Abstract

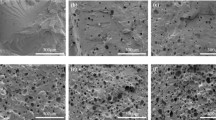

The frequent and continuous use of electronic components results in a gradual increase in temperature, significantly decreasing their effectiveness. In the present study, composites have been fabricated with microencapsulated phase change materials (MicroPCM) integrated into rigid polyurethane (R-PU) foam to regulate the heat accumulation in electronic parts. A seeded-emulsion system was used to synthesize microcapsules based on capric acid (CA) core and poly [methyl methacrylate-co-methacrylic acid] (PMMA-co-MMA) shell material. MicroPCM3 prepared with 2:1 core to shell ratio was integrated into R-PU foam sandwiched between tin panels. The thermal energy flow analysis rate was used to estimate the time required to reach the set temperature of the R-PU foam composites with and without MicroPCMs. Thermal analysis, structural characterization, morphological study of MicroPCMs and R-PU foam composites were performed using differential scanning calorimeter (DSC), Fourier transforms infrared (FTIR), and scanning electron microscopy (SEM). From the thermal analysis of R-PU foam composites at 40 wt.% MicroPCM3 loading, the latent heat of melting, and crystallization were found to be 31.74 ± 1.50 J/g and 31.19 ± 1.50 J/g, respectively. The time needed to reach the set temperature of tin panels was recorded to be 210 ± 5 min, indicating very good thermal energy storage capacity. A 40 wt.% MicroPCM3 loading exhibited better thermal energy storage performance.

Similar content being viewed by others

References

Jouhara H, Żabnieńska-Góra A, Khordehgah N et al (2020) Latent thermal energy storage technologies and applications: a review. Int J Thermofluids 5–6. https://doi.org/10.1016/j.ijft.2020.100039

Amaral C, Vicente R, Marques PAAP, Barros-timmons A (2017) Phase change materials and carbon nanostructures for thermal energy storage: a literature review. Renew Sustain Energy Rev 79:1212–1228. https://doi.org/10.1016/j.rser.2017.05.093

Pagkalos C, Dogkas G, Koukou MK et al (2019) Evaluation of water and paraffin PCM as storage media for use in thermal energy storage applications : a numerical approach. Int J Thermofluids 100006. https://doi.org/10.1016/j.ijft.2019.100006

Kenisarin M, Mahkamov K (2007) Solar energy storage using phase change materials. Renew Sustain Energy Rev 11:1913–1965. https://doi.org/10.1016/j.rser.2006.05.005

Sarier N, Onder E (2007) The manufacture of microencapsulated phase change materials suitable for the design of thermally enhanced fabrics. Thermochim Acta 452:149–160. https://doi.org/10.1016/j.tca.2006.08.002

Zhou Z, Zhang Z, Zuo J et al (2015) Phase change materials for solar thermal energy storage in residential buildings in cold climate. Renew Sustain Energy Rev 48:692–703. https://doi.org/10.1016/j.rser.2015.04.048

Kuznik F, David D, Johannes K, Roux JJ (2011) A review on phase change materials integrated in building walls. Renew Sustain Energy Rev 15:379–391. https://doi.org/10.1016/j.rser.2010.08.019

Li J, Xue P, He H et al (2009) Preparation and application effects of a novel form-stable phase change material as the thermal storage layer of an electric floor heating system. v:871–880. https://doi.org/10.1016/j.enbuild.2009.03.009

Cabeza LF, Castell A, Barreneche C et al (2011) Materials used as PCM in thermal energy storage in buildings: a review. Renew Sustain Energy Rev 15:1675–1695. https://doi.org/10.1016/j.rser.2010.11.018

Iqbal K, Sun D (2014) Development of thermo-regulating polypropylene fiber containing microencapsulated phase change materials. Renew Energy 71:473–479. https://doi.org/10.1016/j.renene.2014.05.063

Babu VR, Arunraj A (2018) Thermo regulated clothing with phase change materials. 4:344–347. https://doi.org/10.15406/jteft.2018.04.00162

Mondal S (2008) Phase change materials for smart textiles - An overview. Appl Therm Eng 28:1536–1550. https://doi.org/10.1016/j.applthermaleng.2007.08.009

Han GGD, Li H Grossman JC of thermal energy in phase-change materials. Nat Commun. https://doi.org/10.1038/s41467-017-01608-y

Qian T, Li J, Ma H, Yang J (2015) The preparation of a green shape-stabilized composite phase change material of polyethylene glycol/SiO2 with enhanced thermal performance based on oil shale ash via temperature-assisted sol-gel method. Sol Energy Mater Sol Cells 132:29–39. https://doi.org/10.1016/j.solmat.2014.08.017

