Abstract

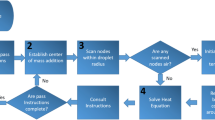

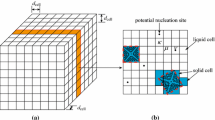

This work introduces a distributed memory machine and octree-based Finite Element (FE) framework for modeling metal Additive Manufacturing (AM) processes. In this sense, an Adaptive Mesh Refinement (AMR) is used to accurately capture the complex geometrical domain and the physical phenomena of AM processes for the part-scale analysis. AMR is used in conjunction with refinement criteria suitable for this problem: (1) a geometric criterion for refining the material deposition path, and (2) an accuracy criterion based on an a-posteriori error-indicator of the displacement field. As a consequence, the geometry and numerical solution are accurately captured whilst the number of FEs is kept controlled along the simulation. Numerical simulations involving growing domains are presented to assess the accuracy and computational efficiency of the framework with different octree-based and structured fixed mesh configurations. The overall performance of the framework is evaluated through a strong scalability analysis to track the evolution of the computational time along the simulation, where all steps composing the AM pipeline are independently analyzed. The strong scalability test consists of a discrete evolving domain with over 15 M active nodes, solved on a High-Performance Computer (HPC) using 2, 048 processors.

Similar content being viewed by others

References

Lumi web page. https://www.lumi-supercomputer.eu/lumis-full-system-architecture-revealed/. Accessed 21 Apr 2023

Thingi10k web page. https://ten-thousand-models.appspot.com/. Accessed 21 Apr 2023

Agelet de Saracibar C, Cervera M, Chiumenti M (1999) On the formulation of coupled thermoplastic problems with phase-change. Int J Plast 15(1):1–34

Agelet de Saracibar C, Cervera M, Chiumenti M (2001) On the constitutive modeling of coupled thermomechanical phase-change problems. Int J Plast 17(12):1565–1622

Ahrens J, Geveci B, Law C (2005) ParaView: an end-user tool for large data visualization, visualization handbook. Elsevier, London

Annavarapu C, Hautefeuille M, Dolbow JE (2012) A robust Nitsche’s formulation for interface problems. Comput Methods Appl Mech Eng 225–228:44–54

Antony K, Arivazhagan N, Senthilkumaran K (2014) Numerical and experimental investigations on laser melting of stainless steel 316l metal powders. J Manuf Process 16(3):345–355

Atallah NM, Canuto C, Scovazzi G (2020) Analysis of the shifted boundary method for the poisson problem in general domains

Babsuka I, Scapolla T (1987) Computational aspects of the h, p and h-p versions of the finite element method. Adv Comput Methods Partial Differ Equ 5:233–240

Babuska I, Elman H (1989) Some aspects of parallel implementation of the finite-element method on message-passing architectures. J Comput Appl Math 27:09

Babuska I, Suri M (1990) The p- and h-p versions of the finite element method, an overview. Comput Methods Appl Mech Eng 80(1):5–26

Badia S, Caicedo MA, Martín AF, Principe J (2021) A robust and scalable unfitted adaptive finite element framework for nonlinear solid mechanics. Comput Methods Appl Mech Eng 386:114093

Badia S, Martín AF, Neiva E, Verdugo F (2021) The aggregated unfitted finite element method on parallel tree-based adaptive meshes. SIAM J Sci Comput 43(3):C203–C234

Badia S, Verdugo F, Martín AF (2018) The aggregated unfitted finite element method for elliptic problems. Comput Methods Appl Mech Eng 336:533–553

Baiges J, Bayona C (2017) Refficientlib: an efficient load-rebalanced adaptive mesh refinement algorithm for high-performance computational physics meshes. SIAM J Sci Comput 39(2):65–95

Baiges J, Chiumenti M, Moreira CA, Cervera M, Codina R (2021) An adaptive finite element strategy for the numerical simulation of additive manufacturing processes. Addit Manuf 37:101650

Baiges J, Codina R, Castañar I, Castillo E (2020) A finite element reduced-order model based on adaptive mesh refinement and artificial neural networks. Int J Numer Meth Eng 121(4):588–601

Barbat G, Cervera M, Venghaus H, Chiumenti M (2022) Objectivity in quasi-brittle structural failure via adaptive formulation and mesh refinement. Theoret Appl Fract Mech 122:103646

Bathe K (2006) Finite element procedures. Prentice Hall, London

Bellet M, Boughanmi O, Fidel G (2012) A partitioned resolution for concurrent fluid flow and stress analysis during solidification: application to ingot casting. Science 33:06

