Abstract

Phenol-formaldehyde resins combined with polymers have a wide range of industrial applications as plugging agents for profile control and enhanced oil recovery. Due to the structural resemblance between lignin and phenol, there are possibilities for environmentally friendly phenol-formaldehyde resin manufacturing. Sulfonated lignin–based phenol-formaldehyde resin was synthesized by partially replacing phenol with lignin, which improved the utilization rate of lignin and achieved the purpose of environmental preservation and resource conservation. Partially hydrolyzed polyacrylamide is the most widely used polymer in chemical methods for enhanced oil recovery. However, the stability of reservoirs with high salt and high temperatures is weak under these conditions. To solve the problem of low oil recovery in high-salt reservoir environments, polymer flooding is adopted, which utilizes high-molecular-weight polymers to raise the viscosity of injected fluids, thereby improving sweep efficiency and altering mobility ratio between oil and injected fluid. We focus on the stability study of different molecular weights partially hydrolyzed polyacrylamide combined with sulfonated lignin – based phenol-formaldehyde resins in metal ions and surfactants. The zeta potential and hydrodynamic diameter of the partially hydrolyzed polyacrylamide – sulfonated lignin – based phenol-formaldehyde resin system in Ca2+ were measured by dynamic light scattering and static light scattering, and the dispersion stability was analyzed. The interfacial energy – modified DLVO theory was introduced to evaluate the stability of its colloidal solution, which made it possible to predict the aggregation behavior of sulfonated lignin – based phenol-formaldehyde resin and the co-migration process of metal cations in real time.

Similar content being viewed by others

Availability of data and materials

All of the material is owned by the authors and no permissions are required.

References

Gu C, Lv Y, Fan X, Zhao C, Dai C, Zhao G (2018) Study on rheology and microstructure of phenolic resin cross-linked nonionic polyacrylamide (NPAM) gel for profile control and water shutoff treatments. J Petrol Sci Eng 169:546–552

Zhang S, Guo J, Gu Y, Zhao Q, Yang R, Yang Y (2020) Polyacrylamide gel formed by Cr(III) and phenolic resin for water control in high-temperature reservoirs. J Petrol Sci Eng 194

Al-Jaber HA, Arsad A, Tahir M, Nuhma MJ, Bandyopadhyay S, Abdulmunem AR, Abdul Rahman AF, Harun ZB, Agi A (2023) Enhancing oil recovery by polymeric flooding with purple yam and cassava nanoparticles. Molecules 28(12)

Ge LC, Zhao C, Zuo MJ, Tang J, Ye W, Wang XG, Zhang YL, Xu C (2022) Review on the preparation of high value-added carbon materials from biomass. J Anal Appl Pyrolysis 168

Moreno A, Sipponen MH (2020) Lignin-based smart materials: a roadmap to processing and synthesis for current and future applications. Mater Horiz 7(9):2237–2257

Xu J, Kong Y, Du B, Wang X, Zhou J (2021) Exploration of mechanisms of lignin extraction by different methods. Environ Prog Sustain Energy

Gao Z, Lang X, Chen S, Zhao C (2021) Mini-review on the synthesis of lignin-based phenolic resin. Energy Fuels 35(22):18385–18395

Di B, Li Z, Lei Y, Wang X, Zhu Y, Qi W, Tian Y (2021) Phenol-enriched hydroxy depolymerized lignin by microwave alkali catalysis to prepare high-adhesive biomass composites. Polym Eng Sci 61(5):1463–1475

Shakeel M, Samanova A, Pourafshary P, Hashmet MR (2021) Experimental analysis of oil displacement by hybrid engineered water/chemical EOR approach in carbonates. J Petrol Sci Eng 207

Wang W, Xu Y, Ge J, Guo H, Wu Q, Mao Y (2022) Phenolic resin gel suitable for medium-temperature and high-salinity reservoirs. J Mol Liq 364

Ran Y, Zhang G, Jiang P, Pei H (2023) Study on water-soluble phenolic resin gels for high-temperature and high-salinity oil reservoir. Gels 9(6)

Moshtaghi M, Eškinja M, Mori G, Griesser T, Safyari M, Cole I (2023) The effect of HPAM polymer for enhanced oil recovery on corrosion behaviour of a carbon steel and interaction with the inhibitor under simulated brine conditions. Corros Sci 217

Seright RS, Wang D (2023) Polymer flooding: Current status and future directions. Pet Sci 20(2):910–921

Kumar D, Ganat T, Lashari N, Ayoub MA, Kalam S, Chandio TA, Negash BM (2022) Experimental investigation of GO-HPAM and SiO2-HPAM composite for cEOR: rheology, interfacial tension reduction, and wettability alteration. Colloids and Surfaces A Physicochem Eng Asp 637

Lashari N, Ganat T, Ayoub MA, Kalam S, Ali I (2023) Coreflood investigation of HPAM/GO-SiO2 composite through wettability alteration. J Mol Liq 371

Kalam S, Kamal MS, Patil S, Hussain SMS (2020) Impact of spacer nature and counter ions on rheological behavior of novel polymer-cationic gemini surfactant systems at high temperature. Polymers 12(5)

