Abstract

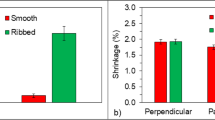

Mold surface temperature is one of the most critical process parameters in injection molding. This study aimed to determine the effect of mold surface temperature on plastic parts in injection molding of high-density polyethylene materials. Other process parameters were kept constant, and samples were prepared by changing mold surface temperatures by the injection molding method. The samples’ mechanical tests, thermal tests, and gloss measurements by a gloss meter were performed, and the amount of warpage and collapses was measured by a video measuring system. Microstructures were examined under a scanning electron microscope. It was observed that the mold surface temperature increased the crystallization rate, tensile and bending strength of the materials, decreased the thicknesses of the crystal lamella and impact strength, and had an effect on the melting temperature of the crystal. The microstructure investigations demonstrated that as the mold surface temperature increased, the cavity formation in the structure increased, and fibrillation decreased due to expansion and cooling time. It was determined that the amount of collapse and warpage was affected by the mold surface temperature and that the increase in the mold surface temperature decreased the amount of collapse and increased the amount of warpage and surface gloss.

Graphic abstract

Similar content being viewed by others

Abbreviations

- T m :

-

Melting temperature

- T m°:

-

Equilibrium melting temperature

- X c :

-

Crystal percentage

- δ e :

-

Surface energy

- ΔH m :

-

Melting enthalpy

- ΔH m°:

-

Enthalpy

- λ :

-

Crystal lamella thickness

References

Chen SC, Li HM, Huang ST, Wang YC (2010) Effect of decoration film on mold surface temperature during in-mold decoration injection molding process. Int Commun Heat Mass Transf 37:501–505. https://doi.org/10.1016/j.icheatmasstransfer.2010.01.005

Kyas K, Cerny J, Stanek M, Manas M, Manas D, Senkerik V, Skrobak A (2012) Measuring of temperature and pressure in injection mold. Int J Math Comput Simul 6(6):600–607

Lucchetta G, Fiorotto M (2013) Influence of rapid mould temperature variation on the appearance of injection-moulded parts. J Mech Eng 59:683–688. https://doi.org/10.5545/sv-jme.2013.1001

Zhou X, Zhang Y, Mao T, Zhou H (2017) Monitoring and dynamic control of quality stability for injection molding process. J Mater Process Technol 249:358–366. https://doi.org/10.1016/j.jmatprotec.2017.05.038

Kurt M, Kaynak Y, Kamber ÖS, Mutlu B, Bakır B, Koklu U (2010) Influence of molding conditions on the shrinkage and roundness of injection molded parts. Int J Adv Manuf Technol 46:571–578. https://doi.org/10.1007/s00170-009-2149-x

Xu Y, Zhang Q, Zhang W, Zhang P (2015) Optimization of injection molding process parameters to improve the mechanical performance of polymer product against impact. Int J Adv Manuf Technol 76:2199–2208. https://doi.org/10.1007/s00170-014-6434-y

Postawa P, Stachowiak T (2015) Mould temperature control during injection moulding process. AIP Conf Proc 1664:110012. https://doi.org/10.1063/1.4918487

Zhang L, Zhou G, Wang G (2017) Formation mechanism of porous structure in plastic parts injected by microcellular injection molding technology with variable mold temperature. Appl Therm Eng 114:484–497. https://doi.org/10.1016/j.applthermaleng.2016.11.180

Chen SC, Lin YW, Chien RD, Li HM (2008) Variable mold temperature to improve surface quality of microcellular injection molded parts using induction heating technology. Adv Polym Technol 27(4):224–232. https://doi.org/10.1002/adv.20133

Nhan PT, Do TT, Son TA, Minh PS (2019) Study on external gas-assisted mold temperature control for improving the melt flow lenght of thin rib products in the injection molding process. Adv Polym Technol. https://doi.org/10.1155/2019/5973403

Bociaga E, Jaruga T, Lubczynska K, Gnatowski A (2010) Warpage of injection moulded parts as the result of mould temperature difference. Arch Mater Sci Eng 44(1):28–34

Minh PS (2014) Study on the mold temperature control fort he core plate during injection molding process. J Polym Text Eng 1(4):14–20

Chen HL, Chen SC, Liao WH, Chien RD, Lin YT (2013) Effects of insert film on asymmetric mold temperature and associated part warpage during-in-mold decoration injection molding of PP parts. Int Commun Heat Mass Transf 41:34–40. https://doi.org/10.1016/j.icheatmasstransfer.2012.11.002

Chen SC, Chang Y, Chang YP, Chen YC, Tseng CY (2009) Effect of cavity surface coating on mold temperature variation and the quality of injection molded parts. Int Commun Heat Mass Transf 36:1030–1035. https://doi.org/10.1016/j.icheatmasstransfer.2009.06.020

Oppelt T, Schulze J, Stein H, Platzer B (2012) Comparison of methods for mould surface heating-part 1: review. Gummi Fasern Kunststoffe 8:518–523. https://doi.org/10.1177/0307174X1203901201

Berger GR, Pacher GA, Pichler A, Friesenbichler W, Gruber DP (2014) Influence of mold surface temperature on polymer part warpage in rapid heat cycle molding. AIP Conf Proc 1593:189. https://doi.org/10.1063/1.4873761

