Abstract

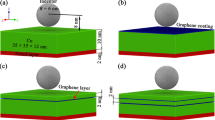

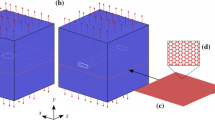

Many researches have shown that nanotwinned structure and graphene reinforcing phase can improve the mechanical properties of aluminum (Al) metal, but the synergistic effect of the two on nanoindentation mechanical response of Al matrix composites is rarely reported. In this research, based on molecular dynamics simulations, the nanoindentation mechanical properties and microscopic deformation mechanisms of graphene/nanotwinned Al matrix composites are studied. The effect of the inclination angle and spacing of the twin boundaries (TBs), the insertion position of the graphene sheet, the graphene coating and the layer number of the graphene sheet on the nanoindentation mechanical properties of the Al matrix composites is analyzed. The nanoindentation mechanical properties of nanotwinned Al strongly depend on the inclination angle of TBs, and the dislocation slip modes mainly includes three types: hard mode I (dislocation pile-up penetration mode), soft mode I (partial dislocation parallel twin boundary slip mode) and hard mode II (dislocation limited slip mode). Moreover, as the twin boundary spacing increases, the dislocation slip mode starts to weaken until the nanoindentation mechanical properties are insensitive to the twin inclination orientation. The insertion of the graphene sheet weakens the indentation mechanical properties of the nanotwinned Al matrix composite, which is attributed to the interaction of the graphene with the dislocations and the subsequent absorption of part of them. The weakening effect depends on the distance between the graphene/Al interface and the plastic zone. What’s more, graphene coating can improve the indentation mechanical properties of composites. In addition to the load bearing effect of graphene in the elastic stage, this strengthening effect is also attributed to the combined action of graphene and TBs in the plastic stage, which makes the dense dislocation network widely distributed around the indentation of graphene coating and induces the interfacial strain hardening.

Similar content being viewed by others

Data Availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

S. Rawal, Metal-matrix composites for space applications. JOM 53, 14–17 (2001)

J.M. Torralba, C.E. da Costa, F. Velasco, P/M aluminum matrix composites: an overview. J. Mater. Process. Tech. 133, 203–206 (2003)

A. Dorri Moghadam, B.F. Schultz, J.B. Ferguson et al., Functional metal matrix composites: self-lubricating, self-healing, and nanocomposites-an outlook. JOM 66, 872–881 (2014)

E.J. Sandoz-Rosado, O.A. Tertuliano, E.J. Terrell, An atomistic study of the abrasive wear and failure of graphene sheets when used as a solid lubricant and a comparison to diamond-like-carbon coatings. Carbon 50, 4078–4084 (2012)

A.M. Rajesh, S. Doddamani, K.K. Mohamed et al., Dry sliding wear simulation of hybrid aluminum metal matrix composites. Adv. Compos. Hybrid Mater. 3, 120–126 (2020)

D.B. Miracle, Metal matrix composites-from science to technological significance. Compos. Sci. Technol. 65, 2526–2540 (2005)

S. Kosti, J. Kundu, C.S. Malvi, Nanoparticles reinforcement effect on the MMC’s characteristics. Adv. Eng. 459–469 (2019)

J. Li, R.A. Laghari, A review on machining and optimization of particle-reinforced metal matrix composites. Int. J. Adv. Manuf. Tech. 100, 2929–2943 (2019)

S. Shankar, A. Balaji, N. Kawin, Investigations on mechanical and tribological properties of Al-Si10-Mg alloy/sugarcane bagasse ash particulate composites. Part. Sci. Technol. 36, 762–770 (2018)

A.D. Moghadam, E. Omrani, P.L. Menezes et al., Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—a review. Compos. B. Eng. 77, 402–420 (2015)

S.E. Shin, H.J. Choi, J.H. Shin et al., Strengthening behavior of few-layered graphene/aluminum composites. Carbon 82, 143–151 (2015)

Y. Kim, J. Lee, M.S. Yeom et al., Strengthening effect of single-atomic-layer graphene in metal-graphene nanolayered composites. Nat. Commun. 4, 2114 (2013)

J.E. Wang, Z.Q. Li, G.L. Fan et al., Reinforcement with graphene nanosheets in aluminum matrix composites. Scripta Mater. 66, 594–597 (2012)

L. Zhao, Q. Guo, Z. Li et al., Strain-rate dependent deformation mechanism of graphene-Al nanolaminated composites studied using micro-pillar compression. Int. J. Plasticity 105, 128–140 (2018)

D.J. Kim, Q.T. Truong, J.I. Kim et al., Ultrahigh-strength multi-layer graphene-coated Ni film with interface-induced hardening. Carbon 178, 497–505 (2021)

X.F. Zhu, Y.B. Zhao, L.P. Ma et al., Graphene coating makes copper more resistant to plastic deformation. Compos. Commun. 12, 106–111 (2019)

