Abstract

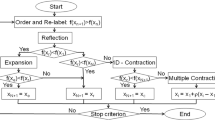

Homogeneous polynomial functions have the potential to provide a general modeling framework for yield surfaces in metal plasticity. They incorporate as particular cases many of the previously proposed yield functions and their fitting capabilities allow for capturing a wide range of yield surface shapes. And yet, there are still two unsolved problems which turn into major obstacles when it comes to actual implementations in both academic and industrial environments: The lack of a general optimization algorithm for the calibration of their parameters and the lack of an efficient computational scheme for their value, gradient and hessian. The difficulty of the first problem is two-fold, necessitating an adequate specification of the experimental input data set and satisfaction of the convexity constraint. The second problem is specific to all high degree polynomials and is comprised of issues such as numerical stability, precision and implementation efficiency. We present practical solutions to both problems: An optimization algorithm that reduces to solving a sequence of quadratic problems and a double Horner evaluation scheme that is optimal (featuring the least number of multiplications). The resulting modeling framework can account for arbitrary input data, experimental or from crystal plasticity predictions. As illustration we show new results regarding the relationship between generalized r-values and the earing profile of deep-drawn cylindrical cups. Practicality is demonstrated by the high level of automation of the entire workflow, from material parameters calibration to finite element simulations, and supporting code (Python scripts and constitutive subroutine) made available at https://github.com/stefanSCS/PolyN.

Similar content being viewed by others

Data availability

All supporting code is made public at: https://github.com/stefanSCS/PolyN. Numerical data (parameters and cup height profiles) for all models and deep-drawing simulations reported here is available in the CM_Data sub-directory of the repository.

Notes

An alternative deformation ratio is \(q=r/(1+r)\) (not to be confused with our usage of q), with the advantage that its variation is limited to [0, 1], e.g., Ch. 10 in [10, 20]. However, the nature of the disturbance remains the same—the asymptote of the extended r-value being replaced by zeros of q.

Regarding notation: Boldface symbols represent tensors/matrices; For a second order tensor/matrix \(\varvec{M}\) and a vector \(\varvec{a}\) the notation \(\varvec{b}=\varvec{M}:\varvec{a}\) stands for the component form \(b_i=\sum _jM_{ij}a_j\); The scalar (dot) product of two vectors is denoted by \(\varvec{a}\cdot \varvec{b}\); The tensor product of two vectors \(\varvec{a}\otimes \varvec{b}\) is defined by \(\left( \varvec{a}\otimes \varvec{b}\right) :\varvec{v}=\left( \varvec{b}\cdot \varvec{v}\right) \varvec{a}\); Under plane stress conditions, a function of the stress tensor \(f=f(\varvec{\sigma })\) is, by virtue of the symmetry of its argument, always regarded a function \(f=f(\sigma _x,\sigma _y,\sigma _{xy})\); In this condensed notation for arguments, the tensor components of the gradient are: \(\nabla f = [\partial f/\partial \sigma _x,\partial f/\partial \sigma _y, (1/2)\partial f/\partial \sigma _{xy}(1/2)\partial f/\partial \sigma _{xy}]\). The summation convention on repeated indexes is not implied; Whenever used, this is stated explicitly.

This requirement can be easily relaxed to 7 data points by interpolating the uniaxial data.

For any even integer \(N\ge 2\), there exists a unique set of coefficients denoted by \(\varvec{a}=M\) that reduces PolyN to the Von Mises yield function. These are found by reducing to identity the equality \(P_N(\varvec{\sigma }) = \left( \sigma _x^2-\sigma _x\sigma _y+\sigma _y^2+3\sigma _{xy}^2\right) ^{(N/2)}\), with \(P_N\) defined in Eq. (8).

For all simulations reported in this subsection we used the corresponding friction and hardening data in Tables-10,32 of [12]. Also, with reference to Fig. 6 and Eq. (33): \(\Phi _D=62.4\), \(\Phi _P=60.0\), \(R_N=5.0\), \(R_S=10.0\), \(\Phi _B=107.5\) \(t_B=1.0\). Finally, we recall that for simulations with classical shell elements the thickness of the blank has no relevance (besides the integration points used for calculating the response to bending).

