Abstract

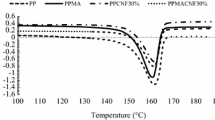

The effects of filler content and chemical treatment on mechanical and thermal properties of polypropylene–chitosan composites were investigated. Filler chemical treatment was carried out by reacting chitosan with organosolv lignin/sodium dodecyl sulphate binary modifying agents under mild condition. Filler–matrix interfacial adhesion enhanced considerably in presence of the binary agent that effectively modified the chitosan surface, leading to increased tensile and impact strength of the composites. Even though the chemical treatments did not change the thermal degradation mechanism of the composites, the obtained results exhibited that the treated composites had better thermal properties than the untreated composites. These finding implies that organosolv lignin-containing binary modifying agents could be a potential reagent to replace synthetic modifying agents.

Similar content being viewed by others

References

Panthapulakkal S, Sain M (2007) Agro-residue reinforced high-density polyethylene composites: fiber characterization and analysis of composite properties. Compos Part A 38:1445–1454

Ashori A, Nourbakhsh A (2009) Characteristics of wood-fiber plastic composites made of recycled materials. Waste Manag 29:1291–1295

Bullions TA, Hoffman D, Gillespie RA, Brien JPO, Lo AC (2006) Contributions of feather fibers and various cellulose fibers to the mechanical properties of polypropylene matrix composites. Compos Sci Technol 66:102–114

Li Y, Hu C, Yu Y (2008) Interfacial studies of sisal fiber reinforced high density polyethylene (HDPE) composites. Compos Part A 39:570–578

Ibrahim MM, Dufresne A, El-Zawawy WK, Agblevor FA (2010) Banana fibers and microfibrils as lignocellulosic reinforcements in polymer composites. Carbohydr Polym 81:811–819

Lee SY, Yang HS, Kim HJ, Jeong CS, Lim BS, Lee JN (2004) Creep behavior and manufacturing parameters of wood flour filled polypropylene composites. Compos Struct 65:459–469

Yang HS, Kim HJ, Park HJ, Lee BJ, Hwang TS (2007) Effect of compatibilizing agents on rice-husk flour reinforced polypropylene composites. Compos Struct 77:45–55

Cardenas G, Anaya P, Plessing CV, Rojas C, Sepulveda J (2008) Chitosan composite films. Biomedical applications. J Mat Sci Mat Med 19:2397–2405

Ku H, Wang H, Pattarachaiyakoop N, Trada M (2011) A review on the tensile properties of natural fiber reinforced polymer composites. Compos Part B 42:856–873

Ramires EC, Gardrat C, Castellan A, Frollini E (2010) Biobased composites from glyoxal-phenolic resins and sisal fibers. Biores Technol 101:1998–2006

Martinez-Camacho AP, Cortez-Rocha MO, Ezquera-Brauer JM, Graciano-Verdugo AZ, Rodriguez-Felix F, Castillo-Ortega MM (2010) Chitosan composite films: thermal, structural, mechanical and antifungal properties. Carbohydr Polym 82:305–315

Mir S, Yasin T, Halley PJ, Siddiqi HM, Nicholson T (2011) Thermal, rheological, mechanical and morphological behaviour of HDPE/chitosan blend. Carbohydr Polym 83:414–421

Valadez-Gonzalez A, Cervantes-Uc JM, Olayo R, Herrera-Franco PJ (1999) Effect of fiber surface treatment on the fiber-matrix bond strength of natural fiber reinforced composites. Compos Part B 30:309–320

Wang Z, Wang E, Zhang S, Wang Z, Ren Y (2009) Effects of cross-linking on mechanical and physical properties of agricultural residues/recycled thermoplastics composites. Indust Crops Products 29:133–138

Salmah H, Azieyanti AN (2011) Properties of recycled polyethylene/chitosan composites: the effect of polyethylene-graft-maleic anhydride. J Reinf Plast Compos 30:195–202

Salmah H, Faisal A, Kamarudin H, Ismail H (2011) The mechanical and thermal properties of chitosan filled polypropylene composites: the effect of acrylic acid. J Vinyl Add Technol 17:125–131

Salmah H, Faisal A, Kamarudin H (2011) Chemical modification of chitosan filled polypropylene (PP) compoites: the effect 3-aminopropyltriethoxysilane on mechanical and thermal properties. Int J Polym Mat 60:429–440

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15:25–33

Megiatto JD, Silva CG, Rosa DS, Frollini E (2008) Sisal chemically modified with lignins: correlation between fibres and phenolic composites properties. Polym Degrad Stab 93:1109–1121