Mlynek J, Knobloch R, Srb R (2015) Mathematical model of the metal mould surface temperature optimization. AIP Conf Proc 1690:020018. https://doi.org/10.1063/1.4936696

Singh G, Verma A (2017) A brief review on injection moulding manufacturing process. Mater Today Proc 4:1423–1433. https://doi.org/10.1016/j.matpr.2017.01.164

Vojnova E (2016) The benefits of a conforming cooling systems the molds in injection moulding process. Procedia Eng 149:535–543. https://doi.org/10.1016/j.proeng.2016.06.702

Liparoti S, Speranza V, Sorrentino A, Titomanlio G (2017) Mechanical properties distribution within polypropylene injection molded samples: effect of mold temperature under uneven thermal conditions. Polymers 9:585. https://doi.org/10.3390/polym9110585

Schwalme G (2014) Inline infrared thermography applied for quality gates and for mould temperature control in the injection moulding process. 58th Ilmenau Scientific Colloquium, Technische Universität Ilmenau 08–12 September. https://d-nb.info/1071094440/34. Accessed 1 May 2020

Hsissou R, Berradi M, El Bouchti ME, El Bachiri A, El Harfi A (2019) Synthesis characterization rheological and morphological study of a new epoxy resin pentaglycidyl ether pentaphenoxy of phosphorus and their composite (PGEPPP/MDA/PN). Polym Bull 76(9):4859–4878. https://doi.org/10.1007/s00289-018-2639-9

Wang X, Zhoo G, Wang G (2013) Research on the reduction of sink mark and warpage of the molded part in rapid heat cycle molding process. Mater Des 47:779–792. https://doi.org/10.1016/j.matdes.2012.12.047

Karagöz İ, Öksüz M (2018) Microstructures occuring in the joined thermoplastics sheets with friction stir welding. J Fac Eng Arch Gazi Univ 33(2):503–518. https://doi.org/10.17341/gazimmfd.416359

Dar UA, Xu YJ, Zakir SM, Saeed MU (2016) The effect of injection molding process parameters on mechanical and fracture behavior of polycarbonate polymer. J Appl Polym Sci 134(7):1–9. https://doi.org/10.1002/app.44474

Banik K (2008) Effect of mold temperature on short and long-term mechanical properties of PBT. Express Polym Lett 2(2):111–117. https://doi.org/10.3144/expresspolymlett.2008.15

Katmer Ş, Karataş Ç (2015) Effects of injection molding conditions on residual stress in HDPE and PP parts. J Fac Eng Arch Gazi Univ 30(3):319–327. https://doi.org/10.17341/gummfd.45855

Erzurumlu T, Ozcelik B (2006) Minimization of warpage and sink index in injection-molded thermoplastic part using Taguchi optimization method. Mater Des 27:853–861. https://doi.org/10.1016/j.matdes.2005.03.017

Mohammadi H, Vincent M, Marand H (2018) Investigating the equilibrium melting-temperature or linear polyethylene using the non-linear Hoffman–Weeks approach. Polymer 146:334–360. https://doi.org/10.1016/j.polymer.2018.05.049

Yang B, Ding MY, Hu L, Li GJ, Miao JB, Gao X, Li XB, Zhang B, Su LF, Chen P, Qian JS (2019) Melt crystallization behavior of injection-molded high-density polyethylene based upon a solidification kinetic analysis. J Macromol Sci Part B Phys 58(1):42–58. https://doi.org/10.1080/00222348.2018.1476429

Fischer EW (1972) Effect of annealing and temperature on the morphological structure of polymers. Pure Appl Chem 31(1–2):113–132. https://doi.org/10.1351/pac197231010113

Iyer K, Margossian M, Muthukumar M (2019) Interlude of metastability in the melting of polymer crystals. J Chem Phys. https://doi.org/10.1063/1.5114645

Chalid M, Fikri AI, Satrio HH, Muhammad JYB, Fatriansyah JF (2017) An investigation of the melting temperature effect on the rate of solidification in polymer using a modified phase field model. Int J Technol 7:1321–1328. https://doi.org/10.14716/ijtech.v8i7.707

Kuzmanović M, Delva L, Cardon L, Ragaert K (2016) The effect of injection molding temperature on the morphology and mechanical properties of PP/PET blends and microfibrillar composites. Polymers 8(10):355. https://doi.org/10.3390/polym8100355

Rastogi S, Spoelstra A, Gossens J, Kemstra P (1997) Chain mobility in polymer systems: on the borderline between solid and melt. 1. Lamellar doubling during annealing of polyethylene. Macromolecules 30(25):7880–7889. https://doi.org/10.1021/ma970519o

Chang TC, Faison E (2001) Shrinkage behavior and optimization of injection molded parts studied by the Taguchi method. Polym Eng Sci 41(5):703–710. https://doi.org/10.1002/pen.10766

Dang XP (2014) General frame works for optimization of plastic injection molding process parameters. Simul Model Pract Theory 41:15–27. https://doi.org/10.1016/j.simpat.2013.11.003

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Karagöz, İ. An effect of mold surface temperature on final product properties in the injection molding of high-density polyethylene materials. Polym. Bull. 78, 2627–2644 (2021). https://doi.org/10.1007/s00289-020-03231-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03231-2