Abstract

We present the laser characteristics of a 5 at.% Tm:YLF crystal using a modular setup at cryogenic temperatures emitting around 2 µm. Continuous-wave laser operation was achieved by pumping the laser crystal using a Volume Bragg Grating-stabilized laser diode emitting at 793 nm. A maximum output power of 6.5 W was achieved at 80 K corresponding to a slope efficiency of 66.0% with respect to the absorbed power with excellent beam quality.

Similar content being viewed by others

1 Introduction

Lasers operating around 2 microns in the spectral range emit in the so-called eye-safe region having real and commercial application in materials processing (laser welding of transparent plastics), laser radar and atmospheric monitoring, chemical and physical research (nonlinear optics and spectroscopy), as well the favorable absorption in water makes such lasers also very useful for medical applications (surgery and therapy) and in defense [1,2,3,4]. All these 2-micron laser applications are relatively young and constantly improving, and some of them need to benefit from better efficiency, shorter pulses (meaning higher peak-power), more energetic pulses, and designs that are more compact. All such novel results represent a challenge in the field of research of diode-pumped solid-state lasers with industrial and scientific applications.

The 2 μm lasers can be achieved by doping the laser host materials with thulium Tm3+ ions (Tm). The “Tm” ion absorbs efficiently around 793 nm and can be directly excited using commercial available AlGaAS laser diodes. Moreover, the Tm ion experiences the two for one cross relaxation mechanism, which results in higher slope efficiency than that of the quantum defect [5]. Nevertheless, due to the quasi-three level nature of the Tm ion, it suffers from reabsorption losses. In addition, the Tm ion will suffer from other parasitic processes such as energy transfer up-conversion (ETU) and excited state absorption (ESA). All these effects will limit the overall laser performance and suffer from poor beam quality.

To suppress the above-mentioned issues, the active medium has to be cooled down to cryogenic temperatures. The cryogenic cooling will significantly improve the key thermo-optic properties of the active medium, such as increased thermal conductivity, decreasing the variation of the refractive index with temperature, dn/dT and decreasing the thermal expansion coefficient, thus minimizing the thermo-optic effects [6, 7], it will also significantly increase the spectroscopic properties such as absorption and emission cross-sections and lifetime of the emitting electronic level. This will allow greater energy accumulation capacity during the Q-switched technique [8] for pulse generation. To date, cryogenic lasers were reported mainly on single-doped Yb, Nd, Ho and codoped (Ho, Tm) laser hosts [9,10,11,12,13,14,15,16]. However, only few results based on single-doped Tm-doped hosts can be seen [17,18,19].

Bearing in mind all the above-mentioned facts, in this work, we paid attention to the Yttrium Lithium Fluoride crystal, LiYF4 (in short YLF), which belongs to the broad fluoride family exhibiting low-phonon energy, broad emission bands and long radiative lifetime, which make these materials very good candidates for high-power laser development in the 2 μm region [20, 21]. Many works based on Tm:YLF have been reported mainly at room temperature [22,23,24,25]. The first cryogenic laser operation of Tm:YLF was reported at liquid nitrogen temperature where their main focus is on near infrared region. The authors reported the operating wavelengths of 816 nm and 1876 nm, with respective slope efficiencies of 46 and 4% [26]. A preliminary cryogenic laser based on Tm:YLF has been demonstrated using broadband pumping in one of our previous works [27] using a long L-shaped asymmetric cavity. At 100 K, a maximum output power of 2.55 W with a slope efficiency of 22.8% was achieved around 1877 nm using 15% output coupling transmission. From that study of absorption spectroscopy and results published in [27], we deduced that a broadband pump source is not suitable for efficient cryogenic laser operation. Stabilized laser diodes should be used to achieve greater efficiency.

Here in this work, we studied the cryogenic laser performance of a 5 at. % Tm:YLF using a Volume Bragg Grating (BVG)-stabilized laser diode as pump source emitting around 793 nm. The novelty of this work lies in using a modular cryogenic compact cavity. This work is the preliminary work prior to the development of high average power lasers based on cryogenic Tm:YLF in the 2 µm spectral region.

