Abstract

It has been well established that the physical performance of nanodevices might be affected by the microstructure. Herein, a two-degree-of-freedom model base on the modified couple stress theory is developed to incorporate the impact of microstructure in the torsion/bending coupled instability of rotational nanoscanner. Effect of microstructure dependency on the instability parameters is determined as a function of the microstructure parameter, bending/torsion coupling ratio, van der Waals force parameter and geometrical dimensions. It is found that the bending/torsion coupling substantially affects the stable behavior of the scanners especially those with long rotational beam elements. Impact of microstructure on instability voltage of the nanoscanner depends on coupling ratio and the conquering bending mode over torsion mode. This effect is more highlighted for higher values of coupling ratio. Depending on the geometry and material characteristics, the presented model is able to simulate both hardening behavior (due to microstructure) and softening behavior (due to torsion/bending coupling) of the nanoscanners.

Similar content being viewed by others

References

X.M. Zhang, F.S. Chau, C. Quan, Y.L. Lam, A.Q. Liu, Sensor Actuators A 90, 73 (2001)

W.H. Lin, Y.P. Zhao, J. Phys. D 40, 1649 (2007)

C. Venkatesh, N. Bhat, 8(1), 129 (2008)

C. Venkatesh, S. Pati, N. Bhat, R. Pratap, Sensors Actuators A 121(2), 480 (2005)

C. Venkatesh, N. Bhat, K.J. Vinoy, S. Grandhi, J. Micro-Nanolith. Mem. 11(1), 013006 (2012)

O. Degani, Y. Nemirovsky, J. Microelectromech. Syst. 11, 20 (2002)

H. Moeenfard, A. Darvishian, M.T. Ahmaidan, J. Mech. Sci. Technol. 26, 537 (2012)

J.E. Ford, V.A. Aksyuk, D.J. Bishop, J.A. Walker, J. Lightwave Technol. 17, 904 (1999)

J.G. Guo, Y.P. Zhao, J. Microelectromech. Syst. 13(6), 1027 (2004)

J.G. Guo, Y.P. Zhao, Int. J. Solids Struct. 43, 675 (2006)

F. Khatami, G. Rezazadeh, Microsyst. Technol. 15, 535 (2009)

H.M. Sedighi, K.H. Shirazi, Acta Mech. Solida Sin. 28(1), 91 (2015)

M.I. Younis, F. Alsaleem, D. Jordy, Int. J. Nonlin. Mech. 42(4), 643 (2007)

M. Taghizadeh, H. Mobki, Arch. Mech. 66(2), 95 (2014)

J.P. Zhao, H.L. Chen, J.M. Huang, A.Q. Liu, Sensors Actuators A 120, 199 (2005)

H. Moeenfard, M.T. Ahmadian, Optik 124(12), 1278 (2013)

Z.X. Xiao, X.T. Wu, W.Y. Peng, K.R. Farmer, J. Microelectromech. Syst. 10, 561 (2001)

Y. Nemirovsky, O. Degani, J. Microelectromech. Syst. 10, 601 (2001)

O. Degani, E. Socher, A. Lipson, T. Leitner, D.J. Setter, S. Kaldor, Y.J. Nemirovsky, Microelectromech. Syst. 7(4), 373 (1998)

H. Moeenfard, A. Darvishian, H. Zohoor, M.T. Ahmadian, J. Mech. Eng. Sci. 226(9), 2361–2372 (2012)

O.B. Degani, Y. Nemirovisky, Sensor Actuators A 97–98, 569 (2001)

J.M. Huang, A.Q. Liu, Z.L. Deng, Q.X. Zhang, J. Ahn, A. Asundi, Sensor Actuators A 115(1), 159 (2004)

G. Rezazadeh, F. Khatami, A. Tahmasebi, Microsyst. Tech. 13, 715 (2007)

Y. Tadi Beni, A. Koochi, A.S. Kazemi, M. Abadyan, Can. J. Phys. 90(10), 963 (2012)

Y. Tadi, Iran J. Sci. B 36(M1), 41 (2012)

N.H. Nguyen, M.Y. Lee, J.S. Kim, D.Y. Lee, Shock Vibration 2015, 672831 (2015)

