Abstract

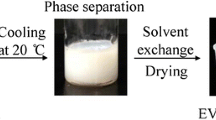

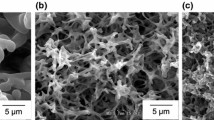

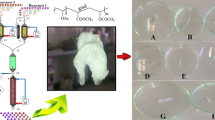

Acetoactylated poly(vinyl alcohol) (AAPVA) monoliths were prepared from polymer solutions via non-solvent-induced phase separation technique for the first time. The morphology of the AAPVA monolith was observed by scanning electron microscopy (SEM) which shown the continuous porous structure existing inside the monolith. A relatively large surface area (102 m2/g) was demonstrated by the Brunauer-Emmett-Teller (BET) analysis. The AAPVA monolith was functionalized by reacting with polyethylenimine (PEI) and glutaraldehyde (GA) successively, through which aldehyde groups were grafted onto the AAPVA monolith. Lipase and horseradish peroxidase (HRP) were successfully immobilized onto the final functionalized AAPVA monolith. On this basis, the present monolith has promising prospect for applications of enzyme immobilization.

Similar content being viewed by others

References

Svec F, Fréchet J (1996) New designs of macroporous polymers and supports: from separation to biocatalysis Science 273:205–211

Rose M, Klein N, Senkovska L, Schrage C, Wollmann P, Böhlmann W, Böhringer B, Fichtner S, Kaskel S (2011) A new route to porous monolithic organic frameworks via cyclotrimerization J Mater Chem 21:711–716

Liu Y, Ren L, Liu Z (2011) A unique boronic acid functionalized monolithic capillary for specific capture, separation and immobilization of cis-diol biomolecules Chem Commun 47:5067–5069

Wang G, Uyama H (2016) Facile synthesis of flexible macroporous polypropylene sponges for separation of oil and water Sci Rep 6:1–6

Barroso T, Casimiro T, Ferraria A, Mattioli F, Aguiar-Ricardo A, Roque A (2014) Hybrid monoliths for magnetically-driven protein separations Adv Func Mater 24:4528–4541

Vlakh E, Tennikova T (2013) Flow-through immobilized enzyme reactors based on monolith: II Kinetics study and application J Sep Sci 36:1149–1167

Choi S, Xie J, Xia Y (2009) Chitosan-based inverse opals: three-dimensional scaffolds with uniform pore structures for cell culture Adv Mater 21:2997–3001

Svec F, Fréchet J (1995) Temperature, a simple and efficient tool for the control of pore-size distribution in macroporous polymers Macromolecules 28:7580–7582

Grasselli M, Smolko E, Hargittai P, Sárfrány Á (2001) From microspheres to monoliths: synthesis of porous supports with tailored properties by radiation polymerization Nucl Instr Meth Phys Res B 185:254–261

Kanamori K, Nakanishi K, Hanada T (2006) Rigid macroporous poly(divnylbenzene) monoliths with a well-defined bicontinuous morphology prepared by living radical polymerization Adv Mater 19:2407–2411

Nguyen A, Irgum K (2006) Epoxy-based monoliths. A novel hydrophilic separation material for liquid chromatography of biomolecules. Chem Mater 18: 6308–6315

Xin Y, Fujimoto T, Uyama H (2012) Facile fabrication of polycarbonate monolith by non-solvent induced phase separation method Polymer 53:2847–2853

Sun X, Fujimoto T, Uyama H (2013) Fabrication of a poly(vinyl alcohol) monolith via thermally impacted non-solvent-induced phase separation Polym J 45:1101–1106

Sun X, Uyama H (2013) A poly(vinyl alcohol)/sodium alginate blend monolith with nanoscale porous structure Nanoscale Res Lett 8:411–415

Sun X, Uyama H (2014) In situ minerization of hydroxyapatite on poly(vinyl alcohol) monolithic scaffolds for tissue engineering Colloid Polym Sci 292:1073–1078

