Abstract

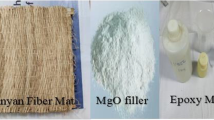

Natural fibers and reinforcing elements are gaining attention from academicians and researchers to be utilized as the reinforcements in composites because of their environment friendly nature and sustainability. The aim of this study is to characterize and analyze the influence of eggshell particles on the mechanical, morphological and thermal properties of jute/cotton fiber reinforced epoxy composites. Composites were analyzed using UTM, SEM, XRD, UV, FTIR, and surface topology (2D and 3D). These experimental results show that addition of more eggshell particles increases the tensile strength but reduces the bending strength. Good thermal stability (300 °C) is obtained for the Jute/cotton/jute/cotton (JCJC) eggshell composites. SEM images confirmed the reinforcement of fibers in resins. FTIR data shows the presence of different active bands in JCJC eggshell composites. EDS analysis reveals the percentage of different compounds present in the composites. Absorption peaks are visualized by UV analysis in composites. The jute/cotton fiber reinforced epoxy composite without eggshell particles are also investigated for better understanding when eggshell particles are available. The findings experimentally prove that the produced composite can be used as an alternative to traditional materials. Beside this, the results of this study would be a noteworthy contribution for designing high performance bio-based composites over synthetic materials in numerous applications such as household products, vessels, and even in the aerospace industry.

Similar content being viewed by others

References

Gowda TG Yashas, Sanjay MR, SubrahmanyaBhat K, Madhu P, Senthamaraikannan P, Yogesha B (2018) Polymer matrix-natural fiber composites: an overview. Cogent Eng 5(1):1446667

Galal S, Chukov D, Tcherdyntsev V, Torokhov V (2019) Effect of formation route on the mechanical properties of the polyethersulfone composites reinforced with glass fibers. Polymers 11(8):1364

Dilyus C, Nematulloev S, Zadorozhnyy M, Tcherdyntsev V, Stepashkin A, Zherebtsov D (2019) Structure, mechanical and thermal properties of polyphenylene sulfide and polysulfone impregnated carbon fiber composites. Polymers 11(4):684

Emanoil L, Lell D, Movahedi N, Codrean C, Fiedler T (2019) Compressive properties of zinc syntactic foams at elevated temperatures. Compos Part B: Eng 167:122–134

Clyne TW, Derek H (2019) An introduction to composite materials. Cambridge University Press, Cambridge

Zagho MM, Hussein EA, Elzatahry AA (2018) Recent overviews in functional polymer composites for biomedical applications. Polymers 10(7):739

Salgado de Assis F, Ferreira CL, Colorado HA (2018) Fique fabric: a promising reinforcement for polymer composites. Polymers 10(3):874

Nima M, lLinul E (2017) Quasi-static compressive behavior of the ex-situ aluminum-alloy foam-filled tubes under elevated temperature conditions. Mater Lett 206:182–184

Dilyus C, Nematulloev S, Torokhov V, Stepashkin A, Sherif G, Tcherdyntsev V (2019) Effect of carbon fiber surface modification on their interfacial interaction with polysulfone. Results Phys 15:102634

Linul E, Linul PA, Valean C, Marsavina L, Silaghi-Perju D (2018) Manufacturing and compressive mechanical behavior of reinforced polyurethane flexible (PUF) foams. In IOP Conf Ser Mater Sci Eng 416:012053

Yongxu D, Li D, Liu L, Gai G (2018) Recent achievements of self-healing graphene/polymer composites. Polymers 10(2):114

Laurent L, Joost Van Der Zwet CM, Jan-Willem D, Slat B, Andrady A, Reisser J (2017) River plastic emissions to the world’s oceans. Nature Commun 8:15611

Sun M, Sun X, Wang Z, Chang M, Li H (2018) The influence of shape memory alloy volume fraction on the impact behavior of polymer composites. Polymers 10(11):1280

Scaffaro R, Maio A, Lopresti F (2018) Physical properties of green composites based on poly-lactic acid or Mater-Bi® filled with PosidoniaOceanica leaves. Compos A Appl Sci Manuf 112:315–327