Zhang L, Pu C (2016) Transportation characteristics of HPAM solution in the micro-fractures. J Dispersion Sci Technol 38(5):686–692

Wu H, Wang Y, Sun B, Liu X, Zhang T, Ma Y, Zhao S (2023) Concentration-dependent effects of humic acid and protein on the stability of hematite nanoparticles in an aqueous environment. J Nanopart Res 25(6)

Zhao D, Li M, Peng B, Lin M, Dong Z (2013) Influence of hydrophobically associating polyacrylamide on dispersion property of water-soluble phenol-for-maldehyde resin. J Dispersion Sci Technol 35(1):22–28

Ishikawa Y, Katoh Y, Ohshima H (2005) Colloidal stability of aqueous polymeric dispersions: effect of pH and salt concentration. Colloids Surf B Biointerfaces 42(1):53–58

Zhao D, Yang H, Wei Y, Yang W, Li Z, Yang W, Tang Z, Wang L, Li J (2023) Feng, H., Molecular modeling of phenol formaldehyde resin-surfactant and its dispersion stability in salt solution. J Polym Res 30(3)

Muneer R, Hashmet MR, Pourafshary P (2022) Predicting the critical salt concentrations of monovalent and divalent brines to initiate fines migration using DLVO modeling. J Mol Liq 352

Hartmann R, Kinnunen P, Illikainen M (2018) Cellulose-mineral interactions based on the DLVO theory and their correlation with flotability. Miner Eng 122:44–52

Zhao D, Yang H, Li Z, Yang W, Li G, Wei Y, Zhang S, Tang Z, Wang L, Li J, Feng H (2022) Effects of the same valence metal cations on the aggregation behavior of PFR. React Funct Polym 179:105363

Takeya M, Shimokawara M, Elakneswaran Y, Nawa T, Takahashi S (2019) Predicting the electrokinetic properties of the crude oil/brine interface for enhanced oil recovery in low salinity water flooding. Fuel 235:822–831

Morán J, Henry C, Poux A, Yon J (2021) Impact of the maturation process on soot particle aggregation kinetics and morphology. Carbon 182:837–846

Ortega-Vinuesa JL, Martın-Rodrıguez A, Hidalgo-Alvarez R (1996) Colloidal stability of polymer colloids with different interfacial properties: mechanisms. J Colloid Interf Sci 184:259–267

Diao Y, Han M, Lopez-Berganza JA, Valentino L, Marinas B, Espinosa-Marzal RM (2017) Reconciling DLVO and non-DLVO forces and their implications for ion rejection by a polyamide membrane. Langmuir 33(36):8982–8992

Wang J, Pan D (2023) Effect of DLVO interactions on the rheology and microstructure of non-Brownian suspensions. Acta Mechanica Sinica 39(6)

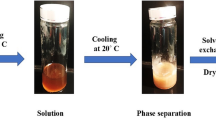

Meng X, Wang L, Wang H, Zhang F, Su T, Cheng K (2022) Development and evaluation of a novel sulfonated phenol-formaldehyde resin with high dispersion stability. Polymers (Basel)14(21)

Meng X, Li M, Lin M, Zhang J, Yang Z, Feng L (2016) Aggregation behavior and reversibility of sulfonated phenol formaldehyde resin. J Dispersion Sci Technol 38(3):328–333

Chen W-H, Wang Y-F, He Z-P, Ding M-C (2020) Improvement of stability of nano-SiO2/HPAM/SDS dispersion systems and its effect on oil displacement performances. Journal of Fuel Chemistry and Technology 48(9):1087–1096

Acknowledgements

We appreciate Dr. Huixia Feng’s insightful conversation. We are grateful that the PetroChina Lanzhou Lubricating Oil R&D Institute and China University of Petroleum (Beijing) provided the measuring tools.

Funding

The Natural Science Foundation of China (Grant numbers: 2020IM030400), the Special Project on Innovative Methods Fund Program of the Ministry of Science and Technology of the People’s Republic of China, and the Natural Science Foundation of China all provided financial support for this study (Grant numbers: 21664009, 51063003).

Author information

Authors and Affiliations

Contributions

Dan Zhao, Weili Yang, and Guanglite Shen performed the measurements. Dan Zhao and Huixia Feng were involved in planning and supervised the work. Weili Yang processed the experimental data, performed the analysis, drafted the manuscript, and designed the figures. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Ethical approval

This declaration is not applicable. Our research does not need to use humans or animals as research objects.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

396_2023_5190_MOESM1_ESM.docx

The Supplementary data provides information on DLVO calculations and High Performance Liquid Chromatography-Mass Spectrometry (HPLC-MS) analysis, which can be accessed for free online (DOCX 882 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, D., Yang, W., Shen, G. et al. HPAM-biomass phenol-formaldehyde resin dispersion system: evaluation of stability. Colloid Polym Sci 302, 199–212 (2024). https://doi.org/10.1007/s00396-023-05190-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-023-05190-2