled aluminum-polyethylene composite. Moreover, nine guards (hands, feet, elbows, knees, and the face block) are installed to minimize the heat exchange between elements and the environment. All elements are uniformly and separately heated. The mean temperature of each shell part is measured at its outer surface with evenly distributed nickel resistance wires. Furthermore, SAM can be connected with a movement simulator, which enables the manikin to perform realistic movements of up to 2.5 km/h walking speed.

Because SAM has no foot segments, the IT,i of representative shoe and sock combinations were measured with the foot simulator as described by Babic et al. (2008) and Bogerd et al. (2012). The foot manikin represents a right foot of size EU 43 and consists of 13 separately heated metal elements. Furthermore, walking can be simulated with a net force of up to 25 kg and with a maximum of 25 steps per minute.

Both manikins are placed in separate climate chambers. The chambers’ temperature and relative humidity can be controlled within ±1°C and ±5%, respectively.

Garments and ensembles

In this study, garments and their combinations typically worn in an office environment are considered. Since SAM has an average male statue, mainly male clothing items were chosen. The detailed properties of all clothing items are summarized Table S1 (supplementary information). To account for different preferences in clothing fit, the t-shirt, long-sleeved shirt (abbreviation: shirt), long-sleeved smart shirt (abbreviation: smart shirt), and jeans were included in different sizes, representing tight (T), regular (R), and loose (L) fits. The clothing items were combined to 23 whole-body and three foot combinations, which are summarized in Table 1 and Fig. 1.

Local clothing area factors

The total clothing area factor fcl accounts for the increase of the total body surface area by the addition of clothing and is defined as follows:

where Adressed is the outer surface area of the dressed body and Anude is the surface area of a nude body (ISO 9920 2009). For the local clothing area factor fcl,i, this definition is applied to all body parts separately.

For obtaining fcl,i of all used garments, a 3D scanner was used to scan the nude and dressed shop window manikin James to obtain the respective surface areas (Psikuta et al. 2012, 2015). In a 3D surface inspection software (Geomagic Control 2014, 3D Systems®, USA), the scans of the nude and dressed manikin were cut according to the defined body parts (Fig. 2a) before fcl,i of the single sections were calculated. In all cases, uncovered areas, e.g., opening of the jacket on the chest, were not considered.

A special case is fcl,i of the skirt since the inner thighs are not covered by a fabric. In this paper, we decided to reduce the nude area of the thighs for the upright, stationary posture of the manikin, since the thighs are close to each other, and therefore, the heat loss is reduced in this area. The nude area of the thighs, in the described case, was determined by drawing a line from the middle front and back of the skirt to the center of the thigh (Fig. 3). Only the skin surface at the outer sides of the thighs (bold lines in Fig. 3) are used for calculating the nude skin area Anude which is needed for computing fcl,i (Eq. (1)). Hence, the inner parts of the thighs were left out. For the measurement with the moving manikin, the whole nude area of the thighs was considered.

For most garments, the surface areas were obtained for three scans. Between the scans, the manikin was redressed to account for differences in draping. All results of fcl,i measured on James can be found in Table S2 and S3 of the supplementary information.

When considered strictly, fcl,i depends on the garment fit at a specific body part. Hence, fcl,i should be adjusted, when using other manikins, human subjects or garment fit. A measure of clothing fit is the ease allowance EA which is the difference between the circumferences of a clothing item (CFcloth, i) and the manikin (or person) (CFman, i) at a specific body landmark (Fig. 2b) (ISO 8559 1989).

The garments were marked and measured at the same positions. All EA were then calculated for all items at the relevant positions. For the skirt, only the EA of the hip was measured. The EA of the clothing items on James are summarized in Table 2. Negative values indicate that the clothing is locally stretched while wearing it. Since the geometry of other manikins and real persons is slightly different, a correction is needed. The fcl,i for thermal manikin SAM are adjusted by measuring the respective circumferences and correcting the EA accordingly (see Table 3).

The fcl,i of the shoe/sock combinations were estimated using the more classical method of calculating the nude and dressed areas using photographs and post-processing them in suitable software, e.g., Photoshop Elements (Adobe Systems Software, Ireland) (McCullough et al. 1985; Havenith et al. 2015).

