Abstract

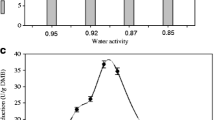

Submerged fermentation (SmF) and solid-state fermentation (SSF) of Aspergillus japonicus PJ01 for multi-enzyme complexes (MEC) production were comparatively studied. The results showed that orange peel and wheat bran were the best substrates for MEC production in SmF and SSF, respectively. After 72 h of cultivation under SmF, the maximal pectinase, CMCase, and xylanase activities reached 2610, 85, and 335 U/gds (units/gram dry substrate), respectively; while after 72 h of cultivation under SSF, these three enzymes’ activities reached 966, 58, and 1004 U/gds, respectively. Effects of ultrasound on extraction of crude enzymes from SSF medium were determined, the maximal activities of pectinase, CMCase, and xylanase increased to 1.20, 1.48, and 1.30-fold, respectively. Apparent different mycelia growths of SSF and SmF were observed by scanning electron microscopy; and different isoforms of the crude enzyme extracts from SSF and SmF were presented by zymogram analysis.

Similar content being viewed by others

References

Brink J, Vries R (2011) Fungal enzyme sets for plant polysaccharide degradation. Appl Microbiol Biotechnol 91:1477–1492

Mamma D, Kourtoglou E, Christakopoulos P (2008) Fungal multienzyme production on industrial by-products of the citrus-processing industry. Bioresour Technol 99:2373–2383

Rodríguez-Fernández DE, Rodríguez-León JA, de Carvalho JC, Sturm W, Soccol CR (2011) The behavior of kinetic parameters in production of pectinase and xylanase by solid-state fermentation. Bioresour Technol 102:10657–10662

Delabona PdS, Pirota RDPB, Codima CA, Tremacoldi CR, Rodrigues A, Farinas CS (2012) Using Amazon forest fungi and agricultural residues as a strategy to produce cellulolytic enzymes. Biomass Bioenerg 37:243–250

van Dyk JS, Sakka M, Sakka K, Pletschke BI (2010) Characterisation of the multi-enzyme complex xylanase activity from Bacillus licheniformis SVD1. Enzyme Microb Technol 47:174–177

Jatinder K, Chadha B, Saini H (2006) Optimization of culture conditions for production of cellulases and xylanases by Scytalidium thermophilum using response surface methodology. World J Microbiol Biotechnol 22:169–176

Sukumaran RK, Singhania RR, Mathew GM, Pandey A (2009) Cellulase production using biomass feed stock and its application in lignocellulose saccharification for bio-ethanol production. Renew Energy 34:421–424

Rezazadeh Bari M, Alizadeh M, Farbeh F (2010) Optimizing endopectinase production from date pomace by Aspergillus niger PC5 using response surface methodology. Food Bioprod Process 88:67–72

Gonçalves D, Teixeira JA, Bazzolli DS, de Queiroz M, de Araújo E (2012) Use of response surface methodology to optimize production of pectinases by recombinant Penicillium griseoroseum T20. Biocatal Agric Biotechnol 1:140–146

Pandey A, Soccol CR, Nigam P, Soccol VT (2000) Biotechnological potential of agro-industrial residues. I: sugarcane bagasse. Bioresour Technol 74:69–80

Hölker U, Lenz J (2005) Solid-state fermentation—are there any biotechnological advantages? Curr Opi Microbiol 8:301–306

Saqib AAN, Hassan M, Khan NF, Baig S (2010) Thermostability of crude endoglucanase from Aspergillus fumigatus grown under solid state fermentation (SSF) and submerged fermentation (SmF). Process Biochem 45:641–646

Kar S, Gauri SS, Das A, Jana A, Maity C, Mandal A, Mohapatra PKD, Pati BR, Mondal KC (2013) Process optimization of xylanase production using cheap solid substrate by Trichoderma reesei SAF3 and study on the alteration of behavioral properties of enzyme obtained from SSF and SmF. Bioprocess Biosyst Eng 36:57–68

Gamarra NN, Villena GK, Gutiérrez-Correa M (2010) Cellulase production by Aspergillus niger in biofilm, solid-state, and submerged fermentations. Appl Microbiol Biotechnol 87:545–551

Kumar S, Sharma H, Sarkar B (2011) Effect of substrate and fermentation conditions on pectinase and cellulase production by Aspergillus niger NCIM 548 in submerged (SmF) and solid state fermentation (SSF). Food Sci Biotechnol 20:1289–1298

Bizukojc M, Ledakowicz S (2010) The morphological and physiological evolution of Aspergillus terreus mycelium in the submerged culture and its relation to the formation of secondary metabolites. World J Microbiol Biotechnol 26:41–54

Wucherpfennig T, Hestler T, Krull R (2011) Morphology engineering-Osmolality and its effect on Aspergillus niger morphology and productivity. Microb Cell Fact 10:58

Pal A, Khanum F (2010) Production and extraction optimization of xylanase from Aspergillus niger DFR-5 through solid-state-fermentation. Bioresour Technol 101:7563–7569

Chen H-Q, Chen X-M, Chen T-X, Xu X-M, Jin Z-Y (2011) Extraction optimization of inulinase obtained by solid state fermentation of Aspergillus ficuum JNSP5-06. Carbohydr Polym 85:446–451

