Abstract

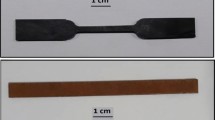

This study aims to investigate the mechanical properties of hybrid polypropylene and ethylene-propylene-monomer (EPDM)-based nanocomposites reinforced with graphene nanosheets, nanoclay, and glass fibers. The response surface methodology was the study design. An internal mixer and a hot press machine were used to prepare the samples, including 0, 1, and 2 wt% of graphene nanosheets, 0, 3, and 6 wt% of nanoclay, 0, 10, and 20 wt% of glass fiber, and 0, 5, and 10 wt% of EPDM. To determine the tensile strength, tensile tests were conducted, and tensile modulus and impact tests were run to assess the impact strength of the compounds. Scanning electron microscopy images were taken to investigate the dispersion of nanoparticles and glass fibers in the polymer. The results showed the formation of agglomeration at high percentages of graphene nanosheets and nanoclay. The addition of lower weights of graphene nanosheets improved the impact strength, tensile strength, and tensile modulus by 23, 46 and 16%, respectively. Also, the use of low weight percentages of nanoclay increased the tensile strength by 21%, and its use at high weight percentages weakened the mechanical properties. The use of glass fibers increased the impact strength and tensile modulus by 18 and 24%, respectively. Its use first increased and then decreased the tensile strength. While the incorporation of EPDM increased the impact strength by 57%, it negatively affected the tensile behavior.

Similar content being viewed by others

References

Rosato D (2004) Reinforced plastics handbook, 3rd edn. Plastic source publication, Concord MA, USA, pp 113–121

Koch C, Ovidko I, Seal S, Veprek S (2007) structural nanocrystalline material, first published. Cambridge University Press, New York, pp 346–347

Thongchom CH, Refahati N, Roodgar Saffari P, Roudgar Saffari P, Nouri Niyaraki M, Sirimontree S, Keawsawasvon S (2022) An experimental study on the effect of nanomaterials and fibers on the mechanical properties of polymer composites. Buildings 12(1):7

Selvakumar V, Palanikumar K, Palanivelu K (2010) Studies of mechanical characterization of Polypropylene/Na-MMT nanocomposites. JMMCE 9(8):671–681

Bikiaris D (2010) Microstracture and properties of polypropylene/carbon nanotube nanocomposites. J Mater 3(4):2884–2946

Ashenai Ghasemi F, Ghasemi I, Nouri Niyaraki M, Daneshpayeh S (2019) Predicting the tensile strength and elongation at break of PP/graphene/glass fiber/EPDM nanocomposites using response surface methodology. Mech Adv Mater Struct 5(29):1537–6532

Daneshpayeh S, Ghasemi FA, Masoumi S, Nouri-Niyaraki M (2020) Prediction of mechanical properties of quaternary nanocomposites based on polypropylene using fuzzy logic. J Elastom Plast 53(1):14–30

Mirzaei J, Fereidoon A, Ghasemi-Ghalebahman A (2021) Experimental analysis of mechanical properties of graphene/kenaf/ basalt reinforced hybrid nanocomposites using response surface methodology. J Braz Soc Mech Sci Eng 43:215

Mirzaei J, Fereidoon A, Ghasemi-Ghalebahman A (2021) Experimental study on mechanical properties of polypropylene nanocomposites reinforced with a hybrid graphene/PP-g-MA/kenaf fiber by response surface methodology. J Elastom Plast 53(8):1063–1089

Mokhtari Dizaji S, Asghar Katbab A, Hajibabazadeh S (2022) Role of interfacial compatibilizer and functionality of rubber phase on micromorphology development and mechanical properties of PP/EPDM/nanosilica ternary nanocomposite. Polym Bull. https://doi.org/10.1007/s00289-022-04112-6

Yoruk O, Bayrak Y, Ates M (2022) Design and assembly of supercapacitor based on reduced graphene oxide/TiO2/polyaniline ternary nanocomposite and its application in electrical circuit. Polym Bull 79:2969–2993. https://doi.org/10.1007/s00289-021-03649-2

Uyor UO, Popoola API, Popoola OM (2022) Nanomechanical evaluation of poly (vinylidene fluoride) nanocomposites reinforced with hybrid graphene nanoplatelets and titanium dioxide. Polym Bull 79:2345–2361. https://doi.org/10.1007/s00289-021-03604-1

Sabet M, Mohammadian E (2022) The inclusion of graphene nanoplatelet on the mechanical, thermal, and electrical characteristics of polycarbonate. Polym Bull. https://doi.org/10.1007/s00289-022-04156-8

Mittal V (2012) Polymer-graphene nanocomposites. RSC Publishing, Cambridge

Wei JT (2015) Epoxy/graphene nanocomposites–processing and properties: a review. RSC Adv 5(90):73510–73524

Galpaya D, Wang M (2014) Preparation of graphene oxide/ epoxy nanocomposites with significantly improved mechanical properties. J Appl Phys 116(5):053518

Rahman M, Adamu M, Hamdan S (2022) Optimization and characterization of acrylonitrile/MAPE/nano-clay bamboo nanocomposites by response surface methodology. Polym Bull 79:3031–3059. https://doi.org/10.1007/s00289-021-03628-7

