Abstract

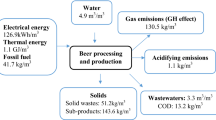

A biofertilizer of Azospirillum brasilense was produced in solid-state culture (SSC) from laboratory to pilot scale. Similar operation conditions (continuous aeration and mild intermittent mixing) and two dimensionless numbers with similar L/D ratio and a similar working volume were applied to reach a scale-up factor of 75. An innovative bioreactor with rotating helical ribbons (15 kg wet matter) was used at pilot scale. A mathematical model was proposed and validated to evaluate the respirometry trends at laboratory and pilot scale exhibiting similar behavior. The cell viability was (1.3 ± 0.4) × 109 and (1.3 ± 0.3) × 109 colony-forming units per gram of initial dry mass at laboratory and pilot scale, at 36 and 43 h, respectively. A. brasilense maintains its viability twelve months of storage at 4 and 30 °C. This is the first report of A. brasilense being cultivated in SSC under controlled conditions. SSC processes involving unicellular microorganisms with tolerance to agitation are a promising technology to produce biofertilizers.

Graphic abstract

Similar content being viewed by others

Availability of data and material

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

FiBL and IFOAM (2020) Organics international (2020): The World of Organic Agriculture.

Willer H, Yussefi M (2007) Organic farming worldwide 2007: overview and main statistics. In: Willer H, Yussefi M (eds) The world of organic agriculture. Statistics and emerging trends 2007, pp 9–16.

Reganold JP, Wachter JM (2016) Organic agriculture in the twenty-first century. Nat Plants 2:15221. https://doi.org/10.1038/nplants.2015.221

Malusá E, Vassilev N (2014) A contribution to set a legal framework for biofertilisers. Appl Microbiol Biotechnol 98:6599–6607. https://doi.org/10.1007/s00253-014-5828-y

Vessey JK (2003) Plant growth promoting rhizobacteria as biofertilizers. In: Plant and soil. pp 571–586

Ritika B, Utpal D (2014) Biofertilizer, a way towards organic agriculture: a review. African J Microbiol Res 8:2332–2343. https://doi.org/10.5897/ajmr2013.6374

Bashan Y, de Bashan LE, Prabhu SR, Hernandez JP (2014) Advances in plant growth-promoting bacterial inoculant technology: formulations and practical perspectives (1998–2013). Plant Soil 378:1–33. https://doi.org/10.1007/s11104-013-1956-x

Amalraj ELD, Venkateswarlu B, Desai S, Kumar GP, Ahmed SKM, Meenakshi T, Sultana U, Pinisetty S, Narasu ML (2013) Effect of polymeric additives, adjuvants, surfactants on survival, stability and plant growth promoting ability of liquid bioinoculant. J Plant Physiol Pathol.https://doi.org/10.1109/CDC.2016.7798382

Kumaresan G, Reetha D (2011) Survival of Azospirillum brasilense in liquid formulation amended with different chemical additives. J Phytol 3:48–51

Trujillo-Roldán MA, Valdez-Cruz NA, Gonzalez-Monterrubio CF, Acevedo-Sánchez EV, Martínez-Salinas C, García-Cabrera RI, Gamboa-Suasnavart RA, Marín-Palacio LD, Villegas J, Blancas-Cabrera A (2013) Scale-up from shake flasks to pilot-scale production of the plant growth-promoting bacterium Azospirillum brasilense for preparing a liquid inoculant formulation. Appl Microbiol Biotechnol 97:9665–9674. https://doi.org/10.1007/s00253-013-5199-9

Albareda M, Rodríguez-Navarro DN, Camacho M, Temprano FJ (2008) Alternatives to peat as a carrier for rhizobia inoculants: solid and liquid formulations. Soil Biol Biochem 40:2771–2779. https://doi.org/10.1016/j.soilbio.2008.07.021

Sangeetha D, Stella D (2012) Survival of plant growth promoting bacterial inoculants in different carrier materials. Int J Pharm Biol Arch 3:170–178

Pandey A (2003) Solid-state fermentation. Biochem Eng J 13:81–84. https://doi.org/10.1016/S1369-703X(02)00121-3

Ashok A, Doriya K, Rao DRM, Kumar DS (2017) Design of solid-state bioreactor for industrial applications: an overview to conventional bioreactors. Biocatal Agric Biotechnol 9:11–18. https://doi.org/10.1016/j.bcab.2016.10.014

Costa JAV, Treichel H, Kumar V, Pandey A (2018) Advances in solid-state fermentation. In: Current Developments in Biotechnology and Bioengineering. Elsevier, pp 1–17

Weinberg ZG, Ashbell G (2003) Eng Aspect Ensil 13:181–188. https://doi.org/10.1016/S1369-703X(02)00130-4

