Abstract

Concrete, a naturally resilient material, often undergoes a series of physio-chemical degradations once exposed to extreme environments (e.g., elevated temperatures). Under such conditions, not only concrete weakens, but also becomes vulnerable to fire-induced spalling; a complex and exceptionally random phenomenon. Despite serious efforts carried out over the past few years, we continue to be short of developing a methodical procedure that enables accurate assessment of concrete under elevated temperatures with due consideration to fire-induced spalling. Unlike traditional works, this study aims at investigating fire behavior of concrete through a modern perspective. In this study, a number of intelligent pattern recognition (IPR) techniques that capitalize on artificial intelligence (AI) are applied to derive expressions able of accurately trace the response of normal and high strength as well as high performance concretes under elevated temperatures. These expressions take into account geometric, material, and specific features of structural components to examine fire response as well as to predict occurrence of fire-induced spalling in concrete structures. These expressions were developed through rigorous and data-driven analysis of actual fire tests and were derived to implicitly account for physio-chemical transformations in concrete and as such do not require collection/input of temperature-dependent material properties nor special analysis/simulation. This study also features the development of an IPR-based database and fire assessment software that can be used to examine fire performance of concrete members and be regularly updated as to continually improve the accuracy of the proposed expressions.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

Notes

Spalling may also occur at relatively higher temperatures in the range of 700–1200 °C due to decarbonation of calcium carbonate and complete dehydration of concrete [9]. This spalling is referred to as thermo-chemical spalling and often occurs in later stages of fire.

References

Takeuchi M, Narikawa M, Matsuo I, Hara K, Usami S (1998) Study on a concrete filled structure for nuclear power plants. Nucl Eng Des. https://doi.org/10.1016/s0029-5493(97)00282-3

Naser M, Chehab A (2018) Materials and design concepts for space-resilient structures. Prog Aerosp Sci 98:74–90. https://doi.org/10.1016/j.paerosci.2018.03.004

Heo Y-S, Sanjayan JG, Han C-G, Han M-C (2010) Synergistic effect of combined fibers for spalling protection of concrete in fire. Cem Concr Res 40:1547–1554. https://doi.org/10.1016/J.CEMCONRES.2010.06.011

Missemer L, Ouedraogo E, Malecot Y, Clergue C, Rogat D (2019) Fire spalling of ultra-high performance concrete: from a global analysis to microstructure investigations. Cem Concr Res 115:207–219. https://doi.org/10.1016/J.CEMCONRES.2018.10.005

Khoury GA (2000) Effect of fire on concrete and concrete structures. Prog Struct Eng Mater 2:429–447. https://doi.org/10.1002/pse.51

Schneider U (1988) Concrete at high temperatures—a general review. Fire Saf J. https://doi.org/10.1016/0379-7112(88)90033-1

Kodur VKR, Cheng F-P, Wang T-C, Sultan MA (2003) Effect of strength and fiber reinforcement on fire resistance of high-strength concrete columns. J Struct Eng 129:253–259. https://doi.org/10.1061/(ASCE)0733-9445(2003)129:2(253)

Phan LT (2008) Pore pressure and explosive spalling in concrete. Mater Struct Constr. https://doi.org/10.1617/s11527-008-9353-2

Liu J-CC, Tan KH, Yao Y (2018) A new perspective on nature of fire-induced spalling in concrete. Constr Build Mater 184:581–590. https://doi.org/10.1016/j.conbuildmat.2018.06.204

Starossek U (2009) Progressive collapse of structures. https://trid.trb.org/view/1138360. Accessed 28 Nov 2018

Ellingwood BR, Dusenberry DO (2005) Building design for abnormal loads and progressive collapse. Comput Civ Infrastruct Eng 20:194–205. https://doi.org/10.1111/j.1467-8667.2005.00387.x

BSI (2004) Design of concrete structures—Part 1–2: general rules—structural fire design. Eurocode. https://doi.org/10.1002/jcp.25002