Bellet M, Fachinotti V, Jaouen O, Chapelle S, Poitrault I, Lusson B (05 2003) Application of the arbitrary eulerian lagrangian finite element formulation to the thermomechanical simulation of casting processes, with focus on pipe shrinkage prediction

Benzley SE, Perry E, Merkley K, Clark B, Sjaardema G (1995) A comparison of all hexagonal and all tetrahedral finite element meshes for elastic and elasto-plastic analysis. In: In Proceedings, 4th International Meshing Roundtable, pp 179–191

Bertoluzza S, Ismail M, Maury B (01 2005) The fat boundary method: semi-discrete scheme and some numerical experiments, vol 40, pp 513–520

Bertoluzza S, Ismaïl M, Maury B (2011) Analysis of the fully discrete fat boundary method. Numer Math 118:49–77

Biswas R, Strawn RC (1998) Tetrahedral and hexahedral mesh adaptation for cfd problems. Appl Numer Math 26(1):135–151

Boman EG, Catalyurek UV, Chevalier C, Devine KD (2012) The Zoltan and Isorropia parallel toolkits for combinatorial scientific computing: partitioning, ordering, and coloring. Sci Program 20(2):129–150

Boyd S, Vandenberghe L (2004) Convex optimization. Cambridge University Press, Cambridge

Braam D (2017–2022) Cura ultimaker. https://github.com/Ultimaker/Cura

Burstedde C, Wilcox L, Ghattas O (2011) p4est: scalable algorithms for parallel adaptive mesh refinement on forests of octrees. SIAM J Sci Comput 33:1103–1133

Burstedde C, Wilcox LC, Ghattas O (2011) p4est: scalable algorithms for parallel adaptive mesh refinement on forests of octrees. SIAM J Sci Comput 33(3):1103–1133

Carraturo M, Giannelli C, Reali A, Vázquez R (2019) Suitably graded THB-spline refinement and coarsening: Towards an adaptive isogeometric analysis of additive manufacturing processes. Comput Methods Appl Mech Eng 348:02

Carraturo M, Hennig P, Alaimo G, Heindel L, Auricchio F, Kastner M, Reali A (2021) Additive manufacturing applications of phase-field-based topology optimization using adaptive isogeometric analysis. GAMM-Mitteilungen 44:08

Carraturo M, Jomo J, Kollmannsberger S, Reali A, Auricchio F, Rank E (2020) Modeling and experimental validation of an immersed thermo-mechanical part-scale analysis for laser powder bed fusion processes. Addit Manuf 36:101498

Carraturo M, Kollmannsberger S, Reali A, Auricchio F, Rank E (2021) An immersed boundary approach for residual stress evaluation in selective laser melting processes. Addit Manuf 46:102077

Carraturo M, Kollmannsberger S, Reali A, Auricchio F, Rank E (2021) An immersed boundary approach for residual stress evaluation in selective laser melting processes. Addit Manuf 46:102077

Carraturo M, Viguerie A, Reali A, Auricchio F (2022) Two-level method part-scale thermal analysis of laser powder bed fusion additive manufacturing. Eng Comput 38:1–14

Castañar I, Baiges J, Codina R, Venghaus H (2022) Topological derivative-based topology optimization of incompressible structures using mixed formulations. Comput Methods Appl Mech Eng 390:114438

Charras GT, Guldberg RE (2000) Improving the local solution accuracy of large-scale digital image-based finite element analyses. J Biomech 33(2):255–259

Cheng B, Price S, Lydon J, Cooper K, Chou K (2014) On process temperature in powder-bed electron beam additive manufacturing: model development and validation. J Manuf Sci Eng 136:061018

Chiumenti M, Cervera M, Agelet de Saracibar C, Dialami N (2013) Numerical modeling of friction stir welding processes. Comput Methods Appl Mech Eng 254:353–369

Chiumenti M, Cervera M, Dialami N, Wu B, Li J, Agelet de Saracibar C (2016) Numerical modeling of the electron beam welding and its experimental validation. Finite Elem Anal Des 121:118–133

Chiumenti M, Cervera M, Moreira CA, Barbat GB (2021) Stress, strain and dissipation accurate 3-field formulation for inelastic isochoric deformation. Finite Elem Anal Des 192:103534

Chiumenti M, Cervera M, Salmi A, Saracibar CD, Dialami N, Matsui K (2010) Finite element modeling of multi-pass welding and shaped metal deposition processes. Comput. Methods Appl. Mech. Engrg. 199(37–40):2343–2359