2 Experimental

2.1 Cryogenic continuous‑wave (CW) laser setup

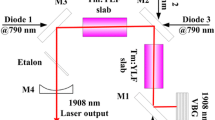

Figure 1a illustrates the schematic diagram of the cryogenic continuous-wave (CW) laser setup. The compact cryogenic cavity includes a plane-plane pump mirror with high-reflective (HR) coating at 1.8–2.1 µm and high transmission (HT) around 800 nm. A set of plane output couplers (OC) with different partial transmission (Toc) of 9, 15, and 30% at 1.8–2.1 µm were used. As active medium a commercial a-cut 5 at. % Tm:YLF crystal with 2 mm thickness and 5×5 mm2 aperture was mounted in a copper holder at normal incidence and was placed in between the two plane mirrors to form a compact plane–plane cavity inside the modular chamber (see Fig. 1b). The advantage of this modular chamber is that one can replace any of the optical elements, such as the pump mirror, active medium or output coupler as desired. To conductively cool the active medium, the copper holder along with the sample were fixed to the cold finger of the closed cycle helium cryostat (CH-204, JANIS), that can provide a cooling power of 13.5 W at 100 K. A Lake Shore temperature controller (DT 670) was used to monitor and maintain the sample temperature, which includes 2 silicon diode sensors and a 50 Ω heater. The modular chamber has the provision to tilt and move the distance of both pump and output coupler mirrors using piezo actuators and were controlled by a computer externally. The whole chamber was maintained at a vacuum pressure of 10–5 mbar to avoid water vapor condensation on the sample surface. A diode laser emitting around 793 nm was used as pump source, with a bandwidth of 0.5 nm stabilized by a Volume Bragg Grating. The fiber-coupled diode had a core diameter of 105 µm and N.A. = 0.22 delivering a maximum output power of 25 W. The radiation from the pump source was imaged to the active medium in a 1:1.5 ratio by two AR-coated achromatic lenses (focal lengths of 100 and 150 mm). The pump spot size was estimated to be ~ 158 µm in the active medium. The total cavity length was around 6 mm that includes sample thickness of 2 mm and pump, and output coupler mirrors were placed 2 mm away from the surface of the sample.

3 Results and discussion

3.1 Cryogenic continuous‑wave laser operation of Tm:YLF

The cryogenic continuous-wave (CW) laser was realized and were characterized in two ways. First, by varying the OC transmissions at a fixed temperature and second, by varying the temperature of the sample at a fixed OC transmission. Figure 2a shows the input–output characteristics of the cryogenic Tm:YLF laser at 80 K by varying the transmission of OC. From the figure, one can infer that Toc = 15% performed better when compared with the others studied transmissions of the OC, and a maximum output power of 6.5 W corresponding to a slope efficiency of 38% was achieved. The laser emitted at 1876 nm for output coupler transmissions 15 and 30% as shown in Fig. 2b. However or Toc = 9%, we observed polarization switching between both polarizations π (E//c) and \(\upsigma (\mathrm{E}\perp \mathrm{c})\). This polarization switching might be due high intracavity power resulting in anisotropic thermal lensing effect on the spot sizes of π and \(\sigma\) cavity modes of Tm:YLF. Figure 2c shows the measured output wavelengths for different incident pump levels. At low pump levels (< 5 W), the π polarization was dominant and emitted at 1876 nm and at high pump power levels (> 13 W), the \(\sigma\) polarization was dominant emitting at 1901 and 1912 nm. Intermediate pump power levels provided laser emission with the two polarization coexisting. The observed laser emission wavelengths are in line with the reported gain cross-section curves for π and \(\sigma\) polarizations [28] calculated for different temperatures and inversion rates. Further investigation on this polarization switching behavior along with cryogenic spectroscopy is under study.

Figure 3a shows the input–output characteristics of the cryogenic Tm:YLF laser by varying the temperature and by fixing the OC to 15%. Here, we chose the best performing OC transmission for this study and the temperature of the sample was varied from 80 to 160 K in step size of 20 K. Laser operation with crystal temperature above 160 K was not considered to avoid the damage of the sample.

