Abstract

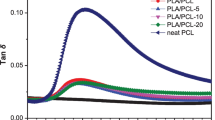

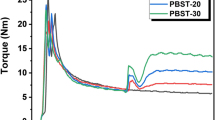

A blend of biodegradable poly(ε-caprolactone) (PCL) and sustainable poly(propylene carbonate) (PPC) was prepared by melt mixing to obtain an excellent balance of performance. The miscibility, morphology, thermal behavior, mechanical, and rheological properties of PCL/PPC blends were investigated. Dynamic mechanical analysis results revealed PCL and PPC were immiscible. Minor phase-separated morphology was observed from SEM for PCL/PPC blends. The incorporation of PPC accelerated the crystallization rate of PCL, whereas reduced the degree of crystallinity. Significant enhancement of stiffness and strength of PCL was achieved by the introduction of PPC. The Young’s modulus and yield strength of blend containing 30 wt% PPC were increased by 65% and 17%, respectively, compared with neat PCL, and the elongation at break was still above 600%. Moreover, the viscosity and elasticity of PCL melt were improved by the presence of PPC. The synergetic improvement in mechanical and rheological properties is important for expanding the application of PCL.

Similar content being viewed by others

References

Samadi K, Francisco M, Hegde S, Diaz CA, Trabold TA, Dell EM, Lewis CL (2019) Mechanical, rheological and anaerobic biodegradation behavior of a poly(lactic acid) blend containing a poly(lactic acid)-co-poly(glycolic acid) copolymer. Polym Degrad Stabil 170:109018

Xia S, Shen Y, Zhou Y, Yao P, Liu Q, Deng B (2018) Biodegradable multiblock copolymers containing poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)], poly(ε-caprolactone), and polyhedral oligomeric silsesquioxane: synthesis, characterization, and tensile property. Colloid Polym Sci 296:1667–1677

Bu X, Li H, Yan S (2017) The propagation of crystal orientation in poly(ε-caprolactone)/poly(vinyl chloride) blend film after removal of induction layer. Colloid Polym Sci 295:1635–1642

Oh HJ, Son JH, Hwang SJ, Kim J, Hyun DC (2017) Fabrication of poly(ε-caprolactone) (PCL) particles with non-spherical geometries via selective dewetting and deposition of the polymer. Colloid Polym Sci 295:1475–1484

Sedov I, Magsumov T, Abdullin A, Yarko E, Mukhametzyanov T, Klimovitsky A, Schick C (2018) Influence of the cross-link density on the rate of crystallization of poly(ε-caprolactone). Polymers 10:902

Bellani CF, Pollet E, Hebraud A, Pereira FV, Schlatter G, Avérous L, Bretas RES, Branciforti MC (2016) Morphological, thermal, and mechanical properties of poly(ε-caprolactone)/poly(ε-caprolactone)-grafted-cellulose nanocrystals mats produced by electrospinning. J Appl Polym Sci 133:43445

Wei Q, Sun D, Zhang K, Wang Y, Guo Y, Wang Y (2021) Research on the miscibility, mechanical properties and printability of polylactic acid/poly (ε-caprolactone) blends: insights from molecular dynamics simulation and experiments. J Mater Sci 56:9754–9768

Mofokeng JP, Luyt AS (2015) Morphology and thermal degradation studies of melt-mixed poly(lactic acid) (PLA)/poly(ε-caprolactone) (PCL) biodegradable polymer blend nanocomposites with TiO2 as filler. Polym Test 45:93–100

Alam F, Verma P, Mohammad W, Teo J, Varadarajan KM, Kumar S (2021) Architected poly(lactic acid)/poly(ε-caprolactone)/halloysite nanotube composite scaffolds enabled by 3D printing for biomedical applications. J Mater Sci 56:14070–14083

Urquijo J, Dagréou S, Guerrica-Echevarría G, Eguiazábal JI (2016) Structure and properties of poly(lactic acid)/poly(ε-caprolactone) nanocomposites with kinetically induced nanoclay location. J Appl Polym Sci 133:43815

IbrahimAkos N, UzirWahit M, Mohamed R, AliYussuf A (2013) Comparative studies of mechanical properties of poly(ε-caprolactone) and poly(lactic acid) blends reinforced with natural fibers. Compos Interface 20:459–467