Local dry thermal resistance

The local dry thermal insulation (IT,i) was measured according to standard EN-ISO 15831 (2004). For the measurements of the whole-body clothing ensembles on SAM, the surface temperature Tskin was set to 34°C, the operative temperature of the environment Top to 21°C and the relative humidity to 40%. The environmental conditions were monitored using a measurement tree with the sensors placed in front of the manikin (ThermCondSys5500 and AirDistSys 5000, Sensor electronic, Poland). The operative temperature and relative humidity was obtained at the height of the waist and their standard deviation was typically around 0.1°C and 1%, respectively. The air speed was measured at three heights, namely ankles, waist, and head. The standard deviation for the air speed varied from about 0.02m/s for lowest air speed to 0.1m/s for largest air speed. In the reference case (test case 1), the air speed was set to 0.2m/s and SAM was in standing position. In these conditions, IT,i of all clothing ensembles (Table 1) were measured. To analyze the influence of varying air speed and the addition of body movement, IT,i of six outfits (nos. 1, 3, 14, 19, 21, 22) was determined in four additional test cases (TC 2–5). In test cases 2 and 3, SAM was in standing position and the air speed was set to 0.4m/s and to 1.0m/s, respectively. For the fourth and fifth test cases, SAM was connected to the moving simulator and air speeds of 0.2m/s and 1.0m/s were used, respectively. The walking speed of the movement simulator was controlled to 2.5 km/h . In all cases, the air was directed from the front of the manikin. The local thermal resistance of the air layer Ia, i was defined as the thermal insulation of the nude manikin. For each condition, three independent measurements were done for Ia, i.

Each clothing ensemble was measured in the relevant test cases at least twice for 45 min. If the difference between the two measurements exceeded 4% for the total dry thermal resistance or 10% for the local dry thermal resistances, an additional repetition was conducted (ISO 15831 2004). In between the experiments, the manikin was redressed to account for differences in the draping of the garments. During the experiments, the dry heat loss \( {\dot{Q}}_{loss,i} \), the skin temperature Tskin,i of all body parts i, and the environmental parameters were recorded. Then, IT,i and the local intrinsic clothing insulation Icl,i of a specific body part i were computed as an average of the last 20 min (steady state) using the measured fcl,i as described in the sections “Local clothing area factors” and “Local clothing area factors” and Eqs. (3) and (4), respectively.

In the case of the foot manikin, the skin temperature set point was set to 35 °C. The air speed in this climate chamber could not be altered. Measurements during the experiments showed that the air speed varied between 0.15m/s and 0.2m/s. The standard deviation of the operative temperature and relative humidity during the experiments in this chamber were 0.1°C and 1%, respectively. To investigate the effect of movement, measurements were performed on the static foot and on the moving foot with a speed of 25 steps per minute (about 1.2 km/h) and a pressure of 25 kg. A larger number of steps per minute would be closer to the walking speed of SAM but is not supported by the current system (Babic et al. 2008; Bogerd et al. 2012). Each shoe/ sock combination was then measured three times for 60 min in each scenario with changing shoes in between measurements. The resulting total clothing insulation IT, foot was determined for the sectors of the foot manikin, which represent the actual foot (below ankle) and are mostly covered by the shoes and socks.

Results and discussion

Local clothing area factors

To obtain fcl,i for the used garments on manikin SAM, the correlation between fcl,i and the EA were investigated. In Fig. 4, the linear fitting and R2 values are shown for all body parts. High linear correlations (R2 value > 0.8) between fcl,i and EA are seen for the upper and lower arm, back, back hip for lower body items as well as the lower and upper leg. For the chest, the R2 value is higher, when the sweater and jacket are excluded from the graph. This observation might be due to the design differences between the sweater, the jacket and the other shirts. For the EA pelvis - fcl,i front hip correlation in Fig. 4e, two linear trend lines are shown, because the EA of the sweater includes the loosely falling main body of the sweater (EA = 22 cm, solid line) and the tight ribbed band (EA = − 10 cm, dashed line). The squared Pearson coefficient is low for the linear correlation including the negative EA of the sweater (R2 = 0.33)and higher when the larger EA is taken into account (R2 = 0.84). Another option to predict fcl,i of the front and back hip of the upper body is to use the correlation to the EA of the waist (Fig. 4f, h). Furthermore, the slope of the linear correlations varies for the different body parts. At the chest, for example, fcl,i for different EA varies only from 1.05 to 1.20. In contrast, fcl,i at the lower arm covers a range from 1.15 to 1.7. Hence, the importance to adjust fcl,i with regard to EA depends on the body part. It can also be noted that fcl,i of some body parts at the same body landmark is very similar. For example, this observation can be seen for fcl,i of the chest and back at the thorax and for the front hip and back at the waist.

