Abstract

In this research, wheat straw (the agricultural by-product from the wheat plant, scientific name Triticum) reinforced unsaturated polyester resin composites were developed by applying a simple and easy technique to improve supportable composite materials. Therefore, untreated and sodium hydroxide-treated wheat straws have been used to form a strong and durable composite. The morphological, chemical and thermal properties of these composites were explained scientifically by using scanning electron microscopy, Fourier-transform infrared spectroscopy, thermogravimetric analysis, differential scanning calorimetry, X-ray diffraction etc. Moreover, these eco-friendly composites were analyzed their mechanical, biodegradability, and water absorption properties and compared them. In detail, the tensile strengths of virgin resin (VR), untreated wheat straw reinforced composite (UTWSC), and 2% sodium hydroxide treated wheat straw reinforced composite (2TWSC) were found to be 11.75, 14.45, and 19.84 N/mm2 respectively. Therefore, the reinforcement performance of tensile strength for 2% sodium hydroxide treated composite of wheat straw (2TWSC) and the composite of untreated wheat straw (UTWSC) increased by ~ 69% and ~ 23% respectively than the composite of virgin resin. Again, the modified composite (2TWSC) was stronger (27%) and more durable (17%) than the untreated composite considering the mechanical strength and biodegradability. The TGA results indicate that the composites are stable up to 315 °C. This modified composite also shows superior crystallinity compared to the untreated one. The typical water absorption behavior follows the Fickian diffusion law. This developed sustainable composite could be used for chair, table, door panel, seatback, dashboard, park bench, cabinet, particleboard, fence, rooftop, etc.

Similar content being viewed by others

References

Lozano R, Huisingh D (2011) Inter-linking issues and dimensions in sustainability reporting. J Clean Prod 19:99–107

Lozano R (2008) Envisioning sustainability three-dimensionally. J Clean Prod 16:1838–1846

Mulinari DR, Guedes JR, Simba BG (2017) Low density polyethylene composites reinforced with Australian King Palm fibers: mechanical and thermal properties. Polym Bull 74:4549–4559

Chowdhury MNK, Ismail AF, Khan MR, Beg MDH, Othman MHD, Gohari RJ, Moslehyani A (2015) Physicochemical and micromechanical investigation of a nanocopper impregnated fibre reinforced nanocomposite. RSC Adv 5:100943–100955

Lilley D, Lofthouse V (2009) Sustainable design education–considering design for behavioural change. Eng Educ 4:29–41

El Messiry M (2017) Natural fiber textile composite engineering. CRC Press

Hansen MA, Kristensen JB, Felby C, Jørgensen H (2011) Pretreatment and enzymatic hydrolysis of wheat straw (Triticum aestivum L.)–the impact of lignin relocation and plant tissues on enzymatic accessibility. Bioresour Technol 102:2804–2811

Gurunathan T, Mohanty S, Nayak SK (2015) A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos Part A Appl Sci Manuf 77:1–25

Sisti L, Totaro G, Vannini M, Celli A (2018) Retting process as a pretreatment of natural fibers for the development of polymer composites Lignocellulosic composite materials. Springer, Cham

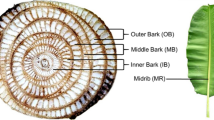

Yu H, Liu R, Shen D, Wu Z, Huang Y (2008) Arrangement of cellulose microfibrils in the wheat straw cell wall. Carbohydr Polym 72:122–127

Sathishkumar TP, Navaneethakrishnan P, Shankar S, Rajasekar R, Rajini N (2013) Characterization of natural fiber and composites–A review. J Reinf Plast Compos 32:1457–1476

Shanmugasundaram L (2009) Green composites: Manufacturing techniques & applications. The Indian textile journal

Rezania S, Din MFM, Taib SM, Sohaili J, Chelliapan S, Kamyab H, Saha BB (2017) Review on fermentative biohydrogen production from water hyacinth, wheat straw and rice straw with focus on recent perspectives. Int J Hydrog Energy 42:20955–20969