ACI 216-14, 216.1-14 Code Requirements for Determining Fire Resistance of Concrete and Masonry Construction Assemblies, American Concrete Institute, ISBN: 9780870319549. https://www.concrete.org/store/productdetail.aspx?ItemID=216114&Language=English&Units=US_Units

Kodur VKR (2018) Innovative strategies for enhancing fire performance of high-strength concrete structures. Adv Struct Eng 10:100. https://doi.org/10.1177/1369433218754335

Phan LT, Carino NJ (2000) Fire performance of high strength concrete: research needs. In: Advanced Technology Structure Engineering, American Society of Civil Engineers, Reston, VA, pp 1–8. https://doi.org/10.1061/40492(2000)181

Ji T, Lin T, Lin X (2006) A concrete mix proportion design algorithm based on artificial neural networks. Cem Concr Res 36:1399–1408. https://doi.org/10.1016/J.CEMCONRES.2006.01.009

Ni H-G, Wang J-Z (2000) Prediction of compressive strength of concrete by neural networks. Cem Concr Res 30:1245–1250. https://doi.org/10.1016/S0008-8846(00)00345-8

McKinney J, Ali F (2014) Artificial neural networks for the spalling classification and failure prediction times of high strength concrete columns. J Struct Fire Eng. https://doi.org/10.1260/2040-2317.5.3.203

Harmathy T (1965) Effect of moisture on the fire endurance of building elements. Moisture Mater Relat Fire. http://www.astm.org/DIGITAL_LIBRARY/STP/PAGES/STP48429S.htm. Accessed 27 Nov 2018

Bažant ZP, Thonguthai W (1979) Pore pressure in heated concrete walls: theoretical prediction. Magn Concr Res 18:200. https://doi.org/10.1680/macr.1979.31.107.67

Hertz KDD (2003) Limits of spalling of fire-exposed concrete. Fire Saf J 38:103–116. https://doi.org/10.1016/S0379-7112(02)00051-6

Bažant ZP, Kaplan MF, Bazant ZP (1996) Concrete at high temperatures: material properties and mathematical models. https://www.scholars.northwestern.edu/en/publications/concrete-at-high-temperatures-material-properties-and-mathematica. Accessed 28 Nov 2018

Ulm F-J, Coussy O, Bažant ZP (1999) The “Chunnel” Fire. I. chemoplastic softening in rapidly heated concrete. J Eng Mech 125:272–282. https://doi.org/10.1061/(asce)0733-9399(1999)125:3(272)

Song T-Y, Han L-H, Tao Z (2015) Structural behavior of SRC beam-to-column joints subjected to simulated fire including cooling phase. J Struct Eng 10:200. https://doi.org/10.1061/(asce)st.1943-541x.0001211

Shah AH, Sharma UK (2017) Fire resistance and spalling performance of confined concrete columns. Constr Build Mater 156:161–174. https://doi.org/10.1016/j.conbuildmat.2017.08.167

Kodur V, Cheng F, Wang T, Latour J, Leroux P (2001) Fire resistance of high-performance concrete columns. doi:http://doi.org/10.4224/20378506

Klingsch EWH (2014) Explosive spalling of concrete in fire. Tese Doutorado. https://doi.org/10.3929/ethz-a-010076314

Kodur V (2014) Properties of concrete at elevated temperatures. ISRN Civ Eng. https://doi.org/10.1155/2014/468510

Kodur V, McGrath R (2003) Fire endurance of high strength concrete columns. Fire Technol 39:73–87. https://doi.org/10.1023/A:1021731327822

Kanéma M, Pliya P, Noumowé A, Gallias J-L (2011) Spalling, thermal, and hydrous behavior of ordinary and high-strength concrete subjected to elevated temperature. J Mater Civ Eng 23:921–930. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000272

