Abstract

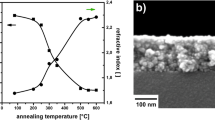

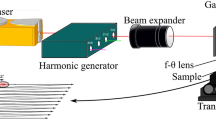

Formation of TiN by femtosecond laser processing in controlled gas atmosphere is reported. A dual-stage process was designed and aimed to first remove and restructure the native oxide layer of titanium surface through laser irradiation under an argon-controlled atmosphere, and then to maximize titanium nitride formation through an irradiation under a nitrogen reactive environment. An extensive XPS study was performed to identify and quantify laser-induced titanium surface chemistry modifications after a single-stage laser process (Ar and N2 individually), and a dual-stage laser process. The importance of each step that composes the dual-stage laser process was demonstrated and leads to the dual-stage laser process for the formation of TiO, Ti2O3 and TiN. In this study, the largest nitride formation occurs for the dual stage process with laser conditions at 4 W/1.3 J cm−2 under argon and 5 W/1.6 J cm−2 under nitrogen, yielding a total TiN composition of 8.9%. Characterization of both single-stage and dual-stage laser process-induced surface morphologies has been performed as well, leading to the observation of a wide range of hierarchical surface structures such as high-frequency ripples, grooves, protuberances and pillow-like patterns. Finally, water wettability was assessed by means of contact angle measurements on untreated titanium surface, and titanium surfaces resulting from either single-stage laser process or dual-stage laser process. Dual-stage laser process allows a transition of titanium surface, from phobic (93°) to philic (35°), making accessible both hydrophilic and chemically functionalized hierarchical surfaces.

Similar content being viewed by others

References

A.Y. Vorobyev, C. Guo, Multifunctional surfaces produced by femtosecond laser pulses. J. Appl. Phys. 117, 033103:1–5 (2015)

A.Y. Vorobyev, C. Guo, Direct femtosecond laser surface nano/microstructuring and its applications. Laser Photonics Rev 7, 3 (2013)

J. Bonse, S.V. Kirner, S. Höhm, N. Epperlein, D. Spaltmann, A. Rosenfeld, J. Krüger, Applications of laser-induced periodic surface structures (LIPSS), Invited Paper Proc. of SPIE Vol. 10092

S. Hammouti, B. Holybee, M. Christenson, M. Szott, K. Kalathiparambil, S. Stemmley, B. Jurczyk, D.N. Ruzic, Wetting of liquid lithium on microtextured fusion-relevant materials by femtosecond exposure. J. Nucl. Mat. (Manuscript submitted for publication)

C. Yao, S. Xu, Y. Ye, Y. Jiang, R. Ding, W. Gao, X. Yuan, The influence of femtosecond laser repetition rates and pulse numbers on the formation of micro/nano structures on stainless steel. J. Alloys Compd. 722, 235–241 (2017)

N. Yasumaru, K. Miyazaki, J. Kiuchi, Fluence dependence of femtosecond-laser-induced nanostructure formed on TiN and CrN. Appl. Phys. A 81, 933–937 (2005)

O. Armbruster, A. Naghilou, M. Kitzler, W. Kautek, Spot size and pulse number dependence of femtosecond laser ablation thresholds of silicon and stainless steel. Appl. Surf. Sci. 396, 1736–1740 (2017)

J. Bonse, J. Krüger, S. Höhm, A. Rosenfeld, Femtosecond laser-induced periodic surface structures. J. Laser Appl. Vol. 24, 4 (2002)

B.K.K. Nayak, M.C.C. Gupta, Self-organized micro/nano structures in metal surfaces by ultrafast laser irradiation. Optics and Lasers Eng. 48, 940–949 (2010)

A. Vorobyev, C. Guo, Femtosecond laser structuring of titanium implants. Appl. Surf. Sci. 253, 7272–7280 (2007)

S. Hammouti, A. Pascale-Hamri, N. Faure, B. Beaugiraud, M. Guibert, C. Mauclair, S. Benayoun, S. Valette, Wear rate control of peek surfaces modified by femtosecond laser. Appl. Surf. Sci. 357, 1541–1551 (2015)

J. Bonse, S.V. Kirner, R. Koter, S. Pentzien, D. Spaltmann, J. Krüger, Femtosecond laser-induced periodic surface structures on titanium nitride coatings for tribological applications. Appl. Surf. Sci. 418(Part B), 572–579 (2017)