Elmessiry M, Deeb E (2016) Analysis of the wheat straw/flax fiber reinforced polymer hybrid composites. J Appl Mech Eng 5:240

Yasina M, Bhuttob AW, Bazmia AA, Karimb S (2010) Efficient utilization of rice-wheat straw to produce value–added composite products. Int J Chem Environ Eng 1:136–143

Dukarska D, Czarnecki R, Dziurka D, Mirski R (2017) Construction particleboards made from rapeseed straw glued with hybrid pMDI/PF resin. Eur J Wood Wood Prod 75:175–184

Madurwar MV, Ralegaonkar RV, Mandavgane SA (2013) Application of agro-waste for sustainable construction materials: a review. Constr Build Mater 38:872–878

Khalil HA, Bhat AH, Yusra AI (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohydr Polym 87:963–979

Joseph A, Baby B, Thomas AB, Krishnan SS (2015) Preparation and characterization of banana reinforced phenol formaldehyde composite. Eur J Adv Eng and Technol 2:85–90

Albano C, Karam A, Domínguez N, Sánchez Y, González J, Aguirre O, Catano L (2005) Thermal, mechanical, morphological, thermogravimetric, rheological and toxicological behavior of HDPE/seaweed residues composites. Compos Struct 71:282–288

Jang YH, Han SO, Sim IN, Kim HI (2013) Pretreatment effects of seaweed on the thermal and mechanical properties of seaweed/polypropylene biocomposites. Compos Part A Appl Sci Manuf 47:83–90

Hassan MM, Wagner MH, Zaman HU, Khan MA (2010) Physico-mechanical performance of hybrid betel nut (Areca catechu) short fiber/seaweed polypropylene composite. J Nat Fibers 7:165–177

Fuqua MA, Huo S, Ulven CA (2012) Natural fiber reinforced composites. Polym Rev 52:259–320

Rahman MR, Hamdan S, Ngaini ZB, Jayamani E, Kakar A, Bakri MKB, Yusof FABM (2019) Cellulose fiber-reinforced thermosetting composites: impact of cyanoethyl modification on mechanical, thermal and morphological properties. Polym Bull 76(8):4295–4311

Chang G, Huang Y, Xie J, Yang H, Liu H, Yin X, Wu C (2016) The lignin pyrolysis composition and pyrolysis products of palm kernel shell, wheat straw, and pine sawdust. Energy Convers Manag 124:587–597

Verma D, Jain S, Zhang X, Gope PC (2016) Green approaches to biocomposite materials science and engineering. IGI Global, USA

Haque ME, Khan MW, Chowdhury MNK (2020) Synthesis, characterization, biocompatibility, thermal and mechanical performances of sawdust reinforced composite. Polym Test 91:106764

Ashori A, Nourbakhsh A (2010) Bio-based composites from waste agricultural residues. Waste Manage 30:680–684

Bénézet JC, Stanojlovic-Davidovic A, Bergeret A, Ferry L, Crespy A (2012) Mechanical and physical properties of expanded starch, reinforced by natural fibres. Ind Crops Prod 37:435–440

Mohammed L, Ansari MN, Pua G, Jawaid M, Islam MS (2015) A review on natural fiber reinforced polymer composite and its applications. Int J Polym Sci 215:1–15

Chowdhury MNK, Ismail AF, Beg MDH, Khan MR, Gohari RJ, Saidin MARB, Ong HR (2016) Control of biodegradability in a natural fibre based nanocomposite as a function of impregnated copper nanoparticles. RSC Adv 6:28937–28946

Rossi V, Cleeve-Edwards N, Lundquist L, Schenker U, Dubois C, Humbert S, Jolliet O (2015) Life cycle assessment of end-of-life options for two biodegradable packaging materials: sound application of the European waste hierarchy. J Clean Prod 86:132–145