Maluk C, Bisby L, Terrasi GP (2017) Effects of polypropylene fibre type and dose on the propensity for heat-induced concrete spalling. Eng Struct. https://doi.org/10.1016/j.engstruct.2017.03.058

Zhang Y, Zeiml M, Maier M, Yuan Y, Lackner R (2017) Fast assessing spalling risk of tunnel linings under RABT fire: From a coupled thermo-hydro-chemo-mechanical model towards an estimation method. Eng Struct 10:200. https://doi.org/10.1016/j.engstruct.2017.03.068

Shakya AM, Kodur VKR (2015) Response of precast prestressed concrete hollowcore slabs under fire conditions. Eng Struct 10:200. https://doi.org/10.1016/j.engstruct.2015.01.018

Seitllari A, Kutay ME (2018) Soft computing tools to predict progression of percent embedment of aggregates in chip seals. Transp Res Rec. https://doi.org/10.1177/0361198118756868

Naser MZ (2018) Deriving temperature-dependent material models for structural steel through artificial intelligence. Constr Build Mater 191:56–68. https://doi.org/10.1016/J.CONBUILDMAT.2018.09.186

Gesoǧlu M, Güneyisi E, Özturan T, Özbay E (2010) Modeling the mechanical properties of rubberized concretes by neural network and genetic programming. Mater Struct Constr. https://doi.org/10.1617/s11527-009-9468-0

Bro R, Smilde A (2014) Principal component analysis. Anal Methods 6:2812. https://doi.org/10.1039/c3ay41907j

Seitllari A (2014) Traffic flow simulation by neuro-fuzzy approach. In: Second international conference on traffic, 2014. https://trid.trb.org/view/1408239. Accessed 28 Nov 2018

Demuth H, Beale M, Hagan M (1992) Neural network toolbox. For Use with MATLAB. The MathWorks Inc, 2000. https://kashanu.ac.ir/Files/Content/neural_network_toolbox_6.pdf

Erdem H (2010) Prediction of the moment capacity of reinforced concrete slabs in fire using artificial neural networks. Adv Eng Softw. https://doi.org/10.1016/j.advengsoft.2009.07.006

Naser M, Abu-Lebdeh G, Hawileh R (2012) Analysis of RC T-beams strengthened with CFRP plates under fire loading using ANN. Constr Build Mater 37:301–309. https://doi.org/10.1016/j.conbuildmat.2012.07.001

Goldberg DE, Holland JH (1988) Genetic algorithms and machine learning. Mach Learn. https://doi.org/10.1023/a:1022602019183

Koza JR (1992) A genetic approach to finding a controller to back up a tractor-trailer truck. 1992 American Control Conference, Chicago, IL, USA, pp 2307–2311. https://doi.org/10.23919/ACC.1992.4792548

Lie T, Woollerton J (1988) Fire resistance of reinforced concrete columns—NRC Publications Archive—National Research Council Canada. doi:http://doi.org/10.4224/20386656

Myllymaki J, Lie T (1991) Fire resistance test of a square reinforced concrete column. doi:http://doi.org/10.4224/20358628

Dotreppe J-C, Franssen J-M, Bruls A, Baus R, Vandevelde P, Minne R, van Nieuwenburg D, Lambotte H (1997) Experimental research on the determination of the main parameters affecting the behaviour of reinforced concrete columns under fire conditions. Magn Concr Res. https://doi.org/10.1680/macr.1997.49.179.117

Rodrigues JPC, Laím L, Correia AM (2010) Behaviour of fiber reinforced concrete columns in fire. Compos Struct 92:1263–1268. https://doi.org/10.1016/j.compstruct.2009.10.029