Tamang JP, Watanabe K, Holzapfel WH (2016) Review: diversity of microorganisms in global fermented foods and beverages. Front Microbiol. https://doi.org/10.3389/fmicb.2016.00377

Kádár Z, Szengyel Z, Réczey K (2004) Simultaneous saccharification and fermentation (SSF) of industrial wastes for the production of ethanol. Ind Crops Prod 20:103–110. https://doi.org/10.1016/j.indcrop.2003.12.015

Yazid NA, Barrena R, Komilis D, Sánchez A (2017) Solid-state fermentation as a novel paradigm for organic waste valorization: a review. Sustain (Switz). https://doi.org/10.3390/su9020224

Lima-Pérez J, López-Pérez M, Viniegra-González G, Loera O (2019) Solid-state fermentation of Bacillus thuringiensis var kurstaki HD-73 maintains higher biomass and spore yields as compared to submerged fermentation using the same media. Bioprocess Biosyst Eng 42:1527–1535. https://doi.org/10.1007/s00449-019-02150-5

Schwan RF, Wheals AE (2004) The microbiology of cocoa fermentation and its role in chocolate quality. Crit Rev Food Sci Nutr 44:205–221. https://doi.org/10.1080/10408690490464104

Flores K, Hadeler KP (2010) The random walk of Azospirillum brasilense. J Biol Dyn 4:71–85. https://doi.org/10.1080/17513750902773914

Givaudan A, Effosse A, Faure D et al (1993) Polyphenol oxidase in Azospirillum lipoferum isolated from rice rhizosphere: evidence for laccase activity in non-motile strains of Azospirillum lipoferum. FEMS Microbiol Lett 108:205–210. https://doi.org/10.1111/j.1574-6968.1993.tb06100.x

Diamantidis G, Effosse A, Potier P, Bally R (2000) Purification and characterization of the first bacterial laccase in the rhizospheric bacterium Azospirillum lipoferum. Soil Biol Biochem 32:919–927. https://doi.org/10.1016/S0038-0717(99)00221-7

Zayed MS (2018) Enhancement the feeding value of rice straw as animal fodder through microbial inoculants and physical treatments. Int J Recycl Org Waste Agric 7:117–124. https://doi.org/10.1007/s40093-018-0197-7

Bashan Y, Levanony H, Whitmoyer RE (1991) Root surface colonization of non-cereal crop plants by pleomorphic Azospirillum brasilense cd. J Gen Microbiol 137:187–196. https://doi.org/10.1099/00221287-137-1-187

González-Blanco P, Saucedo-Castañeda G, Viniegra-González G (1990) Protein enrichment of sugar cane by-products using solid-state cultures of Aspergillus terreus. J Ferment Bioeng 70:351–354. https://doi.org/10.1016/0922-338X(90)90150-U

Saucedo-Castaneda G, Lonsane BK, Krishnaiah MM et al (1992) Maintenance of heat and water balances as a scale-up criterion for the production of ethanol by Schwanniomyces castellii in a solid-state fermentation system. Process Biochem 27:97–107. https://doi.org/10.1016/0032-9592(92)80016-V

Pitol LO, Biz A, Mallmann E et al (2016) Production of pectinases by solid-state fermentation in a pilot-scale packed-bed bioreactor. Chem Eng J 283:1009–1018. https://doi.org/10.1016/j.cej.2015.08.046

Saucedo-Castañeda G, Gutiérrez-Rojas M, Bacquet G et al (1990) Heat transfer simulation in solid substrate fermentation. Biotechnol Bioeng 35:802–808. https://doi.org/10.1002/bit.260350808

Mitchell DA, Krieger N, Berovič M (2006) Solid-state fermentation bioreactors: fundamentals of design and operation

Nava I, Gaime-Perraud I, Huerta-Ochoa S et al (2006) Penicillium commune spore production in solid-state fermentation of coffee pulp at laboratory scale and in a helical ribbons rotating reactor. J Chem Technol Biotechnol 81:1760–1766. https://doi.org/10.1002/jctb.1599

Martínez-Valdez FJ, Martínez-Ramírez C, Martínez-Montiel L, Favela-Torres E, Soto-Cruz NO, Ramírez-Vives F, Saucedo-Castañeda G (2015) Rapid mineralisation of the organic fraction of municipal solid waste. Biores Technol 180:112–118. https://doi.org/10.1016/j.biortech.2014.12.083

Cassán FD, Okon Y, Creus CM (2015) Handbook for Azospirillum: technical issues and protocols. 1–514. https://doi.org/10.1007/978-3-319-06542-7

Saucedo-Castañeda G, Trejo-Hernández MR, Lonsane BK et al (1994) On-line automated monitoring and control systems for CO2 and O2 in aerobic and anaerobic solid-state fermentations. Process Biochem 29:13–24. https://doi.org/10.1016/0032-9592(94)80054-5