Faisal A, Salmah H, Kamarudin H (2013) Effect of sodium dodecyl sulphate on mechanical and thermal properties of polypropylene/chitosan composites. J Thermoplast Compos Mat 26:878–892

Kosikova B, Duris M, Demianova V (2000) Conversion of lignin biopolymer into surface-active derivatives. Europ Polym J 36:1209–1212

Ibrahim MNM, Haras MRA, Sipaut CS, Aboul-Enein HY, Mohamed AA (2010) Preparation and characterization of a newly water soluble lignin graft copolymer from oil palm lignocellulosic waste. Carbohydr Polym 80:1102–1110

Mishra SB, Mishra AK, Kaushik NK, Khan MA (2007) Study of performance properties of lignin-based polyblends with polyvinyl chloride. J Mat Process Technol 183:273–276

Digabel FL, Averous L (2006) Effects of lignin content on the properties of lignocellulose-based biocomposites. Carbohydr Polym 66:537–545

Wang M, Leitch M, Xu CC (2009) Synthesis of phenol-formaldehyde resol resins using organosolv pine lignins. Europ Polym J 45:3380–3388

Thielemans W, Wool RP (2005) Lignin esters for use in unsaturated thermosets: lignin modification and solubility. Biomacromolecules 6:1895–1905

Silva EAB, Zabkovaa M, Araujoa JD, Cateto CA, Barreiro MF, Belgacem M (2009) An integrated process to produce vanillin and lignin-based polyurethanes from kraft lignin. Chem Eng Res Design 87:1276–1292

Ibrahim M, Glasser WG (1999) Steam-assisted biomass fractionation. Part III: a quantitative evaluation of the “clean fractionation” concept. Biores Technol 70:181–192

Hage RE, Brosse N, Chrusciel L, Sanchez L, Sannigrahi P, Ragauskas A (2009) Characterization of milled wood lignin and ethanol organosolv lignin from miscanthus. Polym Degrad Stab 94:1632–1638

Thielemans W, Can E, Morye SS, Wool RP (2002) Novel applications of lignin in composite materials. J Appl Polym Sci 83:323–331

Joseph PV, Joseph K, Thomas S, Pillai CKS, Prasad VS (2003) The thermal and crystallization studies of short sisal fibre reinforced polypropylene composites. Compos Part A 34:253–266

Lundquist K (1992) Proton (1H) NMR spectroscopy. In: Lin SY, Dence CW (eds) Methods in lignin chemistry. Springer, Berlin, pp 242–249

Dányádi L, Renner K, Móczó J, Pukánszky B (2007) Wood flour filled polypropylene composites: interfacial adhesion and micromechanical deformations. Polym Eng Sci 47:1246–1255

Renner K, Kenyó C, Móczó J, Pukánszky B (2010) Micromechanical deformation processes in PP/wood composites: particle characteristics, adhesion, mechanisms. Compos Part A 41:1653–1661

Yang HS, Wolcott MP, Kim HS, Kim S, Kim HJ (2007) Effect of different compatibilizing agents on the mechanical properties of lignocellulosic material filled polyethylene bio-composites. Compos Struct 79:369–375

Mousavioun P, Doherty WOS (2010) Chemical and thermal properties of fractionated bagasse soda lignin. Indust Crops Prod 31:52–58

Kim HS, Choi SW, Lee BH, Kim S, Kim HJ, Cho CW (2007) Thermal properties of bio flour-filled polypropylene biocomposites with different pozzolan contents. J Therm Anal Cal 89:821–827

Kadla JF, Kubo S (2004) Lignin-based polymer blends: analysis of intermolecular interactions in lignin-synthetic polymer blends. Compos Part A 35:395–400

Borysiak S (2007) Determination of nucleating ability of wood for non-isothermal crystallization of polypropylene. J Therm Anal Cal 88:455–462

Gray DG (2008) Transcrystallization of polypropylene at cellulose nanocrystal surfaces. Cellulose 15:297–301

Acknowledgments

Research funding from the fundamental research grant scheme (FRGS) by the Ministry of Education of Malaysia is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tanjung, F.A., Husseinsyah, S., Hussin, K. et al. Mechanical and thermal properties of organosolv lignin/sodium dodecyl sulphate binary agent-treated polypropylene/chitosan composites. Polym. Bull. 73, 1427–1445 (2016). https://doi.org/10.1007/s00289-015-1556-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-015-1556-4