Hass R (1986) Practical rules for the design of reinforced concrete and composite columns submitted to fire. Technical rep, 69. https://scholar.google.com/scholar?hl=en&as_sdt=0%2C23&q=Hass+R+%281986%29+Practical+rules+for+the+design+of+reinforced+concrete+and+composite+columns+submitted+to+fire&btnG=#d=gs_cit&u=%2Fscholar%3Fq%3Dinfo%3A9LwQtwODy_oJ%3Ascholar.google.com%2F%26output%3Dcite%26scirp%3D0%26hl%3Den

Kodur V, McGrath R, Latour J, MacLaurin J (2000) Experimental studies on the fire endurance of high-strength concrete columns. https://doi.org/10.4224/20378032

AS 3600 (2009) Concrete structures. Sydney: Standards Association of Australia; 2009. ISBN: 0-7337-9347-9. https://infostore.saiglobal.com/en-us/Standards/AS-3600-2009-98877_SAIG_AS_AS_274461/

Naser M, Naser MZ (2018) www.mznaser.com/fireassessmenttools. Accessed 5 May 2019

Witteveen J, Twilt L (1981) A critical view on the results of standard fire resistance tests on steel columns. Fire Saf J 4:259–270. https://doi.org/10.1016/0379-7112(81)90029-1

Vo-Duy T, Ho-Huu V, Dang-Trung H, Nguyen-Thoi T (2016) A two-step approach for damage detection in laminated composite structures using modal strain energy method and an improved differential evolution algorithm. Compos Struct 147:42–53. https://doi.org/10.1016/J.COMPSTRUCT.2016.03.027

Lee EWM, Yuen RKK, Lo SM, Lam KC, Yeoh GH (2004) A novel artificial neural network fire model for prediction of thermal interface location in single compartment fire. Fire Saf J 39:67–87. https://doi.org/10.1016/S0379-7112(03)00092-4

Cobaner M, Unal B, Kisi O (2009) Suspended sediment concentration estimation by an adaptive neuro-fuzzy and neural network approaches using hydro-meteorological data. J Hydrol 367:52–61. https://doi.org/10.1016/J.JHYDROL.2008.12.024

Khan A, Kim HS (2018) Assessment of delaminated smart composite laminates via system identification and supervised learning. Compos Struct 206:354–362. https://doi.org/10.1016/J.COMPSTRUCT.2018.08.014

Kalfat R, Nazari A, Al-Mahaidi R, Sanjayan J (2016) Genetic programming in the simulation of Frp-to-concrete patch-anchored joints. Compos Struct 138:305–312. https://doi.org/10.1016/J.COMPSTRUCT.2015.12.005

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

This section illustrates two examples with procedure into applying the IPR-derived expressions to evaluate susceptibility of a typical RC column to fire-induced spalling as well as fire resistance of the same column. This column, named M6S150, was tested by Shah and Sharma [25], and achieved a fire resistance of 289 min after undergoing spalling; and has the following features:

-

1.

Concrete type, fc = 63 MPa,

-

2.

Cross sectional size, b × h = 300 × 300 mm2,

-

3.

Concrete cover, c, 40 mm,

-

4.

Magnitude of applied loading, P = 1858 kN,

-

5.

Concentric loading, ec = 0 mm,

To check for fire-induced spalling in this column:

Using MLR:

Using DL:

Implementing the matrix provided in Table 1, DL reveals Spalling = 1(Spalling occurs)

Using GP:

To verify this:

Fire resistance of this column can be evaluated using the following approaches:

Using MLR:

Using DL:

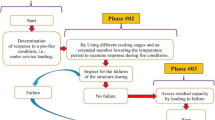

Implementing the matrix provided in Table 1 and fire assessment tool shown in Fig. 3, the fire resistance of this columns comes to, FR= 244.3 min (within 18% of measured fire resistance)

Using GP:

Rights and permissions

About this article

Cite this article

Naser, M.Z., Seitllari, A. Concrete under fire: an assessment through intelligent pattern recognition. Engineering with Computers 36, 1915–1928 (2020). https://doi.org/10.1007/s00366-019-00805-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-019-00805-1