Abstract

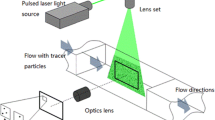

In this study, a numerical simulation using computational fluid dynamics (CFD) was used to investigate the hydrodynamic characteristics of circular ponds with three different impellers (hydrofoil, four-pitched-blade turbine, and grid plate). The reliability of the CFD model was validated by particle image velocimetry (PIV). Hydrodynamic analyses were conducted to evaluate the average velocity magnitude along the light direction (U z), turbulence properties, average shear stress, pressure loss and the volume percentage of dead zone inside circular ponds. The simulation results showed that U z value of hydrofoil was 58.9, 40.3, and 28.8 % higher than those of grid plate with single arm, grid plate with double arms and four-pitched blade turbines in small-scale circular ponds, respectively. In addition, hydrofoil impeller with down-flow operation had outstanding mixing characteristics. Lastly, the results of Chlorella pyrenoidosa cultivation experiments indicated that the biomass concentration of hydrofoil impeller with down-flow operation was 65.2 and 88.8 % higher than those of grid plate with double arms and four-pitched-blade turbine, respectively. Therefore, the optimal circular pond mixing system for microalgae cultivation involved a hydrofoil impeller with down-flow operation.

Similar content being viewed by others

Abbreviations

- D :

-

Diameter of impellers (m)

- T :

-

Diameter of circular ponds (m)

- W :

-

Width of baffles (mm)

- e :

-

Thickness of baffles (mm)

- W 0 :

-

Distance between the end of baffles and the wall of ponds (mm)

- h 0 :

-

Depth of deionized water (mm)

- \(\alpha ,\;\beta ,\;\gamma\) :

-

Inclination angle to agitation axis for different impellers (°)

- C :

-

Distance between the end of the impeller and the bottom of the circular pond (mm)

- V tip :

-

Impeller tip velocity (m s−1)

- U z :

-

Average velocity magnitude along the light direction (m s−1)

- N :

-

Rotation speed (rpm)

- z :

-

The height of liquid (m)

- R :

-

Radial distance (m)

- \(C_{\text{s1}} ,\;C_{\text{s2}}\) :

-

Coefficient in k-ε equation

- \(\alpha_{\text{k}} ,\;\alpha_{\varepsilon }\) :

-

Coefficient in k-ε equation

- TKE:

-

Turbulent kinetic energy (J kg−1)

- D z :

-

The volume percentage of dead zone (%)

- Pv:

-

Power per unit volume (w m−3)

- Η :

-

Error of measured parameters and simulation setting values (%)

References

Chen Y, Wang JF, Zhang W, Chen L, Gao LL, Liu TZ (2013) Forced light/dark circulation operation of open pond for microalgae cultivation. Biomass Bioenerg 56:464–470

Bitog JP, Lee IB, Oh HM, Hong SW, Seo IH, Kwon KS (2014) Optimised hydrodynamic parameters for the design of photobioreactors using computational fluid dynamics and experimental validation. Biosyst Eng 122:42–61

Hreiz R, Sialve B, Jerome, Morchain Escudie R, Steyer JP, Guiraud P (2014) Experimental and numerical investigation of hydrodynamics in raceway reactors used for algaculture. Chem Eng J 250:230–239

Lee YK (2001) Microalgal mass culture systems and methods: their limitation and potential. J Appl Phycol 13:307–315

Piero M, Armenante, Chou CC (1996) Velocity profiles in a baffled vessel with single or double pitched-blade turbines. AIChE J 1:42–54

Fox RO (2006) CFD models for analysis and design of chemical reactors. Adv Biochem Eng Biot 31:231–305

Xia JY, Wang SJ, Zhang SL, Zhong JJ (2008) Computational investigation of fluid dynamics in a recently developed centrifugal impeller bioreactor. Biochem Eng J 38:406–441

Bitog JP, Lee IB, Lee CG, Kim KS, Hwang HS, Hong SW, Seo IH, Kwon KS, Mostafa E (2011) Application of computational fluid dynamics for modeling and designing photobioreactors for microalgae production: a review. Comput Electron Agr 76:131–147

Wu LB, Li Z, Song YZ (2009) Numerical investigation of flow characteristics and irradiance history in a novel photobioreactor. Afr J Biotechnol 8:4672–4679

Hall DO, Fernandez FGA, Guerrero EC, Rao KK, Grima EM (2003) Outdoor helical tubular photobioreactors for microalgae production: modeling of fluid dynamics and mass transfer and assesement of biomass productivity. Biotechnol Bioeng 86:62–73

Pruvost J, Pottier L, Legrand J (2006) Numerical investigation of hydrodynamic and mixing conditions in a torus photobioreactor. Chem Eng Sci 61:4476–4489