Correlation of local clothing area factors fcl,i and ease allowances EA. a EA-fcl upper arm. b EA-fcl lower arm. c EA thorax-fcl chest (w/o sweater, jacket). d EA thorax-fcl back. e EA pelvis-fcl front hip. f EA waist-fcl front hip. g EA pelvis-fcl back hip (upper body). h EA waist-fcl back hip (upper body). i EA pelvis-fcl front hip (lower body). j EA pelvis-fcl back hip (lower body). k EA thigh-fcl upper leg. l EA-fcl lower leg

To estimate fcl,i of the whole-body ensembles in relation to SAM (Table 4), the following procedure was applied:

-

The linear correlations, as shown in Fig. 4a–d, f, h–l were applied.

-

It is assumed that the outermost garment defines fcl,i of a specific body part.

-

In the case of SAM, the hip is defined from the waist downwards (Fig. 2), and hence, it is mainly covered by the upper body garment. Therefore, fcl,i for the hip is taken mostly from the upper body garment. For the cases where the long-sleeved smart shirt is worn inside the dress pants, fcl,i of the hips of these trousers is taken.

-

Skirt: No equation can be used to calculate the reduction of fcl,i because of the larger upper legs on SAM. For the jeans and pants, fcl,i of the upper legs was reduced by 0.10 to 0.15. Therefore, fcl,i of the upper leg of the skirt is also reduced from 2.29 to 2.15 for the stationary and from 1.5 to 1.35 for the moving manikin as an estimation.

For the shoe/sock combinations, fcl,i were approximated with the 2D photo method and are as follows:

-

Ballerina/ nylon socks: 1.2

-

Sneakers/ athletic socks: 1.4

-

Business shoes/ athletic socks: 1.3

For tight clothing items, the described method can lead to calculated fcl,i below 1. This situation happens when the circumference of a specific body part on a manikin or human subject is larger than the one of the original manikin (James), so that the EA for the larger body becomes negative. For example, the calculated fcl,i of the tight jeans on the upper leg (outfit 10 and 11) and the tight long-sleeved shirt on the front hip (outfit 5) were 0.94 and 0.99, respectively. However, in reality the garment will stretch and the minimum value can only be the circumference of the specific body part with added thickness of the fabric. For the tight jeans on the upper leg the calculation reads fcl, i, min = (58 cm + 2 ∙ π · 0.067 cm)/58 cm = 1.007 and for the tight long-sleeved shirt on the hip it is fcl, i, min = (93 cm + 2 ∙ π · 0.087 cm)/93 cm = 1.006. Hence, these minimal values were used for further calculations.

Comparison to values found in the literature

As mentioned in the “Introduction,” there are very few values for fcl,i in the literature. In fact, the ones found in Nelson et al. (2005) are attributed to entire clothing items, and not to single body parts. Since the air gaps between the clothing item and the body surface can vary for different body parts, this may lead to false values for some body parts covered by the clothing item, especially if its area is small compared to the area of the whole garment. For example, fcl,i of the long-sleeved shirt with shirt collar in Nelson et al. (2005) is 1.24. This value is slightly higher but comparable to fcl,i of the chest, back, front and back hip of the regular long-sleeved smart shirt in this paper (1.12–1.17). However, it is much lower than fcl,i of the upper and lower arm (1.43 and 1.71, respectively). Another issue is that the fit of the clothing items are described very briefly with general terms such as “fitted” or “loose.” The straight, long trousers in Nelson et al. (2005), for instance, have a fcl,i of 1.20 in the “fitted” case. However, this value is by 0.1 to 0.2 larger than the values obtained for the measured tight jeans (outfits 10–11) and also the regular fitting jeans (outfits 1–8) of this study on the hip and upper leg. A larger fcl,i would mean that a smaller adjacent air insulation value is subtracted from the measured total thermal insulation of garment to calculate the intrinsic clothing insulation of a specific body part (see Eq. (4)). For example, the upper leg has an air layer insulation of 0.08 m2 K/W. fcl,i of 1.0 and 1.2 would lead to the subtraction of 0.08 m2 K/W or 0.067 m2 K/W of air insulation, respectively, which is a difference of 16% in the intrinsic clothing insulation. Hence, a more exact measurement for the fit of clothing items, such as the ease allowance may help to avoid the mentioned inaccuracies.

