Abstract

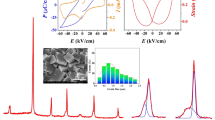

Ba0.85Ca0.15Ti0.90Sn0.09Zr0.01O3 ceramics were prepared by the conventional solid-state route. The effect of different sintering temperatures (1250 °C, 1350 °C, and 1450 °C) on the structural, dielectric, piezoelectric, and microstructure of the samples was investigated. The ceramics exhibited a tetragonal structure with a space group of P4mm and demonstrated a stable crystal structure despite the different sintering temperatures. The ceramic samples obtained similar Curie temperature, Tc approximately ~ 60 °C. Among all, the sample sintered at 1450 °C showed an improved pellet’s relative density with the highest dielectric constant, εr value at Tc of 6615. The sintering effect gives ~ 53% increment on dielectric constant at Tc due to the enhancement of the pellet density from 80.35% (sintered at 1250 °C) up to 91.21% (sintered at 1450 °C). Meanwhile, the sample sintered at 1250 °C obtained the highest piezoelectric constant, d33 value, due to the small grain size of 5.186 µm, which might lead to more 90° domain wall motion. The equivalent circuit analysis shows that the electrical microstructures of the samples were influenced by their ceramic microstructures. The sample sintered at 1450 °C exhibits an excellent fit using two sets of the parallel resistor, R and capacitor, C; R1–C1 (grain) and R2–C2 (grain boundary) elements. However, samples sintered at 1350 °C and 1250 °C required a constant phase element (CPE) to fit the R2–C2 element.

Similar content being viewed by others

References:

H.C. Song, S.W. Kim, H.S. Kim, D.G. Lee, C.Y. Kang, S. Nahm, Piezoelectric energy harvesting design principles for materials and structures: material figure-of-merit and self-resonance tuning. Adv. Mater. 32(51), 2002208 (2020)

D.B. Deutz, J.A. Pascoe, B. Schelen, S. Van Der Zwaag, D.M. De Leeuw, P. Groen, Analysis and experimental validation of the figure of merit for piezoelectric energy harvesters. Mater. Horiz. 5(3), 444–453 (2018)

Muhsen, K. N. D. K., Osman, R. A. M., Idris, M. S., Nadzri, N. I. M., & Jumali, M. H. H. (2021). Effect of sintering temperature on (Ba0.85Ca0.15)(SnxZr0.1-xTi0.9)O3 for piezoelectric energy harvesting applications. Ceramics International, 47(9), 13107–13117.

D.J. Shin, J. Kim, J.H. Koh, Piezoelectric properties of (1–x) BZT-xBCT system for energy harvesting applications. J. Eur. Ceram. Soc. 38(13), 4395–4403 (2018)

M. Acosta, N. Novak, V. Rojas, S. Patel, R. Vaish, J. Koruza, G.A. Rossetti Jr., J. Rödel, BaTiO3-based piezoelectrics: fundamentals, current status, and perspectives. Appl. Phys. Rev. 4(4), 041305 (2017)

Muhsen, K. N. D. K., Osman, R. A. M., & Idris, M. S. (2020). The effects of Ca, Zr and Sn substitutions into a ternary system of BaTiO3–BaSnO3–BaZrO3 towards its dielectric and piezoelectric properties: a review. Journal of Materials Science: Materials in Electronics, 1–13.

W. Liu, X. Ren, Large piezoelectric effect in Pb-free ceramics. Phys. Rev. Lett. 103(25), 257602 (2009)

Tian, Y., Wei, L., Chao, X., Liu, Z., & Yang, Z. (2013). Phase transition behavior and large piezoelectricity near the morphotropic phase boundary of lead‐free (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 ceramics. Journal of the American Ceramic Society, 96(2), 496–502.

W. Liu, J. Wang, X. Ke, S. Li, Large piezoelectric performance of Sn doped BaTiO3 ceramics deviating from quadruple point. J. Alloy. Compd. 712, 1–6 (2017)

K.N.D.K. Muhsen, R.A.M. Osman, M.S. Idris, Giant anomalous dielectric behaviour of BaSnO3 at high temperature. J. Mater. Sci.: Mater. Electron. 30(8), 7514–7523 (2019)

I.A. Alagdal, A.R. West, Oxygen stoichiometry, conductivity and gas sensing properties of BaSnO3. J. Materials Chem. C 4(21), 4770–4777 (2016)

I. Coondoo, N. Panwar, D. Alikin, I. Bdikin, S.S. Islam, A. Turygin, V.Y. Shur, A.L. Kholkin, A comparative study of structural and electrical properties in lead-free BCZT ceramics: influence of the synthesis method. Acta Mater. 155, 331–342 (2018)