Ferreira FV, Ivanei FP, de Souza SF, Lucia HIM, Liliane MFL (2019) Polymer composites reinforced with natural fibers and nanocellulose in the automotive industry: a short review. J Compos Sci 3(2):51

NathalieBergström LL (2017) Nanocellulose-based foams and aerogels: processing, properties, and applications. J Mater Chem A 5(31):16105–16117

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110(6):3479–3500

Pegoretti A, Fabbri E, Migliaresi C, Pilati F (2004) Intraply and interply hybrid composites based on E-glass and poly (vinyl alcohol) woven fabrics: tensile and impact properties. Polym Int 53(9):1290–1297

Batu T, Lemu HG (2020) Investigation of mechanical properties of false banana/glass fiber reinforced hybrid composite materials. Results Mater 8:100152

Sathish S, Ganapathy T, Bhoopathy T (2014) Experimental testing on hybrid composite materials. Appl Mech Mater 592:339–343

Anne Š, Jankauskaitė V, Bekampienė P, Norkaitis J (2013) Vegetable fiber pre-tensioning influence on the composites reinforcement. Polymer Compos 34(9):1533–1537

Gironès J, Lopez JP, Vilaseca F, Herrera-Franco PJ, Mutje P (2011) Biocomposites from Musa textilis and polypropylene: evaluation of flexural properties and impact strength. Compos Sci Technol 71(2):122–128

Tacon AGJ (1982) Utilisation of chick hatchery waste: the nutritional characteristics of day-old chicks and eggshells. Agricultural Wastes 4(5):335–343

Maedeh M, Lahijani P, Mohamed AR (2014) Refractory dopant-incorporated CaO from waste eggshell as sustainable sorbent for CO2: capture experimental and kinetic studies. Chem Eng J 243:455–464

Pettinato M, Chakraborty S, Arafat HA, Calabro V (2015) Eggshell: a green adsorbent for heavy metal removal in an MBR system. Ecotoxicol Environ Safety 121:57–62

Wimonlak S, Pakdeechote P, Suppakarn N, Ruksakulpiwat Y (2013) Application of calcined eggshell powder as functional filler for high density polyethylene. Polymer-Plastics Technol Eng 52(10):1025–1033

Supri A, Ismail H, Shuhadah S (2010) Effect of polyethylene-grafted maleic anhydride (PE-g-MAH) on properties of low density polyethylene/eggshell powder (LDPE/ESP) composites. Polymer-Plastics Technol Eng 49(4):347–353

Lin Z, Zhang Z, Mai K (2012) Preparation and properties of eggshell/β-polypropylene bio-composites. J Appl Polym Sci 125(1):61–66

Surendra Kumar D, Kumar Srivastava A, Kumar Chopkar M (2019) Wear study of chicken eggshell-reinforced Al6061 matrix composites. Trans Indian Instit Metals 72(1):73–84

Hayajneh MT, Almomani MA, Mu’ayyad, M (2019) Effects of waste eggshells addition on microstructures, mechanical and tribological properties of green metal matrix composite. Sci Eng Compos Mater 26(1):423–434

Witoon T (2011) Characterization of calcium oxide derived from waste eggshell and its application as CO2 sorbent. Ceram Int 37(8):3291–3298

Katz Solomon H, and William Woys W (2003) Encyclopedia of food and culture. Scribner,

S, Maria Fernanda Carvalho (2012) "Obtenção e caracterização de nanocristais de celulose a partir de algodão cru e polpakraft."

Fahim M, Navin C (eds) (2008) Tribology of natural fiber polymer composites. Elsevier, Amsterdam

Rakesh K (2014) Polymer-matrix composites: types, applications, and performance. Nova Science Publishers

Qiaole H, Zhang Y, Mao Y, Memon H, Qiu Y, Wei Y, Liu W (2019) A comparative study on interlaminar properties of l-shaped two-dimensional (2d) and three-dimensional (3d) woven composites. Appl Compos Mater 26(3):723–744

Larguech S, Triki A, Ramachandran M, Kallel A (2020) Dielectric properties of jute fibers reinforced poly (lactic acid)/poly (butylene succinate) blend matrix. J Polym Environ 29:1–17