Dry thermal resistance

The results for Icl,i of the whole-body clothing ensembles and Ia, i of all test cases are shown in Table 5. For the sock/shoe combinations, IT,i in the non-moving case is 0.11 m2 K/W for the ballerinas with nylon socks and 0.13 m2 K/W for both the sneakers and business shoes combined with the athletic socks. These values are reduced by movement to 0.09 m2 K/W and 0.12 m2 K/W, respectively. The air layer insulation could only be determined for the non-moving foot and is 0.09 m2 K/W. Hence, Icl,i of the sneakers, business shoes and ballerinas for the non-moving foot manikin can be computed by Eq. (4). Their values are 0.07 m2 K/W, 0.06 m2 K/W, and 0.04 m2 K/W, respectively.

Comparison to values found in the literature

For a clothing ensemble consisting of a t-shirt and jeans, the measured Icl,i of this study, namely outfit 1 and 4 (with regular and loose t-shirt, respectively), can be compared to four other studies (Nelson et al. 2005; Havenith et al. 2012; Lee et al. 2013; Lu et al. 2015) as shown in Table 6. For the empirical equations by Havenith et al. (2012) an air temperature of 22°C is assumed. The comparison in Table 6 reveals that the differences in Icl,i vary depending on the body part. For example, Icl,i of the upper arm found in the literature are comparable to ones measured in this study. For the back, the values from the literature are generally smaller than from outfit 1 or 4. The most variance between the studies and our values is seen at the front and back hip. These observed variations might be caused by the distinct material and fit of the garments. Garments made of thicker material and with a looser fit, i.e., larger air gap, would result in increased clothing insulation values. Moreover, the differences in the construction, setup, and posture of the used manikins can affect the result. For example, SAM has pronounced anatomical shoulder blades, unlike most of the other thermal manikins with simplified or smoothed body shapes, which creates a higher clothing insulation through a larger air gap when the clothing is on. Moreover, the manikin in Lee et al. (2013) was in sitting position, which causes smaller air gaps at the back, pelvis, thigh, and calf. Also, in a sitting position, the draping of the clothing is different than in upright position (Mert et al. 2017). Another issue comparing different studies is that the body parts are defined differently. This difference especially occurs for the torso. In Lee et al. (2013), for instance, the torso is divided in the chest, back and pelvis, whereas in Lu et al. (2015) it consists of the chest, back, abdomen and pelvis. In these regions, the clothing draping pattern can differ as discussed by Frackiewicz-Kaczmarek et al. (2015). Another factor that can cause different Icl,i is slight variations in the environmental conditions. For example, the air speed in the studies by Lee et al. (2013) and Lu et al. (2015) is 0.1m/s and 0.15m/s, respectively, whereas the air speed in this study was set to 0.2m/s. However, the compared papers do not contain all of this information. Hence, it is difficult for users of thermophysiological or thermal sensation models to extract the most suitable set of Icl,i for a specific simulation case.

The intrinsic clothing insulation of the business shoes and sneakers are also included in Table 6 and compared to the values found in the mentioned studies. In general, the variation of the values for the foot dry insulation is high with this study’s values being the lowest. The range of the measured values (excluding the value by Nelson et al. (2005)) is 0.6–0.13 m2K/W. In an inter-laboratory test on thermal foot manikins by Kuklane et al. (2005), the effective insulation values also varied by ± 0.3–0.6 m2K/W depending on the tested shoe/sock combination. When compared to the measurements on army boots on the same foot manikin by Bogerd et al. (2012), IT,i of the business shoes and sneakers are in line with IT,i of army boots which was around 0.18 m2K/W.

