Abstract

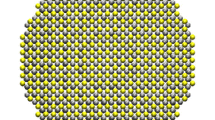

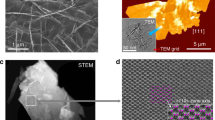

The molecular dynamics simulations of quasi-static compression of SiC nanoparticles (NPs) with diameters from 5 to 40 nm are performed in the temperature range from 0.1 to 3500 K. The crystalline NPs with hexagonal, 6H-SiC, and cubic, 3C-SiC, lattices, as well as amorphous NPs, are compressed along [001], [110], and [111] crystallographic directions with either plane indenters or periodic boundary conditions. The dominant mechanism of deformation depends on the type of the SiC polymorph, NP size, temperature, and lattice orientation with respect to the compression direction. For small NPs at low temperature, the compression mostly induces amorphization of 6H-SiC NPs and formation of rock-salt phase core in 3C-SiC NPs, while the compressive stress only marginally depends on the lattice orientation. For large NPs, the deformation induces formation of multiple dislocations and slip planes that result in the material fragmentation. The morphology and number of fragments strongly depend on the SiC polymorph and lattice orientation. The fragmentation of large 6H-SiC NPs preferentially occurs along {0001} plane independently on the compression direction. An increase in temperature promotes the dislocation nucleation with subsequent fragmentation and relative motion of large fragments. As a result, the average stress at large deformation tends to increase with the NP size at small temperatures and to decrease at elevated temperatures. On average, 6H-SiC NPs compressed along [001] direction demonstrate stronger resistance to compression in the regime of plastic deformation compared to 3C-SiC NPs and other lattice orientations.

Similar content being viewed by others

References

G. L. Harris, Properties of silicon carbide. (Institute of Electrical Engineers, London), No. 13 (1995)

B.M. Kumar, Y.W. Kim, D.S. Lim, W.S. Seo, Influence of small amount of sintering additives on unlubricated sliding wear properties of SiC ceramics. Ceram. Int. 37(8), 3599–3608 (2011)

N.P. Padture, In situ-toughened silicon carbide. J. Amer. Ceram. Soc. 77(2), 519–523 (1994)

V. Presser, K.G. Nickel, Silica on silicon carbide. Crit. Rev. Solid State Mater. Sci. 33(1), 1–99 (2008)

P. Mélinon, B. Masenelli, F. Tournus, A. Perez, Playing with carbon and silicon at the nanoscale. Nat. Mater. 6(7), 479–490 (2007)

T. Yamamoto, M. Olsson, S. Hogmark, Three body abrasive wear of ceramic materials. Wear 174(1–2), 21–31 (1994)

Y. Şahin, Abrasive wear behaviour of SiC/2014 aluminium composite. Tribol. Int. 43(5–6), 939–943 (2010)

X.F. Zhang, G.Y. Lee, D. Chen, R.O. Ritchie, L.C. De Jonghe, Abrasive wear behavior of heat-treated ABC-silicon carbide. J. Am. Ceram. Soc. 86(8), 1370–1378 (2003)

K. Daviau, K.K. Lee, High-pressure, high-temperature behavior of silicon carbide: A review. Crystals 8(5), 217 (2018)

G. Ervin Jr., Oxidation behavior of silicon carbide. J. Amer. Ceram. Soc. 41(9), 347–352 (1958)

M.F. Gazulla, M.P. Gomez, M. Orduna, A. Barba, Physico-chemical characterisation of silicon carbide refractories. J. Eur. Ceram. Soc. 26(15), 3451–3458 (2006)

V. Matějka, Y. Lu, L. Jiao, L. Huang, G.S. Martynková, V. Tomášek, Effects of silicon carbide particle sizes on friction-wear properties of friction composites designed for car brake lining applications. Tribol. Int. 43(1–2), 144–151 (2010)