Tohid D, Safian A, Sheikhzadeh M (2020) The crashworthiness performance of integrally woven sandwich composite panels made using natural and glass fibers. J Compos Mater 55:0021998320964847

Agnivesh Kumar S, Narang HK, Bhattacharya, S (2017) Mechanical properties of natural fibre polymer composites. J Polym Eng 37(9):879–895

Erdem S, Ucar N, Gulmez T (2018) Effect of stacking sequence on tensile, flexural and thermomechanical properties of hybrid flax/glass and jute/glass thermoset composites. Journal of Industrial Textiles 48(2):494–520

Khan J, Khan M (2015) The use of jute fibers as reinforcements in composites biofiber reinforcements in composite materials. Elsevier, Amsterdam

Fang L, Deng S, Zhang J (2017) Mechanical properties of epoxy and its carbon fiber composites modified by nanoparticles. J Nanomater 2017:1–9

Toro P, Quijada R, Arias JL, Yazdani-Pedram M (2007) Mechanical and morphological studies of poly (propylene)-filled eggshell composites. Macromol Mater Eng 292(9):1027–1034

Gbadeyan OJ, Adali S, Bright G, Sithole B, Awogbemi O (2020) Studies on the mechanical and absorption properties of achatinafulica snail and eggshells reinforced composite materials. Compos Struct 239:112043

Oladele IO, Agbabiaka OG, Adediran AA, Akinwekomi AD, Balogun AO (2019) Structural performance of poultry eggshell derived hydroxyapatite based high density polyethylene bio-composites. Heliyon 5(10):02552

Suttivutnarubet C, Jaturapiree A, Chaichana E (2016) Synthesis of polyethylene/coir dust hybrid filler via in situ polymerization with zirconocene/MAO catalyst for use in natural rubber biocomposites. IranPolym J 25:841–848

Padmanabhan SK, Salvatore L, Gervaso F, Catalano M, Taurino A, Sannino A, Licciulli A, Virginia W (2015) Synthesis and characterization of collagen scaffolds reinforced by eggshell derived hydroxyapatite for tissue engineering. J Nanosci Nanotechnol 15:504–509

Matějka V, Fu Z, Kukutschová J, Qi S, Jiang S, Zhang X, Yun R, Vaculík M, Heliová M, Lu Y (2013) Jute fibers and powderized hazelnut shells as natural fillers in non-asbestos organic non-metallic friction composites. Mater Des 51:847–853

Alaneme KK, Aluko AO (2012) Fracture toughness and tensile properties of ascast and age-hardened aluminium (6063)-silicon carbide particulate composites. ScientiaIranica 19:992–996

Chawla N, Shen YL (2001) Mechanical behavior of particle reinforced metal matrix composites. Adv Eng Mater 3:357–370

Zheng KL, Wei XS, Yan B, Yan PF (2020) Ceramic waste SiC particle-reinforced Al matrix composite brake materials with a high friction coefficient. Wear 458:203424

Kede H, Quan Ngoc Tran L, Kureemun U, Teo W, Pueh Lee H (2019) Vibroacoustic behavior and noise control of flax fiber-reinforced polypropylene composites. J Nat Fib 16(5):729–743

Matej B, Zorkovská A, Fabián M, Girman V, Briančin J (2015) Eggshell biomaterial: Characterization of nanophase and polymorphs after mechanical activation. Adv Powder Technol 26(6):1597–1608

Hwang C-L, Huynh T-P (2015) Effect of alkali-activator and rice husk ash content on strength development of fly ash and residual rice husk ash-based geopolymers. Constr Build Mater 101:1–9

Chattopadhyay S, Sen R (2012) A comparative performance evaluation of jute and eggshell matrices to immobilize pancreatic lipase. Process Biochem 47(5):749–757

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rahman, A., Chowdhury, M.A., Shuvho, M.B.A. et al. Fabrication and characterization of jute/cotton bio-composites reinforced with eggshell particles. Polym. Bull. 80, 931–957 (2023). https://doi.org/10.1007/s00289-021-04049-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-04049-2