Abstract

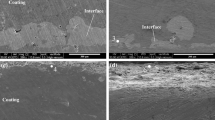

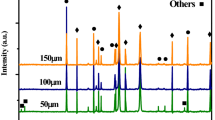

Stainless steel coatings are widely used in abrasive and corrosive environments due to their surface properties, and also to their techno-economic impact. Stainless steel coating deposited by Twin-Wire Arc Spray (TWAS) and post-annealed at the vacuum conditions presented very interesting mechanical and corrosion properties, while their tribological behavior, i.e. friction and wear resistance needs further improvement. To enhance those properties, Plasma Immersion Ion Implantation (PIII) technique was used to nitride the coating, afterward, the coatings microstructures were surveyed using Scanning Electron Microscope (SEM), Energy Dispersive Spectroscopy (EDS), X-Ray Diffraction (XRD) and Atomic Force Microscopy (AFM). Mechanical properties of the coatings were investigated through nanoindentation tests. The tribological properties were also evaluated. A comparison of the obtained results revealed that the hardness of the nitrided coatings could reach 16 GPa, representing a 50% increase compared to the non-nitrided stainless steel coatings. The friction coefficient showed to be 3 times lower after PIII nitriding. Moreover, the wear rate was reduced by 2 orders of magnitude.

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Y. Jirásková, S. Havlíček, O. Schneeweiss et al., J. Magn. Magn. Mater. 434, 477–488 (2001)

J. Lutz, J.W. Gerlach, S. Mändl, Phys. Status Solidi 205, 980–984 (2008)

S. Mändl, Plasma Process. Polym. 4, 239–245 (2008)

M.H. Farazmand, H. Khorsand, H. Ebrahimnezhad-Khaljiri, Metallogr. Microstruct. Anal. 7, 711–723 (2018)

B.C.E.S. Kurelo, W.R. DeOliveira, F.C. Serbena et al., Surf. Coat. Technol. 353, 199–209 (2018)

A. Lanterne, T. Desrues, C. Lorfeuvre et al., Prog. Photovoltaics 27(12), 1081–1091 (2019)

J.F. Lerat, T. Desrues, J. LePerchec et al., Enrgy Proced. 92, 697–701 (2016)

S. Mukherjee, J. Chakraborty, S. Gupta et al., Surf. Coat. Technol. 156(1–3), 103–109 (2002)

Y. Chen, B. Xu, Y. Liu et al., Trans. Nonferrous Metals Soc. China 18, 603–609 (2008)

K. Chemaa, M. Kezrane, S. Hassani et al., J. Mater. Eng. Perform. (2022). https://doi.org/10.1007/s11665-022-06830-4

K. Chemaa, M. Kezrane, S. Hassani et al., Appl. Phys. A 128(7), 1–10 (2022)

K. Chemaa, S. Hassani, M. Kezrane et al., Appl. Phys. A 128(2), 1–13 (2022)

M.M. Alim, N. Saoula, R. Tadjine et al., Eur. Phys. J. Appl. Phys. 75(3), 30801 (2016)

M. Al-Raeei, Chem. Thermodyn. Ther. Anal. 6, 100046 (2022)

P. Shukla, S. Singh, Pramana 94(1), 1–8 (2020)

S.V. Adichtchev, N.V. Surovtsev, J. Phys. Condens. Matter 33(49), 495102 (2021)

M. Tošić, I. Terzić, R. Gligorijević, Vac. 40, 131–134 (1990)

R. Valencia, R. López-Callejas, A. Muñoz-Castro et al., Brazilian. J. Phys. 34, 1594–1597 (2004)

K. Kostov, M. Ueda, M. Lepiensky et al., Surf. Coat. Technol. 186, 204–208 (2004)

J.F. Lin, K.W. Chen, C.C. Wei et al., Surf. Coat. Technol. 197, 28–38 (2005)

L. Shen, N. Wang, J. Nanomater. 2011, 1–5 (2011)

D. Vempaire, S. Miraglia, A. Sulpice et al., J. Magn. Magn. Mater. 272–276, E843–E844 (2004)

J.C. Caicedo, L. Yate, J. Montes, Surf. Coat. Technol. 205, 2947–2953 (2011)

P. Gao, S. Cao, J. Li et al., J. Alloys Compd. 684, 188–194 (2016)

B. Dikici, H. Yilmazer, I. Ozdemir et al., J. Therm. Spray Technol. 25, 704–714 (2016)

S. García-Rodríguez, A.J. López, B. Torres et al., Surf. Coat. Technol. 287, 9–19 (2016)

S. García-Rodríguez, B. Torres, A.J. López et al., Surf. Coat. Technol. 359, 73–84 (2019)

Q.Y. Wang, Y.C. Xi, Y.H. Zhao et al., Mater. Charact. 127, 239–247 (2017)

X.M. Meng, J.B. Zhang, W. Han et al., Appl. Surf. Sci. 258, 700–704 (2011)

M.M. Alim, R. Tadjine, A. Keffous et al., (2020) In: By A. Belasri, S.A. Beldjilali (eds) Proceedings of the 1st international conference on renewable energy and energy conversion. Springer, Singapore. p. 523

M. Meyers, K. Chawla, Mechanical Behavior of Materials, 2nd edn. (Cambridge University Press, New York, 2009)

K. Chemaa, S. Hassani, M. Gaceb et al., Surf. Eng. 37, 732–738 (2020)

H. Guo, S. Zhang, W. Sun et al., J. Mater. Sci. Technol. 35, 865–874 (2019)

K. Chemaa, S. Hassani, M. Gaceb, J. Mater. Eng. Perform. 30, 8023–8029 (2021)

L. Pranevicius, C. Templier, J.P. Rivière et al., Surf. Coat. Technol. 135(2–3), 250–257 (2001)

S.Y. Sirin, E. Kaluc, Mater. Design (1980–2015) 36, 741–747 (2012)

E. Song, B. Hwang, S. Lee et al., Mater. Sci. Eng. A 429, 189–195 (2006)

M. Alishavandi, M.A.R. Khollari, M. Ebadi et al., J Alloy Compd. 832, 153964 (2020)

F. Borgioli, E. Galvanetto, F.P. Galliano et al., Wear 260(7–8), 832–837 (2006)

Acknowledgements

The most of this work was done in the centre for the development of advanced technology (CDTA) Algiers, Algeria. The authors are grateful to the staffs of this centre. The authors are also grateful to Algérie Métallisation Company, and the Semiconductor Technology Research Centre for Energetics (CRTSE) Algiers, Algeria.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chemaa, K., Hassani, S., Kezrane, M. et al. Effect of Plasma Immersion Ion Implantation (PIII) nitriding on austenitic stainless steel multilayer coatings. Appl. Phys. A 129, 149 (2023). https://doi.org/10.1007/s00339-023-06435-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06435-1