References

Banabic D, Comsa DS, Sester M, Selig M, Kubli W, Mattiasson K, Sigvant M (2008) Influence of constitutive equations on the accuracy of prediction in sheet metal forming simulation. Numisheet, September 1–5, 2008-Interlaken, Switzerland

Barlat F, Lian J (1989) Plastic behavior and stretchability of sheet metals. Part 1: a yield function for orthotropic sheets under plane stress conditions. Int J Plast 5:51–66

Barlat F, Brem JC, Yoon J-W, Chung K, Dick RE, Lege DJ, Pourboghrat F, Choi S-H, Chu E (2003) Plane stress yield function for aluminum alloy sheets? Part 1: theory. Int J Plast 19:1297–1319

Barlat F, Aretz H, Yoon J-W, Karabin ME, Brem JC, Dick RE (2005) Linear transformation based anisotropic yield function. Int J Plast 21:1009–1039

Biswas A, Kalidindi SR, Hartmaier A (2022) A hybrid approach for the efficient computation of polycrystalline yield loci with the accuracy of the crystal plasticity finite element method. Model Simul Mater Sci Eng 30:025015

Boehler JP (1987) Application of tensors functions in solids mechanics, CISM Courses and Lectures, vol 292. Springer, Berlin

Boyd S, Vandenberghe L (2004) Convex optimization. Cambridge University Press. Python code at https://cvxopt.org/

Bron F, Besson J (2004) A yield function for anisotropic materials. Application to aluminum alloys. Int J Plast 20:937–963

Belytschko T, Liu WK, Moran B (2006) Nonlinear finite elements for continua and structures. Wiley, Chichester, UK

Gawad J, Van Bael A, Eyckens P, Samaey G, Van Houtte P, Roose D (2013) Hierarchical multi-scale modeling of texture induced plastic anisotropy in sheet forming. Comput Mater Sci 66:65–83

Gotoh M (1977) A theory of plastic anisotropy based on a yield function of fourth order (plane stress): part I and II. Int J Mech Sci 19:505

Habraken AM, Aksen TA, Alves JL, Amaral RL, Betaieb E, Chandola N, Corallo L, Cruz DJ, Duchêne L, Engel B, Esener E, Firat M, Sörensen PF, Lopez JG, Ghiabakloo H, Kestens AI, Lian J, Lingam R, Liu W, Ma J, Menezes LF, Minh TN, Miranda SS, Neto DM, Pereira AFG, Prates PA, Reuter J, Baudard BR, Ulloa CR, Sener B, Shen F, Van Bael A, Verleysen P, Barlat F, Cazacu O, Kuwabara T, Lopes A, Oliveira MC, Santos AD, Vincze G (2022) Analysis of ESAFORM 2021 cup drawing benchmark of an Al alloy, critical factors for accuracy and efficiency of FE simulations. Int J Mater Form 15:61

Hershey AV (1954) The plasticity of anisotropic aggregate of anisotropic face centered cubic crystals. J Appl Mech 21:241–249

Hill R (1948) A theory of the yielding and plastic flow of anisotropic metals. Proc R Soc Lond Ser A 193A(1033):281–297

Hill R (1950) The mathematical theory of plasticity. Clarendon Press, Oxford, UK

Hill R (1967) The essential structure of constitutive laws for metal composites and polycrystals. J Mech Phys Solids 15:79–95

Hosford WF (1972) A generalized isotropic yield criterion. J Appl Mech 39:607–609

Hosford WH, Caddell RM (1993) Metal forming: mechanics and metallurgy (2nd edn). PTR Prentice Hall, Upper Saddle River, NJ, USA. Ch-14

Karafillis AP, Boyce MC (1993) A general anisotropic yield criterion using bounds and a transformation weighting tensor. J Mech Phys Solids 41:1859–1886

Kocks UF, Tomé CN, Wenk H-R (2000) Texture and anisotropy: preferred orientations in polycrystals and their effect on material properties. Cambridge University Press, Cambridge

Liu W, Huang J, Pang Y, Zhu K, Li S, Ma J (2023) Multi-scale modelling of evolving plastic anisotropy during Al-alloy sheet forming. Int J Mech Sci 247:108168