Szabo OE, Csiszar E, Koczka B, Kiss K (2015) Ultrasonically assisted single stage and multiple extraction of enzymes produced by Aspergillus oryzae on a lignocellulosic substrate with solid-state fermentation. Biomass Bioenerg 75:161–169

Subhedar PB, Gogate PR (2014) Enhancing the activity of cellulase enzyme using ultrasonic irradiations. J Mol Catal B Enzym 101:108–114

Szabó OE, Csiszár E (2013) The effect of low-frequency ultrasound on the activity and efficiency of a commercial cellulase enzyme. Carbohydr Polym 98:1483–1489

Wang F, Ma A-Z, Guo C, Zhuang G-Q, Liu C-Z (2013) Ultrasound-intensified laccase production from Trametes versicolor. Ultrason Sonochem 20:118–124

Avhad DN, Rathod VK (2014) Ultrasound stimulated production of a fibrinolytic enzyme. Ultrason Sonochem 21:182–188

Szabo OE, Csiszar E, Toth K, Szakacs G, Koczka B (2015) Ultrasound-assisted extraction and characterization of hydrolytic and oxidative enzymes produced by solid state fermentation. Ultrason Sonochem 22:249–256

Teather RM, Wood PJ (1982) Use of Congo red-polysaccharide interactions in enumeration and characterization of cellulolytic bacteria from the bovine rumen. Appl Environ Microbiol 43:777–780

Liu S (2004) Analysis and measurement in papermaking industry. China Chemical Industry Press, Beijing

Díaz AB, Bolívar J, de Ory I, Caro I, Blandino A (2011) Applicability of enzymatic extracts obtained by solid state fermentation on grape pomace and orange peels mixtures in must clarification. LWT Food Sci Technol 44:840–846

Ghose T (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268

Bailey MJ, Biely P, Poutanen K (1992) Interlaboratory testing of methods for assay of xylanase activity. J Biotechnol 23:257–270

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Liu G, Xu Z, Cen P (2000) A morphologically structured model for mycelial growth and secondary metabolite formation. Chin J Chem Eng 8:46–51

Lo Y-C, Huang C-Y, Cheng C-L, Lin C-Y, Chang J-S (2011) Characterization of cellulolytic enzymes and bioH2 production from anaerobic thermophilic Clostridium sp. TCW1. Bioresour Technol 102:8384–8392

Ncube T, Howard RL, Abotsi EK, van Rensburg ELJ, Ncube I (2012) Jatropha curcas seed cake as substrate for production of xylanase and cellulase by Aspergillus niger FGSCA733 in solid-state fermentation. Ind Crops Prod 37:118–123

Naidu G, Panda T (1998) Production of pectolytic enzymes-a review. Bioprocess Biosyst Eng 19:355–361

Heerd D, Yegin S, Tari C, Fernandez-Lahore M (2012) Pectinase enzyme-complex production by Aspergillus spp. in solid-state fermentation: a comparative study. Food Bioprod Process 90:102–110

Delabona PdS, Pirota RDPB, Codima CA, Tremacoldi CR, Rodrigues A, Farinas CS (2013) Effect of initial moisture content on two Amazon rainforest Aspergillus strains cultivated on agro-industrial residues: biomass-degrading enzymes production and characterization. Ind Crops Prod 42:236–242

Brijwani K, Oberoi HS, Vadlani PV (2010) Production of a cellulolytic enzyme system in mixed-culture solid-state fermentation of soybean hulls supplemented with wheat bran. Process Biochem 45:120–128

Dhillon GS, Oberoi HS, Kaur S, Bansal S, Brar SK (2011) Value-addition of agricultural wastes for augmented cellulase and xylanase production through solid-state tray fermentation employing mixed-culture of fungi. Ind Crops Prod 34:1160–1167

Soni R, Nazir A, Chadha BS (2010) Optimization of cellulase production by a versatile Aspergillus fumigatus fresenius strain (AMA) capable of efficient deinking and enzymatic hydrolysis of Solka floc and bagasse. Ind Crops Prod 31:277–283

Vargas LHM, Pião ACS, Domingos RN, Carmona EC (2004) Ultrasound effects on invertase from Aspergillus niger. World J Microbiol Biotechnol 20:137–142

Liu D, Zeng X-A, Sun D-W, Han Z (2013) Disruption and protein release by ultrasonication of yeast cells. Innov Food Sci Emerg Technol 18:132–137

Badhan AK, Chadha BS, Sonia KG, Saini HS, Bhat MK (2004) Functionally diverse multiple xylanases of thermophilic fungus Myceliophthora sp. IMI 387099. Enzyme Microb Technol 35:460–466

Acknowledgments

This work was supported by a Grant from the National High Technology Research and Development Program of China (863 Program) (No. 2011AA100804), Hunan Provincial Innovation Foundation for Postgraduate (CX2013B084), and Open-End Fund for the Valuable and Precision Instruments of Central South University (CSUZC2014003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Pj., Xia, Jl., Shan, Y. et al. Comparative study of multi-enzyme production from typical agro-industrial residues and ultrasound-assisted extraction of crude enzyme in fermentation with Aspergillus japonicus PJ01. Bioprocess Biosyst Eng 38, 2013–2022 (2015). https://doi.org/10.1007/s00449-015-1442-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-015-1442-3