Abhari AR, Abhari FM, Jannat B (2021) Synthesis and characterization of surface-modified PVC/NanoClay/Tween60 as a super hydrophilic membrane: application in the nanofiltration of organic dyes from aqueous solution. Polym Bull. https://doi.org/10.1007/s00289-021-03888-3

Q T, Baird D G, (2006) Preparation of polymer–clay nanocomposites and their properties. Adv Polym Technol 25(4):270–285

Karimi MH, Saeid MSMM, Ahmadjo AH, Rostami-Darounkola MR (2021) Improvement in the thermal and mechanical properties of PP/Clay nanocomposite using novel ethoxylated oxidized PE wax as a compatibilizer. Polym Compos 43(1):389–398

Brizuela Guerra N, Ferreira E, Duarte J (2022) Effect of hydration conditions in thermal and mechanical properties of injection-molded glass fiber/polyamide-6. Polym Bull. https://doi.org/10.1007/s00289-022-04111-7

Abedinzadeh R, Faraji Nejad M (2021) Effect of embedded shape memory alloy wires on the mechanical behavior of self-healing graphene-glass fiber-reinforced polymer nanocomposites. Polym Bull 78:3009–3022. https://doi.org/10.1007/s00289-020-03253-w

Infanta Mary Priya I, Vinayagam BK (2021) Detection of damages on biaxial GFRP composite material using non-destructive technique. Polym Bull 78:2569–2603. https://doi.org/10.1007/s00289-020-03228-x

Ansari MJ, Jabbaripour B (2019) Manufacture and comparison of mechanical properties of reinforced polypropylene nanocomposite with carbon fibers and calcium carbonate nanoparticles. IJME 6(5):1–12

Esmizadeh E, Sahraeian R, Naderi Gh, Esfandeh M (2019) Mechanical behavior of nanoperlite/nanoclay hybrid nanocomposites based on polyethylene: experimental and numerical validation of hyperelastic models. J Sci Technol Compos 6(2):283–293

Wang W, Tang L (2003) Mechanical properties and morphological structures of short glass fiber reinforced PP/EPDM composite. Eur Polym J 39(11):2129–2134

Helson M, Ramos DM (2006) Analysis of thermal properties and impact strength of PP/SRT, PP/EPDM and PP/SRT/EPDM mixtures in single screw extruder. Polym Test 25(4):498–503

Pol MH, Liaghat GhH, Yeganeh EM, Afrouzian A (2015) Experimental investigation of nanoclay and nanosilica particles effects on mechanical properties of glass epoxy composites. Modares Mech Eng 14(16):76–82

Ghasemi I, Karrabi M, Mohammadi M, Azizi H (2010) Evaluating the effect of processing conditions and organoclay content on the properties of styrene-butadiene rubber/ organoclay nanocomposites by response surface methodology. EXPRESS Polym Lett 4(2):62–70

Montgomery DC (2005) Design and analysis of experiments. Wiley, New York

Nouri Niyaraki M, Ashenai Ghasemi F, Ghasemi I, Daneshpayeh S (2018) Experimental analysis of graphene nanoparticles and glass fiber effect on mechanical and thermal properties of polypropylene/EPDM based nanocomposites. J Sci Technol Compos 05(02):169–176

Nouri Niyaraki M, Ashenai Ghasemi F, Ghasemi I, Daneshpayeh S (2021) Predicting of Impact strength and elastic modulus of polypropylene/EPDM/Graphene/Glass fiber nanocomposites by response surface methodology. Tehnicki glasnik 15(2):169–177

Rahman NA, Hassan A, Yahya R, Ruth Anayimi L (2012) Microstructural, thermal, and mechanical properties of injection-molded glass fiber/nanoclay/polypropylene composites. J Reinf Plast Compos 31(4):269–281

Chaharmahali M, Hamzeh Y, Ebrahimi G, Ashori A, Ghasemi I (2014) Effect of nano-graphene on the physic-mechanical properties of bagasse/polypropylene composites. Polym Bull 71(2):337–349

Liu H, Wang G, Mai Y, Zeng Y (2011) on fracture toughness of nano-particle modified epoxy. Compos B Eng 42(8):2170–2175

Rahman NA, Hassan A, Yahya R, Ruth Anayimi L (2013) Impact properties of glassfiber/ Polypropylene composites: the influence of fiber loading, specimen geometry and test temperature. Fibers Polym 14(11):1877–1885

Stpckreiter W, Schninger R, andkastl J (2013) Glass fiber reinforced polypropylene. US008519044B2

Okabe T, Nishikava M (2009) GLS strength prediction of glass-fiber-reinforced polypropylene. J Mater Sci 44:331–334

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Niyaraki, M.N., Mirzaei, J. & Taghipoor, H. Evaluation of the effect of nanomaterials and fibers on the mechanical behavior of polymer-based nanocomposites using Box–Behnken response surface methodology. Polym. Bull. 80, 9507–9529 (2023). https://doi.org/10.1007/s00289-022-04517-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04517-3