Abstract

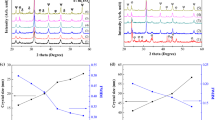

Tetragonal-phase BaTiO3 powders of particle size 370 nm were synthesized by microwave sintering at 850 °C. The raw materials were BaCO3, TiO2, and alanine. SiC microspheres were used as microwave conductors. The effects of the holding time, sintering aids, and SiC addition on the preparation of BaTiO3 were investigated. The results indicate that the addition of SiC as a microwave acceptor leads to formation of microwave micro-regions. This enables uniform heating of the raw materials and decreases the calcination temperature needed to obtain BaTiO3. Alanine coordinates with Ba, and this loosens the metal–CO3 bond and promotes separation of CO2, decreases the BaCO3 decomposition temperature, and provides a higher nucleation site density. It gives an idea about the microwave solid-state synthesis of BaTiO3 powder.

Similar content being viewed by others

References

X. Luo, S. Yuan, X. Pan, C. Zhang, S. Du, Y. Liu, ACS Appl. Mater. Inter. (2017). https://doi.org/10.1021/acsami.7b02580

Y. Wang, K. Miao, W. Wang, Y. Qin, J. Eur. Ceram. Soc. (2017). https://doi.org/10.1016/j.jeurceramsoc.2017.01.035

N. Liu, W. Zhao, J. Rong, J. Am. Ceram. Soc. (2018). https://doi.org/10.1111/jace.15339

J. Li, K. Inukai, Y. Takahashi, A. Tsuruta, W. Shin, J. Asian Ceram. Soc. (2018). https://doi.org/10.1016/j.jascer.2017.05.001

P. Xue, Y. Hu, W. Xia, H. Wu, X. Zhu, J. Alloys Compd. (2017). https://doi.org/10.1016/j.jascer.2017.05.001

J. Li, K. Inukai, Y. Takahashi, A. Tsuruta, W. Shin, Materials (2018). https://doi.org/10.3390/ma11050712

Z. Zhu, W. Zhu, Curr. Appl. Phys. (2018). https://doi.org/10.1016/j.cap.2018.04.016886-892

R. Ashiri, RSC Adv. (2016). https://doi.org/10.1039/c5ra22942a

S.-S. Ryu, D.-H. Yoon, J. Mater. Sci. (2007). https://doi.org/10.1007/s10853-007-1537-6

Y.A. Huang, B. Lu, D.D. Li, Z.H. Tang, Y.B. Yao, T. Tao, B. Liang, S.G. Lu, Ceram Int. (2017). https://doi.org/10.1016/j.ceramint.2017.09.027

J. Li, K. He, Z.-H. Zhou, H. Huang, L. Zhang, C.-G. Lou, H.-Y. Yu, Ceram. Int. (2017). https://doi.org/10.1016/j.ceramint.2017.07.229

H. Jiao, K. Zhao, R. Shi, L. Ma, Y. Tang, Cryst. Res. Technol. (2018). https://doi.org/10.1002/crat.201700107

A.Z. Simões, F. Moura, T.B. Onofre, M.A. Ramirez, J.A. Varela, E. Longo, J. Alloys Compd. (2010). https://doi.org/10.1016/j.jallcom.2010.08.143

K. Hongo, S. Kurata, A. Jomphoak, M. Inada, K. Hayashi, R. Maezono, Inorg. Chem. (2018). https://doi.org/10.1021/acs.inorgchem.8b00381

S. Ahda, S. Misfadhila, P. Parikin, T.Y.S.P. Putra, IOP Conf. Ser. Mater. Sci. Eng. (2017). https://doi.org/10.1088/1757-899x/176/1/012048

S.-S. Ryu, J. Kore. Powd. Met. Inst. (2012). https://doi.org/10.4150/kpmi.2012.19.4.310

C. Ando, H. Kishi, H. Oguchi, M. Senna, J. Am. Ceram. Soc. (2006). https://doi.org/10.1111/j.1551-2916.2006.00917.x

R. Yanagawa, M. Senna, C. Ando, H. Chazono, H. Kishi, J. Am. Ceram. Soc. (2007). https://doi.org/10.1111/j.1551-2916.2007.01498.x

O.G. Gromov, A.P. Kuzmin, G.B. Kunshina, R.M. Usmanov, E.P. Lokshin, Russ. J. Appl. Chem. (2008). https://doi.org/10.1134/s1070427208110025

R. Rotaru, C. Peptu, P. Samoila, V. Harabagiu, J. Am. Ceram. Soc. (2017). https://doi.org/10.1111/jace.15003

H. Itasaka, K.I. Mimura, K. Kato, Nanomaterials (2018). https://doi.org/10.3390/nano8090739

M. Bi, Y. Hao, J. Zhang, M. Lei, K. Bi, Nanoscale (2017). https://doi.org/10.1039/c7nr05212j

T.-T. Lee, C.-Y. Huang, C.-Y. Chang, I.K. Cheng, C.-L. Hu, C.-Y. Su, C.-T. Lee, M. Fujimoto, Int. Appl. Ceram. Technol. (2013). https://doi.org/10.1111/ijac.12072

T.M. Khan, M. Zakria, R.I. Shakoor, S. Hussain, Appl. Phys. A (2016). https://doi.org/10.1007/s00339-016-9766-7

L. Zhang, J.X. Wen, Z.X. Zhang, J. Yang, H. Huang, Q.Y. Hu, H.R. Zhuang, H.Y. Yu, Phys. B (2019). https://doi.org/10.1016/j.physb.2019.02.002

Y. Zhang, L. Wang, D. Xue, Powder Technol. (2012). https://doi.org/10.1016/j.powtec.2011.11.043

H.-W. Lee, S. Moon, C.-H. Choi, D.K. Kim, S.J. Kang, J. Am. Ceram. Soc. (2012). https://doi.org/10.1111/j.1551-2916.2012.05085.x

K. Tsuzuku, M. Couzi, J. Mater. Sci. (2012). https://doi.org/10.1007/s10853-012-6310-9

J.C. Niepce, G. Thomas, Solid State lonics. (1990). https://doi.org/10.1016/0167-2738(90)90472-4

M.T. Buscaglia, M. Bassoli, V. Buscaglia, R. Alessio, J. Am. Ceram. Soc. (2005). https://doi.org/10.1111/j.1551-2916.2005.00451.x

C. Ando, H. Chazono, H. Kishi, Key Eng. Mater. (2004). https://doi.org/10.4028/www.scientific.net/KEM.269.161

C. Ando, K. Tsuzuku, T. Kobayashi, H. Kishi, S. Kuroda, M. Senna, J. Mater. Sci. Mater. Electron. (2008). https://doi.org/10.1007/s10854-008-9804-0

Acknowledgements

We thank the Science and Technology Major Project of Guangxi (AA18118001), Guangxi Key Laboratory of Information Materials Foundation (No. 171021-Z).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qian, H., Zhu, G., Xu, H. et al. Preparation of tetragonal barium titanate nanopowders by microwave solid-state synthesis. Appl. Phys. A 126, 294 (2020). https://doi.org/10.1007/s00339-020-03472-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-03472-y