In Fig. 3a, it is evidenced, that the output power and slope efficiency increase with decrease of temperature. This increase of the output power and slope efficiency is mainly due to the significant reduction of reabsorption at the laser wavelength and improvement of thermo-optic, thermo-mechanical and spectroscopic properties of Tm:YLF. Out of all the temperatures, 80 K performed better compared to the other temperatures. We also measured the output laser wavelength for different temperatures and are shown in Fig. 3b. Figure 3b shows the measured laser spectrum from 80 to 160 K for an incident power of 10.98 W. The laser emission was close to 1876 nm corresponding to π (E//c crystallographic axis) polarization in all cases. A short blue shift of the laser wavelength at 160 K was observed (3 nm shorter), indicating that at 160 K, part of the electronic population of the ground state constituted a quasi-three level laser. For lower temperatures, the Tm laser acts as a four-level laser without reabsorption losses. We also measured the absorption in the crystal at 80 K under non-lasing condition being 57% by taking into consideration the Fresnel losses on the surface crystal as well as a second pass of the pump due to the partial reflection of the non-absorbed pump on the output coupler. Using this absorption value, we estimated the slope efficiency with respect to the absorbed power (see Fig. 4a). A maximum output power of 6.5 W was achieved at an absorbed pump power of 9.97 W. The slope efficiency with respect to the absorbed power amounts to 66.0%. We also measured a very high quality far field Gaussian beam profile obtained at maximum output power (6.5 W at 80 K), shown in Fig. 4b.

4 Conclusions

We presented cryogenic laser operation of Tm:YLF using a modular setup pumped by a VBG-stabilized laser diode emitting around 793 nm. A maximum output power of 6.5 W corresponding to a slope efficiency of 66% with respect to absorbed power was achieved at 80 K with very good beam quality. Further power scaling is anticipated when we use powerful pump diode, longer crystals and higher heat load cryostats. Future work will focus on pulsed laser operation implementing Cr:ZnS and Cr:ZnSe as saturable absorbers in the compact cavity to generate high-energy laser pulses.

Data availability

The data that support the findings of this study are available from the corresponding author, [X.M.], upon reasonable request.

References

K. Scholle, P. Fuhrberg, P. Koopmann, S. Lamrini, 2 μm laser sources and their possible applications, in frontiers in guided wave optics and optoelectronics 21 by B Pal (INTECH Open Access Publisher, Rijeka, 2010)

J. Yu, B. C. Trieu, M. Petros, Y. Bai, P. J. Petzar, G. J. Koch, U. N. Singh, and M. J. Kavaya: Proc. SPIE 6409 (2006)

S.S. Chen, J. Yu, M. Petros, Y. Bai, U.N. Singh, M.J. Kavaya, Proc. SPIE 5653, 175 (2005)

Z. Pan, P. Loiko, Y. Wang, Y. Zhao, H. Yuan, K. Tang, X. Dai, H. Cai, J.M. Serres, S. Slimi, E.B. Salem, E. Dunina, A. Kornienko, L. Fomicheva, J.L. Doualan, P. Camy, W. Chen, U. Griebner, V. Petrov, M. Aguiló, F. Díaz, R.M. Solé, X. Mateos, J. Alloys Compd. 853, 157100 (2021)

A. Godard, C R Phys. 8, 1100 (2007)

D.C. Brown, IEEE, J. Sel. Top. Quantum Electron. 11, 587 (2005)

R.L. Aggarwal, D.J. Ripin, J.R. Ochoa, T.Y. Fan, J. Appl. Phys. 98, 103514 (2005)

J. Koerner, T. Lühder, J. Reiter, I. Uschmann, H. , Marschner, V. Jambunathan, A. Lucianetti, T. Mocek, J. Hein, M.C. Kaluza, J. Lumin. 202, 427 (2018)

T.Y. Fan, IEEE J. Sel. Top. Quantum Electron. 13, 448 (2007)

D. Rand, D. Miller, D.J. Ripin, T.Y. Fan, Cryogenic Yb3+-doped materials for pulsed solid-state laser applications [Invited]. Opt. Mater. Express 1, 434 (2011)