P. Kumar, V.K. Srivastava, Tribological behaviour of C/C–SiC composites—A review. J. Adv. Ceram. 5(1), 1–12 (2016)

N.S. Samir, M.A. Radwan, M.A. Sadek, H.A. Elazab, Preparation and characterization of bullet-proof vests based on polyamide fibers. Int. J. Eng. Technol. (UAE) 7(3), 1290–1294 (2018)

D. Varshney, S. Shriya, M. Varshney, N. Singh, R. Khenata, Elastic and thermodynamical properties of cubic (3C) silicon carbide under high pressure and high temperature. J. Theor. Appl. Phys. 9(3), 221–249 (2015)

D. Chrobak, N. Tymiak, A. Beaber, O. Ugurlu, W.W. Gerberich, R. Nowak, Deconfinement leads to changes in the nanoscale plasticity of silicon. Nature Nanotechnol. 6(8), 480–484 (2011)

H.G. Craighead, Nanoelectromechanical systems. Science 290(5496), 1532–1535 (2000)

J. Hu, Z. Zhong, F. Zhang, W. Xing, W. Jin, N. Xu, High-efficiency, synergistic ZnO-coated SiC photocatalytic filter with antibacterial properties. Ind. Eng. Chem. Res. 55(23), 6661–6670 (2016)

Y. Du, A.B. Li, X.X. Zhang, Z.B. Tan, R.Z. Su, F. Pu, L. Geng, Enhancement of the mechanical strength of aluminum foams by SiC nanoparticles. Mater. Lett. 148, 79–81 (2015)

P. Wan, L. Gao, J. Wang, Approaching ultra-low thermal conductivity in β-SiC nanoparticle packed beds through multiple heat blocking mechanisms. Scr. Mater. 128, 1–5 (2017)

P. Wan, J. Wang, Highly porous nano-SiC with very low thermal conductivity and excellent high temperature behavior. J. Eur. Ceram. Soc. 38(2), 463–467 (2018)

W. Wang, H. Wang, Y. Liu, H. Nie, W. Cheng, Effect of SiC nanoparticles addition on the microstructures and mechanical properties of ECAPed Mg9Al-1Si alloy. J. Mater. Res. 32(3), 615 (2017)

A. Raihan Mohammad Siddique, F. Kratz, S. Mahmud, and B. Van Heyst (2019), Energy conversion by nanomaterial-based trapezoidal-shaped leg of thermoelectric generator considering convection heat transfer effect. J. Energy Resour. Technol. 141(8), 082001

J. Li, Q. Tan, J.F. Li, D.W. Liu, F. Li, Z.Y. Li, M. Zou, K. Wang, BiSbTe-based nanocomposites with high ZT: The effect of SiC nanodispersion on thermoelectric properties. Adv. Funct. Mater. 23(35), 4317–4323 (2013)

H. Liu, G. She, L. Mu, W. Shi, Porous SiC nanowire arrays as stable photocatalyst for water splitting under UV irradiation. Mater. Res. Bull. 47(3), 917–920 (2012)

M. Naeimirad, A. Zadhoush, R.E. Neisiany, Fabrication and characterization of silicon carbide/epoxy nanocomposite using silicon carbide nanowhisker and nanoparticle reinforcements. J. Comp. Mater. 50(4), 435–446 (2016)

N.R. Taylor, W. Kuang, M. Saeidijavash, P. Kandlakunta, Y. Zhang, L.R. Cao, Direct printing of metal contacts on 4H-SiC for radiation detection. AIP Adv. 9(9), 095041 (2019)

J.S. Ponraj, S.C. Dhanabalan, G. Attolini, G. Salviati, SiC nanostructures toward biomedical applications and its future challenges. Crit. Rev. Solid State Mater. Sci. 41(5), 430–446 (2016)

A.J. Rosenbloom, D.M. Sipe, Y. Shishkin, Y. Ke, R.P. Devaty, W.J. Choyke, Nanoporous SiC: A candidate semi-permeable material for biomedical applications. Biomed. Microdevices 6(4), 261–267 (2004)