N. Epperlein, F. Menzel, K. Schwibber, R. Koter, J. Bonse, J. Sameith, J. Krüger, J. Toepel, Influence of femtosecond laser produced nanostructures on biofilm growth on steel. Appl. Surf. Sci 418, 420–424 (2017)

D. Hoeche, P. Schaaf, Laser nitriding: Investigations on the model system TiN. A review. Heat Mass Transf 47(5), 519–540 (2010)

P. Schaaf, T.M. Kahle, E. Carpene, Reactive laser plasma coating formation. Surf. Coat. Technol. 200, 608–611 (2005)

E. Carpene, M. Shinn, P. Schaaf, Free-electron laser surface processing of titanium in nitrogen atmosphere. Appl. Surf. Sci. 247, 307–312 (2005)

E. Carpene, P. Schaaf, M. Han, K. Lieb, M. Shinn, Reactive surface processing by irradiation with excimer laser, Nd: YAG laser, free electron laser and Ti: sapphire laser in nitrogen atmosphere. Appl. Surf. Sci. 186, 195–199 (2002)

J. Krüger, W. Kautek, Ultrashort pulse laser interaction with dielectrics and polymers. Adv. Polym. Sci. 168, 247–290 (2004)

J.M. Liu, Simple technique for measurements of pulsed Gaussian-beam spot sizes. Opt. Lett. 7(5), 196–198 (1982)

V. Belaud, S. Valette, G. Stremsdoerfer, B. Beaugiraud, E. Audouard, S. Benayoun, Femtosecond laser ablation of polypropylene: a statistical approach of morphological data. Scanning 36, 209–217 (2014)

D. Nečas, P. Klapetek, Gwyddion: an open-source software for SPM dataanalysis. Centr. Eur. J. Phys. 10(1), 181–188 (2012)

E. McCafferty, J.P. Wightman, An X-ray photoelectron spectroscopy sputter profile study of the native air-formed oxide film on titanium. Appl. Surf. Sci. 1431, 92–100 (1999)

T. Choudhury, S.O. Saied, J.L. Sullivan, A.M. Abbot, Reduction of oxides of iron, cobalt, titanium and niobium by low-energy ion bombardment. J. Phys. D Appl. Phys. 22 8, 1185 (1989)

A.F. Carley, P.R. Chalker, J.C. Riviereand, M.W. Roberts, The identification and characterisation of mixed oxidation states at oxidised titanium surfaces by analysis of X-ray photoelectron spectra. J. Chem. Soc. Faraday Trans. 1 Phys. Chem. Condens. Phases 83(2), 351–370 (1987)

N.C. Saha, H.G. Tompkins, Titanium nitride oxidation chemistry: An X-ray photoelectron spectroscopy study. J. Appl. Phys. 72(7), 3072–3079 (1992)

F.F.K.S.H. Esaka, K. Furuya, H. Shimada, M. Imamura, N. Matsubayashi, H. Sato, T. Kikuchi, Comparison of surface oxidation of titanium nitride and chromium nitride films studied by X-ray absorption and photoelectron spectroscopy. J. Vac. Sci. Technol. A Vac. Surf. Films 15(5), 2521–2528 (1997)

P. Prieto, R.E. Kirby, X-ray photoelectron spectroscopy study of the difference between reactively evaporated and direct sputter-deposited TiN films and their oxidation properties. J. Vac. Sci. Technol. A Vac. Surf. Films 13(6), 2819–2826 (1995)

X.L. Mao, W.T. Chan, M.A. Shannon, R.E. Russo, Plasma shielding during picosecond laser sampling of solid materials by ablation in He versus Ar atmosphere. J. Appl. Phys. 74, 4915–4922 (1993)

R. Buividas, M. Mikutis, S. Juodkazis, Surface and bulk structuring of materials by ripples with long and short laser pulses: recent advances. Prog. Quantum Electron. 38, 119–156 (2014)

J. Bonse, A. Rosenfeld, J. Krüger, On the role of surface plasmon polaritons in the formation of laser-induced periodic surface structures upon irradiation of silicon by femtosecond laser pulses. J. Appl. Phys. 106, 104910 (2009)