Al-Zuhair S (2007) Production of biodiesel: possibilities and challenges Biofuels Bioprod Biorefin 1:57–66

Poppe J, Fernandez-Lafuente R, Rodrigues R, Ayub M (2015) Enzymatic reactors for biodiesel synthesis: present status and future prospects Biotechnol Adv 33:511–525

Rios G, Belleville M, Paolucci D, Sanchez J (2004) Progress in enzymatic membrane reactors—a review J Membr Sci 242:189–196

Krenkova J, Svec F (2009) Less common applications of monoliths: IV. Recent developments in immobilized enzyme reactors for proteomics and biotechnology. J Sep Sci 32: 706–718

Wen L, Gao A, Cao Y, Svec F, Tan T, Lv Y (2016) Layer-by-layer assembly of metal-organic frameworks in macroporous polymer monolith and their use for enzyme immobilization Macromol Rapid Commun 37:551–557

Han W, Xin Y, Hasegawa U, Uyama H (2014) Enzyme immobilization on polymethacrylate-based monolith fabricated via thermally induced phase separation Polym Degrad Stabil 109:362–366

Hori N, Asai K, Takemura A (2008) Effect of the ethylene/vinyl acetate ratio of ethylene-vinyl acetate emulsion on the curing behavior of an emulsion polymer isocyanate adhesive for wood J Wood Sci 54:294–299

Bradford M (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding Anal Biochem 72:248–254

Patel A, Li S, Yuan J, Wei Y (2006) In situ encapsulation of horseradish peroxidase in electrospun porous silica fibers for potential biosensor applications Nano Lett 6:1042–1046

Sun X, Sun G, Wang X (2017) Morphology modeling for polymer monolith obtained by non-solvent-induced phase separation Polymer 108:432–441

Sing K (1982) Reporting physisorption data for gas/solid systems Pure Appl Chem 54:2201–2218

Coleman N, Hench L (2000) A gel-derived mesoporous silica reference material for surface analysis by gas sorption 1. Textural features Ceram Int 26:171–178

Bonnaud L, Pascault J, Sautereau H, Zhao J, Jia D (2004) Effect of reinforcing glass fibers on morphology and properties of thermoplastic modified epoxy-aromatic diamine matrix Polym Compos 25:368–374

Wang G, Uyama H (2015) Reactive poly(ethylene-co-vinyl alcohol) monoliths with tunable pore morphology for enzyme immobilization Colloid Polym Sci 293:2429–2435

Bayramoğlu G, Arıca (2008) Enzymatic removal of phenol and p-chlorophenol in enzyme reactor: horseradish peroxidase immobilized on magnetic beads. J Hazard Mater 156(1): 148–155

Lee J, Kwak H, Yun H, Kim Y, Lee K (2016) Methyl cellulose nanofibrous mat for lipase immobilization via cross-linked enzyme aggregates Macromol Res 24:218–225

Lai Y, Lin S (2005) Application of immobilized horseradish peroxidase for the removal of p-chlorophenol from aqueous solution Process Biochem 40:1167–1174

Qian Y, Chen P, He G, Huang X, Xu Z (2014) Preparation of polyphosphazene hydrogels for enzyme immobilization Molecules 19(7):9850–9863

Acknowledgements

This study was funded by the General Financial Grant from the China Postdoctoral Science Foundation (No. 2016M601474), the Fundamental Research Funds for the Central Universities, and “111 Project” Biomedical Textile Materials Science and Technology, China (No. B07024), the Initial Research Funds for Young Teachers of Donghua University, the Natural Science Foundation of Jiangsu Province for Youth (No. BK20160496), and the Scientific Research Foundation of Jiangsu University (No. 16JDG030).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Sun, X., Xin, Y., Wang, X. et al. Functionalized acetoacetylated poly(vinyl alcohol) monoliths for enzyme immobilization: a phase separation method. Colloid Polym Sci 295, 1827–1833 (2017). https://doi.org/10.1007/s00396-017-4160-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-017-4160-3