Larson N, Ghandehari H (2012) Polymeric conjugates for drug delivery. Chem Mater 24:840–853

Tian H, Tang Z, Zhuang X, Chen X, Jing X (2012) Biodegradable synthetic polymers: Preparation, functionalization and biomedical application. Prog Polym Sci 37:237–280

Domb AJ, Kumar N (2011) Biodegradable polymers in clinical use and clinical development. Wiley, Berlin

Graupner N, Herrmann AS, Müssig J (2009) Natural and man-made cellulose fibre-reinforced poly (lactic acid) (PLA) composites: an overview about mechanical characteristics and application areas. Compos Part A Appl Sci Manuf 40(6–7):810–821

Azwa ZN, Yousif BF, Manalo AC, Karunasena W (2013) A review on the degradability of polymeric composites based on natural fibres. Mater Des 47:424–442

Uddin N, Abro AM, Purdue JD, Vaidya U (2013) Developments in fiber-reinforced polymer (FRP) composites for civil engineering: thermoplastic composites for bridge structures. Elsevier, Amsterdam

Silva JVF, Bianchi NA, Oliveira CAB, Caraschi JC, de Souza AJD, Molina JC, de Campos CI (2019) Characterization of composite formed by cement and wheat straw treated with sodium hydroxide. BioResources 14:2472–2479

Nayak RK, Ray BC (2017) Water absorption, residual mechanical and thermal properties of hydrothermally conditioned nano-Al2O3 enhanced glass fiber reinforced polymer composites. Polym Bull 74:4175–4194

Chowdhury MNK, Beg MDH, Khan MR, Mina MF (2013) Modification of oil palm empty fruit bunch fibers by nanoparticle incorporation and alkali treatment. Cellulose 20:1477–1490

Alam AKMM, Beg MDH, Prasad DMR, Khan MR, Mina MF (2012) Structures and performances of simultaneous ultrasound and alkali treated oil palm empty fruit bunch fiber reinforced poly (lactic acid) composites. Compos Part A Appl Sci Manuf 43:1921–1929

Rahman MR, Hamdan S, Jayamani E, Kakar A, Bakri MKB, Yusof FABM (2019) Tert-butyl catechol/alkaline-treated kenaf/jute polyethylene hybrid composites: impact on physico-mechanical, thermal and morphological properties. Polym Bull 76:763–784

Ray D, Sarkar BK, Basak RK, Rana AK (2004) Thermal behavior of vinyl ester resin matrix composites reinforced with alkali-treated jute fibers. J Appl Polym Sci 94:123–129

Da Silva EJ, Marques ML, Velasco FG, Junior CF, Luzardo FM, Tashima MM (2017) A new treatment for coconut fibers to improve the properties of cement-based composites–Combined effect of natural latex/pozzolanic materials. SM&T 12:44–51

Cady NC, Behnke JL, Strickland AD (2011) Copper-based nanostructured coatings on natural cellulose: Nanocomposites exhibiting rapid and efficient inhibition of a multi-drug resistant wound pathogen, A. baumannii, and mammalian cell biocompatibility in vitro. Adv Funct Mater 21:2506–2514

Mariatti M, Nasir M, Ismail H (2001) The effects of hole locations and hole sizes on damaged behaviour of woven thermoplastic composites. Polym Test 20:179–189

Acknowledgments

The authors are gratefully acknowledging the financial support of Bangladesh University of Engineering & Technology, Dhaka, Bangladesh (Grant number: 0417034001F).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. The authors declare the following financial interests/personal relationships which may be considered as potential competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Haque, M.E., Khan, M.W. & Rani, M. Studies on morphological, physico-chemical and mechanical properties of wheat straw reinforced polyester resin composite. Polym. Bull. 79, 2933–2952 (2022). https://doi.org/10.1007/s00289-021-03630-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03630-z