Liu XH, Min J, Pan CM, Gao ZM, Chen WM (2008) Investigation of turbulence kinetic energy dissipation Rate in a stirred tank using large eddy PIV approach. Chin J Process Eng 8:425–431

Roy S, Acharya S, Cloeter MD (2010) Flow structure and the effect of macro-instabilities in a pitched-blade stirred tank. Chem Eng Sci 65:3009–3024

Guang YC, Markk S, Jarek K, Mika R, Olli S (2010) Particle Image Velocimetry (PIV) application in the measurement of indoor air distribution by an active chilled beam. Build Environ 45:1932–1940

Vakili MH, Esfahany MN (2009) CFD analysis of turbulence in a baffled stirred tank, a three compartment model. Chem Eng Sci 64:351–362

Zhang QH, Xia W, Xue SZ, Liang KH, Cong W (2012) Study of hydrodynamic characteristics in tubular photobioreactors. Bioproc Biosyst Eng 10:1007–1018

Perner I, Posten C, Broneske J (2003) CFD optimization of a plate photobioreactor used for cultivation of microalgae. Eng Life Sci 3:287–291

Su ZF, Kang RJ, Shi SY, Cong W, Cai ZL (2010) Study on the destabilization mixing in the flat plate photobioreactor by means of CFD. Biomass Bioenergy 34:1879–1884

Huang J, Li Y, Wan M, Yan Y, Feng F, Qu X, Wang J, Shen G, Li W, Fan J (2014) Novel flat-plate photobioreactors for microalgae cultivation with special mixers to promote mixing along the light gradient. Bioresour Technol 159:8–16

Xu L, Liu R, Wang F, Liu CZ (2012) Development of a draft-tube airlift bioreactor for Botryococcus braunii with an optimized inner structure using computational fluid dynamics. Bioresour Technol 119:300–305

Sompech K, Chisti Y, Srinophakun T (2012) Design of raceway ponds for producing microalgae. Rev Environ Sci Bio 3:387–397

Han F, Huang J, Li Y, Wang W, Fan J, Shen G (2012) Enhancement of microalgal biomass and lipid productivities by a model of photoautotrophic culture with heterophic cells as seed. Bioresour Technol 118:431–437

Hou SD, Zhang Z, Wang YC, Shi LT (2000) Numerical simulation of turbulent flow in stirred tank agitated by axial impeller. J Chem Ind and Eng (CHN) 51:70–76

Feng LF, Wang JJ, Wang K, Cu XP (2002) The recent progress of fluid mixing technology. Chem Eng (CHN) 30:70–74

Grima EM, Fernandez FGA, Camacho FG, Chisti Y (1999) Photobioreactors: light regime, mass transfer, and scale-up. Prog Ind Microbiol 35:231–247

Luo HP, Kemoun A, Al-Dahhan MH, Sevilla JMF, Sanchez JLG, Camacho FG, Grima EM (2003) Analysis of photobioreactors for culturing high-value microalgae and cyanobacteria via an advanced diagnostic technique: CARPT. Chem Eng Sci 58:2519–2527

Mazzuca Sobczuk T, Garcia Camacho F, Molina Grima E, Chisti Y (2006) Effects of agitation on the microalgae Phaeodactylum tricornutum and Porphyridium cruentum. Bioproc Biosyt Eng 28:243–250

Kaewpintong K, Shotipruk A, Powtongsook S, Pavasant P (2007) Photoautotrophic high-density cultivation of vegetative cells of Haematococcus pluvialis in airlift bioreactor. Bioresour Technol 98:288–295

Garcia Camacho F, Gomez C, Mazzuca Sobczuk T, Molina Grima E (2000) Effects of mechanical and hydrodynamic stress in agitated, sparged cultures of Porphyridium cruentum. Process Biochem 35:1045–1050

Pruvost J, Legrand J, Legentilhomme P, Muller-Feuga A (2002) Simulation of microalgae growth in limiting light conditions: flow effect. AIChE J 48:1109–1120

David C, Matteo P, David C, Mario R, Tredici, Liliana R, Niccolo B, Graziella CZ, Paolo B (2013) Review of energy balance in raceway ponds for microalgae cultivation: Re-thinking a traditional system is possible. Appl Energ 102:101–111

Toru S, Shinsuke U, Yoshihiro T, Yutaka K (2006) Invention of outdoor closed type photobioreactor for microalgae. Energ Convers Manage 47:79–791

Acknowledgments

This research was funded by National Basic Research Program China (973 Program: 2011CB200903).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Meng, C., Huang, J., Ye, C. et al. Comparing the performances of circular ponds with different impellers by CFD simulation and microalgae culture experiments. Bioprocess Biosyst Eng 38, 1347–1363 (2015). https://doi.org/10.1007/s00449-015-1376-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-015-1376-9