Y.M. Zhang, X.Y. Zhuang, R. Lackner, Stability analysis of shotcrete supported crown of NATM tunnels with discontinuity layout optimization. Int. J. Numer. Anal. Methods Geomech. (2018). https://doi.org/10.1002/nag.2775

Z. Sun, Y.M. Zhang, Y. Yuan et al., Stability analysis of a fire-loaded shallow tunnel by means of a thermo-hydro-chemo-mechanical model and discontinuity layout optimization. Int. J. Numer. Anal. Methods Geomech. (2019). https://doi.org/10.1002/nag.2991

Y.M. Zhang, H.A. Mang, Global cracking elements: a novel tool for Galerkin-based approaches simulating quasi-brittle fracture. Int. J. Numer. Methods Eng. 121, 2462–2480 (2020)

Y.M. Zhang, X.Y. Zhuang, Cracking elements method for dynamic brittle fracture. Theor. Appl. Fract. Mec. 102, 1–9 (2019)

Y.M. Zhang, X.Y. Zhuang, Cracking elements: a self-propagating strong discontinuity embedded approach for quasi-brittle fracture. Finite Elem. Anal. Des. 144, 84–100 (2017)

T. Rabczuk, G. Zi, S. Bordas et al., A simple and robust three-dimensional cracking-particle method without enrichment. Comput. Method. Appl. M. 199, 2437–3245 (2010)

N. Vu-Bac, M. Silani, T. Lahmer et al., A unified framework for stochastic predictions of mechanical properties of polymeric nanocomposites. Comp. Mater. Sci. 96, 520–535 (2015)

N. Vu-Bac, R. Rafiee, X. Zhuang et al., Uncertainty quantification for multiscale modeling of polymer nanocomposites with correlated parameters. Compos. B. Eng. 68, 446–464 (2015)

N. Vu-Bac, T. Lahmer, X. Zhuang et al., A software framework for probabilistic sensitivity analysis for computationally expensive models. Adv. Eng. Softw. 100, 19–31 (2016)

N. Vu-Bac, X. Zhuang, T. Rabczuk, Uncertainty quantification for mechanical properties of polyethylene based on fully atomistic model. Materials. 12(21), 3613 (2019)

B. Liu, N. Vu-Bac, X. Zhuang et al., Stochastic multiscale modeling of heat conductivity of polymeric clay nanocomposites. Mech. Mater. 142, 103280 (2020)

X. Wang, W. Xiao, L.G. Wang et al., Investigation on mechanical behavior of multilayer graphene reinforced aluminum composites. Phys. E. 123, 114172 (2020)

S.W. Chang, A.K. Nair, M.J. Buehler, Nanoindentation study of size effects in nickel-graphene nanocomposites. Phil. Mag. Lett. 93, 196–203 (2013)

W.X. Peng, K. Sun, R. Abdullah et al., Strengthening mechanisms of graphene coatings on Cu film under nanoindentation: a molecular dynamics simulation. Appl. Surf. Sci. 487, 22–31 (2019)

A. Klemenz, L. Pastewka, S.G. Balakrishna et al., Atomic scale mechanisms of friction reduction and wear protection by graphene. Nano Lett. 14, 7145–7152 (2014)

Z.X. Wu, Y.W. Zhang, D.J. Srolovitz, Dislocation-twin interaction mechanisms for ultrahigh strength and ductility in nanotwinned metals. Materials 57, 4508–4518 (2009)

Y.B. Wang, B. Wu, M.L. Sui, Dynamical dislocation emission processes from twin boundaries. Appl. Phys. Lett. 93, 041906 (2008)

K. Konopka, J. Mizera, J.W. Wyrzykowski, The generation of dislocations from twin boundaries and its effect upon the flow stresses in FCC metals. J. Mater. Process. Tech. 99, 255–259 (2000)

V.G. Konakov, O.Y. Kurapova, N.N. Novik et al., Nanotwinned copper-graphene composite: synthesis and microstructure. Rev. Adv. Mater. Sci. 45, 1–7 (2016)

O.Y. Kurapova, V.G. Konakov, A.S. Grashchenko et al., Nanotwinned copper-graphene composites with high hardness. Rev. Adv. Mater. Sci. 48, 71–77 (2017)

K.X. Wei, F.L. Jia, W. Wei et al., Flexible nanotwinned graphene/copper composites as thermal management materials. ACS Appl. Nano Mater. 3, 4810–4817 (2020)

D. Bhattacharyya, X.Y. Liu, A. Genc et al., Heterotwin formation during growth of nanolayered Al-TiN composites. Appl. Phys. Lett. 96, 093113 (2010)

J.W. Li, J.G. Guo, L.J. Zhou, Molecular dynamics studies on mechanical properties of graphene/nanotwinned aluminum matrix composites. Phys. E. 147, 115597 (2023)

X. Zhao, C. Lu, A.K. Tieu et al., Deformation mechanisms in nanotwinned copper by molecular dynamics simulation. Mat. Sci. Eng. A-Struct. 687, 343–351 (2017)

