Abstract

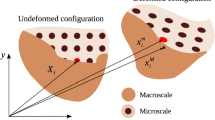

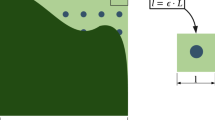

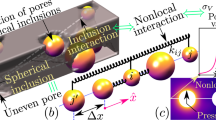

We present an extension of a multiscale micromorphic theory to three-dimensional problems for porous materials, where a clear scale separation is not given. Following the multiscale micromorphic framework of Biswas and Poh (J Mech Phys Solids 102:187–208, 2017), macroscopic governing equations of a micromorphic continuum are derived from a classical continuum on the microscale by means of a kinematic field decomposition. The macro–microenergy equivalence is guaranteed via the Hill–Mandel condition. For linear elasticity problems, generalized elasticity tensors are determined via several RVE computations once and for all, avoiding concurrent RVE computations for an online structural analysis. A three-dimensional implementation is revealed in detail. A comparative study with direct numerical simulations and first-order multiscale computations shows that the computational multiscale micromorphic method has sufficient accuracy and computational efficiency, thus providing a powerful tool for design and practical engineering applications of porous materials.

Similar content being viewed by others

References

Biswas, R., Poh, L.H.: A micromorphic computational homogenization framework for heterogeneous materials. J. Mech. Phys. Solids 102, 187–208 (2017)

Zhang, S.: Research and application progress of foam metal. Powder Metall. Technol. 34(3), 6 (2016)

Wang, Z., Cao, X., Ma, H.: Effect of microstructure on meso-mechanical properties of porous materials. J. Taiyuan Univ. Technol. 37(1), 1–4 (2006)

Hill, R.: Elastic properties of reinforced solids: some theoretical principles. J. Mech. Phys. Solids 11, 357–372 (1963)

Feyel, F., Chaboche, J.L.: Fe2 multiscale approach for modelling the elastoviscoplastic behaviour of long fibre SiC/Ti composite materials. Comput. Methods Appl. Mech. Eng. 183(3–4), 309–330 (2000)

Moulinec, H., Suquet, P.: A numerical method for computing the overall response of nonlinear composites with complex microstructure. Comput. Methods Appl. Mech. Eng. 157(1–2), 69–94 (1998)

Matouš K., Geers, M. G. D., Kouznetsova, V. G., Yvonnet, J.: Homogenization methods and multiscale modeling: nonlinear problems. Encyclopedia of computational mechanics second edition, pp. 1–34 (2017)

Liang, L., Ju, X., Mahnken, R., Xu, Y., Zhou, W.: A nonuniform transformation field analysis for composites with strength difference effects in elastoplasticity. Int. J. Solids Struct. 228, 111103 (2021)

Xu, Y., Ju, X., Mahnken, R., Liang, L.: NTFA-enabled goal-oriented adaptive space-time finite elements for micro-heterogeneous elastoplasticity problems. Comput. Methods Appl. Mech. Eng. 398, 115199 (2022)

Dvorak, G.J., Benvensite, Y.: On transformation strains and uniform fields in multiphase elastic media. Proc. R. Soc. Lond. 437(A), 291–310 (1992)

Michel, J.C., Suquet, P.: Nonuniform transformation field analysis. Int. J. Solids Struct. 40, 6937–6955 (2003)

Michel, J.C., Suquet, P.: A model-reduction approach in micromechanics of materials preserving the variational structure of constitutive relations. J. Mech. Phys. Solids 90, 254–285 (2016)

Bessa, M.A., Liu, Z., Liu, W.K.: Self-consistent clustering analysis: an efficient multi-scale scheme for inelastic heterogeneous materials. Comput. Methods Appl. Mech. Eng. 306, 319–341 (2016)

Gibson, L.J.: Cellular solids. MRS Bull. 28(4), 270–274 (2003)

Feng, M., Zhuang, S., Wu, C., Yuan, Z.: Numerical study of micromechanical properties of porous materials based on homogenization method. J. Mater. Sci. Eng. 19(4), 5 (2001)

Fu, C., Liu, P., Li, T.: Tensile strength of metal materials with high porosity. Rare Metal Mater. Eng. 29(002), 94–100 (2000)

Zhao, S., Wang, X., Xu, Y., Wu, P., Liang, L.: Realization of elastic-plastic multiscale analysis and its application in particle reinforced composites. Compos. Mater. Sci. Technol. 34(9), 10 (2017)

Onck, P., Andrews, E.W., Gioux, G., Gibson, L.J.: Size effects in ductile cellular solids. Part II: experimental results. Int. J. Mech. Sci. 43(3), 701–713 (2001)

Geers, M.G. D., Kouznetsova, V.G., A. M, W.: Multi-scale second-order computational homogenization of multi-phase materials: a nested finite element solution strategy. Comput. Methods Appl. Mech. Eng. 193(48–51), 5525–5550 (2004)

Becker, G., Nguyen, V.D., Noels, L.: Multiscale computational homogenization methods with a gradient enhanced scheme based on the discontinuous galerkin formulation. Comput. Methods Appl. Mech. Eng. 260, 63–77 (2013)

