Abstract

One parameter frequently considered to be relevant for superspreading of trisiloxane surfactants is surface tension kinetics. In the scientific literature, some experimental results reported for trisiloxane surfactants are in contradiction with fundamental concepts of surfactant monomer diffusion. Therefore, maximum bubble pressure tensiometry has been used to determine dynamic surface tension (DST) of two types of trisiloxane surfactants: superspreader and non-superspreader. Results show that both surfactants behave similarly at concentrations below critical micelle concentration (CMC), as expected. The CMC curves, as determined by drop shape analysis, confirmed that the more hydrophilic non-superspreader has a higher CMC as compared to the more hydrophobic superspreader. Accordingly, the lower surfactant monomer concentration of the superspreader results in a higher DST than the non-superspreader at the same surface age. So, in contrary to claims in the literature, there is nothing mysterious or unexpected concerning the surface tension behavior of trisiloxane surfactants.

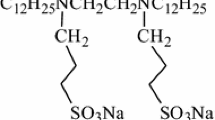

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Superspreading is the ability of some trisiloxane surfactants to cause the fast spreading of aqueous solutions over hydrophobic substrates [1,2,3]. Typically, 50 µL of a 0.1% solution of a superspreading surfactant leads to a wetted area of 7–8 cm in diameter within 1 min (see supplement of [2]). This phenomenon was first reported about 50 years ago and has been intensively investigated by the scientific community, but over several decades, no agreement on the mode of action could be reached [2, 3]. Although it has been proven experimentally that surface tension gradients do not play a role in driving superspreading [4], Marangoni flow is still considered by many authors to be relevant for superspreading, for unknown reasons [5,6,7,8]. A more feasible explanation for the mode of action of superspreading, which is also in agreement with basic thermodynamics, takes into account the different phase behavior of superspreader and non-superspreader, its potential influence on the adsorption layer at the hydrophobic substrate, and hence differences in interfacial tension solid/liquid. The superspreading process could then happen via a rolling action at the droplet’s three-phase contact line, whereas the surfactant molecules are supplied through unzippering of bilayers formed by the superspreading surfactants [3]. Although it is a fascinating subject, the superspreading process and its mode of action is beyond the scope of this paper.

In order to better elucidate further details of the wetting performance of trisiloxane surfactants, it is helpful to investigate the influence of parameters such as dynamic surface tension (DST), substrate hydrophobicity, surfactant concentration, and evaporation. Although superspreading is a rather slow process taking about 60 s, some authors claim that superspreading trisiloxane surfactants exhibit unusually fast surface tension dynamics, which they consider to be relevant to drive the superspreading process [9, 10]. Svitova et al. [10] studied the dynamic surface tension of four trisiloxane surfactants using drop volume tensiometry and found that a more hydrophilic, non-superspreading trisiloxane surfactant had a higher DST at the same surface age as compared to a more hydrophobic, superspreading one. A puzzling finding has been reported by Sankaran et al. [9], who investigated the influence of two non-ionic trisiloxane surfactants (superspreader and non-superspreader) on foam films. In this work, also, pendant drop tensiometry was used to study the adsorption kinetics of those surfactants. Surprisingly, the authors claim that the more hydrophilic non-superspreader surfactant has a lower CMC and a several orders of magnitude slower adsorption kinetics than the superspreader. This has been suggested to be the reason for the comparably low stability of the foam films of the non-superspreading surfactants.

These counter-intuitive results motivated us to examine the dynamic surface tension of superspreading and non-superspreading trisiloxane surfactants in more detail using maximum bubble pressure tensiometry. Those DST results are explained by using the critical micelle concentrations (CMC), which were measured for both surfactants. Those results are useful to eliminate misconceptions about the surface tension behavior of superspreading and non-superspreading trisiloxane surfactants.

Materials and methods

Surfactant solutions preparation

Two nonionic trisiloxane surfactants were used in experiments: the superspreading BREAK-THRU® S240, (M(D′E6P3OH)M), MW: 730 g/mol and the non-superspreading BREAK-THRU® S233, (M(D′E10P2OH)M), MW: 850 g/mol, both by Evonik Operations GmbH [2]. All solutions have been freshly prepared using a stock solution (0.1% v/v) of each surfactant in type 1 water, rigorously shaken by hand and then diluted aiming to obtain different concentrations of surfactant solutions. Those solutions were then placed in an ultrasonic bath for 10 min (Sonorex Digitec DT 103 H, Bandelin Electronic GmbH).

