Abstract

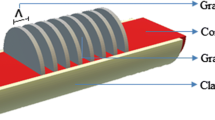

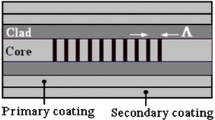

Recently, many researches have been conducted on a Taper Fiber Bragg Grating (TFBG) as a temperature sensor in a wide range of applications due to its significant merits. Besides, the majority of these researches have been focused on improving the sensor performance. In this work, the temperature sensitivity is enhanced by coating the sensor with four different materials Polymer, In, Zn and TiN with different coated layer thicknesses. This study presents the impact of the thickness layers of these materials on the overall performance of the TFBG temperature sensor. Different coating techniques are carried out which gave a uniform crystalline structure of the coated layer. Optical spectrum analyzer is used to monitor the Bragg wavelength shift of the TFBG sensor under different temperature values (25–150 °C). The results approve that the coating materials could enhance the temperature sensitivity depending on the material type and coating thickness, additionally, these coating layers sever as a protect layers for the grating area from the external environmental factors. For further investigation, simulation work is carried out using MATLAB; and there are good agreement between experimental and simulation studies. The results show that the layers with thickness of 50 µm, 15 µm, 7.5 µm and 12 µm were optimum thicknesses that gave a higher wavelength shift; hence higher temperature sensitivity for Polymer, Zn, TiN and In coating layers, respectively. Within these values, the temperature sensitivities were estimated to be 1.793 pm/°C, 2.351 pm/°C, 2.893 pm/°C and 3.547 pm/°C which enhanced approximately by factor 2, 3, 4 and 6 for Polymer, Zn, TiN and In coating layers respectively compared with sensitivity of bare TFBG sensor. This work will significantly enrich the knowledge of enhancing the sensor performance by polymer or metal coating approach.

Similar content being viewed by others

Data availability

The data are available upon request by emailing the author.

References

Y. Deng, T. Yang, B. Lou, K. Yu, G. Song, S. Dai, A sensitivity difference approach to overcome temperature influence on a fiber optic force sensor with a pair of FBGs. Sens. Actu. A Phys. (2022). https://doi.org/10.1016/j.sna.2022.113645

G. Yan, T. Wang, L. Zhu, F. Meng, W. Zhuang, A novel strain-decoupled sensitized FBG temperature sensor and its applications to aircraft thermal management. Opt. Laser Technol. (2021). https://doi.org/10.1016/j.optlastec.2020.106597

R. Tong, Y. Zhao, H. Hu, J. Qu, Large measurement range and high sensitivity temperature sensor with FBG cascaded Mach-Zehnder interferometer. Opt. Laser Technol. (2020). https://doi.org/10.1016/j.optlastec.2019.106034

Y. Du, Q. Han, H. Hu, M. Sang, X. Zhao, X. Song, H. Wang, T. Liu, High-sensitivity refractive index and temperature sensor based on cascading FBGs and droplet-like fiber interferometer. Sens. Actuator A Phys. (2019). https://doi.org/10.1016/j.sna.2019.111631

R. Li, Y. Tan, Y. Chen, L. Hong, Z. Zhou, Investigation of sensitivity enhancing and temperature compensation for fiber Bragg grating (FBG)-based strain sensor. Opt. Fiber Technol. (2019). https://doi.org/10.1016/j.yofte.2019.01.009

Z.S. Alshaikhli, W.A. Hekmat, H. Wang, Bi-functional coated tapered LPFG sensor: gas and temperature sensing. Math. Model. Eng. (2022). https://doi.org/10.18280/mmep.090333

D. Sengupta, M. Shankar, S. Parne, R. Prasad, K. S. Narayana, P. Kishore, An improved low temperature sensing using PMMA coated FBG. In: 2011 Asia Communications and Photonics Conference and Exhibition (2011). https://doi.org/10.1117/12.904606

T. Mizunami, H. Tatehata, H. Kawashima, High-sensitivity cryogenic fiber-Bragggrating temperature sensors using Teflon substrates. Meas. Sci. Technol. (2001). https://doi.org/10.1088/0957-0233/12/7/329

U. Sampath, D. Kim, H. Kim, M. Song, Polymer-coated FBG sensor for simultaneous temperature and strain monitoring in composite materials under cryogenic conditions. Appl. Opt. (2018). https://doi.org/10.1364/AO.57.000492

S. Parne, R.L.N. Sai Prasad, S.G. Dipankar, Polymer-coated fiber Bragg grating sensor for cryogenic temperature measurements. Microw. Opt. Technol. Lett. (2011). https://doi.org/10.1002/mop.25914

V. Mishra, M. Lohar, A. Amphawan, Improvement in temperature sensitivity of FBG by coating of different materials. Optik (2016). https://doi.org/10.1016/j.ijleo.2015.10.014

B. Wei, W. Lei, X. Gao, Study on temperature sensing properties of different fiber Bragg grating at low temperature. In: Proceedings of the 18th International Conference on Estimation, Detection and Information Fusion, Washington DC, USA (2015). https://doi.org/10.1109/ICEDIF.2015.7280230

C. Lupi, F. Felli, L. Ippoliti, Lead coating to improve Fiber Bragg Grating sensitivity at cryogenic temperatures. In: Proceedings of the 17th International Society for Optical Engineering (2005). https://doi.org/10.1117/12.624224

Y. Li, K. Yang, X. Li, Temperature sensing characteristics of metal coated FBG during dynamic cooling process. Opt. Fiber Technol. (2018). https://doi.org/10.1016/j.yofte.2018.08.013

F.G. Khalid, A.Q. Raheema, Z.S. Alshakhli, M.A. Fakhri, Preparation of nano indium oxide for optoelectronics application. AIP Conf. Proc. (2020). https://doi.org/10.1063/5.0000187

