Abstract

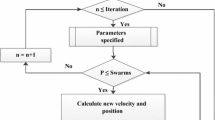

A hybrid neural model (HNM) and particle swarm optimization (PSO) was used to optimize ethanol production by a flocculating yeast, grown on cashew apple juice. HNM was obtained by combining artificial neural network (ANN), which predicted reaction specific rates, to mass balance equations for substrate (S), product and biomass (X) concentration, being an alternative method for predicting the behavior of complex systems. ANNs training was conducted using an experimental set of data of X and S, temperature and stirring speed. The HNM was statistically validated against a new dataset, being capable of representing the system behavior. The model was optimized based on a multiobjective function relating efficiency and productivity by applying the PSO. Optimal estimated conditions were: S0 = 127 g L−1, X0 = 5.8 g L−1, 35 °C and 111 rpm. In this condition, an efficiency of 91.5% with a productivity of 8.0 g L−1 h−1 was obtained at approximately 7 h of fermentation.

Similar content being viewed by others

Abbreviations

- A1 :

-

Initial value of horizontal asymptote

- A2 :

-

Final value of horizontal asymptote

- ANN:

-

Artificial neural network

- dx:

-

Model increment

- Ftab :

-

Tabled value for the Fisher Test F

- HNM:

-

Hybrid neural model

- n:

-

Number of samples

- nv :

-

Number of variables estimated

- N:

-

Stirring speed (rpm)

- p:

-

Number of model parameters

- P:

-

Product concentration (g L−1)

- Pf :

-

Final product concentration (g L−1)

- PSO:

-

Particle Swarm Optimization

- RSD:

-

Residual standard deviation (%)

- S:

-

Substrate concentration (g L−1)

- S0 :

-

Initial substrate concentration (g L−1)

- Sf :

-

Final substrate concentration (g L−1)

- T:

-

Time (h)

- tf :

-

Final time (h)

- x:

-

Model variable

- x0 :

-

Average value between horizontal asymptotes

- X:

-

Cell concentration (g L−1)

- X0 :

-

Initial cell concentration (g L−1)

- ε:

-

Error (%)

- μS :

-

Specific substrate consumption rate (gsubs.g −1cell .h−1)

- μP :

-

Specific product production rate (gproduct.g −1cell .h−1)

- μX :

-

Specific growth rate of cells (h−1)

- cal:

-

Calculated

- exp:

-

Experimental

- min:

-

Minimum

- max:

-

Maximum

- n:

-

Normalized

References

Anderson ST (2012) The demand for ethanol as a gasoline substitute. J Environ Econ Manage 63(2):151–168. https://doi.org/10.1016/j.jeem.2011.08.002

(IEA), I.E. A. (2015) Medium-term renewable energy market report. OECD/IEA, Paris

International Energy Agency (2017) Renewables 2017: analysis and forecasts to 2022—executive summary. J Qual Participat. https://doi.org/10.1073/pnas.0603395103

Neelakandan T, Usharani G (2009) Optimization and production of bioethanol from cashew Apple juice using immobilized yeast cells by Saccharomyces cerevisiae. Am Eur J Sci Res 4:85–88

Karuppaya M, Sasikumar E, Viruthagiri T, Vijayagopal V (2010) Optimization of process variables using response surface methodology (RMS) for ethanol production from cashew apple juice by Saccharomyces cerevisiae. Asian J Food Agro Ind 3:462–473

Pinheiro ÁDT, da Silva Pereira A, Barros EM, Antonini SRC, Cartaxo SJM, Rocha MVP, Gonçalves LRB (2017) Mathematical modeling of the ethanol fermentation of cashew apple juice by a flocculent yeast: the effect of initial substrate concentration and temperature. Bioprocess Biosyst Eng 40(8):1221–1235. https://doi.org/10.1007/s00449-017-1782-2

Pereira AD, Pinheiro ÁD, Rocha MV, Gonçalves LR, Cartaxo SJ (2019) A new approach to model the influence of stirring intensity on ethanol production by a flocculant yeast grown on cashew apple juice. Canad J Chem Eng 97:1253–1262. https://doi.org/10.1002/cjce.23419

Pinheiro ADT, Rocha MVP, Macedo GR, Gonçalves LRB (2008) Evaluation of cashew apple juice for the production of fuel ethanol. Appl Biochem Biotechnol 148(1–3):227–234. https://doi.org/10.1007/s12010-007-8118-7

Marques WL, Raghavendran V, Ugarte B (2015) Sucrose and Saccharomyces cerevisiae: a relationship most sweet. FEMS Yeast Res. https://doi.org/10.1093/femsyr/fov107

Rich JO, Anderson AM, Leathers TD, Bischoff KM, Liu S, Skory CD (2020) Microbial contamination of commercial corn-based fuel ethanol fermentations. Bioresource Technol Rep 11(April):100433. https://doi.org/10.1016/j.biteb.2020.100433

Ruchala J, Kurylenko OO, Dmytruk KV, Sibirny AA (2020) Construction of advanced producers of first- and second-generation ethanol in Saccharomyces cerevisiae and selected species of non-conventional yeasts (Scheffersomyces stipitis, Ogataea polymorpha). J Ind Microbiol Biotechnol 47(1):109–132. https://doi.org/10.1007/s10295-019-02242-x

Gong C, Cao N, Du J, Tsao G (1999) Ethanol production from renewable resources. Adv Biochem Eng Biotechnol 65:207–242

Lei J, Zhao X, Ge X, Bai F (1998) Ethanol tolerance and the variation of plasma membrane composition of yeast floc populations with different size distribution. J Biotechnol 2:35–43