DST and CMC measurements

The dynamic surface tension (DST) for each surfactant solution was measured using a maximum bubble pressure tensiometer (MPT-C, LAUDA Scientific GmbH) and showed good reproducibility. The DST measurements were made using a capillary with an inner diameter of 0.15 cm, immersed approximately 1 cm into solution. Due to low concentration of the surfactant solutions, their density was considered to be equal to that of water. Drop shape analysis was employed to determine the critical micelle concentration (CMC) for each surfactant by using a pendant drop tensiometer (DataPhysics OCA 25). The measurements were made inside a closed cuvette containing water to prevent evaporation. In all cases, the surfactants reached equilibrium within several 100 s, except for the very lowest concentrations. Therefore, the values at a drop age of 500 s were taken as static surface tension values.

Results and discussion

In order to eliminate misconceptions about superspreading trisiloxane surfactants, we have examined the DST of the superspreading surfactant S240 and the non-superspreading surfactant S233. To do so, a LAUDA MPT-C tensiometer was chosen because of its reliable performance especially at short adsorption times [11]. The concentration of the surfactant solutions ranged from 0.01 to 0.1% v/v; they were chosen to cover concentrations below the CMC commonly reported for trisiloxane surfactants [1] up to the concentration of 0.1% as typically used in superspreading experiments.

Figure 1 shows the dynamic surface tension (DST) values at different concentrations for each surfactant. In both charts, the surface tension decreases over time, but the equilibrium is not reached at the surface ages used in our bubble pressure tensiometry experiments. As expected, the higher the surfactant concentration, the faster the decay in surface tension. It can be also observed that the most pronounced decrease in surface tension happens at short times, which can be explained by the fact that at early stages, there is a lot of empty space at the interface for the surfactant monomers to adsorb, revealing that the process is diffusion-controlled [12]. In addition, only the lowest surfactant concentration shows a dynamic surface tension of about 72 mN/m (surface tension of water at 25 °C) in the beginning of the measurement, while the others already have a lower DST even at very short times (< 20 ms). This same behavior was also reported by Fainerman et al. [13] when studying C12DMPO solutions at different concentrations. This finding shows that at higher surfactant concentrations (values above CMC), there is already a significant amount of surfactant adsorbed at the liquid/gas interface even at the lowest surface ages which could be studied.

In order to better compare the behavior of superspreader and non-superspreader, we plotted the DST values for all surfactant concentrations at a specific surface age of 100 ms. This time was chosen because at this point, the values of DST are not that close to each other. The concentrations, which were initially presented in v/v %, have been converted to mmol/L in order to avoid any discussions about the amount of each surfactant in solution, although the average molecular weights of the two surfactants were not very different. Figure 2 reveals that both surfactants have similar performances at low concentrations (up to about 50 mmol/L), but from this point on, the decrease in surface tension is more pronounced for the non-superspreader, which has a lower DST than the superspreader in all concentrations.

The fact that the first two data points at the lowest concentrations are almost identical seemed at first sight counter-intuitive. However, this behavior is highly reproducible and can be explained as follows. The reason for the identical behavior of both surfactants is that below CMC, the amount of freely available surfactant monomers is identical to the amount of surfactant added. Above CMC, however, the amount of free surfactant monomers is given by the CMC. This interpretation was confirmed by determining the CMC values of the two surfactants. Therefore, our data shown in Fig. 2 are easy to explain; however, they disagree with the results reported by Sankaran et al. [9] and Svitova et al. [10]. It should be noted that the surface tension data in [10] has been determined using the drop volume method, which is unable to capture the surface tension kinetics at the relevant time scales. The supposedly faster dynamics of S240 is a sign of slightly lower static surface tension of a more hydrophobic surfactant.

Our results suggest that DST of S240 and S233 is determined solely by the surfactant concentration. Previous studies have suggested that different mechanisms might govern adsorption kinetics [14,15,16]. While some authors believe that only diffusion controls monomers adsorption to interfaces [17], others defend the idea that an adsorption barrier might also be an influencing factor [14,15,16, 18]. An adsorption barrier prevents the surfactant to adsorb and would be a result of increased surface pressure, less space in surface to monomers to adsorb and molecule orientation, since molecules of higher molecular weight may take a longer time to reorganize themselves to adsorb on interface [12]. Considering the chemical structure of S240 and S233, molecule orientation would hardly be a limiting process for adsorption, since both surfactants do not carry a long, straight hydrophobic alkyl chain, but a rather short and flexible heptamethyltrimethylsilyl hydrophobic group.