Otero JA, Manuel E, Cooper H, Pérez- R (2020) Thermal expansion effects on the one-dimensional liquid-solid phase transition in high temperature phase change materials Thermal expansion effects on the one-dimensional liquid-solid phase transition in high temperature phase change materials. 025125. https://doi.org/10.1063/1.5086049

Hu H, Jin X, Zhang X (2017) Effect of supercooling on the solidification process of the phase change material. 105:4321–4327. https://doi.org/10.1016/j.egypro.2017.03.905

Xu X, Dong Z, Memon SA et al (2017) Preparation and supercooling modification of salt hydrate phase change materials based on CaCl2·2H2O/CaCl2. Materials (Basel) 10. https://doi.org/10.3390/ma10070691

Kee SY, Munusamy Y, Ong KS et al (2017) Thermal performance study of composite phase change material with polyacrylic and conformal coating. Materials (Basel) 10. https://doi.org/10.3390/ma10080873

Fan L, Khodadadi JM (2011) Thermal conductivity enhancement of phase change materials for thermal energy storage : a review §. Renew Sustain Energy Rev 15:24–46. https://doi.org/10.1016/j.rser.2010.08.007

Xu T, Li Y, Chen J, Liu J (2017) Solar energy materials and solar cells preparation and thermal energy storage properties of LiNO 3 -KCl-NaNO 3/expanded graphite composite phase change material. Sol Energy Mater Sol Cells 169:215–221. https://doi.org/10.1016/j.solmat.2017.05.035

Sundararajan S, Samui AB, Kulkarni PS (2017) Versatility of polyethylene glycol (PEG) in designing solid-solid phase change materials (PCMs) for thermal management and their application to innovative technologies. J Mater Chem A 5:18379–18396. https://doi.org/10.1039/c7ta04968d

Sundararajan S, Samui AB, Kulkarni PS (2017) Shape-stabilized poly(ethylene glycol) (PEG)-cellulose acetate blend preparation with superior PEG loading via microwave-assisted blending. Sol Energy 144:32–39. https://doi.org/10.1016/j.solener.2016.12.056

Salaün F, Devaux E, Bourbigot S, Rumeau P (2009) Influence of process parameters on microcapsules loaded with n-hexadecane prepared by in situ polymerization. Chem Eng J 155:457–465. https://doi.org/10.1016/j.cej.2009.07.018

Fu Z, Su L, Li J, et al. (2014) Thermochimica acta elastic silicone encapsulation of n -hexadecyl bromide by microfluidic approach as novel microencapsulated phase change materials 590:24–29. https://doi.org/10.1016/j.tca.2014.06.008

Al-shannaq R, Farid M, Al-muhtaseb S, Kurdi J (2015) Solar energy materials & solar cells emulsion stability and cross-linking of PMMA microcapsules containing phase change materials. Sol Energy Mater Sol Cells 132:311–318. https://doi.org/10.1016/j.solmat.2014.08.036

Sánchez L, Sánchez P, Carmona M et al (2008) Influence of operation conditions on the microencapsulation of PCMs by means of suspension-like polymerization. Colloid Polym Sci 286:1019–1027. https://doi.org/10.1007/s00396-008-1864-4

Alič B, Šebenik U, Krajnc M (2012) Microencapsulation of butyl stearate with melamine-formaldehyde resin: effect of decreasing the pH value on the composition and thermal stability of microcapsules. Exp Polym Lett 6:826–836. https://doi.org/10.3144/expresspolymlett.2012.88

Naikwadi AT, Samui AB, Mahanwar PA (2020) Solar energy materials and solar cells melamine-formaldehyde microencapsulated n-tetracosane phase change material for solar thermal energy storage in coating. Sol Energy Mater Sol Cells 215:110676. https://doi.org/10.1016/j.solmat.2020.110676

Li W, Xiang ZX, Chen WX et al (2012) Fabrication and morphological characterization of microencapsulated phase change materials (MicroPCMs) and microcapsules containing MicroPCMs for thermal energy storage. Energy 38:249–254. https://doi.org/10.1016/j.energy.2011.12.005

Yang JM, Kim JS (2018) The microencapsulation of calcium chloride hexahydrate as a phase-change material by using the hybrid coupler of organoalkoxysilanes. J Appl Polym Sci 135:1–10. https://doi.org/10.1002/app.45821

Ma Y, Chu X, Tang G, Yao Y (2013) Synthesis and thermal properties of acrylate-based polymer shell microcapsules with binary core as phase change materials. Mater Lett 91:133–135. https://doi.org/10.1016/j.matlet.2012.09.084

Zhang B, Zhang Z, Kapar S et al (2019) Microencapsulation of Phase change materials with polystyrene/ cellulose nanocrystal hybrid shell via pickering emulsion polymerization. https://doi.org/10.1021/acssuschemeng.9b04134