Chiumenti M, Lin X, Cervera M, Lei W, Zheng Y, Huang W (2017) Numerical simulation and experimental calibration of additive manufacturing by blown powder technology. Part I: thermal analysis. Rapid Protot J 23(2):448–463

Chiumenti M, Neiva E, Salsi E, Cervera M, Badia S, Moya J, Chen Z, Lee C, Davies C (2017) Numerical modelling and experimental validation in selective laser melting. Addit Manuf 18:171–185

Contuzzi N, Campanelli S, Ludovico A (2011) 3d finite element analysis in the selective laser melting process. Int J Simul Modell 10:113–121

da Silva GA, Beck AT, Sigmund O (2019) Stress-constrained topology optimization considering uniform manufacturing uncertainties. Comput Methods Appl Mech Eng 344:512–537

Dai L, Shaw L (2002) Distortion minimization of laser-processed components through control of laser scanning patterns. Rapid Protot J 8:270–276

de Prenter F, Verhoosel C, van Zwieten G, van Brummelen E (2017) Condition number analysis and preconditioning of the finite cell method. Comput Methods Appl Mech Eng 316:297–327

Denlinger ER, Gouge M, Irwin J, Michaleris P (2017) Thermomechanical model development and in situ experimental validation of the laser powder-bed fusion process. Addit Manuf 16:73–80

Denlinger ER, Heigel JC, Michaleris P (2015) Residual stress and distortion modeling of electron beam direct manufacturing Ti-6Al-4V. Proc Inst Mech Eng Part B J Eng Manuf 229(10):1803–1813

Denlinger ER, Irwin J, Michaleris P (2014) Thermomechanical modeling of additive manufacturing large parts. J Manuf Sci Eng 136(6):69

Denlinger ER, Michaleris P (2016) Effect of stress relaxation on distortion in additive manufacturing process modeling. Addit Manuf 12:51–59

Dialami N, Cervera M, Chiumenti M, de Saracibar CA (2017) Local-global strategy for the prediction of residual stresses in fsw processes. Int J Adv Manuf Technol 88(9):3099–3111

Doitrand A, Fagiano C, Irisarri F-X, Hirsekorn M (2015) Comparison between voxel and consistent meso-scale models of woven composites. Compos A Appl Sci Manuf 73:143–154

Duster A, Rank E (2001) The p-version of the finite element method compared to an adaptive h-version for the deformation theory of plasticity. Comput Methods Appl Mech Eng 190:1925–1935

de Souza Neto DRJOEA, Peric D (2008) Computational methods for plasticity: theory and applications. Wiley, London

Eberly D (2002) Dynamic collision detection using oriented bounding boxes. Geometric tools Inc, London

Fang G, El Said B, Ivanov D, Hallett SR (2016) Smoothing artificial stress concentrations in voxel-based models of textile composites. Compos A Appl Sci Manuf 80:270–284

Finkel R, Bentley J (1974) Quad trees: a data structure for retrieval on composite keys. Acta Informatica 4(1):1–9

Gear CW (1971) Numerical initial value problems in ordinary differential equations. Prentice Hall, Englewood Chiffs

Gottschalk S, Manocha D, Lin MC (2000) Collision queries using oriented bounding boxes. PhD thesis, University of North Carolina at Chapel Hill

Gouge M, Denlinger E, Irwin J, Li C, Michaleris P (2019) Experimental validation of thermo-mechanical part-scale modeling for laser powder bed fusion processes. Addit Manuf 29:100771

Guldberg R, Hollister S, Charras G (1998) The accuracy of digital image-based finite element models

Holke J (2018) Scalable algorithms for parallel tree-based adaptive mesh refinement with general element types

Hollister SJ, Riemer BA (1993) Digital-image-based finite element analysis for bone microstructure using conjugate gradient and gaussian filter techniques. In: Mathematical Methods in Medical Imaging II, volume 2035, pp 95–106. SPIE

Hughes TJR (1980) Generalization of selective integration procedures to anisotropic and nonlinear media. Int J Numer Meth Eng 15(9):1413–1418

Hughes TJR (1987) Finite element method: linear static and dynamic finite element analysis. Prentice-Hall, Englewood Cliffs

Hussein A, Hao L, Yan C, Everson R (2013) Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting. Mater Des 1980–2015(52):638–647

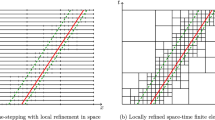

Kollmannsberger S, Kopp P (2021) On accurate time integration for temperature evolutions in additive manufacturing. GAMM-Mitteilungen 44(4):e202100019