Since we have used the CMC argument above to explain the two different regimes observed in Fig. 2, we had to determine CMCs of both surfactants by measuring the static surface tensions at different concentrations using pendant drop tensiometry. The results of these measurements are presented in Fig. 3. It can be seen that for both surfactants, the solutions with higher concentration reach equilibrium faster than those with lower concentration. The time chosen to take the value of static surface tension in order to plot the CMC curves (Fig. 4) was 500 s. It should be noted that in case of S240, one should rather use the term CAC (critical aggregation concentration), since superspreading trisiloxane surfactants are known to form bilayer aggregates (e.g., vesicles) rather than micelles [2].

The pendant drop technique revealed that the CAC value for S240 is somewhat lower than the CMC value for S233. By observing both surface tension curves presented in Fig. 4, one can say that there is no sharp break in any of them, which is to be expected for surfactants with homolog distributions; the numbers of ethylene oxide (EO) and propylene oxide (PO) given in the chemical structures are only average values. According to ISO 4311:1979, such curves do not allow to give a value for the CMCs [19]. However, it can be seen that surface tension of S240 reaches the equilibrium value (static surface tension) at lower concentrations than in case of S233, which is also in accordance with the measurements reported by Kumar et al. [20], since they also found a higher critical micelle concentration for the non-superspreading surfactant. The higher CMC value of S233 can be associated to its greater number of ethoxy groups [7], which makes this surfactant more hydrophilic than S240.

Our second motivation to study the CMC/CAC was to check the questionable data presented by Sankaran et al. [9], showing a lower CMC for the more hydrophilic non-superspreading surfactant. From a physicochemical point of view, the explanation for the CMC data given by Sankaran et al. [9] in terms of aggregation behavior, strong H-bonds between the polyether headgroups locking the surfactant monomers into the micelles (only in case of the non-superspreader, but not the superspreader) are not plausible. The observed changes in surface tension over the course of hours (via captive bubble experiments using a pendant drop tensiometer) cannot be related to micelle kinetics of such low molecular weight nonionic surfactants. One much more plausible explanation is that the observed changes in surface tension are the first signs of hydrolysis, since trisiloxane surfactants are prone to this phenomenon [21], which is more likely for the more hydrophilic, micelle-forming surfactant. One of the hydrolysis products, hexamethyldisiloxane, is hydrophobic and volatile; it can contribute to surface tension reduction only in the captive bubble mode as used in [9], but not in “normal” pendant drop measurements.

Conclusions

We have looked into surface tension kinetics of two types of trisiloxane surfactants (superspreader and non-superspreader) by using maximum bubble pressure tensiometry. Results show that both surfactants have the same DST behavior at concentrations below critical micelle concentration (CMC) for S233 or critical aggregation concentration (CAC) for S240, which is to be expected. The CMC curves, i.e., the plots of static surface tension (as determined by drop shape analysis) vs. concentration confirmed that the more hydrophilic non-superspreader has a higher CMC as compared to CAC of a more hydrophobic superspreader. Accordingly, the lower surfactant monomer concentration of the superspreader results in a higher DST than the non-superspreader at the same surface age. Therefore, there is nothing mysterious or unexpected concerning the surface tension behavior of trisiloxane surfactants, as it was reported in the literature previously.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Change history

18 October 2023

A Correction to this paper has been published: https://doi.org/10.1007/s00396-023-05184-0

References

Ananthapadmanabhan KP, Goddard ED, Chandar P (1990) A study of the solution, interfacial and wetting properties of silicone surfactants. Colloids Surf 44:281–297. https://doi.org/10.1016/0166-6622(90)80202-F

Venzmer J (2011) Superspreading — 20 years of physicochemical research. Curr Opin Colloid Interface Sci 16:335–343. https://doi.org/10.1016/j.cocis.2010.11.006

Venzmer J (2021) Superspreading – has the mystery been unraveled? Adv Colloid Interface Sci 288:102343. https://doi.org/10.1016/j.cis.2020.102343

Wang X, Venzmer J, Bonaccurso E (2016) Surfactant-enhanced spreading of sessile water drops on polypropylene surfaces. Langmuir 32:8322–8328. https://doi.org/10.1021/acs.langmuir.6b01357

Nikolov AD, Wasan DT, Chengara A et al (2002) Superspreading driven by Marangoni flow. Adv Colloid Interface Sci 96:325–338. https://doi.org/10.1016/S0001-8686(01)00087-2

Kovalchuk NM, Dunn J, Davies J, Simmons MJH (2019) Superspreading on hydrophobic substrates: effect of glycerol additive. Colloids and Interfaces 3:51. https://doi.org/10.3390/colloids3020051