Soto-Cruz O, Favela-Torres E, Saucedo-Castañeda G (2002) Modelling of growth, lactate consumption, and volatile fatty acid complex media. Springs 193–200

Amaral PFF, Ferreira TF, Fontes GC, Coelho MAZ (2009) Glycerol valorization: new biotechnological routes. Food Bioprod Process 87:179–186. https://doi.org/10.1016/j.fbp.2009.03.008

Mouginot C, Kawamura R, Matulich KL, Berlemont R, Allison SD, Amend AS, Martiny AC (2014) Elemental stoichiometry of Fungi and Bacteria strains from grassland leaf litter. Soil Biol Biochem 76:278–285. https://doi.org/10.1016/j.soilbio.2014.05.011

Burdman S, Jurkevitch E, Schwartsburd B, Hampel M, Okon Y (1998) Aggregation in Azospirillum brasilense: Effects of chemical and physical factors and involvement of extracellular components. Microbiology 144:1989–1999. https://doi.org/10.1099/00221287-144-7-1989

Itzigsohn R, Yarden O, Okon Y (1995) Polyhydroxyalkanoate analysis in Azospirillum brasilense. Can J Microbiol 41:73–76. https://doi.org/10.1139/m95-171

Bashan Y, Trejo A, de-Bashan LE, (2011) Development of two culture media for mass cultivation of Azospirillum spp. and for production of inoculants to enhance plant growth. Biol Fertil Soils 47:963–969. https://doi.org/10.1007/s00374-011-0555-3

Soccol CR, da Costa ESF, Letti LAJ, Karp SG, Woiciechowski AL, Vandenberghe LP (2017) Recent developments and innovations in solid state fermentation. Biotechnol Res Innov 1:52–71. https://doi.org/10.1016/j.biori.2017.01.002

Zhao ZM, Xi JT, Xu JF et al (2019) Enhancement of Bacillus subtilis growth and sporulation by two-stage solid-state fermentation strategy. Processes. https://doi.org/10.3390/pr7100644

Graham-Weiss L, Bennett ML, Paau AS (1987) Production of bacterial inoculants by direct fermentation on nutrient-supplemented vermiculite. Appl Environ Microbiol 53:2138–2141

Mulyukin AL, Suzina NE, Pogorelova AYu, Antonyuk LP, Duda VI, El-Registan GI (2009) Diverse morphological types of dormant cells and conditions for their formation in Azospirillum brasilense. Microbiology 78:33–41. https://doi.org/10.1134/S0026261709010056

Lopez-Ramirez N, Volke-Sepulveda T, Gaime-Perraud I, Saucedo-Castañeda G, Favela-Torres E (2018) Effect of stirring on growth and cellulolytic enzymes production by Trichoderma harzianum in a novel bench-scale solid-state fermentation bioreactor. Biores Technol 265:291–298. https://doi.org/10.1016/j.biortech.2018.06.015

Nishio N, Tai K, Nagai S (1979) Hydrolase production by Aspergillusniger in solid-state cultivation. Eur J Appl Microbiol Biotechnol 8:263–270. https://doi.org/10.1007/BF00508790

Narahara H, Koyama Y,Yoshida T, Pichangkura S, Ueda R, Taguchi HJ (1982) Growth and enzyme production in a solid-state culture of Aspergillus oryzae. J Ferment Technol 311–319

Acknowledgments

Candida Martinez-Ramirez is grateful to Mexican Council of Science and Technology (CONACyT), Mexico, for a PhD scholarship (265657). Many thanks to Dr. José Sepúlveda and Dr. Cristina Acosta-García for your support in SEM observations. Authors thank the financial support of CONACYT and Rubén Saucedo-Castañeda (RSC) from PIASSA, Culiacán, Sin., México. (225171). This work is dedicated to the memory of RSC.

Funding

Candida Martinez-Ramirez is grateful to Mexican Council of Science and Technology (CONACyT), Mexico, for a PhD scholarship (project 265657). Authors thank the financial support of CONACYT and Rubén Saucedo-Castañeda (RSC) from PIASSA, Culiacán, Sin., México (project 225171).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and experimental design. Material preparation, data collection and analysis of data were performed by CM-R, RE-C, RF-C, JAM-R, GR-S, and GS-C.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethics approval

Not applicable.

Consent to participate

All the authors give their consent to participate in this manuscript.

Consent for publication

All the authors give their consent to publication in this paper.

Code availability

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Martínez-Ramírez, C., Esquivel-Cote, R., Ferrera-Cerrato, R. et al. Solid-state culture of Azospirillum brasilense: a reliable technology for biofertilizer production from laboratory to pilot scale. Bioprocess Biosyst Eng 44, 1525–1538 (2021). https://doi.org/10.1007/s00449-021-02537-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-021-02537-3