Finotti PFM, Costa LC, Capote TSO, Scarel-Caminaga RM, Chinelatto MA (2017) Immiscible poly(lactic acid)/poly(ε-caprolactone) for temporary implants: compatibility and cytotoxicity. J Mech Behav Biomed Mater 68:155–162

Przybysz-Romatowska M, Haponiuk J, Formela K (2020) Poly(ε-caprolactone)/poly(lactic acid) blends compatibilized by peroxide initiators: comparison of two strategies. Polymers 12:228

Maglio G, Migliozzi A, Palumbo R, Immirzi B, Volpe MG (2015) Compatibilized poly(ε-caprolactone)/poly(L-lactide) blends for biomedical uses. Macromol Rapid Comm 20:236–238

Duarte MAT, Hugen RG, Martins ES, Pezzin APT, Pezzin SH (2006) Thermal and mechanical behavior of injection molded poly(3-hydroxybutyrate)/poly(ε-caprolactone) blends. Mater Res 9:25–27

Qiu Z, Yang W, Ikehara T, Nishi T (2005) Miscibility and crystallization behavior of biodegradable blends of two aliphatic polyesters. Poly(3-hydroxybutyrate-co-hydroxyvalerate) and poly(ε-caprolactone) Polymer 46:11814–11819

Gaudio CD, Ercolani E, Nanni F, Bianco A (2011) Assessment of poly(ε-caprolactone)/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) blends processed by solvent casting and electrospinning. Mater Sci Eng A 528:1764–1772

Sousa FM, Cavalcanti FB, Marinho VAD, Morais DDS, Almeida TG, Carvalho LH (2021) Effect of composition on permeability, mechanical properties and biodegradation of PBAT/PCL blends films. Polym Bull. https://doi.org/10.1007/s00289-021-03745-3

Correa AC, Carmona VB, Simão JA, Mattoso LHC, Marconcini JM (2017) Biodegradable blends of urea plasticized thermoplastic starch (UTPS) and poly(ε-caprolactone) (PCL): Morphological, rheological, thermal and mechanical properties. Carbohyd Polym 167:177–184

Hubackova J, Dvorackova M, Svoboda P, Mokrejs P, Kupec J, Pozarova I, Alexy P, Bugaj P, Machovsky M, Koutny M (2013) Influence of various starch types on PCL/starch blends anaerobic biodegradation. Polym Test 32:1011–1019

Kusumi R, Inoue Y, Shirakawa M, Miyashita Y, Nishio Y (2008) Cellulose alkyl ester/poly(ε-caprolactone) blends: characterization of miscibility and crystallization behaviour. Cellulose 15:1–16

Xu Y, Wang C, Stark NM, Cai Z, Chu F (2012) Miscibility and thermal behavior of poly (ε-caprolactone)/long-chain ester of cellulose blends. Carbohyd Polym 88:422–427

Muthuraj R, Mekonnen T (2018) Recent progress in carbon dioxide (CO2) as feedstock for sustainable materials development: Co-polymers and polymer blends. Polymer 145:348–373

Phillips O, Schwartz JM, Kohl PA (2016) Thermal decomposition of poly(propylene carbonate): end-capping, additives, and solvent effects. Polym Degrad Stab 125:129–139

Lorenzo MLD, Ovyn R, Malinconico M, Rubino P, Grohens Y (2016) Peculiar crystallization kinetics of biodegradable poly(lactic acid)/poly(propylene carbonate) blends. Polym Eng Sci 55:2698–2705

Yao M (2011) Modification of poly(lactic acid)/poly(propylene carbonate) blends through melt compounding with maleic anhydride. Express Polym Lett 5:937–949

Qin S, Yu C, Chen X, Zhou H, Zhao L (2018) Fully biodegradable poly(lactic acid)/poly(propylene carbonate) shape memory materials with low recovery temperature based on in situ compatibilization by dicumyl peroxide. Chinese J Polym Sci 36:783–790

Corre YM, Bruzaud S, Grohens Y (2013) Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and poly(propylene carbonate) blends: an efficient method to finely adjust properties of functional materials. Macromol Mater Eng 298:1176–1183

