Abstract

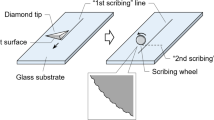

The possibility of using laser systems to form beams with special spatial configurations has been studied. The laser systems applied had a self-conjugate cavity based on the elements of copper vapor lasers (LT-5Cu, LT-10Cu, LT-30Cu) with an average power of 5, 10, or 30 W. The active elements were pumped by current pulses of duration 80–100 ns. The duration of laser generation pulses was up to 25 ns. The generator unit included an unstable cavity, where one reflector was a special mirror with a reflecting coating. Various original optical schemes used were capable of exploring spatial configurations and energy characteristics of output laser beams in their interaction with micro- and nanoparticles fabricated from various materials. In these experiments, the beam dimensions of the obtained zones varied from 0.3 to 5 µm, which is comparable with the minimum permissible dimensions determined by the optical elements applied. This method is useful in transforming a large amount of information at the laser pulse repetition rate of 10–30 kHz. It was possible to realize the high-precision micromachining and microfabrication of microscale details by direct writing, cutting and drilling (with the cutting width and through-hole diameters ranging from 3 to 100 µm) and produce microscale, deep, intricate and narrow grooves on substrate surfaces of metals and nonmetal materials. This system is used for producing high-quality microscale details without moving the object under treatment. It can also be used for microcutting and microdrilling in a variety of metals such as molybdenum, copper and stainless steel, with a thickness of up to 300 µm, and in nonmetals such as silicon, sapphire and diamond with a thickness ranging from 10 µm to 1 mm with different thermal parameters and specially designed laser beam.

Similar content being viewed by others

References

C.E. Little, Metal Vapour Lasers Physics Engineering and Applications (J. Wiley and Sons Ltd., Chichester, UK, 1999), p. 620

A.G. Grigoryants, M.A. Kazaryan, N.A. Lyabin, Copper Vapor Lasers: Design, Characteristics and Applications (Fizmatlit, Moscow, 2005)

A.G. Grigoryants, I.N. Shiganov, A.I. Misyurov, Technological Processes of Laser Treatment (Bauman MSTU, Moscow, 2006)

M.A. Kazaryan, K.I. Zemskov, V.V. Savranskii, G.A. Shafeev, Light laser projection microscope. Laser Electro-Opt. 4, 44 (1980)

V.M. Batenin et al., Laser on Self-Terminating Transitions of Metal Atoms (Fizmatlit, Moscow, 2011)

A.N. Korolev, E.N. Kotyurgin, N.A. Lyabin, Status and prospects of automated laser technological installations “Karavella” type development for precision micromachining of materials for microwave technology production at the “NPP Istok”. Electronics, vol. 1 Microwave Technol. 2(501), 45–52 (2009)

N.A. Lyabin, A.G. Grigoryants, M.A. Kazaryan, Modern automated industrial laser systems “Karavella-1” and “Karavella-1 M” for precision micromachining of materials for electronic devices. High Technol. Mech. Eng. 9, 19–26 (2014)

N.A. Lyabin, A.D. Chursin, V.I. Klimenko, et al., Modern automated industrial laser systems “Karavella-2” and “Karavella-2 M” for precision micromachining of thin sheet materials for IEP production. High Technol. Mech. Eng. 10, 41–48 (2014)

N.A. Lyabin, A.D. Chursin, V.S. Paramonov, et al., Copper vapor laser with one-beam radiation of diffraction quality and its capabilities for microprocessing of materials for electronic engineering products. Sci. Edu. Electron. J. 8, 30–62 (2014). 1 doi: 0.7463/0814.0720903

N.A. Lyabin, Investigation of copper vapor pulsed laser with industrial active elements of “Kulon” series using one convex mirror mode and its capabilities for technological applications, Sci. Edu. Electron. J. 6, 1–15 (2014). doi: 10.7463/0614.0717060

Acknowledgments

This work has been partially supported by RFBR, Projects No. 15-02-03559, 14-02-00602, 14-02-31515, 14-02-92019.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Asratyan, A.A., Bulychev, N.A., Feofanov, I.N. et al. Laser processing with specially designed laser beam. Appl. Phys. A 122, 434 (2016). https://doi.org/10.1007/s00339-016-9797-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-9797-0