V. Jambunathan, L. Horackova, P. Navratil, A. Lucianetti, T. Mocek, IEEE Photonics Tech. Lett. 28, 1328 (2016)

S.P. David, V. Jambunathan, F.X. Yue, B.J.L. Garrec, A. Lucianetti, T. Mocek, Opt. Mater. Express 9, 4669 (2019)

S.J. Yoon, J.I. Mackenzie, Opt. Express 22, 8069 (2014)

M. Ganija, A. Hemming, N. Simakov, K. Boyd, J. Haub, P. Veitch, J. Munch, Opt. Express 25, 31889 (2017)

Y. Du, T. Dai, H. Sun, H. Kang, H. Xia, J. Tian, X. Chen, B. Yao, Crystals 11, 798 (2021)

W. Wang, X. Yang, Y. Shen, L. Li, L. Zhou, Y. Yang, Y. Bai, W. Xie, G. Ye, XYu. Appl, Phys. B Appl. Phys. B 124, 82 (2018)

T.Y. Fan, J.R. Ochoa, P.A. Reed, IEEE J. Quantum Electron. 51(10), 1700605 (2015)

Z. Hubka, J. Šulc, H. Jelínková, K. Nejezchleb, V. Škoda SPIE Photonics Eur. Int. Soc. Opt. Photon. 98930Q (2016)

F. Yue, V. Jambunathan, S.P. David, X. Mateos, M. Aguiló, F. Díaz, J. Šulc, A. Lucianetti, T. Mocek, Appl. Phys. B 126, 44 (2020)

F. Cornacchia, A. Toncelli, M. Tonelli, Prog. Quantum Electron 33, 61 (2009)

P. Loiko, J. Serres, X. Mateos, S. Tacchini, M. Tonelli, S. Veronesi, D. Parisi, A. Di Lieto, K. Yumashev, U. Griebner, V. Petrov, Opt. Mater. Express 7(3), 844 (2017)

S. So, J.I. Mackenzie, D.P. Shepherd, W.A. Clarkson, J.G. Betterton, E.K. Gorton, Appl. Phys. B 84, 389 (2006)

M. Schellhorn, S. Ngcobo, C. Bollig, Appl. Phys. B. 94, 195–198 (2009)

A. Berrou, O.J.P. Collett, D. Morris, M.J.D, Opt. Express 26 10559–10572 (2018)

U. Demirbas, J. Thesinga, E. Beyatli, M. Kellert, M. Pergament, F.X. Kärtner, Opt. Express 30, 41219 (2022)

C.E. Aleshire, C.X. Yu, P.A. Reed, T.Y. Fan, Opt. Express 25, 13408 (2017)

F. Yue, V. Jambunathan, S.P. David, J. Reiter, J. Körner, D. Klöpfel, J. Hein, M.C. Kaluza, A. Lucianetti, T. Mocek, Proc. SPIE 11033, 110330E (2019)

U. Demirbas, J. Thesinga, M. Kellert, F.X. Kärtner, M. Pergament, Opt. Mater. Express 12, 4712 (2022)

Acknowledgements

Grant PID2019-108543RB-I00 funded by MCIN/AEI/10.13 039/501100011033. This work has been possible with the support of the Secretaria d’Universitats i Recerca del Departament d’Empresa i Coneixement de la Generalitat de Catalunya, the European Union (UE), and the European Social Fund (ESF) (2021 FI_B1 00170). This work was co-financed by the European Regional Development Fund and the state budget of the Czech Republic (project HiLASE CoE: Grant No. CZ.02.1.01/0.0/0.0/15_006/0000674) and by the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 739573.

Funding

Open access funding provided by Universitat Rovira i Virgili.

Author information

Authors and Affiliations

Contributions

AA: investigation. VJ: conceptualization, investigation and methodology, writing and editing–original draft. SS: investigation and methodology, JMS: conceptualization, MA: funding acquisition and review and editing, FA: funding acquisition, review and editing, XM: writing—review and editing, funding acquisition, and supervision, MS: supervision, resources, review and editing and TM: supervision, funding acquisition, review and editing. All the authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Alles, A., Jambunathan, V., Slimi, S. et al. Cryogenic Tm:LiYF4 laser around 2 µm. Appl. Phys. B 129, 41 (2023). https://doi.org/10.1007/s00340-023-07970-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-023-07970-8