Abstract

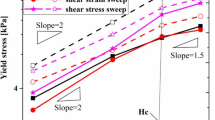

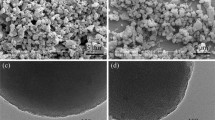

In this study, shear thickening fluid (STF) samples with different mass fractions were prepared by uniformly dispersing high-purity spherical silica powder in the polyethylene glycol (PEG) medium using the ball milling process. The influence of nano-particles on the shear and compression thickening effects of the STF dispersion system was investigated through the addition of fumed silica. Furthermore, the ball milled carbonyl iron powders (CIPs) with different particle sizes were dispersed uniformly in the STFs to prepare magnetorheological-STF (MR-STF) samples. The rheological properties of the developed STF and MR-STF samples were studied experimentally through a rheometer, and the results show that a lower temperature leads to a more obvious shear thickening effect of the STFs and that a smaller critical shear rate value promotes this effect. A higher content of silica powder also causes a more significant shear thickening effect of the STFs. Moreover, the addition of nano-fumed silica can significantly enhance the shear thickening effect, and the transition from continuous to discontinuous STFs can be realized by increasing the fumed silica mass fraction. Similarly, higher contents of silica powder and nano-fumed silica in the compression mode result in a more obvious thickening effect. In addition, the size of the CIP particles and the magnetic field strength directly affect the shear thickening effect of the MR-STFs. Specifically, under the same ferromagnetic particle mass fraction, the larger the CIP particles, the higher the applied magnetic induction intensity. Although a significant MR effect can be obtained, a certain inhibitory weakening effect is produced for the shear thickening behavior of the MR-STFs. Finally, considering the results in combination with the hydro-clustering and jamming theories, a mechanism was established to reveal the influence of different silica powder contents and nano-fumed silica fillings on the shear and compression thickening effects of STFs. Besides, a mechanism was proposed for the inhibition of the shear thickening effect of the MR-STFs by the ordered structures formed by CIP particles of different sizes in a magnetic field.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available on request from the corresponding author, upon reasonable request.

References

Lin K, Zhou AN, Liu HJ et al (2020) Shear thickening fluid damper and its application to vibration mitigation of stay cable. Structures 26:214–223

Guo YC, Wei YP, Zhou JL et al (2019) Impact and usage of the shear thickening fluid (STF) material in damping vibration of bolted flange joints. Smart Mater Struct 28:095005

Lim J, Kim SW (2020) Enhanced damping characteristics of carbon fiber reinforced polymer–based shear thickening fluid hybrid composite structures. J Intell Mater Syst Struct 31(20):2291–2303

Zhang JS, Wang Y, Deng HX et al (2022) A high anti-impact STF/Ecoflex composite structure with a sensing capacity for wearable design. Compos B 233:109656

Zhang JS, Wang Y, Zhou JY et al (2021) Intralayer interfacial sliding effect on the anti-impact performance of STF/Kevlar composite fabric. Compos A 145:106401

Yuan F, Liu S, Zhou JY et al (2020) A smart Kevlar-based triboelectric nanogenerator with enhanced anti-impact and self-powered sensing properties. Smart Mater Struct 29:125007

James NM, Han ED, de la Cruz RAL et al (2018) Interparticle hydrogen bonding can elicit shear jamming in dense suspensions. Nat Mater 17(11):965–970

Gamonpilas C, Morris JF, Denn MM (2016) Shear and normal stress measurements in non-Brownian monodisperse and bidisperse suspensions. J Rheol 60(2):289–296

Ye F, Zhu W, Jiang WQ et al (2013) Influence of surfactants on shear-thickening behavior in concentrated polymer dispersions. J Nanopart Res 15(12):2122

Liu M, Chen S, Wang S et al (2017) PVP immobilized SiO2 nanospheres for high-performance shear thickening fluid. J Nanopart Res 19(7):234

Zhao MM, Zhang JQ, Liu YL et al (2022) Rheological characteristics analysis of shear thickening fluids based on response surface methodology. Mater Res Express 9(2):025701

Mostafizur RM, Aziz ARA, Saidur R et al (2014) Effect of temperature and volume fraction on rheology of methanol based nanofluids. Int J Heat Mass Transf 77:765–769

Jiang WF, Xuan SH, Gong XL (2015) The role of shear in the transition from continuous shear thickening to discontinuous shear thickening. Appl Phys Lett 106(15):151902

Jiang WF, Peng GJ, Ma Y et al (2017) Measuring the mechanical responses of a jammed discontinuous shear-thickening fluid. Appl Phys Lett 111(20):201906

Qin JB, Zhang GC, Ma ZL et al (2016) Effects of ionic structures on shear thickening fluids composed of ionic liquids and silica nanoparticles. RSC Adv 6(85):81913–81923

Qin JB, Zhang GC, Shi XT (2016) Viscoelasticity of shear thickening fluid based on silica nanoparticles dispersing in 1-butyl-3-methylimidizolium tetrafluoroborate. J Dispersion Sci Technol 37(11):1599–1606

Li W, Xiong DS, Zhao XD et al (2016) Dynamic stab resistance of ultra-high molecular weight polyethylene fabric impregnated with shear thickening fluid. Mater Des 102:162–167