H. Chen, X. Wang, F. Xue, Y. Huang, K. Zhou, D. Zhang, 3D printing of SiC ceramic: Direct ink writing with a solution of preceramic polymers. J. Eur. Ceram. Soc. 38(16), 5294–5300 (2018)

X. Lv, F. Ye, L. Cheng, S. Fan, Y. Liu, Fabrication of SiC whisker-reinforced SiC ceramic matrix composites based on 3D printing and chemical vapor infiltration technology. J. Eur. Ceram. Soc. 39(11), 3380–3386 (2019)

S. Alekseev, E. Shamatulskaya, M. Volvach, S. Gryn, D. Korytko, I. Bezverkhyy, V. Iablokov, V. Lysenko, Size and surface chemistry tuning of silicon carbide nanoparticles. Langmuir 33(47), 13561–13571 (2017)

N.W. Jepps, T.F. Page, Polytypic transformations in silicon carbide. Prog. Cryst. Growth Charact. Mater. 7(1–4), 259–307 (1983)

T. Jikimoto, T. Tsukamoto, A. Kinoshita, Y. Satoh, M. Hirai, M. Kusaka, M. Iwami, T. Nakata, Photoemission study of 6H-SiC (0001) Si face. Appl. Surf. Sci. 117(118), 794–797 (1997)

L.S. Ramsdell, Studies on silicon carbide. Am. Mineralogist: J. Earth Planet. Mater. 32(1–2), 64–82 (1947)

F. Bechstedt, P. Käckell, A. Zywietz, K. Karch, B. Adolph, K. Tenelsen, J. Furthmüller, Polytypism and properties of silicon carbide. Phys. Status Solidi B 202(1), 35–62 (1997)

L. Patrick, Inequivalent sites and multiple donor and acceptor levels in SiC polytypes. Phys. Rev. 127(6), 1878 (1962)

Q. He, J. Fei, C. Tang, J. Zhong, L. Meng, Mechanical behavior of silicon carbide nanoparticles under uniaxial compression. J. Nanoparticle Res. 18(3), 68 (2016)

I. Szlufarska, R.K. Kalia, A. Nakano, P. Vashishta, A molecular dynamics study of nanoindentation of amorphous silicon carbide. J. Appl. Phys. 102(2), 023509 (2007)

N. Zhang, Q. Deng, Y. Hong, L. Xiong, S. Li, M. Strasberg, W. Yin, Y. Zou, C.R. Taylor, G. Sawyer, Y. Chen, Deformation mechanisms in silicon nanoparticles. J. Appl. Phys. 109(6), 063534 (2011)

D. Kilymis, C. Gérard, L. Pizzagalli, Ductile deformation of core-shell Si-SiC nanoparticles controlled by shell thickness. Acta Mater. 164, 560–567 (2019)

B. Jiang, G.J. Weng, A theory of compressive yield strength of nano-grained ceramics. Int. J. Plast. 20(11), 2007–2026 (2004)

J. Tersoff, Modeling solid-state chemistry: Interatomic potentials for multicomponent systems. Phys. Rev. B. 39(8), 5566 (1989)

J. Tersoff, Erratum: Modeling solid-state chemistry: Interatomic potentials for multicomponent systems. Phys. Rev. B. 41(5), 3248 (1990)

F. Shimojo, I. Ebbsjö, R.K. Kalia, A. Nakano, J.P. Rino, P. Vashishta, Molecular dynamics simulation of structural transformation in silicon carbide under pressure. Phys. Rev. Lett. 84(15), 3338 (2000)

P. Vashishta, R.K. Kalia, A. Nakano, J.P. Rino, Interaction potential for silicon carbide: A molecular dynamics study of elastic constants and vibrational density of states for crystalline and amorphous silicon carbide. J Appl. Phys. 101, 103515 (2007)

A.C. Van Duin, S. Dasgupta, F. Lorant, W.A. Goddard, ReaxFF: a reactive force field for hydrocarbons. J. Phys. Chem. A 105(41), 9396–9409 (2001)