For the ballerinas, no comparable values were found. In Lee et al. (2013), the sandals have a local intrinsic insulation value of around 0.4 clo (0.06 m2K/W), and in Kuklane et al. (2009), the described sandal has an effective insulation (IT,i − Ia, i) of 0.06 m2K/W. In both cases, the values are higher than for the ballerinas, even though a similar range would be expected. Three issues can be raised on these shoe insulation measurements. Firstly, the two sandals touched the ground during measurements, whereas the non-moving foot was hanging free. Hence, there was no convection on the sole of the sandals, which can result in overall higher IT,i. Secondly, the sandals of the study by Kuklane et al. (2009) have the highest effective sole insulation (0.261 m2K/W) in the study, which also results in relatively high IT,i for the whole sandals. Lastly, the shoe insulation depends on the included sectors of the foot manikin in the calculation. For this study, the sectors of the foot manikin below the ankle were used. However, the ballerinas, for instance, do not cover the dorsal foot, which means that IT,i of the whole foot will be less than IT,i of the covered areas. In our case, the values are 0.11 m2K/W and 0.13 m2K/W, respectively. Conclusively, these issues should be considered and reported in studies on shoe insulation measurements to be able to do a fair comparison. This information will also help to choose the best values to use in thermophysiological models.

Effect of air speed and body movement

For six outfits (1, 3, 14, 19, 21, 22), Icl,i was obtained for two additional air speeds and body movement (Table 5, Fig. 5). Also, the correction factors were calculated using test case 1 as the reference and can be found in Table S4 to Table S7 in the supplementary materials. Additionally, the graphs showing the influence of increased air speed and the addition of body movement on IT,i are given in Fig. S1. In general, the effect of increased air speed and body movement are more pronounced, but comparable, in IT,i, because the air layer is excluded for Icl,i. For the upper and lower arm, chest, front hip, upper and lower leg the increase in air speed and addition of body movement mostly reduced Icl,i. At an air speed of 0.4m/s, the reduction is minor and mostly within the standard deviation of Icl,i. For an air speed of 1.0m/s, low influence can be found for the upper and lower leg (except when a skirt is worn), whereas the reduction can reach up to 30–40% at the arms and chest. The effect of body movement is generally larger than for the increase in air speed for these body parts. This observation is more pronounced for upper legs with pants than with jeans. For the chest and front hip, the increase to an air speed of 1.0m/s or the addition of body movement yielded similar results. The differences of the effect of body movement on the reduction in Icl,i might be caused by differences in the pumping effect, which is more pronounced for looser fitting clothing and on moving body parts. Hence, the pumping effect will be smaller for the relatively small movement of the torso when the manikin is in motion mode, and larger at the arms and legs, especially for looser fitting garments such as the pants. For the back and back hip, the results are more diverse. Surprisingly, the increase of air speed and body movement leads to an increase in Icl,i in a large number of cases. This outcome might be caused by two possible issues: (1) as mentioned above, the anatomy of SAM results is an unnaturally hollow back and (2) the direction of the wind from the front to the back results in the displacement of the garments towards the back. In both cases, the air gap between the manikin’s skin and garment(s) will increase for higher air speeds until a critical speed is reached, where the air will leave through the lower opening of the shirt. Due to the hollow back, this critical wind speed value might be relatively high compared to other manikins, causing the rise in Icl,i for at least a wind speed of 0.4m/s. The addition of body movement might emphasis this effect for low wind speeds, since the upper garment might to be push upwards creating a larger air gap due to the attachment of the legs to the moving simulator.

