Abstract

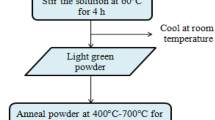

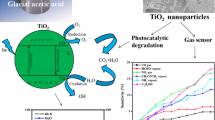

Hafnium oxide (HfO2) nanoparticulate powders were synthesized via a single step sol gel route using citric acid and ethylene glycol as chelating agent and polymerizing agent, respectively. In order to burn off the volatile components and produce crystalline HfO2 nanoparticles, the powders were calcined at moderately high temperatures ranging from 500 to 800 °C for 1 h each. The crystal structures of the nanoparticles were ascertained by powder X-ray diffraction. The nanocrystals in powder form had monoclinic structure and preferred orientation of the nanocrystals along (−111) direction was evident. The morphologies of the HfO2 nanopowders were studied by Field Emission Scanning Electron Microscope (FESEM). Morphologies of the nanopowder were observed to change with calcination temperatures. The optical properties of the HfO2 nanoparticles were evaluated by UV–Vis Diffuse Reflectance Spectroscopy (DRS). A small change in the band gap energy of HfO2 nanoparticles was observed with a change in the calcination temperature. In order to study the electrical and gas sensing properties of HfO2 nanoparticles, the powders were pressed into pellets with 12.0 mm diameter and 1.5 mm thickness. Gas sensing properties of HfO2 pellets were investigated by exposing them to formaldehyde gas inside closed chambers. The sensitivity of HfO2 towards formaldehyde gas initially increased with an increase in the calcination temperature due to increased porosity and decreased resistance of the HfO2 pellet. The HfO2 powder calcined at 700 °C showed highest sensitivity of 91.2% towards 264 ppm formaldehyde gas. The sensitivity declined with further increase in the calcination temperature because the HfO2 pellet became less porous thereby. Selectivity of the HfO2 sensor was tested with three volatile organic compound gases: acetone, ethanol and formaldehyde. Highest response was recorded for the formaldehyde gas.

Similar content being viewed by others

References

K.C. Das, S.P. Ghosh, N. Tripathy, D.H. Kim, T.I. Lee, J.M. Myoung, J.P. Kar, Ceram. Int. 42, 138 (2016)

Y. Yang, K. Li, G. Liu, Z. Zhao, J. Mater. Sci. Technol. 33, 1195 (2017)

K. Tiwari, S. C. Sharma, N. Hozhabri, AIP Adv. 6, 045217 (2016).

A. Q. Wang, J. Wang, M. J. D’lallo, J. E. Platten, J. C. Crifasi, B. P. Roy, Thin Solid Films 592, 232 (2015).

J. Gu, H. Wei, F. Ren, Q. Fan, G. Xu, X. Chen, S. Song, S. Dou, J. Zhao, Y. Li, J. Alloys Compd. 858, 158337 (2021).

J. F. Ihlefeld, T. S. Luk, S. W. Smith, S. S. Fields, S. T. Jaszewski, D. M. Hirt, W. T. Riffe, S. Bender, C. Constantin, M. V. Ayyasamy, P. V. Balachandran, P. Lu, M. David Henry, P. S. Davids, J. Appl. Phys. 128, 034101 (2020).

Y. Wang, J. Feng, Z. Cao, H. Zhu, Appl. Phys. A 115, 1409 (2014)

D. Pradhan, S. Das, T.P. Dash, Superlattices Microstruct. 98, 203 (2016)

A. Das, Adv. Mater. Lett. 7, 123 (2016)

D. Salado-Leza, E. Mendoza-Mendoza, J. A. Castillo-Ramírez, C. Escudero-Lourdes, L. A. García-Cerda, Mater. Lett. 274, 128048 (2020).

A. Ramadoss, S.J. Kim, J. Alloys Compd. 544, 115 (2012)

A. de F. Soares, S. H. Tatumi, R. R. Rocca, L. C. Courrol, J. Lumin. 219, (2020).

L.A. González, S. Gálvez-Barboza, E. Vento-Lujano, J.L. Rodríguez-Galicia, L.A. García-Cerda, Ceram. Int. 46, 13466 (2020)

M. Li, Z.-X. Jin, W. Zhang, Y.-H. Bai, Y.-Q. Cao, W.-M. Li, D. Wu, A.-D. Li, Sci. Rep. 9, 10438 (2019)

X.-Y. Zhang, C.-H. Hsu, S.-Y. Lien, S.-Y. Chen, W. Huang, C.-H. Yang, C.-Y. Kung, W.-Z. Zhu, F.-B. Xiong, X.-G. Meng, Nanoscale Res. Lett. 12, 324 (2017)

I. Karaduman, S. Acar, Mod. Phys. Lett. B 31, 1750284 (2017)

I. Karaduman, Ö. Barin, D. E. Yıldız, S. Acar, J. Appl. Phys. 118, 174501 (2015).

S.M.A. Durrani, Sensors Actuators B Chem. 120, 700 (2007)

S.M.A. Durrani, M.F. Al-Kuhaili, Mater. Chem. Phys. 109, 56 (2008)