Shan L, Tian Y, Meng YG et al (2015) Influences of medium and temperature on the shear thickening behavior of nano fumed silica colloids. Acta Physica Sinica 64(6):068301

Chen Q, Zhu W, Ye F et al (2014) pH effects on shear thickening behaviors of polystyrene-ethylacrylate colloidal dispersions. Mater Res Express 1(1):015303

Wei MH, Sun L, Zhang CW et al (2019) Shear-thickening performance of suspensions of mixed ceria and silica nanoparticles. J Mater Sci 54(1):346–355

Sun L, Lv YR, Wei MH et al (2020) Shear thickening fluid based on silica with neodymium oxide nanoparticles. Bull Mater Sci 43(1):132

Wei RB, Dong B, Sun ZW et al (2021) Characterization of the rheological behaviors and mechanical properties of fabrics impregnated by different shear thickening fluids at changing temperatures. Smart Mater Struct 30:085009

Li S, Wang J, Cai W et al (2016) Effect of acid and temperature on the discontinuous shear thickening phenomenon of silica nanoparticle suspensions. Chem Phys Lett 658:210–214

Liu XQ, Bao RY, Wu XJ et al (2015) Temperature induced gelation transition of a fumed silica/PEG shear thickening fluid. RSC Adv 5(24):18367–18374

Yu M, Qiao XY, Dong XJ et al (2018) Shear thickening effect of the suspensions of silica nanoparticles in PEG with different particle size, concentration, and shear. Colloid Polym Sci 296(7):1119–1126

Shahbaz SR, Berkalp OB (2020) Effect of MWCNTs addition, on the mechanical behaviour of FRP composites, by reinforcement grafting and matrix modification. J Ind Text 50(2):205–223

Wei MH, Lv YR, Sun L et al (2020) Rheological properties of multi-walled carbon nanotubes/silica shear thickening fluid suspensions. Colloid Polym Sci 298(3):243–250

Gurgen S (2019) Tuning the rheology of nano-sized silica suspensions with silicon nitride particles. J Nano Res 56:63–70

Liu XG, Li Y, Xue WD et al (2018) Shear-thickening behavior of Fe-ZSM5 zeolite slurry and its removal with alumina/boehmites. Int J Miner Metall Mater 25(6):682–688

Hoffman RL (1982) Discontinuous and dilatant viscosity behavior in concentrated suspensions III. Necessary conditions for their occurrence in viscometric flows. Adv Colloid Interface Sci 17(1):161–184

Hoffman RL (1998) Explanations for the cause of shear thickening in concentrated colloidal suspensions. J Rheol 42(1):111–123

Wagner NJ, Brady JF (2009) Shear thickening in colloidal dispersions. Phys Today 62(10):27–32

Egres RG, Wagner NJ (2005) The rheology and microstructure of acicular precipitated calcium carbonate colloidal suspensions through the shear thickening transition. J Rheol 49(3):719–746

Olsson P, Teitel S (2007) Critical scaling of shear viscosity at the jamming transition. Phys Rev Lett 99(17):178001

Crawford NC, Williams SKR, Boldridge D et al (2013) Liberatore, Shear-induced structures and thickening in fumed silica slurries. Langmuir 29(42):12915–12923

Crawford NC, Williams SKR, Boldridge D et al (2013) Shear thickening and defect formation of fumed silica CMP slurries. Colloids Surf A 436:87–96

Galindo-Rosales FJ, Rubio-Hernandez FJ, Sevilla A (2011) An apparent viscosity function for shear thickening fluids. J Nonnewton Fluid Mech 166(5–6):321–325

Zhang XZ, Li WH, Gong XL (2008) Study on magnetorheological shear thickening fluid. Smart Mater Struct 17:015051

Sokolovski V, Tian TF, Ding J et al (2020) Fabrication and characterisation of magnetorheological shear thickening fluids. Front Mater 7:595100

Yang J, Sun SS, Li WH et al (2015) Development of a linear damper working with magnetorheological shear thickening fluids. J Intell Mater Syst Struct 26(14):1811–1817

Liu B, Du CB, Deng HX et al (2022) Mechanical properties of magneto-sensitive shear thickening fluid absorber and application potential in a vehicle. Compos Part A Appl Sci Manuf 154:106782

Jolly MR, Carlson JD, Muoz BC (1996) A model of the behaviour of magnetorheological materials. Smart Mater Struct 5(5):607–614

Funding

This work was supported by Wuhu scientific and technological project (Grant no. 2022JC14), the Ph.D. Research Startup Foundation of Anhui Polytechnic University (Grant no. S022020069), the Key Research Foundation of Anhui Polytechnic University (Grant no. KZ42020240), and the National Science Foundation Granted by the Department of Education, Anhui Province (Grant no. KJ2020A0260).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, F., Xu, Z. & Gu, J. Effects of nano-fumed silica and carbonyl iron powder of different particle sizes on the rheological properties of shear thickening fluids. Colloid Polym Sci 301, 539–555 (2023). https://doi.org/10.1007/s00396-023-05087-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-023-05087-0