Influence of air speed and body movement on local intrinsic clothing insulation. a Outfit 1 (reg. t-shirt, reg. jeans). b Outfit 3 (regular smart shirt, regular jeans). c Outfit 14 (regular smart shirt tucked in dress pants). d Outfit 19 (regular t-shirt, sweater, regular jeans). e Outfit 21 (undershirt, regular smart shirt tucked in dress pants, jacket). f Outfit 22 (regular smart shirt tucked in shirt, tights)

In the published literature for overall clothing insulation, general equations are given for the reduction of IT due increased air speeds and body movement (Nilsson 1997; Nilsson et al. 2000; Havenith and Nilsson 2004; ISO 9920 2009). However, the effect of increased air speed and the addition of body movement cannot be generalized for our measurements, i.e., the local total and intrinsic clothing insulation. For the thermo-physiological modeling, this finding means that the effect of increased air speed and body movement should be considered separately for each body part rather than using a general reduction factor for the whole body as suggested in ISO 9920 (2009).

Effect of clothing fit

For this study, the four clothing items t-shirt, long-sleeved shirt, long-sleeved smart shirt, and jeans were available in different fits. In Fig. 6, their Icl,i are shown in relation to their EA at the respective body landmarks for outfits with one clothing layer. In most cases, Icl,i increases for larger EA. These differences are relatively small for the lower arm, lower leg and back hip, but larger for the upper arm, chest, back, front hip, and upper leg. The Icl,i of the smart shirt at the hips have more variation because it is combined with a larger variety of lower body garments, which overlap at the hips. Therefore, it is concluded that the knowledge of the exact fit, i.e. measurement of EA, is important when Icl,i values are published.

Correlation of local intrinsic clothing insulation and ease allowances. a EA-Icl upper arm. b EA-Icl lower arm. c EA thorax-Icl chest. d EA thorax-Icl back. e EA pelvis-Icl front hip (upper body). f EA pelvis-I back hip (upper body). g EA pelvis-Icl front hip (lower body). h EA pelvis-Icl back hip (lower body). i EA thigh-Icl upper leg. j EA-Icl lower leg

Correlation of local ease allowance and local clothing insulation

In this study, Icl,i of specific garments were measured. To apply these results to other research projects with similar outfits, the correlation between the local EA and Icl,i values for single layer outfits was investigated. In our range of EA the trend might be approximated as linear, because EA is linearly correlated to air gap thickness (Frackiewicz-Kaczmarek et al. 2015; Mert et al. 2017) and air gap thickness, in turn, is close-to-linearly correlated to the heat transfer coefficient for the air gap range of 4 – 32 mm as investigated by Mert et al. (2017). The range of air gap thickness investigated in this paper is well covered by this study, and Fig. 6 provides the linear correlation, R2 values and root-mean-square deviation (rmsd) for all body parts.

High linear correlations (R2 > 0.85) and low rmsd values can be found for the upper and lower arm, chest, back, and upper leg. Hence, Icl,i could be estimated using the provided linear correlations for other garments, manikins or human subjects. In contrast, the linear correlation at the front and back hip is weak (R2 < 0.6) and the results are more diverse. The main reason is that the clothing items of the upper and lower body overlap at this body part. Hence, a second air gap influences the result, which is not represented by EA measurement. The effect of this air gap can, for example, be seen in the difference of the regular smart shirt being tucked in the dress pants or not (0.14 vs 0.18 m2K/W, respectively; Table 5). However, the R2 value does not increase much if EA of the waist is used or only the upper body garments worn with the regular jeans are considered. Hence, for estimating Icl,i at the hip for other garments, further factors, e.g., width of second air gap, should be considered. In the case of the lower leg, Icl,i is very similar for all clothing items regardless of their fit (low R2 and low rsmd). Hence, Icl,i for the lower leg cannot be predicted by a correlation equation, but might be assumed to be approximately 0.08 m2K/W. One reason for this result might be that the shape of the lower leg is very versatile ranging from 23 to 39 cm. The EA was measured at the widest place, and according to Table 2, there was a large selection of different EA. This is also shown by the steeper slope of fcl,i vs EA in Fig. 4l. However, thermally, it seems that even for small EA the air gap at the lower part of the lower leg were relatively large. According to the dry heat transfer theory, the change in heat loss is minimal for further increase in air gap (Mert et al. 2016, 2017). Hence, the heat loss for all trousers is comparable.

The found correlations provide only an estimation of Icl,i values for single layer outfits. For clothing ensembles with multiple layers, a correlation to EA cannot be expected, because this measurement does not include information about the number of layers and their air gaps. In future research, it could be investigated if an additional clothing layer would result in a similar increase in Icl,i for a variety of single layer clothing ensembles.