Kollmannsberger S, Özcan A, Carraturo M, Zander N, Rank E (2018) A hierarchical computational model for moving thermal loads and phase changes with applications to selective laser melting. Comput Math Appl 75(5):1483–1497

Li C, Denlinger ER, Gouge MF, Irwin JE, Michaleris P (2019) Numerical verification of an octree mesh coarsening strategy for simulating additive manufacturing processes. Addit Manuf 30:100903

Li C, Fu C, Guo Y, Fang F (2016) A multiscale modeling approach for fast prediction of part distortion in selective laser melting. J Mater Process Technol 229:703–712

Lu X, Chiumenti M, Cervera M, Li J, Lin X, Ma L, Zhang G, Liang E (2021) Substrate design to minimize residual stresses in directed energy deposition am processes. Mater Des 202:109525

Lu X, Chiumenti M, Cervera M, Zhang G, Lin X (2022) Mitigation of residual stresses and microstructure homogenization in directed energy deposition processes. Eng Comput 5:24

Lu X, Lin X, Chiumenti M, Cervera M, Hu Y, Ji X, Ma L, Huang W (2019) In situ measurements and thermo-mechanical simulation of Ti-6Al-4V laser solid forming processes. Int J Mech Sci 153–154:119–130

Lu X, Lin X, Chiumenti M, Cervera M, Hu Y, Ji X, Ma L, Yang H, Huang W (2019) Residual stress and distortion of rectangular and S-shaped Ti-6Al-4V parts by directed energy deposition: modelling and experimental calibration. Addit Manuf 26:166–179

Lu X, Lin X, Chiumenti M, Cervera M, Li J, Ma L, Wei L, Hu Y, Huang W (2018) Finite element analysis and experimental validation of the thermomechanical behavior in laser solid forming of Ti-6Al-4V. Addit Manuf 21:30–40

Ma L, Bin H (2007) Temperature and stress analysis and simulation in fractal scanning-based laser sintering. Int J Adv Manuf Technol 34:898–903

Main A, Scovazzi G (2018) The shifted boundary method for embedded domain computations. Part I: Poisson and stokes problems. J Comput Phys 372:972–995

Matsumoto M, Shiomi M, Osakada K, Abe F (2002) Finite element analysis of single layer forming on metallic powder bed in rapid prototyping by selective laser processing. Int J Mach Tools Manuf 42(1):61–67

Maury B (2001) A fat boundary method for the poisson problem in a domain with holes. J Sci Comput 16:319–339

Meagher D (1982) Geometric modeling using octree encoding. Comput Graphics Image Process 19(2):129–147

Michaleris P (2014) Modeling metal deposition in heat transfer analyses of additive manufacturing processes. Finite Elem Anal Des 86:51–60

Moreira CA, Barbat GB, Cervera M, Chiumenti M (2022) Accurate thermal-induced structural failure analysis under incompressible conditions. Eng Struct 261:114213

Moreira CA, Caicedo MA, Cervera M, Chiumenti M, Baiges J (2022) A multi-criteria h-adaptive finite-element framework for industrial part-scale thermal analysis in additive manufacturing processes. Eng Comput 5:96

Neiva E, Badia S (2021) Robust and scalable h-adaptive aggregated unfitted finite elements for interface elliptic problems. Comput Methods Appl Mech Eng 380:113769

Neiva E, Badia S, Martín AF, Chiumenti M (2019) A scalable parallel finite element framework for growing geometries. application to metal additive manufacturing. Int J Numer Meth Eng 119(11):1098–1125

Neiva E, Chiumenti M, Cervera M, Salsi E, Piscopo G, Badia S, Martín AF, Chen Z, Lee C, Davies C (2020) Numerical modelling of heat transfer and experimental validation in powder-bed fusion with the virtual domain approximation. Finite Elem Anal Des 168:103343

Ozcan A, Kollmannsberger S, Jomo J, Rank E (2019) Residual stresses in metal deposition modeling: Discretizations of higher order. Comput Math Appl 78(7):2247–2266

Pal D, Patil N, Zeng K, Teng C, Xu S, Sublette T, Stucker B (2014) Enhancing simulations of additive manufacturing processes using spatiotemporal multiscaling

Patil N, Ganeriwala R, Solberg JM, Hodge NE, Ferencz RM (2021) Benchmark multi-layer simulations for residual stresses and deformation in small additively manufactured metal parts. Addit Manuf 45:102015