Nguyen, V.D., Noels, L.: Computational homogenization of cellular materials. Int. J. Solids Struct. 51(11), 2183–2203 (2014)

Geers, M.G.D., Kouznetsova, V.G., Brekelmans, W.A.M.: Multi-scale second-order computational homogenization of multi-phase materials: a nested finite element solution strategy. Comput. Methods Appl. Mech. Eng. 193(48), 5525–5550 (2004). (Advances in Computational Plasticity)

Geers, M.G.D., Kouznetsova, V.V., Brekelmans, W.A.M.: Multi-scale constitutive modelling of heterogeneous materials with a gradient-enhanced computational homogenization scheme. Int. J. Numer. Methods Eng. 54, 1235–1260 (2002)

Eringen, A. C.: . Mechanics of micromorphic materials. In: Applied Mechanics, pp. 131–138. Springer (1966)

Mindlin, R.D.: Micro-structure in linear elasticity. Arch. Ration. Mech. Anal. 16, 51–78 (1964)

Liu, Q., Li, X., Zhang, J.: A micro-macro homogenization approach for discrete particle assembly: Cosserat continuum modeling of granular materials. Int. J. Solids Struct. 47(2), 291–303 (2010)

Adomeit, G.: Determination of elastic constants of a structured material. In: Kröner, E. (ed.) Mechanics of Generalized Continua, pp. 80–82. Springer, Berlin (1968)

Forest, S.: Mechanics of generalized continua: construction by homogenizaton. Le Journal de Physique IV 8(PR4), Pr4-39 (1998)

Bigoni, D., Drugan, W.J.: Analytical derivation of Cosserat Moduli via homogenization of heterogeneous elastic materials. J. Appl. Mech. 74(4), 741–753 (2006). (04)

Feyel, F.: A multilevel finite element method (fe2) to describe the response of highly non-linear structures using generalized continua. Comput. Methods Appl. Mech. Eng. 192(28/30), 3233–3244 (2003)

Hütter, G.: On the micro-macro relation for the microdeformation in the homogenization towards micromorphic and micropolar continua. J. Mech. Phys. Solids 127, 62–79 (2019)

Jänicke, R., Steeb, H.: Wave propagation in periodic microstructures by homogenisation of extended continua. Comput. Mater. Sci. 52(1), 209–211 (2012)

Ju, X., Mahnken, R.: Goal-oriented adaptivity for linear elastic micromorphic continua based on primal and adjoint consistency analysis. Int. J. Numer. Meth. Eng. 112(8), 1017–1039 (2017)

Liang, L., Ju, X., Mahnken, R., Xu, Y.: Goal-oriented mesh adaptivity for inverse problems in linear micromorphic elasticity. Comput. Struct. 257, 106671 (2021)

Xu, Y., Ju, X., Mahnken, R., Liang, L.: Goal-oriented error estimation and h-adaptive finite elements for hyperelastic micromorphic continua. Comput. Mech. 69, 847–863 (2022)

Ju, X., Mahnken, R.: Goal-oriented h-type adaptive finite elements for micromorphic elastoplasticity. Comput. Methods Appl. Mech. Eng. 351, 297–329 (2019)

Hütter, G.: Homogenization of a Cauchy continuum towards a micromorphic continuum. J. Mech. Phys. Solids 99, 394–408 (2017)

Rokoš, O., Ameen, M.M., Peerlings, R.H.J., Geers, M.G.D.: Micromorphic computational homogenization for mechanical metamaterials with patterning fluctuation fields. J. Mech. Phys. Solids 123, 119–137 (2019)

Shedbale, A.S., Biswas, R., Poh, L.H.: Nonlinear analyses with a micromorphic computational homogenization framework for composite materials. Comput. Methods Appl. Mech. Eng. 350, 362–395 (2019)

Poh, L.H., Biswas, R., Shedbale, A.S.: A micromorphic computational homogenization framework for auxetic tetra-chiral structures. J. Mech. Phys. Solids 135, 103801 (2020)

Ganghoffer, J.-F., Wazne, A., Reda, H.: Frontiers in homogenization methods towards generalized continua for architected materials. Mech. Res. Commun. 130, 104114 (2023)

Biswas, R., Yuan, Z., Poh, L.H.: Accelerated offline setup of homogenized microscopic model for multi-scale analyses using neural network with knowledge transfer. Int. J. Numer. Meth. Eng. 124(13), 3063–3086 (2023)

Hütter, G.: Interpretation of micromorphic constitutive relations for porous materials at the microscale via harmonic decomposition. J. Mech. Phys. Solids 171, 105135 (2023)

Hill, R.: Elastic properties of reinforced solids: some theoretical principles. J. Mech. Phys. Solids 11(5), 357–372 (1963)

Miehe, C.: Computational micro-to-macro transitions for discretized micro-structures of heterogeneous materials at finite strains based on the minimization of averaged incremental energy. Comput. Methods Appl. Mech. Eng. 192(5–6), 559–591 (2003)

Mahnken, R., Ju, X.: Goal-oriented adaptivity based on a model hierarchy of mean-field and full-field homogenization methods in linear elasticity. Int. J. Numer. Meth. Eng. 121, 277–307 (2020)

Acknowledgements

The work described in this paper was supported by the Zhejiang Provincial Natural Science Foundation of China (Grant No: LQ21A020002) and the National Natural Science Foundation of China (Grant Nos. 12002309, 52275164).