Enriquez E, Mohanty AK, Misra M (2017) Biobased blends of poly(propylene carbonate) and poly(hydroxybutyrate-co-hydroxyvalerate): fabrication and characterization. J Appl Polym Sci 134:44420

El-Hadi AM (2017) Improvement of the miscibility by combination of poly(3-hydroxy butyrate) PHB and poly(propylene carbonate) PPC with additives. J Polym Environ 25:728–738

Zhang S, Sun X, Ren Z, Li H, Yan S (2015) The development of a bilayer structure of poly(propylene carbonate)/poly(3-hydroxybutyrate) blends from the demixed melt. Phys Chem Chem Phys 17:32225–32231

Henke L, Zarrinbakhsh N, Endres HJ, Misra M, Mohanty AK (2017) Biodegradable and bio-based green blends from carbon dioxide-derived bioplastic and poly (butylene succinate). J Polym Environ 25:499–509

Calderon BA, Mccaughey MS, Thompson CW, Sobkowicz MJ (2019) Blends of renewable poly(butylene succinate) and poly(propylene carbonate) compatibilized with maleic anhydride using quad screw reactive extrusion. Ind Eng Chem Res 58:487–495

Zeng S, Wang S, Xiao M, Han D, Meng Y (2011) Preparation and properties of biodegradable blend containing poly (propylene carbonate) and starch acetate with different degrees of substitution. Carbohyd Polym 86:1260–1265

Peng S, Wang X, Dong L (2010) Special interaction between poly (propylene carbonate) and corn starch. Polym Composite 26:37–41

Feng J, Liu X, Bao R, Yang W, Xie B, Yang M (2015) Suppressing phase coarsening in immiscible polymer blends using nano-silica particles located at the interface. RSC Adv 5:74295–74303

Yeh JT, Wu CJ, Tsou CH, Chai W, Chow JD, Huang C, Chen K, Wu C (2009) Study on the crystallization, miscibility, morphology, properties of poly(lactic acid)/poly(ε-caprolactone) blends. Polym Plast Technol 48:571–578

Bikiaris DN, Papageorgiou GZ, Achilias DS, Pavlidou E, Stergiou A (2007) Miscibility and enzymatic degradation studies of poly(ε-caprolactone)/poly(propylene succinate) blends. Eur Polym J 43:2491–2503

Jiang G, Wang F, Zhang S, Huang H (2020) Structure and improved properties of PPC/PBAT blends via controlling phase morphology based on melt viscosity. J Appl Polym Sci 137:48924

Cheung YW, Stein RS (1994) Critical analysis of the phase behavior of poly(ecapro1actone) (PCL)/polycarbonate (PC) blends. Macromolecules 27:2512–2519

Hao Y, Yang H, Zhang H, Mo Z (2018) Miscibility, crystallization behaviors and toughening mechanism of poly(butylene terephthalate)/thermoplastic polyurethane blends. Fiber Polym 19:1–10

Pang MZ, Qiao JJ, Jiao J, Wang SJ, Xiao M, Meng YZ (2008) Miscibility and properties of completely biodegradable blends of poly(propylene carbonate) and poly(butylene succinate). J Appl Polym Sci 107:2854–2860

Simões CL, Viana JC, Cunha AM (2009) Mechanical properties of poly(ε-caprolactone) and poly(lactic acid) blends. J Appl Polym Sci 112:345–352

Rosa DS, Lopes DR, Calil MR (2007) The influence of the structure of starch on the mechanical, morphological and thermal properties of poly (ε-caprolactone) in starch blends. J Mater Sci 42:2323–2328

Bragança FC, Rosa DS (2003) Thermal, mechanical and morphological analysis of poly(ε-caprolactone), cellulose acetate and their blends. Polym Adv Technol 14:669–675

Funding

This work is supported by the Chinese Academy of Science and Technology Service Network Planning (KFJ-STS-QYZD-140).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Y., Cheng, H., Yu, M. et al. Blends of biodegradable poly(ε-caprolactone) and sustainable poly(propylene carbonate) with enhanced mechanical and rheological properties. Colloid Polym Sci 300, 59–68 (2022). https://doi.org/10.1007/s00396-021-04931-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-021-04931-5