Ortiz-Muñiz B, Carvajal-Zarrabal O, Torrestiana-Sanchez B, Aguilar-Uscanga MG (2010) Kinetic study on ethanol production using Saccharomyces cerevisiae ITV-01 yeast isolated from sugar canemolasses. J Chem Technol Biotechnol 85(10):1361–1367. https://doi.org/10.1002/jctb.2441

Domingues L, Vicente AA, Lima N, Teixeira JA (2000) Applications of yeast flocculation in biotechnological processes. Biotechnol Bioprocess Eng 5(4):288–305. https://doi.org/10.1007/BF02942185

Volesky B, Votruba J (1992) Modeling and optimization of fermentation processes. Elsevier, Boca Raton

Saraceno A, Curcio S, Calabrò V, Iorio G (2010) A hybrid neural approach to model batch fermentation of “ricotta cheese whey” to ethanol. Comput Chem Eng 34:1590–1596

Feyo de Azevedo S, Dahm B, Oliveira FR (1997) Hybrid modelling of biochemical processes: a comparison with the conventional approach. Comput Chem Eng 21:751–756

Thompson ML, Kramer MA (1994) Modeling chemical processes using prior knowledge and neural networks. AIChE J 40(8):1328–1340. https://doi.org/10.1002/aic.690400806

Costa A, Henrique ASW, Alves T, Filho R, Lima EL (1999) A hybrid neural model for the optimization of fed-batch fermentations. Braz J Chem Eng. https://doi.org/10.1590/S0104-66321999000100006

Silva RG, Cruz AJG, Hokka CO, Giordano RLC, Giordano RC (2000) A hybrid feedforward neural network model for the cephalosporin C production process. Braz J Chem Eng 17:587–598

Sivapathasekaran C, Mukherjee S, Ray A, Gupta A, Sen R (2010) Artificial neural network modeling and genetic algorithm based medium optimization for the improved production of marine biosurfactant. Bioresource Technol 101(8):2884–2887. https://doi.org/10.1016/j.biortech.2009.09.093

Dhanarajan G, Mandal M, Sen R (2014) A combined artificial neural network modeling-particle swarm optimization strategy for improved production of marine bacterial lipopeptide from food waste. Biochem Eng J 84:59–65. https://doi.org/10.1016/j.bej.2014.01.002

Bhattacharya S, Dineshkumar R, Dhanarajan G, Sen R, Mishra S (2017) Improvement of ε-polylysine production by marine bacterium Bacillus licheniformis using artificial neural network modeling and particle swarm optimization technique. Biochem Eng J 126:8–15. https://doi.org/10.1016/j.bej.2017.06.020

Huang J, Mei L-H, Xia J (2006) Application of artificial neural network coupling particle swarm optimization algorithm to biocatalytic production of GABA. Biotechnol Bioeng 96(5):924–931. https://doi.org/10.1002/bit

Cockshott AR, Sullivan GR (2001) Improving the fermentation medium for Echinocandin B production part II: particle swarm optimization. Process Biochem 36(7):661–669. https://doi.org/10.1016/S0032-9592(00)00261-2

Serapião ABS (2009) PID Tuning By Swarm Optimization Strategies. In Proceedings of the 8th Brazilian Conference on Dynamics. Bauru-SP

Dineshkumar R, Dhanarajan G, Dash SK, Sen R (2015) An advanced hybrid medium optimization strategy for the enhanced productivity of lutein in Chlorella minutissima. Algal Res 7:24–32. https://doi.org/10.1016/j.algal.2014.11.010

Pinheiro ÁD, Barros EM, Rocha LA, da Rocha Ponte VM, de Macedo AC, Rocha MV, Gonçalves LR (2020) Optimization and scale-up of ethanol production by a flocculent yeast using cashew apple juice as feedstock. Braz J Chem Eng. https://doi.org/10.1007/s43153-020-00068-0

Wisselink HW, Toirkens MJ, Berriel MDRF, Winkler AA, Van Dijken JP, Pronk JT, Van Maris AJA (2007) Engineering of Saccharomyces cerevisiae for efficient anaerobic alcoholic fermentation of L-arabinose. Appl Environ Microbiol 73(15):4881–4891. https://doi.org/10.1128/AEM.00177-07

Cleran Y, Thibault J, Cheruy A, Corrieu G (1991) Comparison of prediction performances between models obtained by the group method of data handling and neural networks for the alcoholic fermentation rate in enology. J Ferment Bioeng 71(5):356–362. https://doi.org/10.1016/0922-338X(91)90350-P

Salehi M, Mohammadpour A, Mohammadi M, Aminghafari M (2018) A modified F-test for hypothesis testing in large-scale data. J Biopharm Stat 28(6):1078–1089. https://doi.org/10.1080/10543406.2018.1436557

Jiao B, Lian Z, Gu X (2008) A novel particle swarm optimization algorithm for permutation flow-shop scheduling to minimize makespan. Chaos Sol Fract. https://doi.org/10.1016/j.chaos.2006.05.082

Balat M, Balat H (2009) Recent trends in global production and utilization of bio-ethanol fuel. Appl Energy 86(11):2273–2282. https://doi.org/10.1016/j.apenergy.2009.03.015

Acknowledgements

The authors would like to thank CAPES, CNPq and FUNCAP (from Brazil) for the financial support that made this work possible. The authors also thank Professor Sandra Regina Ceccato Antonini for the yeast Saccharomyces cerevisiae CCA008 and Embrapa Agroindustria Tropical (Ceará, Brazil) for the Cashew Apple Juice.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

da Silva Pereira, A., Pinheiro, Á.D.T., Rocha, M.V.P. et al. Hybrid neural network modeling and particle swarm optimization for improved ethanol production from cashew apple juice. Bioprocess Biosyst Eng 44, 329–342 (2021). https://doi.org/10.1007/s00449-020-02445-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-020-02445-y