Author information

Authors and Affiliations

Contributions

XJ: Writing—original draft, conceptualization, methodology. KG: Writing—original draft, methodology, software. JH: data curation, visualization. HR: software, validation. HC: validation. YX: conceptualization, supervision. LL: conceptualization, supervision.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Technical details for three-dimensional periodic boundary conditions

In the following, several details are given for the three-dimensional periodic boundary condition in Sect. 3.1. By means of interpolation of corresponding corner displacements in Eq. (25), Eq. (23) becomes

Here, \(h=\frac{2{\varvec{y}_{1}}}{l}\), \(g=\frac{2{\varvec{y}_{2}}}{l}\) and \(k=\frac{2{\varvec{y}_{3}}}{l}\) represent the normalized coordinates of the analogous node pairs at the front–back, top–bottom and left–right boundary pairs, respectively. Similarly, by means of linear interpolation of corresponding corner displacements, Eq. (24) becomes

which are similar to the formulas in a two-dimensional implementation in [1].

Appendix B: Numerical determination of the elasticity tensors

The elasticity tensors \({{{\varvec{C}}}^{m}}\), \({{{\varvec{E}}}^{n}}\) and \({\varvec{D}}\) are computed similarly to the work [1]. For our three-dimensional implementation, the macroscopic elasticity operator is obtained by condensing the microscopic finite element equations. In the microscale, the finite element equation system reads

where \(\underline{\underline{\hat{K}}}\) is the global stiffness matrix of the RVE and \(\underline{{\hat{r}}}\) represents the residual force. Then, the global stiffness matrix is partitioned as follows

where the subscript d denotes the dependent degrees of freedom involved in the periodic boundary conditions (23) and (24). There holds \({{\underline{{\hat{u}}}}_{d}}=\underline{\underline{{\hat{C}}}}{{\underline{{\hat{u}}}}_{i}}\) for the independent degrees of freedom \({{\underline{{\hat{u}}}}_{i}}\), with the correlation matrix \(\underline{\underline{{\hat{C}}}}\). By means of a static condensation [22], Eq. (B.1) reduces to

where

In order to impose the constraint (30), dummy degrees of freedom with the subscript \(\tilde{\lambda }\) are introduced as

where \(\underline{\underline{W}}\) and \({{\underline{{\hat{u}}}}_{I}}\) represent the coefficient matrix in Eq. (30) and degrees of freedom along the hole surfaces, respectively. Next, we rewrite Eq. (B.5) as

where \({{\underline{{\hat{u}}}}_{{{I}_{d}}}}\) and \({{\underline{{\hat{u}}}}_{a}}\) denote the dependent degrees of freedom to be eliminated at the hole surface and the remaining degrees of freedom in Eq. (B.3), respectively. As a result, Eq. (B.3) becomes

where \(\underline{\underline{I}}\) is the identity matrix. On the basis of Eqs. (B.6), (B.7) is further condensed to

where

The equation system (B.8) is next partitioned as

with the subscripts p and f denoting the corner and the internal free nodes, respectively. By a further condensation [22], Eq. (B.10) finally reduces to

In the numerical implementation, the displacements of the corner nodes of the RVE are prescribed by Eq. (25) as

Due to the relation \({{\underline{{\hat{u}}}}_{{\tilde{\lambda }}}}=\underline{{\tilde{H}}}\) in Eq. (B.5), the RVE problem is solved after Eq. (B.11).

Under the periodic boundary conditions (A.1) and (A.2), only corner nodes contribute to Eq. (14). Accordingly, the macroscopic stress tensors are computed by

From Eqs. (B.11) and (B.13), the components for the elasticity tensors \({{{\varvec{C}}}^{m}}\), \({{{\varvec{E}}}^{n}}\) and \({\varvec{D}}\) in the macroscopic constitutive relations (20) are computed by

with \(i,j,k,l,m,n=1,2,3\) and \(\underline{\alpha },\underline{\beta }=1,2,\cdots ,9\). Taking \(\underline{\underline{{\bar{K}}}}_{pp(i,l)}^{(ab)}\) as an example for notation, the superscripts a and b denote the partition in the matrix \({{\underline{\underline{{\bar{K}}}}}_{pp}}\), whereas the subscripts i and l are indices for components.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ju, X., Gao, K., Huang, J. et al. A three-dimensional computational multiscale micromorphic analysis of porous materials in linear elasticity. Arch Appl Mech 94, 819–840 (2024). https://doi.org/10.1007/s00419-024-02549-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-024-02549-x