Nikolov A, Wasan D (2015) Current opinion in superspreading mechanisms. Adv Colloid Interface Sci 222:517–529. https://doi.org/10.1016/j.cis.2014.03.006

Chengara A, Nikolov AD, Wasan DT (2007) Spreading of a water drop triggered by the surface tension gradient created by the localized addition of a surfactant. Ind Eng Chem Res 46:2987–2995. https://doi.org/10.1021/ie060695y

Sankaran A, Karakashev SI, Sett S et al (2019) On the nature of the superspreaders. Adv Colloid Interface Sci 263:1–18. https://doi.org/10.1016/j.cis.2018.10.006

Svitova T, Hoffmann H, Hill RM (1996) Trisiloxane surfactants: surface/interfacial tension dynamics and spreading on hydrophobic surfaces. Langmuir 12:1712–1721. https://doi.org/10.1021/la9505172

Fainerman VB, Miller R (2004) Maximum bubble pressure tensiometry—an analysis of experimental constraints. Adv Colloid Interface Sci 108–109:287–301. https://doi.org/10.1016/j.cis.2003.10.010

Eastoe J, Dalton JS (2000) Dynamic surface tension and adsorption mechanisms of surfactants at the air–water interface. Adv Colloid Interface Sci 85:103–144. https://doi.org/10.1016/S0001-8686(99)00017-2

Fainerman VB, Kazakov VN, Lylyk SV et al (2004) Dynamic surface tension measurements of surfactant solutions using the maximum bubble pressure method – limits of applicability. Colloids Surf A Physicochem Eng Asp 250:97–102. https://doi.org/10.1016/j.colsurfa.2004.01.041

Chang H-C, Hsu C-T, Lin S-Y (1998) Adsorption kinetics of C 10 E 8 at the air−water interface. Langmuir 14:2476–2484. https://doi.org/10.1021/la970923g

Lin S-Y, Tsay R-Y, Lin L-W, Chen S-I (1996) Adsorption kinetics of C 12 E 8 at the air−water interface: adsorption onto a clean interface. Langmuir 12:6530–6536. https://doi.org/10.1021/la9605798

Eastoe J, Dalton JS, Rogueda PGA, Griffiths PC (1998) Evidence for activation−diffusion controlled dynamic surface tension with a nonionic surfactant. Langmuir 14:979–981. https://doi.org/10.1021/la971241w

Ward AFH, Tordai L (1946) Time-dependence of boundary tensions of solutions I. The role of diffusion in time-effects. J Chem Phys 14:453–461. https://doi.org/10.1063/1.1724167

Liggieri L, Ravera F, Passerone A (1996) A diffusion-based approach to mixed adsorption kinetics. Colloids Surf A Physicochem Eng Asp 114:351–359. https://doi.org/10.1016/0927-7757(96)03650-3

ISO 4311 (1979) Anionic and non-ionic surface active agents – determination of the critical micellization concentration – method by measuring surface tension with a plate, stirrup or ring

Kumar N, Couzis A, Maldarelli C (2003) Measurement of the kinetic rate constants for the adsorption of superspreading trisiloxanes to an air/aqueous interface and the relevance of these measurements to the mechanism of superspreading. J Colloid Interface Sci 267:272–285. https://doi.org/10.1016/S0021-9797(03)00530-7

Radulovic J, Sefiane K, Shanahan MER (2009) On the effect of pH on spreading of surfactant solutions on hydrophobic surfaces. J Colloid Interface Sci 332:497–504. https://doi.org/10.1016/j.jcis.2008.12.078

Funding

Open Access funding enabled and organized by Projekt DEAL. The research leading to these results received funding from the European Union’s Horizon 2020 research and innovation program under the Marie Skłodowska-Curie grant agreement number 955612 (NanoPaInt).

Author information

Authors and Affiliations

Contributions

Conceptualization: Joachim Venzmer. Experiments and investigation: Seforah Silva and Joachim Venzmer. Writing — original draft preparation: Seforah Silva. Writing — review and editing: Joachim Venzmer and Tatiana Gambaryan-Roisman. Supervision: Joachim Venzmer and Tatiana Gambaryan-Roisman. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Silva, S.C.M., Gambaryan-Roisman, T. & Venzmer, J. Surface tension behavior of superspreading and non-superspreading trisiloxane surfactants. Colloid Polym Sci 301, 739–744 (2023). https://doi.org/10.1007/s00396-023-05106-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-023-05106-0