Y. Bai, A. Matousek, P. Tofel, V. Bijalwan, B. Nan, H. Hughes, T.W. Button, (Ba, Ca)(Zr, Ti)O3 lead-free piezoelectric ceramics—the critical role of processing on properties. J. Eur. Ceram. Soc. 35(13), 3445–3456 (2015)

Jiang, M., Lin, Q., Lin, D., Zheng, Q., Fan, X., Wu, X., Sun, H., Wan, Y. & Wu, L. (2013). Effects of MnO2 and sintering temperature on microstructure, ferroelectric, and piezoelectric properties of Ba0.85Ca0.15Ti0.90Zr0.10O3 lead-free ceramics. J. Materials Sci., 48(3), 1035–1041.

H.I. Humburg, M. Acosta, W. Jo, K.G. Webber, J. Rödel, Stress-dependent electromechanical properties of doped (Ba1−xCax)(ZryTi1− y)O3. J. Eur. Ceram. Soc. 35(4), 1209–1217 (2015)

A. Di Loreto, A. Frattini, M.G. Stachiotti, Influence of post-calcination grinding on the properties of Ba0.85Ca0.15Zr0.1Ti0.9O3 lead-free piezoceramics. Mater. Lett. 191, 69–72 (2017)

Muhsen, K. N. D. K., Osman, R. A. M., & Idris, M. S. (2019). Structure refinement and impedance analysis of Ba0.85Ca0.15Zr0.10Ti0.90O3 ceramics sintered in air and nitrogen. Journal of Materials Science: Materials Electron., 30(23), 20673–20686.

A.R. West, D.C. Sinclair, N. Hirose, Characterization of electrical materials, especially ferroelectrics, by impedance spectroscopy. J. Electroceram. 1(1), 65–71 (1997)

V. Paunovic, V.V. Mitic, M. Djordjevic, Z. Prijic, Niobium doping effect on BaTiO3 structure and dielectric properties. Ceram. Int. 46(6), 8154–8164 (2020)

Wang, Z., Wang, J., Chao, X., Wei, L., Yang, B., Wang, D., & Yang, Z. (2016). Synthesis, structure, dielectric, piezoelectric, and energy storage performance of (Ba0.85Ca0.15)(Ti0.9Zr0.1)O3 ceramics prepared by different methods. Journal of Materials Science: Materials Electron., 27(5), 5047–5058.

H. Sun, S. Duan, X. Liu, D. Wang, H. Sui, Lead-free Ba0.98Ca0.02Zr0.02Ti0.98O3 ceramics with enhanced electrical performance by modifying MnO2 doping content and sintering temperature. J. Alloy. Compd. 670, 262–267 (2016)

A.R. West, T.B. Adams, F.D. Morrison, D.C. Sinclair, Novel high capacitance materials:-BaTiO3: La and CaCu3Ti4O12. J. Eur. Ceram. Soc. 24(6), 1439–1448 (2004)

R.A. Osman, N. Maso, A.R. West, Bismuth zinc niobate pyrochlore, a relaxor-like non-ferroelectric. J. Am. Ceram. Soc. 95(1), 296–302 (2012)

Osman, R. A., & Idris, M. S. (2013). Electrical properties of fresnoite Ba2TiSi2O8 using impedance spectroscopy,Advanced Materials Research (Vol. 795, pp. 640–643). Trans Tech Publications Ltd.

Osman, R. A., & West, A. R. (2011). Electrical characterization and equivalent circuit analysis of (Bi1.5Zn0.5)(Nb0.5Ti1.5)O7 pyrochlore, a relaxor ceramic, Journal of Applied Physics, 109(7), 074106.

D.C. Sinclair, Characterisation of electro-materials using ac impedance spectroscopy. Boletín de la Sociedad Española de Cerámica y Vidrio 34(2), 55–65 (1995)

A.R. West, M. Andres-Verges, Impedance and modulus spectroscopy of ZnO varistors. J. Electroceram. 1(2), 125–132 (1997)

Muhsen, K. N. D. K., Osman, R. A. M., Idris, M. S., Jumali, M. H. H., & Jamil, N. H. B. (2019). Enhancing the dielectric properties of (Ba0.85Ca0.15)(SnxZr0.10−xTi0.90)O3 lead-free ceramics by stannum substitution. J. Materials Sci, 30(23), 20654–20664 https://imagej.nih.gov/ij/

G.H. Kwei, A.C. Lawson, S.J.L. Billinge, S.W. Cheong, Structures of the ferroelectric phases of barium titanate. J. Phys. Chem. 97(10), 2368–2377 (1993)