Future research

In this paper, the local clothing insulation and local clothing area factors of a number of typical office clothing ensembles are calculated and analyzed for an upright position of the manikin SAM. However, a typical office situation also includes the sitting position. The measurements on SAM for this posture could not be conducted due to technical reasons. The largest influence of a sitting position can be expected for the contact areas with the chair, namely back hip and upper legs, and minor changes might be expected due to variations in draping of the clothing on the other body parts (Mert et al. 2016, 2017). Two effects are to be expected at these body parts: (1) the air layer between the skin and the clothing is reduced, and (2) the clothing insulation is influenced by the insulation of the chair. The first point was investigated by Mert et al. (2017). The second point raises the question regarding the kind of chair to be used and if measurements should be done for several chairs. Also, it might be inquired if the effect of the chair can be generalized.

This study also discusses the effect of the wind directed from the front to the back of the manikin on the resulting, relatively large, clothing insulation values of the back. Hence, future research may consider to vary the direction of the air to investigate the effect on the results. Then, the most appropriate value for a certain situation or the average might be considered depending on the application.

Conclusion

This study extends the database of local clothing insulation and local clothing area factors of typical office clothing ensembles. For the local clothing area factors, empirical equations are provided to adjust the value for different garments, manikins or human subjects using the ease allowance as a reference. The local clothing insulation of most body parts are decreased by increased air speed and added body movement. However, the reduction is different for all body parts and therefore, cannot be generalized. Moreover, the fit of the garments also influences the local clothing insulation value. It is suggested to use the ease allowance for specifying the exact fit, rather than using general terms such as “fitted” or “loose.” In the case of single layer clothing combinations, the local clothing insulation correlates linearly to the ease allowance for most body parts covered with a single layer. In general, this study emphasizes the need for well documented measurements to get reproducible results and to choose accurate clothing parameters for thermo-physiological and thermal sensation modeling.

References

Arens E, Bauman F, Johnston LP, Zhang H (1991) Testing of localized ventilation systems in a new controlled environment chamber. Indoor Air 1:263–281

Babic M, Lenarcic J, Zlajpah L et al (2008) A device for simulating the thermoregulatory responses of the foot: estimation of footwear insulation and evaporative resistance. J Mech Eng 54:628–638

Bogerd CP, Brühwiler PA, Rossi RM (2012) Heat loss and moisture retention variations of boot membranes and sock fabrics: a foot manikin study. Int J Ind Ergon 42:212–218

Foda E, Sirén K (2012) Design strategy for maximizing the energy-efficiency of a localized floor-heating system using a thermal manikin with human thermoregulatory control. Energy Build 51:111–121

Frackiewicz-Kaczmarek J, Psikuta A, Bueno M-A, Rossi RM (2015) Effect of garment properties on air gap thickness and the contact area distribution. Text Res J 85:1907–1918

Havenith G, Nilsson HO (2004) Correction of clothing insulation for movement and wind effects, a meta-analysis. Eur J Appl Physiol 92:636–640

Havenith G, Fiala D, Błażejczyk K et al (2012) The UTCI-clothing model. Int J Biometeorol 56:461–470

Havenith G, Ouzzahra Y, Kuklane K et al (2015) A database of static clothing thermal insulation and vapor permeability values of non-Western ensembles for use in ASHRAE standard 55, ISO 7730, and ISO 9920. ASHRAE Trans 121:197–215

ISO 15831 (2004) Clothing - Physiological effects - Measurement of thermal insulation by means of a thermal manikin

ISO 8559 (1989) Garment construction and anthropometric surveys—body dimensions

ISO 9920 (2009) Ergonomics of the thermal environment—estimation of thermal insulation and water vapour resistance of a clothing ensemble

Kuklane K, Holmér I, Anttonen H et al (2005) Inter-laboratory tests on thermal foot models. Elsevier Ergon B Ser 3:449–457. https://doi.org/10.1016/S1572-347X(05)80071-0

Kuklane K, Ueno S, Sawada SI, Holmér I (2009) Testing cold protection according to en ISO 20344: is there any professional footwear that does not pass? Ann Occup Hyg 53:63–68. https://doi.org/10.1093/annhyg/men074