Neto DM, Oliveira MC, Dick RE, Alves JL, Menezes LF (2022) Non-uniform effect of the contact conditions on the earing profile in cylindrical cups of anisotropic materials. Key Eng Mater 926:1188–1194

Rice JR (1971) Inelastic constitutive relations for solids: an internal-variable theory and its application to metal plasticity. J Mech Phys Solids 19:433–455

Roters F, Diehl M, Shanthraj P, Eisenlohr P, Reuber C, Wong SL, Maiti T, Ebrahimi A, Hochrainer T, Fabritius H-O, Nikolov S, Friak M, Fujita N, Grilli N, Janssens KGF, Jia N, Kok PJJ, Ma D, Meier F, Werner E, Stricker M, Weygand D, Raabe D (2019) DAMASK: the Dusseldorf advanced material simulation kit for modeling multi-physics crystal plasticity, thermal, and damage phenomena from the single crystal up to the component scale. Comput Mater Sci 158:420–478

Simo JC, Hughes TJR (2000) Computational inelasticity. Springer-Verlag, New York

Soare SC, Yoon J-W, Cazacu O (2008) On the use of homogeneous polynomials to develop anisotropic yield functions with applications to sheet forming. Int J Plast 24:915–944

Soare SC, Barlat F (2010) Convex polynomial yield functions. J Mech Phys Solids 58:1804–1818

Soare SC, Barlat F (2011) A study of the Yld 2004 yield function and one extension in polynomial form: a new implementation algorithm, modeling range, and earing predictions for aluminum alloy sheets. Eur J Mech A/Solids 30:807–819

Soare SC (2022) A parameter identification scheme for the orthotropic Poly6 yield function satisfying the convexity condition. Eur J Mech A/Solids 92:104467

Soare SC (2023) Bezier5YS and SHYqp: a general framework for generating data and for modeling symmetric and asymmetric orthotropic yield surfaces. Eur J Mech A/Solids 97:104781

Swift HW (1939) Drawing tests for sheet metal. Proc Inst Automob Eng 34:361

Tian H, Brownell B, Baral M, Korkolis YP (2017) Earing in cup-drawing of anisotropic Al-6022-T4 sheets. Int J Mater Form 10:329–343

Tong W (2018) On the certification of positive and convex Gotoh’s fourth-order yield function. IOP Conf Ser J Phys 1063:012093

Tong W (2018) Calibration of a complete homogeneous polynomial yield function of six degrees for modeling orthotropic steel sheets. Acta Mech 229:2495–2519

Van Houtte P, Clarke AP, Saimoto S (1993) A quantitative analysis of earing during deep drawing. In: Morris JG, Westerman EJ, Morris PL (eds) Aluminum alloys for packaging. TMS, Warrendale, PA, pp 261–273

Van Houtte P, Yerra SK, Van Bael A (2009) The facet method: a hierarchical multilevel modelling scheme for anisotropic convex plastic potentials. Int J Plast 25:332–360

Varjú PP (2007) Approximation by homogeneous polynomials. Constr Approx 26:317–337

Vegter H, Boogaard AH (2006) A plane stress yield function for anisotropic sheet material by interpolation of biaxial stress states. Int J Plast 22:557–580

Yoshida F, Hamasaki H, Umeori T (2013) A user-friendly 3D yield function to describe anisotropy of steel sheets. Int J Plast 45:119–139

Younas N, Chalal H, Abed-Meraim F (2020) Finite element simulation of sheet metal forming processes using non-quadratic anisotropic plasticity models and solid-shell finite elements. Procedia Manuf 47:1416–1423

Zhang K, Holmedal B, Hopperstad OS, Dumoulin S, Gawad J, Van Bael A, Van Houtte P (2015) Multi-level modelling of mechanical anisotropy of commercial pure aluminium plate: crystal plasticity models, advanced yield functions and parameter identification. Int J Plast 66:3–30

Acknowledgements

The Max-Planck-Institut für Eisenforschung GmbH is gratefully acknowledged for providing the computational resources.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Soare, S.C., Diehl, M. Calibration and fast evaluation algorithms for homogeneous orthotropic polynomial yield functions. Comput Mech (2023). https://doi.org/10.1007/s00466-023-02408-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00466-023-02408-6