Y.L. Choua, C.W. Wub, R. Jhanga, C. Chianga, A novel optical fiber temperature sensor with polymer-metal alternating structure. Opt. Laser Technol. (2019). https://doi.org/10.1016/j.optlastec.2019.02.036

W. Zhang, D, J. Webb, Performances of PMMA-based optical fiber bragg grating sensor in extended temperature range, photonics (2021). https://doi.org/10.3390/photonics8060180

Z.S. Alshaikhli, W.A. Hekmat, A.H. Al- Hamdani, H.T. Hashim, The spherical aberration correction by using bending and lens splitting: a compression. AIP Conf. Proc. 2398, 020005 (2022). https://doi.org/10.1063/5.0093382

H. Zhang, L. Wang, X. Su, H. Yan, J. Wang, P. Cheng, Fiber Bragg grating temperature sensor coated with graphene thin film. In: Proc. SPIE 11340, AOPC 2019: Optical Fiber Sensors and Communication (2019). https://doi.org/10.1117/12.2547299

N. Saidin, N.F.H. Kamarozaman, F. S. Roslan, A.A. M. Ralib, L. K. Sing, Graphene-oxide coated on fiber bragg grating for temperature sensor. In: 2021 8th International Conference on Computer and Communication Engineering (ICCCE) (2021). https://doi.org/10.1109/ICCCE50029.2021.9467205

N.F.N. Naim, S. Anuar, S.S. Sarnin, N. Yaa’cob, Design of metal plate temperature sensor based on fiber bragg grating (FBG). Indones. J. Electr. Eng. (2019). https://doi.org/10.11591/ijeecs.v15.i3.pp1282-1289

K.N. Koo, A.F. Ismail, M.H.D. Othman, A. Samavati, Z.S. Tai, M.A. Rahman, H. Bakhtiar, M.A. Mat, Fabrication and modification of temperature FBG sensor: role of optical fiber type and Cu sputtered thickness. Phys. Scr. (2020). https://doi.org/10.1088/1402-4896/abb05c

N.F. Mansor, R.K. Raja Ibrahim, Temperature sensitivity of FBG coating with zinc oxide and silicon carbide. J. Conf. Phys. (2020). https://doi.org/10.1088/1742-6596/1892/1/012033

A. Pospori, C.A.F. Marques, O. Bang, D.J. Webb, P. André, Polymer optical fiber Bragg grating inscription with a single UV laser pulse. Opt. Express (2017). https://doi.org/10.1364/OE.25.009028

Z.S. Alshaikhli, H. Wang, Low temperature sensor based on etched LPFG with different materials coating math. Model Eng (2022). https://doi.org/10.18280/mmep.090502

R. Min, B. Ortega, C. Marques, Fabrication of tunable chirped mPOF Bragg gratings using a uniform phase mask. Opt. Express (2018). https://doi.org/10.1364/OE.26.004411

C. Marques, A. Leal-Júnior, S. Kumar, Multifunctional integration of optical fibers and nanomaterials for aircraft systems. Materials (2023). https://doi.org/10.3390/ma16041433

G. Hegde, M.V.N. Prasad, S. Asokan, Temperature compensated diaphragm based Fiber Bragg Grating (FBG) sensor for high pressure measurement for space applications. Microelectron. Eng. (2021). https://doi.org/10.1016/j.mee.2021.111615

Z.S. Alshaikhli, W.A. Hekmat, H. Wang, The study of temperature and refractive index sensitivity of polyimide coated etched (3LPGs-FBG) sensor. AIP Conf. Proc. (2023). https://doi.org/10.1063/5.0119268

Z.S. Alshaikhli, W.A. Hekmat, Analysis of pressure and temperature sensitivity based on coated cascade FBG-LPFG sensor, advances in intelligent computing and communication. Lect. Notes Netw. Syst. (2022). https://doi.org/10.1007/978-981-19-0825-5_53

J.G. Ortega-Mendoza, F. Chávez, P. Zaca-Morán, C. Felipe, G.F. Pérez-Sánchez, G. Beltran-Pérez, O. Goiz, R. Ramos-Garcia, Selective photo deposition of zinc nanoparticles on the core of a single-mode optical fiber. Opt. Express (2013). https://doi.org/10.1364/OE.21.006509

Z. Wen, L. Zhu, M. Dong, X. Lou, F. Liu, A temperature fiber sensor based on tapered fiber bragg grating fabricated by femtosecond laser. Appl. Sci. (2018). https://doi.org/10.3390/app8122616

Z.S. Alshaikhli, L.A. Salman, W.A. Hekmat, FBG humidity and temperature sensor based on ANN for environment application: sensitivity improvement. J. Opt. (India) (2023). https://doi.org/10.1007/s12596-023-01412-6

Z.S. Alshaikhli, Structural health monitoring of underground pipelines using polyimide coated LPFG-FBG-LPFG: simultaneous modeling of temperature and pressure effects. J. Opt. (India) (2023). https://doi.org/10.1007/s12596-023-01314-7

Acknowledgements

I appreciate the support obtained from Laser and Optoelectronics Engineering Department/ University of Technology – Iraq.

Funding

This research was not funded by any public institution or private sector.

Author information

Authors and Affiliations

Contributions

Author contributed to the whole study conception and design. Material preparation, data collection and analysis were performed by ZSA. The first draft of the manuscript and final manuscript were written by ZSA. The author read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The author has no competing interests.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alshaikhli, Z.S. A comparative study on polymer and metals coated TFBG temperature sensor: coating thickness impact. Appl. Phys. A 130, 127 (2024). https://doi.org/10.1007/s00339-023-07269-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-07269-7