Shi J, Wu X, Fu X, Sun R (2015) Thermochimica Acta Synthesis and thermal properties of a novel nano encapsulated phase change material with PMMA and SiO 2 as hybrid shell materials. Thermochim Acta 617:90–94. https://doi.org/10.1016/j.tca.2015.08.022

Hu ZX, Hu XM, Cheng WM, Lu W (2019) Influence of synthetic conditions on the performance of melamine–phenol-formaldehyde resin microcapsules. High Perform Polym 31:197–210. https://doi.org/10.1177/0954008318758489

Hawlader MNA, Uddin MS, Khin MM (2003) Microencapsulated PCM thermal-energy storage system. Appl Energy 74:195–202. https://doi.org/10.1016/S0306-2619(02)00146-0

Huang J, Lu S, Kong X et al (2013) Form-stable phase change materials based on eutectic mixture of tetradecanol and fatty acids for building energy storage: Preparation and performance analysis. Materials (Basel) 6:4758–4775. https://doi.org/10.3390/ma6104758

Ghaban R, Duong J, Patel D et al (2020) Solvent-assisted nanochannel encapsulation of a natural phase change material in polystyrene hollow fibers for high-performance thermal energy storage. https://doi.org/10.1021/acsaem.0c01788

Cedeño FO, Prieto MM, Espina A, García JR (2001) Measurements of temperature and melting heat of some pure fatty acids and their binary and ternary mixtures by differential scanning calorimetry. Thermochim Acta 369:39–50. https://doi.org/10.1016/S0040-6031(00)00752-8

Gupta R, Kedia S, Saurakhiya N et al (2016) Composite nanofibrous sheets of fatty acids and polymers as thermo-regulating enclosures. Sol Energy Mater Sol Cells 157:676–685. https://doi.org/10.1016/j.solmat.2016.07.033

Kant K, Shukla A, Sharma A (2016) Ternary mixture of fatty acids as phase change materials for thermal energy storage applications. Energy Rep. https://doi.org/10.1016/j.egyr.2016.10.002

Yang C, Fischer L, Maranda S, Worlitschek J (2015) Rigid polyurethane foams incorporated with phase change materials: a state-of-the-art review and future research pathways. Energy Build 87:25–36. https://doi.org/10.1016/j.enbuild.2014.10.075

Saha MC, Kabir ME, Jeelani S (2008) Enhancement in thermal and mechanical properties of polyurethane foam infused with nanoparticles. Mater Sci Eng A 479:213–222. https://doi.org/10.1016/j.msea.2007.06.060

Borreguero AM, Valverde JL, Peijs T et al (2010) Characterization of rigid polyurethane foams containing microencapsulated Rubitherm® RT27. Part i J Mater Sci 45:4462–4469. https://doi.org/10.1007/s10853-010-4529-x

You M, Zhang XX, Li W, Wang XC (2008) Effects of MicroPCMs on the fabrication of MicroPCMs/polyurethane composite foams. Thermochim Acta 472:20–24. https://doi.org/10.1016/j.tca.2008.03.006

Borreguero AM, Talavera B, Rodriguez JF et al (2013) Enhancing the thermal comfort of fabrics for the footwear industry. https://doi.org/10.1177/0040517513481872

Jaguemont J, Omar N, Van Den BP, Van MJ (2017) Phase-change materials (PCM) for automotive applications: a review. Appl Therm Eng. https://doi.org/10.1016/j.applthermaleng.2017.12.097

Castellón C, Medrano M, Roca J et al (2010) Effect of microencapsulated phase change material in sandwich panels 35:2370–2374. https://doi.org/10.1016/j.renene.2010.03.030

Kováčik J (2017) Closed-cell aluminium foams with phase change material. Met Foam 1:42–48. https://doi.org/10.23977/metf.2017.11003

Amaral C, Pinto SC, Silva T et al (2020) Development of polyurethane foam incorporating phase change material for thermal energy storage. J Energy Storage 28:101177. https://doi.org/10.1016/j.est.2019.101177

Acknowledgements

The author thanks the Institute of Chemical Technology, Mumbai, for availing all-instrumental facilities required for the work, and the Defense Research and Development Organization (DRDO), New Delhi, India, for providing financial assistance (Grant number: NRB/4003/PG/387 dated 17-01-2017).

Funding

Defense Research and Development Organization (DRDO), New Delhi, India (Grant number: NRB/4003/PG/387 dated 17-01-2017).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Naikwadi, A., Samui, A. & Mahanwar, P. Experimental investigation of rigid polyurethane foam/microencapsulated phase change material composite for thermal energy storage in electronic component. Polym. Bull. 79, 10095–10114 (2022). https://doi.org/10.1007/s00289-021-03961-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03961-x