A.W. Hewat, Structure of rhombohedral ferroelectric barium titanate. Ferroelectrics 6(1), 215–218 (1973)

W. Travis, E.N.K. Glover, H. Bronstein, D.O. Scanlon, R.G. Palgrave, On the application of the tolerance factor to inorganic and hybrid halide perovskites: a revised system. Chem. Sci. 7(7), 4548–4556 (2016)

S.F. Hoefler, G. Trimmel, T. Rath, Progress on lead-free metal halide perovskites for photovoltaic applications: a review. Monatshefte für Chemie-Chemical Monthly 148(5), 795–826 (2017)

S. Behara, T. Thomas, Stability and amphotericity analysis in rhombohedral ABO3 perovskites. Materialia 13, 100819 (2020)

N.A. Benedek, C.J. Fennie, Why are there so few perovskite ferroelectrics? J. Phys. Chem. C 117(26), 13339–13349 (2013)

Rabe, K. M., Dawber, M., Lichtensteiger, C., Ahn, C. H., & Triscone, J. M. (2007). Modern physics of ferroelectrics: Essential background. Phys. Ferroelectrics, 1–30.

Woodward, P. M. (1997). Octahedral tilting in perovskites. I. Geometrical considerations. Acta Crystallographica Section B 53(1), 32–43.

Woodward, P. M. (1997). Octahedral tilting in perovskites. II. Structure stabilizing forces. Acta Crystallographica Section B, 53(1), 44–66.

Van Horn, J. D. (2001). Electronic table of Shannon ionic radii. Electron. Table, 0–0.

R.D. Shannon, Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallographica Secti. A 32(5), 751–767 (1976)

G. Arlt, D. Hennings, G. De With, Dielectric properties of fine-grained barium titanate ceramics. J. Appl. Phys. 58(4), 1619–1625 (1985)

Stevels, J. M. (1957). The electrical properties of glass. In: Electrical Conductivity II/Elektrische Leitungsphänomene II (pp. 350–391). Springer, Berlin, Heidelberg.

U. Sukkha, W. Vittayakorn, R. Muanghlua, S. Niemcharoen, B. Boonchom, N. Vittayakorn, Phase transition behavior of the (1–x) PbZrO3− x Ba(Al1/2Nb1/2)O3 solid solution. J. Am. Ceram. Soc. 95(10), 3151–3157 (2012)

M.E. Lines, A.M. Glass, Principles and applications of ferroelectrics and related materials (Oxford University Press, 2001)

D Jr, C. W. (2007). Materials science and engineering, an introduction. John Wiley & Sons. Inc.–New York, USA.

M.L.V. Mahesh, V.B. Prasad, A.R. James, Effect of sintering temperature on the microstructure and electrical properties of zirconium doped barium titanate ceramics. J. Mater. Sci.: Mater. Electron. 24(12), 4684–4692 (2013)

J.J. Biendicho, A.R. West, Impedance characterisation of LiFePO4 ceramics. Solid State Ionics 226, 41–52 (2012)

B.E. McNealy, J.L. Hertz, On the use of the constant phase element to understand variation in grain boundary properties. Solid State Ionics 256, 52–60 (2014)

E.J. Abram, D.C. Sinclair, A.R. West, A strategy for analysis and modelling of impedance spectroscopy data of electroceramics: doped lanthanum gallate. J. Electroceram. 10(3), 165–177 (2003)

J.T. Irvine, D.C. Sinclair, A.R. West, Electroceramics: characterization by impedance spectroscopy. Adv. Mater. 2(3), 132–138 (1990)

P. Zheng, J.L. Zhang, Y.Q. Tan, C.L. Wang, Grain-size effects on dielectric and piezoelectric properties of poled BaTiO3 ceramics. Acta Mater. 60(13–14), 5022–5030 (2012)

Y. Tan, J. Zhang, C. Wang, G. Viola, H. Yan, Enhancement of electric field-induced strain in BaTiO3 ceramics through grain size optimization. Physica Status Solidi (A) 212(2), 433–438 (2015)

Acknowledgements

This work was financially supported by the Ministry of Higher Education Malaysia through the Fundamental Research Grant Scheme 2018 (FRGS Grant No.: FRGS/1/2018/STG07/UNIMAP/02/4).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Muhsen, K.N.D.K., Osman, R.A.M., Idris, M.S. et al. Effect of sintering temperature on the dielectric, impedance and piezoelectric properties of Ba0.85Ca0.15Ti0.90Sn0.09Zr0.01O3 ceramics. Appl. Phys. A 128, 505 (2022). https://doi.org/10.1007/s00339-022-05631-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-022-05631-9