F. Xu, C. Zhou, and H.-P. Ho, J. Alloys Compd. 858, 158294 (2021).

S. Ramanavičius, M. Petrulevičiene, J. Juodkazyte, A. Grigucevičiene, A. Ramanavičius, Materials (Basel). 13, (2020).

Z. Cai, S. Park, J. Mater. Res. Technol. 9, 271 (2020)

J. Huang, Y. Liu, Y. Wu, X. Li, Am. J. Anal. Chem. 08, 60 (2017)

M. Dutt, A. Ratan, M. Tomar, V. Gupta, V. Singh, J. Phys. Chem. Solids 145, 109536 (2020).

E. Sennik, N. Kilinc, Z.Z. Ozturk, J. Alloys Compd. 616, 89 (2014)

S. Ramanavicius, A. Ramanavicius, Sensors 20, 6833 (2020)

I. Karaduman, Ö. Barin, S. Acar, J. Korean Phys. Soc. 68, 1334 (2016)

A. B. Mukhopadhyay, J. F. Sanz, C. B. Musgrave, Phys. Rev. B 73, 115330 (2006).

A.L. Patterson, Phys. Rev. 56, 972 (1939)

P. Bindu, S. Thomas, J. Theor. Appl. Phys. 8, 123 (2014)

H. Adachi, Y. Miyajima, M. Sato, N. Tsuji, Mater. Trans. 56, 671 (2015)

S. Mourdikoudis, R.M. Pallares, N.T.K. Thanh, Nanoscale 10, 12871 (2018)

P.S. Bauer, H. Amenitsch, B. Baumgartner, G. Köberl, C. Rentenberger, P.M. Winkler, Nat. Commun. 10, 1122 (2019)

F. Cerbu, O. Madia, D. V. Andreev, S. Fadida, M. Eizenberg, L. Breuil, J. G. Lisoni, J. A. Kittl, J. Strand, A. L. Shluger, V. V. Afanas’ev, M. Houssa, A. Stesmans, Appl. Phys. Lett. 108, 222901 (2016).

S. Papernov, M. D. Brunsman, J. B. Oliver, Opt. Express 26, 17608 (2018).

Lontio Fomekong and Saruhan, Chemosensors 7, 42 (2019)

S. Cui, H. Pu, S.A. Wells, Z. Wen, S. Mao, J. Chang, M.C. Hersam, J. Chen, Nat. Commun. 6, 8632 (2015)

S.-H. Chuang, H.-C. Lin, C.-H. Chen, J. Alloys Compd. 534, 42 (2012)

V. Kiisk, S. Lange, K. Utt, T. Tätte, H. Mändar, I. Sildos, Phys. B Condens. Matter 405, 758 (2010)

J. Ni, Q. Zhou, Z. Li, Z. Zhang, Appl. Phys. Lett. 93, 011905 (2008).

N. Yamazoe, K. Shimanoe, C. Sawada, Thin Solid Films 515, 8302 (2007)

Y. Xu, X. Tian, Y. Fan, Y. Sun, Sensors Actuators B Chem. 309, 127719 (2020).

A. Avila-García, M. García-Hipólito, Sensors Actuators B Chem. 133, 302 (2008)

S. Capone, G. Leo, R. Rella, P. Siciliano, L. Vasanelli, M. Alvisi, L. Mirenghi, A. Rizzo, J. Vac. Sci. Technol. A Vacuum, Surfaces, Film. 16, 3564 (1998).

I. Karaduman, Ö. Barin, M. Özer, S. Acar, J. Electron. Mater. 45, 3914 (2016)

V. Amiri, H. Roshan, A. Mirzaei, G. Neri, A.I. Ayesh, Sensors 20, 3096 (2020)

W. Tan, Q. Yu, X. Ruan, X. Huang, Sensors Actuators B Chem. 212, 47 (2015)

L. Gao, H. Fu, J. Zhu, J. Wang, Y. Chen, H. Liu, J. Mater. Res. 35, 2208 (2020)

S. Lin, D. Li, J. Wu, X. Li, S.A. Akbar, Sensors Actuators B Chem. 156, 505 (2011)

J. Wang, H. Deng, X. Li, C. Yang, Y. Xia, Sensors Actuators B Chem. 304, 127317 (2020).

X. Fu, P. Yang, X. Xiao, D. Zhou, R. Huang, X. Zhang, F. Cao, J. Xiong, Y. Hu, Y. Tu, Y. Zou, Z. Wang, H. Gu, J. Alloys Compd. 797, 666 (2019)

Z.-W. Chen, Y.-Y. Hong, Z.-D. Lin, L.-M. Liu, X.-W. Zhang, Electron. Mater. Lett. 13, 270 (2017)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chattopadhyay, A., Nayak, J. Enhanced room temperature sensitivity of undoped HfO2 nanoparticles towards formaldehyde gas. Appl. Phys. A 127, 904 (2021). https://doi.org/10.1007/s00339-021-05072-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-05072-w