Y. Liu, Y.F. Duan, J.J. Zhang, Atomistic investigation of anisotropic nanoindentation behavior of nanotwinned aluminum containing inclined twin boundaries. Nanomaterials 8, 695 (2018)

C. Zhang, A. Godbole, G. Michal et al., High shock resistance and self-healing ability of graphene/nanotwinned Cu nanolayered composites. J. Alloy. Compd. 860, 158435 (2021)

L.Q. Pei, C. Lu, X. Zhao et al., Brittle versus ductile behaviour of nanotwinned copper: a molecular dynamics study. Acta Mater. 89, 1–13 (2015)

S. Plimpton, Fast parallel algorithms for short-range molecular-dynamics. J. Comput. Phys. 117, 1–19 (1995)

Y. Mishin, D. Farkas, M.J. Mehl et al., Interatomic potentials for monoatomic metals from experimental data and ab initio calculations. Phys. Rev. B 59, 3393–3407 (1999)

D.W. Brenner, O.A. Shenderova, J.A. Harrison et al., Sinnott A second-generation reactive empirical bond order (REBO) potential energy expression for hydrocarbons. J. Phys-Condens. Mat. 14, 783–802 (2002)

N. Silvestre, B. Faria, J.N. Canongia Lopes, Compressive behavior of CNT-reinforced aluminum composites using molecular dynamics. Compos. Sci. Technol. 90, 16–24 (2014)

W.H. Wang, Q. Peng, Y.Q. Dai et al., Distinctive nanofriction of graphene coated copper foil. Comput. Mater. Sci. 117, 406–411 (2016)

L. Verlet, Computer “experiments” on classical fluids. I. Thermodynamical properties of Lennard-Jones molecules. Health Phys. 22, 79–85 (1967)

A. Stukowski, Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool. Model. Simul. Mater. Sc. 18, 015012 (2010)

H. Tsuzuki, P.S. Branicio, J.P. Rino, Structural characterization of deformed crystals by analysis of common atomic neighborhood. Comput. Phys. Commun. 177, 518–523 (2007)

A. Stukowski, V.V. Bulatov, A. Arsenlis, Automated identification and indexing of dislocations in crystal interfaces. Model. Simul. Mater. Sc. 20, 085007 (2012)

X.C. Fan, Z.Y. Rui, H. Cao et al., Nanoindentation of γ-TiAl with different crystal surfaces by molecular dynamics simulations. Materials 12, 770 (2019)

K.A. Afanasyev, F. Sansoz, Strengthening in gold nanopillars with nanoscale twins. Nano Lett. 7, 2056–2062 (2007)

A.J. Cao, Y.G. Wei, S.X. Mao, Deformation mechanisms of face-centered-cubic metal nanowires with twin boundaries. Appl. Phys. Lett. 90, 151909 (2007)

I. Shabib, R.E. Miller, Deformation characteristics and stress-strain response of nanotwinned copper via molecular dynamics simulatiob. Acta Mater. 57, 4364–4437 (2009)

A. Stukowski, K. Albe, D. Farkas, Nanotwinned FCC metals: strengthening versus softening mechanisms. Phys. Rev. B 82, 224103 (2010)

Z.S. You, X.Y. Li, L.J. Gui et al., Plastic anisotropy and associated deformation mechanisms in nanotwinned metals. Acta Mater. 61, 217–227 (2013)

J.W. Xiao, H.Z. Yang, H.X. Liu et al., Strengthening-softening transition in yield strength of nanotwinned Cu. Scripta Mater. 162, 372–376 (2019)

X.Y. Li, Y.J. Wei, L. Lu et al., Dislocation nucleation governed softening and maximum strength in nano-twinned metals. Nature 464, 877–880 (2010)

V.H. Vardanyan, H.M. Urbassek, Dislocation interactions during nanoindentation of nickel-graphene nanocomposites. Comp. Mater. Sci. 170, 109158 (2019)

A. Montazeri, A. Mobarghei, Nanotribological behavior analysis of graphene/metal nanocomposites via MD simulations: new concepts and underlying mechanisms. J. Phys. Chem. Solids 115, 49–58 (2018)

H. Hertz, On the contact of elastic solids. J. Reine Angew. Math. 92, 156 (1882)

G. Ziegenhain, H.M. Urbassek, A. Hartmaier, Influence of crystal anisotropy on elastic deformation and onset of plasticity in nanoindentation: a simulational study. J. Appl. Phys. 107, 061807 (2010)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant no. 12172250), the Innovative Group Project of National Natural Science Foundation of China (Grant no. 12021002) and the Major Program of National Natural Science Foundation of China (Grant no. 11890682).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, JW., Guo, JG. & Qu, CY. Molecular dynamics investigation on nanoindentation mechanical response of graphene/nanotwinned aluminum matrix composites. Appl. Phys. A 129, 456 (2023). https://doi.org/10.1007/s00339-023-06739-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06739-2