R. Clausius, On a mechanical theorem applicable to heat. Philos. Mag. J. Sci. 40(265), 122–127 (1870)

A.P. Thompson, S.J. Plimpton, W. Mattson, General formulation of pressure and stress tensor for arbitrary many-body interaction potentials under periodic boundary conditions. J. Chem. Phys. 131(15), 154107 (2009)

D.J. Evans, B.L. Holian, The Nosé-Hoover thermostat. J. Chem. Phys. 83(8), 4069–4074 (1985)

O. Aluko, E. J. Pineda, T. M. Ricks, and S. M. Arnold (2019), Molecular dynamics simulations of silicon carbide, boron nitride and silicon for ceramic matrix composite applications, NASA Report 220305

S. Plimpton, Fast parallel algorithms for short-range molecular dynamics. J. Comp. Phys. 117(1), 1–19 (1993)

P.S. Sokolov, V.A. Mukhanov, T. Chauveau, V.L. Solozhenko, On melting of silicon carbide under pressure. J. Superhard Mater. 34(5), 339–341 (2012)

Z. Mingdi, M. Matsumoto, Molecular dynamics study of 3C-SiC surface properties. Funct. Nanostructures 1(3), 120–124 (2018)

R.T. Dolloff, in Research study to determine the phase equilibrium relations of selected metal carbides at high temperatures, ed. by W.A.D.D.T.R. Report No (Research Laboratory of National Carbon Company Division of Union Carbide, 1960), pp. 60–143

K. Daviau, K.K.M. Lee, Decomposition of silicon carbide at high pressures and temperatures. Phys. Rev. B 96, 174102 (2017)

P.T.B. Schaffer, A review of the structure of silicon carbide. Acta Crystallographica B 25(3), 477–488 (1969)

Y. Kidokoro, K. Umemoto, K. Hirose, Y. Ohishi, Phase transition in SiC from zinc-blende to rock-salt structure and implications for carbon-rich extrasolar planets. Am. Miner. 102(11), 2230–2234 (2017)

M. Yoshida, A. Onodera, M. Ueno, K. Takemura, O. Shimomura, Pressure-induced phase transition in SiC. Phys. Rev. B 48(14), 10587–10590 (1993)

A. Stukowski, K. Able, Extracting dislocations and non-dislocation crystal defects from atomistic simulation data. Model. Simul. Mater. Sci. Eng. 18(8), 085001 (2010)

A. Stukowski, K. Able, Dislocation detection algorithm for atomistic simulations. Model. Simul. Mater. Sci. Eng. 18(2), 025016 (2010)

P.F. Zou, R.F.W. Bader, A topological definition of a Wigner-Seitz cell and the atomic scattering factor. Acta Crystallogr. A 50(6), 714–725 (1994)

Y. Hong, N. Zhang, M.A. Zaeem, Metastable phase transformation and deformation twinning induced hardening-stiffening mechanism in compression of silicon nanoparticles. Acta Mater. 145, 8–18 (2018)

J.J. Brian, L. Yang, X.R. Niu, G.F. Wang, Orientation-dependent deformation mechanisms of bcc niobium nanoparticles. Philos. Mag. 98(20), 1848–1864 (2018)

D. Kilymis, C. Gérard, J. Amodeo, U.V. Waghmare, L. Pizzagalli, Uniaxial compression of silicon nanoparticles: an atomistic study on the shape and size effects. Acta Mater. 158, 155–166 (2018)

A. Stukowski, Visualization and analysis of atomistic simulation data with OVITO – the open visualization tool. Model. Simul. Mater. Sci. Eng. 18(1), 015012 (2009)

Acknowledgements

This work was supported by NSF through award CMMI-1554589. The computational support is provided by the Alabama Supercomputer Center. The visualization and post-processing of the results of MD simulations are performed using the OVITO software [66].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kayang, K.W., Volkov, A.N. Mechanical properties, phase transitions, and fragmentation mechanisms of 6H, 3C, and amorphous SiC nanoparticles under compression. Appl. Phys. A 127, 921 (2021). https://doi.org/10.1007/s00339-021-05066-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-05066-8