N.A. Fleck, G.M. Muller, M.F. Ashby, J.W. Hutchinson, Acta Metall. Mater. 42(2), 475 (1994)

B. Akgöz, Ö. Civalek, Curr. Appl. Phys. 11, 1133–1138 (2011)

B. Akgoz, O. Civalek, Int. J. Eng. Sci. 49(11), 1268 (2011)

J. Abdi, A. Koochi, A.S. Kazemi, M. Abadyan, Smart Mater. Struct. 20(5), 055011 (2011)

Y. Tadi Beni, A. Koochi, M. Abadyan, Physica E 43, 979 (2011)

J.G. Guo, Y.P. Zhao, Int. J. Solids Struct. 43, 675 (2006)

Y. Tadi Beni, M. Abadyan, Int. J. Mod. Phys. B 27(18), 1350083 (2013)

F. Yang, A.C.M. Chong, D.C.C. Lam, P. Tong, Int. J. Solids Struct. 39(10), 2731 (2002)

P. Tong, F. Yang, D.C.C. Lam, J. Wang, Key Eng. Mater. 261–263, 11–22 (2004)

C.L. Dym, I.H. Shames, Solid Mechanics: A Variational Approach (Railway Publishing House, Beijing, 1984)

N.H. Nguyen, B.D. Lim, D.Y. Lee, Int. J. Precision Eng. Manufact. 16(4), 749–754 (2015)

N.H. Nguyen, B.D. Lim, D.Y. Lee, Struct. Eng. Mech. 54(1), 189–198 (2015)

G.C. Tsiatas, J.T. Katsikadelis, Eur. J. Mech. A-Solid 30, 741–747 (2011)

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

In order to calculate the elastic moment M elas of the nanobeam based on MCST, one can start with the Saint-Venant’s approach and assume the displacement field as [36]:

where u 1 , u 2 and u 3 are the displacement along the X, Y and Z direction, respectively. Furthermore, Ω is the angle of twist per unit length along the beam, and the function Φ(X, Y) is the warping function depending on X and Y only. For more details about warping effect, see [37, 38].

The governing equation of the torsional bar based on MCST can be obtained as (see [35, 39] for details):

with the boundary conditions of:

In the above relations, ρ, n(n x ,n y ) and s(−n y ,n x ) are the curvature, the unit vector normal to the boundary and the unit tangent to the boundary, respectively [35, 39].

Appendix 2

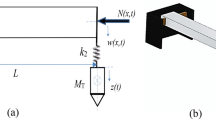

It should be noted that for thick and short beam (i.e., L/t < 20) the Timoshenko beam model should be used [26]. However, the difference between the 1-DOF and 2-DOF results is negligible for L/t < 20, and simple 1-DOF model can be used (see Fig. 6). Hence, the Euler–Bernoulli beam theory is employed in this work. Based on the Euler–Bernoulli beam theory, components of the displacement vector for bending beam are expressed as [36]

where u 1 , u 2 and u 3 are the displacement along the X, Y and Z direction, respectively.

By substituting this displacement field in Eq. (2) and substituting the results in Eq. (1), the bending elastic energy, U b, can be determined as:

The work by the external forces can be obtained as:

As a trial solution for deflection of the nanobeam, the first mode shape which satisfies the boundary conditions can be selected as:

By substituting Eq. (33) in Eq. (31), the total energy of system, П, can be written as:

By imposing the minimum energy for equilibrium, i.e., \(\frac{\partial \varPi }{\partial \delta } = 0\), we obtain relations (24) for nanobeam.

Rights and permissions

About this article

Cite this article

Keivani, M., Abadian, N., Koochi, A. et al. A 2-DOF microstructure-dependent model for the coupled torsion/bending instability of rotational nanoscanner. Appl. Phys. A 122, 927 (2016). https://doi.org/10.1007/s00339-016-0458-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0458-0