Patil RB, Yadava V (2007) Finite element analysis of temperature distribution in single metallic powder layer during metal laser sintering. Int J Mach Tools Manuf 47(7):1069–1080

Ren J, Liu J, Yin J (2010) Simulation of transient temperature field in the selective laser sintering process of w/ni powder mixture. In: International Conference on Computer and Computing Technologies in Agriculture, pp 494 – 503

Rivet I, Dialami N, Cervera M, Chiumenti M, Valverde Q (2023) Mechanical analysis and optimized performance of g-code driven material extrusion components. Addit Manuf 61:103348

Saloustros S, Cervera M, Kim S, Chiumenti M (2021) Accurate and locking-free analysis of beams, plates and shells using solid elements. Comput Mech 67:03

Steven Chapra RC (2014) Numerical methods for engineers, 7th edn. McGraw-Hill, New York

Svärd H (2015) Interior value extrapolation: a new method for stress evaluation during topology optimization. Struct Multidiscip Optim 51:613–629

Venghaus H, Chiumenti M, Baiges J, Juhre D, Castañar I (2023) An accurate approach to simulate friction stir welding processes using adaptive formulation refinement. Finite Elem Anal Des 224:103986

Verdugo F, Martín AF, Badia S (2019) Distributed-memory parallelization of the aggregated unfitted finite element method. Comput Methods Appl Mech Eng 357:112583

Viguerie A, Bertoluzza S, Auricchio F (2020) A fat boundary-type method for localized nonhomogeneous material problems. Comput Methods Appl Mech Eng 364:112983

Viguerie A, Carraturo M, Reali A, Auricchio F (2022) A spatiotemporal two-level method for high-fidelity thermal analysis of laser powder bed fusion. Finite Elem Anal Des 210:103815

Zhang Y, Chen Q, Guillemot G, Gandin CA, Bellet M (2018) Numerical modelling of fluid and solid thermomechanics in additive manufacturing by powder-bed fusion: continuum and level set formulation applied to track- and part-scale simulations. Comptes Rendus Mecanique 6:96

Zhang Y, Guillemot G, Bernacki M, Bellet M (2018) Macroscopic thermal finite element modeling of additive metal manufacturing by selective laser melting process. Comput Methods Appl Mech Eng 331:514–535

Zienkiewicz O, Taylor R (2000) The finite element method, vol 1, 5th edn. Butterworth-Heinemann, London

Zienkiewicz OC, Zhu JZ (1987) A simple error estimator and adaptive procedure for practical engineerng analysis. Int J Numer Meth Eng 24(2):337–357

Zienkiewicz OC, Zhu JZ (1992) The superconvergent patch recovery and a posteriori error estimates. part 1: the recovery technique. Int J Numer Meth Eng 33(7):1331–1364

Zienkiewicz OC, Zhu JZ (1992) The superconvergent patch recovery and a posteriori error estimates. Part 2: error estimates and adaptivity. Int J Numer Meth Eng 33(7):1365–1382

Zienkiewicz OC, Zhu JZ, Gong NG (1989) Effective and practical h-p-version adaptive analysis procedures for the finite element method. Int J Numer Meth Eng 28(4):879–891

Acknowledgements

The financial support from the Spanish Ministry of Economy and Competitiveness, through the Severo Ochoa Programme for Centres of Excellence in R &D (CEX2018-000797-S), is gratefully acknowledged. This work has been supported by the European Union’s horizon 2020 research and innovation programme (H2020-DT-2019-1 No. 872570) under the KYKLOS 4.0 Project (An Advanced Circular and Agile Manufacturing Ecosystem based on rapid reconfigurable manufacturing process and individualized consumer preferences) and by the Ministry of Science, Innovation and Universities (MCIU) via: the PriMuS project (Printing pattern based and MultiScale enhanced performance analysis of advanced Additive Manufacturing components, ref. num. PID2020-115575RB-I00). The strong-scaling simulations were done on the LUMI supercomputer at Kajaani, Finland. The authors acknowledge PRACE for granting access to the resources of LUMI via Project EHPC-DEV-2022D12-013. The support of the Red Española de Supercomputación (RES) and the European PRACE network is acknowledged. The authors gratefully acknowledge ArcelorMittal for their valuable contributions and support in this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Moreira, C.A., Caicedo, M.A., Cervera, M. et al. An accurate, adaptive and scalable parallel finite element framework for the part-scale thermo-mechanical analysis in metal additive manufacturing processes. Comput Mech 73, 983–1011 (2024). https://doi.org/10.1007/s00466-023-02397-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-023-02397-6