G.A. Martsinovskii, G.D. Shandybina, D.S. Smirnov, S.V. Zabotnov, L.A. Golovan, V.Yu.. Timoshenko, P.K. Kashkarov, Ultrashort excitations of surface polaritons and waveguide modes in semiconductors. Opt. Spectrosc 105, 67–72 (2008)

J. Reif, F. Costache, M. Henyk, S.V. Pandelov, Ripples revisited: non-classical morphology at the bottom of femtosecond laser ablation craters in transparent dielectrics. Appl. Surf. Sci. 197–198, 891–895. (2002)

A. Borowiec, H.K. Haugen, Subwavelength ripple formation on the surfaces of compound semiconductors irradiated with femtosecond laser pulses. Appl. Phys. Lett. 82, 4462–4464 (2003)

D. Dufft, A. Rosenfeld, S.K. Das, R. Grunwald, J. Bonse, Femtosecond laser-induced periodic surface structures revisited: a comparative study on ZnO. J. Appl. Phys. 105 034908 (2009). https://doi.org/10.1063/1.3074106

J.E. Sipe, J.F. Young, J.S. Preston, H.M. van Driel, Laser-induced periodic surface structure. I. Theory. Phys. Rev. B: Condens. Matter 27, 1141–1154 (1983)

J.F. Young, J.S. Preston, H.M. van Driel, J.E. Sipe, Laser-induced periodic surface structure. II. Experiments on Ge, Si, Al, and brass. Phys. Rev. B Condens. Matter 27(2), 1155–1172 (1983)

J. Schille, R. Ebert, U. Loeschner, P. Regenfuss, T. Suess, H. Exner, Micro structuring with highly repetitive ultrashort laser pulses, in Proceedings of LPM 2008 (June)—The 9th international symposium on laser precision microfabrication, Quebec, Canada

J. Lehr, F. de Marchi, L. Matus, J. MacLeod, F. Rosei, A.-M. Kietzig, The influence of the gas environment on morphology and chemical composition of surfaces micro-machined with a femtosecond laser. Appl. Surf. Sci. 320, 455–465 (2014)

T. Smausz, T. Csizmadia, C. Tápai, J. Kopniczky, A. Oszkó, M. Ehrhardt, P. Lorenz, K. Zimmer, A. Prager, B. Hopp, Study on the effect of ambient gas on nanostructure formation on metal surfaces during femtosecond laser ablation for fabrication of low-reflective surfaces. Appl. Surf. Sci. 389, 1113–1119 (2016)

B.K. Nayak, M.C. Gupta, K.W. Kolasinski, Formation of nano-textured conical microstructures in titanium metal surface by femtosecond laser irradiation. Appl. Phys. A Mater. Sci. Process. 90, 399–402 (2008)

S. Ju, J.P. Longtin, Effects of a gas medium on ultrafast laser beam delivery and materials processing. J. Opt. Soc. Am. B Opt. Phys. 21, 1081–1088 (2004)

P.G. de Gennes, Wetting: statics and dynamics. Rev. Mod. Phys. 57, 827 (1985)

F.M. El-Hossary, N.Z. Negm, A.M. Abd El-Rahman, M. Raaif, A. A. Abd Elmula, Properties of titanium oxynitride prepared by RF plasma, ACES 5, 1–14 (2015)

P. Bizi-Bandoki, S. Benayoun, S. Valette, B. Beaugiraud, E. Audouard, Modifications of roughness and wettability properties of metals induced by femtosecond laser treatment. Appl. Surf. Sci. 257, 5213–5218 (2011)

A.-M. Kietzig, S.G. Hatzikiriakos, P. Englezos, Patterned superhydrophobic metallic surfaces. Langmuir 25(8), 4821–4827 (2009)

Acknowledgements

This work was supported by the DOE Phase II SBIR/STTR (award number DE-SC0011851) and Starfire Industries LLC. Parts of this research were carried out in the Frederick Seitz Materials Research Laboratory Central Facilities, University of Illinois, which is partially supported by the U.S. Department of Energy under Grant nos. DEFG02-07ER46453 and DE-FG02-07ER46471.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hammouti, S., Holybee, B., Zhu, W. et al. Titanium nitride formation by a dual-stage femtosecond laser process. Appl. Phys. A 124, 411 (2018). https://doi.org/10.1007/s00339-018-1824-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-1824-x