Lee J, Zhang H, Arens E (2013) Typical clothing ensemble insulation levels for sixteen body parts. In: CLIMA Conference 2013, pp 1–9

Lu Y, Wang F, Wan X, Song G, Zhang C, Shi W (2015) Clothing resultant thermal insulation determined on a movable thermal manikin. Part II: effects of wind and body movement on local insulation. Int J Biometeorol 59:1487–1498

McCullough EA, Jones BW, Huck J (1985) A comprehensive data base for estimating clothing insulation. ASHRAE Trans 91:29–47

McCullough EA, Jones BW, Tamura T (1989) A Data Base for determining the evaporative resistance of clothing. ASHRAE Trans 95:316–328

Melikov AK, Arakelian RS, Halkjaer L, Fanger PO (1994) Spot cooling. Part 2: recommendations for design of spot-cooling systems. ASHRAE Trans 100:500–510

Mert E, Böhnisch S, Psikuta A, Bueno MA, Rossi RM (2016) Contribution of garment fit and style to thermal comfort at the lower body. Int J Biometeorol 60:1995–2004

Mert E, Psikuta A, Bueno M-A, Rossi RM (2017) The effect of body postures on the distribution of air gap thickness and contact area. Int J Biometeorol 61:363–375

Nelson DA, Curlee JS, Curran AR, Ziriax JM, Mason PA (2005) Determining localized garment insulation values from manikin studies: computational method and results. Eur J Appl Physiol 95:464–473

Nilsson HO (1997) Analysis of two methods of calculating the total insulation. In: Nilsson HO, Holmér I (eds) Proceedings of a European Seminar on Thermal Manikin Testing (1IMM). Department of Ergonomics, Arbetslivsinstitutet, Solna, pp 17–22

Nilsson HO, Anttonen H, Holmér I (2000) New algorithms for prediction of wind effects on cold protective clothing. In: Kuklane K, Holmér I (eds) 1st European Conference on Protective Clothing. Arbete och Hälsa 8, Stockholm, pp 17–20

Parkinson T, de Dear RJ, Candido C (2015) Thermal pleasure in built environments: alliesthesia in different thermoregulatory zones. Build Res Inf 3218:1–14

Psikuta A, Frackiewicz-Kaczmarek J, Frydrych I, Rossi RM (2012) Quantitative evaluation of air gap thickness and contact area between body and garment. Text Res J 82:1405–1413

Psikuta A, Frackiewicz-Kaczmarek J, Mert E, Bueno MA, Rossi RM (2015) Validation of a novel 3D scanning method for determination of the air gap in clothing. Measurement 67:61–70

Richards M, Mattle N (2001) A sweating agile thermal manikin (SAM) developed to test complete clothing systems under Normal and extreme conditions. In: Human factors and medicine panel symposium - blowing hot and cold: protecting against climatic extremes. Dresden, Germany, pp 1–7

Seppänen O, Fisk WJ, Lei QH (2006) Room temperature and productivity in office work. In: Healthy Buildings Conference. Lisbon

Urlaub S, Werth L, Steidle A, van Treeck C, Sedlbauer K (2013) Methodik zur Quantifizierung der Auswirkung von moderater Wärmebelastung auf die menschliche Leistungsfähigkeit. Bauphysik 35:38–44

Veselá S, Kingma BRM, Frijns AJH (2017) Local thermal sensation modeling—a review on the necessity and availability of local clothing properties and local metabolic heat production. Indoor Air 27:216–272

Veselý M, Zeiler W (2014) Personalized conditioning and its impact on thermal comfort and energy performance—a review. Renew Sust Energ Rev 34:401–408

Acknowledgments

The authors would like to thank Max Aeberhard for the technical support and the performance of additional measurements at Empa, St. Gallen.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(PDF 597 kb)

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Veselá, S., Psikuta, A. & Frijns, A.J.H. Local clothing thermal properties of typical office ensembles under realistic static and dynamic conditions. Int J Biometeorol 62, 2215–2229 (2018). https://doi.org/10.1007/s00484-018-1625-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00484-018-1625-0